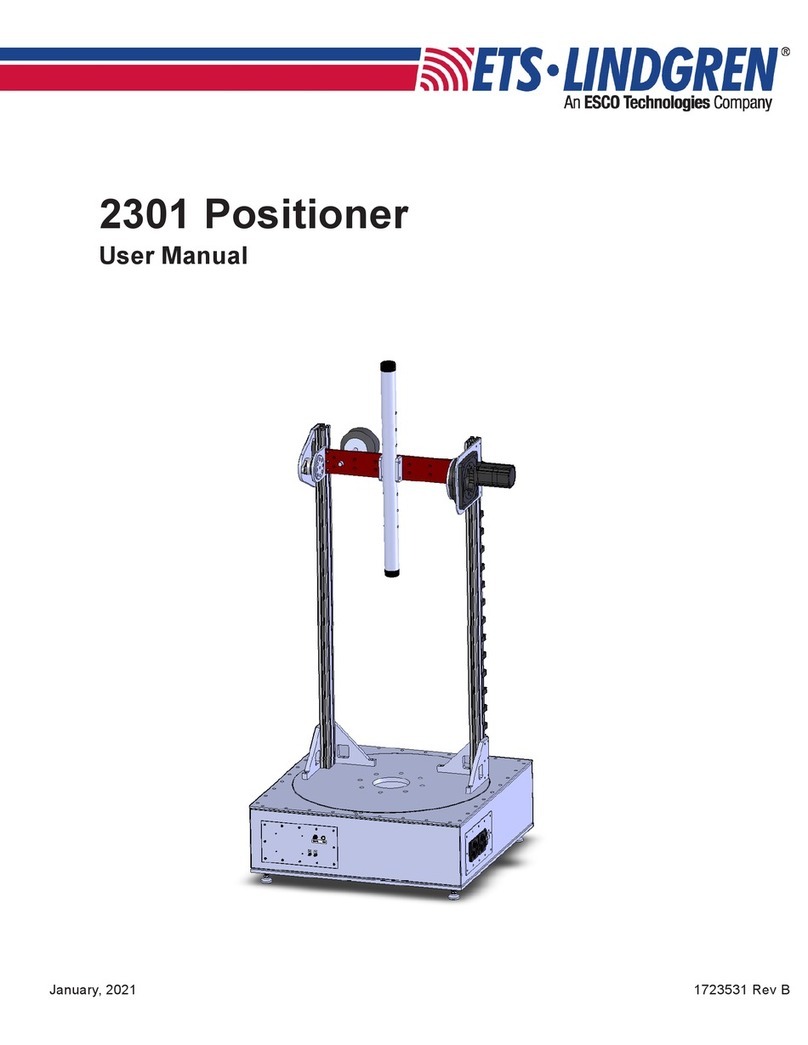

3

TABLE OF CONTENTS

NOTES, CAUTIONS, WARNINGS . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

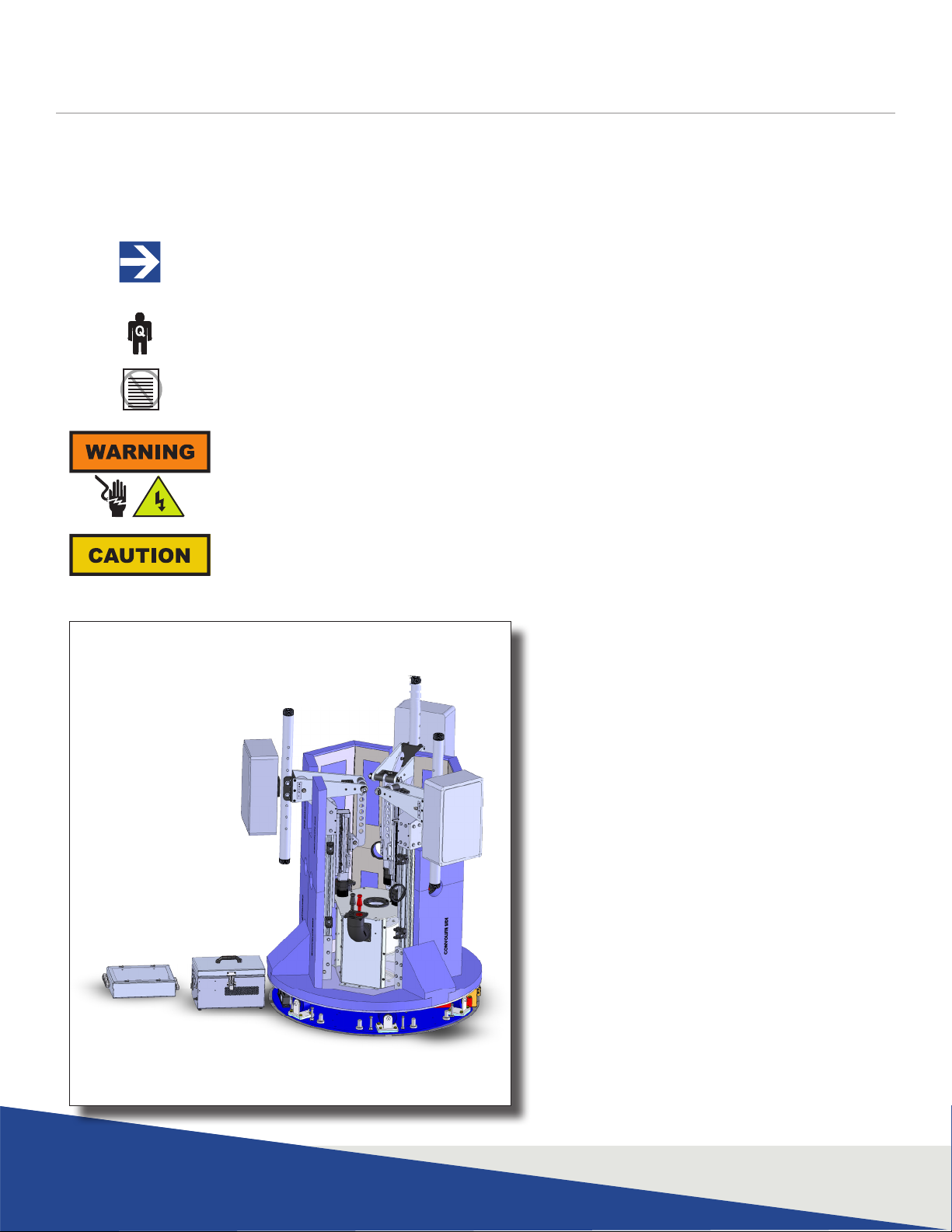

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Model 2303 Positioner Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .6

EMCenter Modular RF Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Optional Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

ETS-Lindgren Product Information Bulletin . . . . . . . . . . . . . . . . . . . . . . . .6

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6-Month Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

12-Month Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

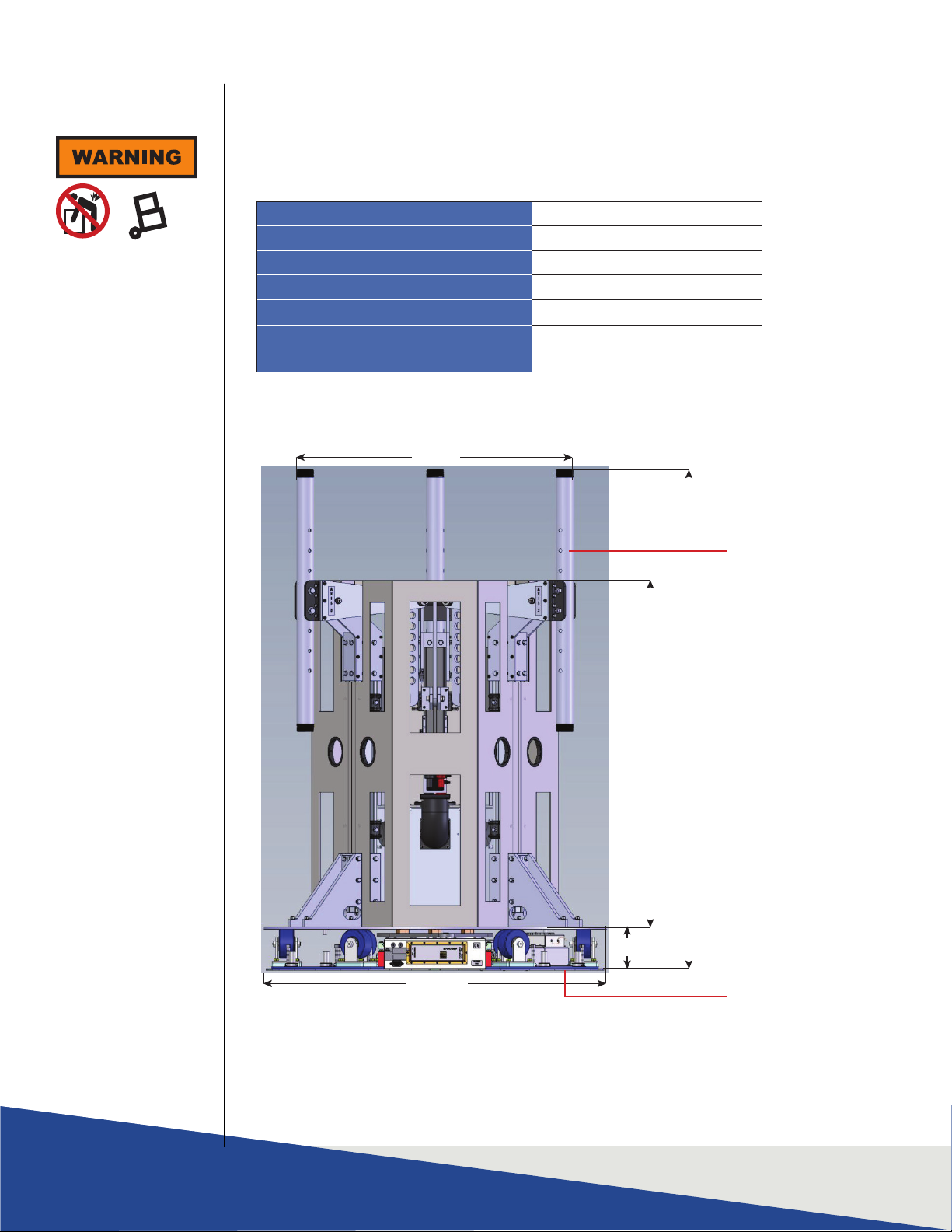

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pre-Installation Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 12

Elevation Axes Input / Output Connections . . . . . . . . . . . . . . . . . . . . . . . 12

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fiber Optic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Turntable Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2303 Positioner Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General Command Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

NETWORK CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . 24

Network Factory Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Changing the Positioner IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Reset to Factory Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Computer Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Background Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Multiple Devices in a LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31