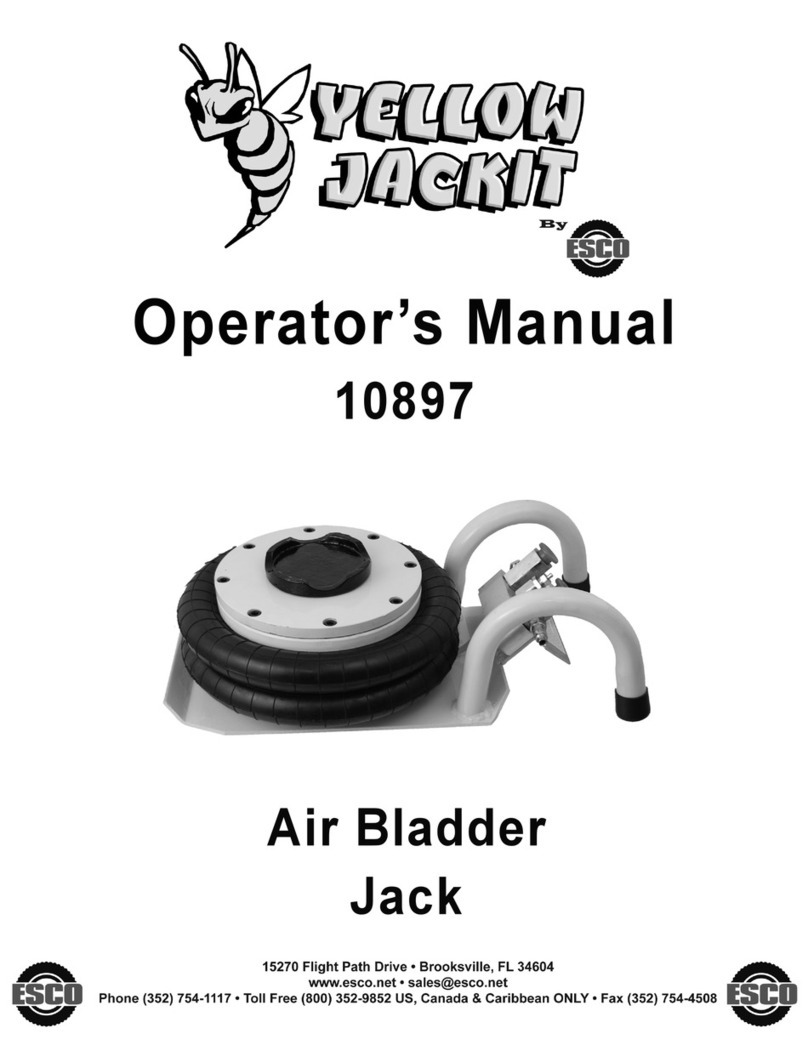

Esco YELLOW JACKIT 10399 User manual

Other Esco Jack manuals

Popular Jack manuals by other brands

Omega Lift Equipment

Omega Lift Equipment 18122C Operating instructions & parts manual

Pittsburgh

Pittsburgh 58816 Owner's manual & safety instructions

Unimec

Unimec TP Assembly instructions

Sonic

Sonic 4800703 instructions

BGS technic

BGS technic 70039 instruction manual

TradeQuip

TradeQuip 1128T owner's manual

VEVOR

VEVOR TJD-12000SP-F quick start guide

ULTIMATE SPEED

ULTIMATE SPEED URW 2 A1 HYDRAULIC TROLLEY JACK operating instructions

Stels

Stels 51131 user manual

Valex

Valex 1650520 Translation of the original instructions

Clarke

Clarke CTJ2500QLG Operating & maintenance instructions

Pfaff

Pfaff Merkur M0 Operating instruction