ESCO Equipment Supply Company 3

1.17 DO NOT use brake fluid or any other improper fluid and avoid mixing different types of oil when

adding hydraulic oil. Only a good quality hydraulic jack oil can be used.

1.18 DO NOT expose the jack to rain or any other kind of bad weather.

1.19 If the jack need repairing and/or there are any parts that need to be replaced, have it repaired by

authorized technicians and only use the replacement parts supplied by the manufacturer.

1.20 WARNING: the warnings, cautions and instructions discussed in this instruction manual cannot cover

all possible conditions and situations that may occur. It must be understood by the operator that

common sense and caution are factors which cannot be built into this product, but must be supplied

by the operator.

2. SPECIFICATIONS

Capacity Min Height Ram

Travel Screw

Adj. Max

Height Air Pressure Air Inlet Fitting

20 Ton 10.3”

262mm 6.3”

160mm 3.3”

84mm 19.92”

506mm 0.75-0.85MPa 1/4" NPT

3. OPERATING INSTRUCTIONS

WARNING

Ensure that you read, understand and apply the safety instructions and warnings before use.

Ensure that you have familiarized yourself thoroughly with the product and the hazards associated

with its improper use.

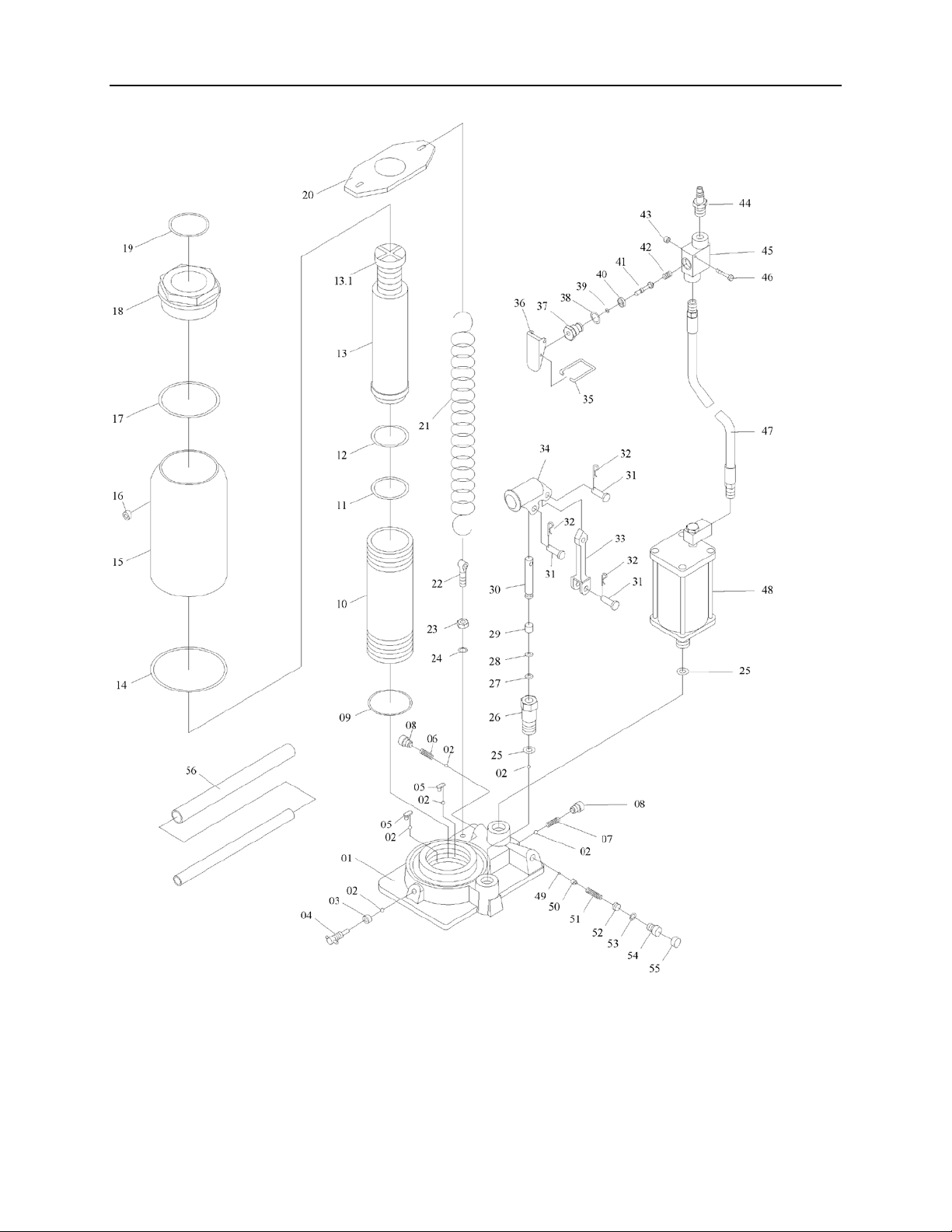

3.1 Before first use of this product, pour a teaspoon of good quality air tool lubricant into the hose quick

coupler-male(44) of the air quick coupler-female, then connect it to air source and turn on the air valve

and work for 3 seconds to evenly distribute lubricant.

3.2 Use the slotted end of the handle(56) to turn the release valve(04) clockwise until it is firmly closed.

3.3 Apply the emergency brake and use wheel chocks to block all wheels to prevent any movement of

the vehicle being lifted.

3.4 Place the jack into position and adjust the extension screw(13.1) as needed.

NOTE: Check in your vehicle owner's manual for the location of recommended lift point.

3.5 Connect the air quick coupler-male into the shop air supply hose quick coupler-female, then turn on

the air valve.

3.6 Raise the load to desired height, turn off the air valve and immediately USE JACK STANDS with

adequate capacity to support the load.

3.7 When air source is not available, insert the big end of the handle into the handle bracket(34), pump it

manually to raise the load to desired height. Then immediately transfer the load to appropriate support

devices such as jack stands.

WARNING! Be sure all tools and personnel are clear before lowering load.

3.8 When work is done, raise load enough to carefully remove the jack stands. Then SLOWLY and