SAFETY

4

IMPORTANT SAFETY INFORMATION

SPECIFICATIONS

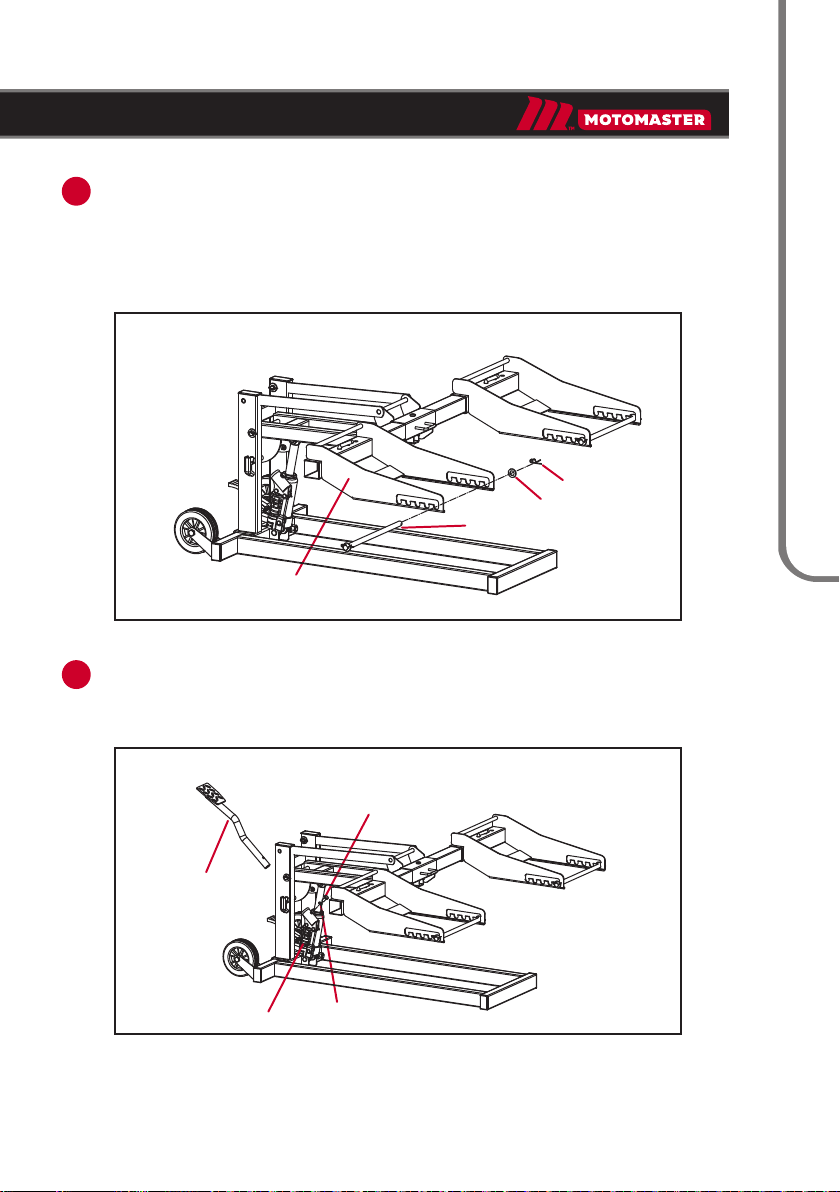

Rated Capacity Maximum Lift Height

300 lb (136 kg) 23 13 / 16" (60.5 cm)

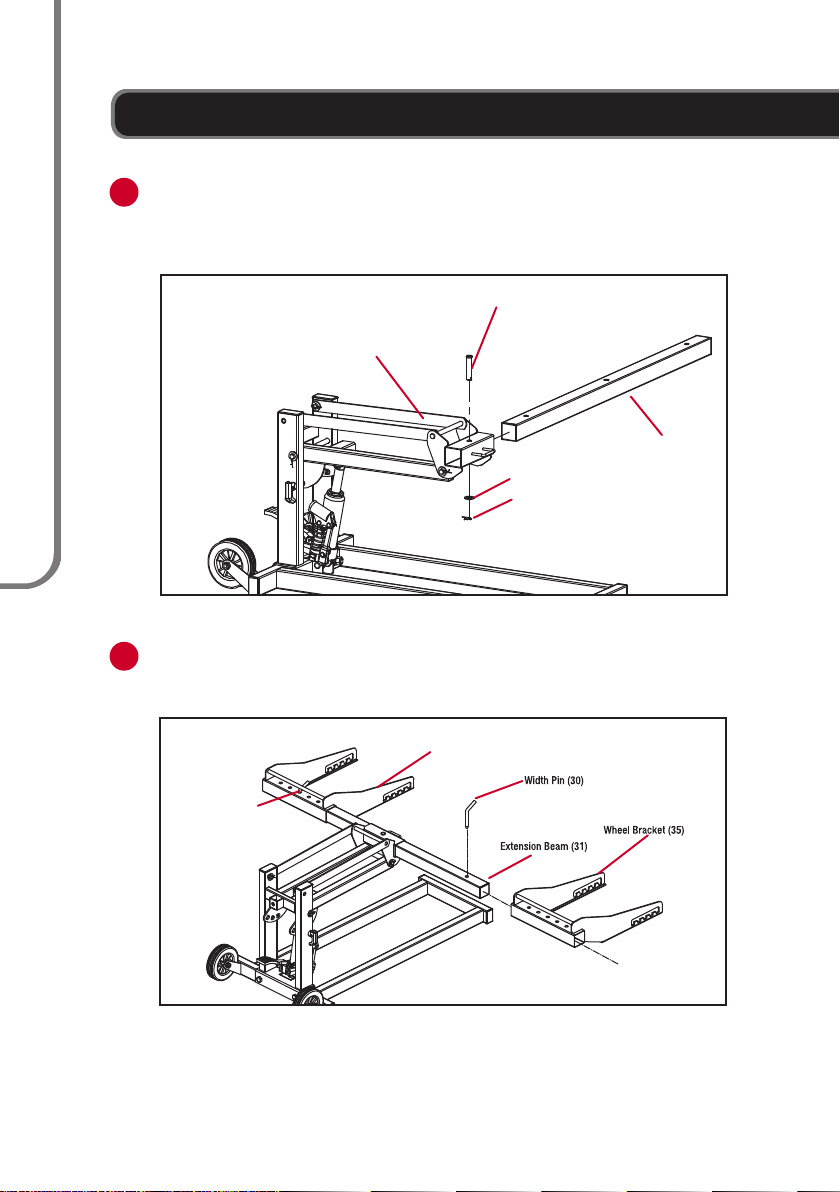

Axle Width

36 – 50 1/2" (91.4 – 128.3 cm)

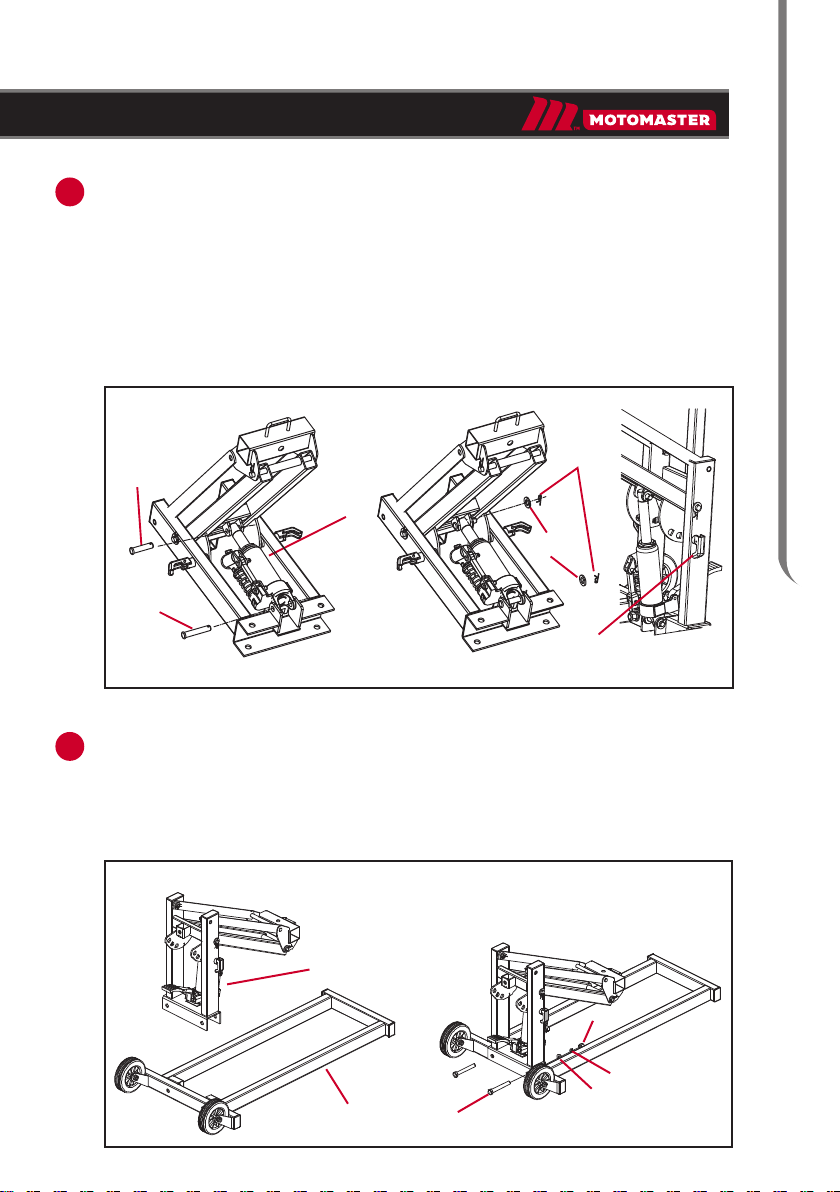

Assembly Precautions

Failure to heed these warnings may result in personal injury and/or property damage.

• Assemble only according to these instructions. Improper assembly can create

hazards.

• Wear ANSI-approved safety goggles and heavy-duty work gloves during assembly.

• Keep assembly area clean and well lit.

Use Precautions

• Study, understand, and follow all instructions before operating this device.

• Do not exceed rated capacity.

• Use only on hard, level surfaces.

• Load wheels equally.

• Lift only on areas of the vehicle as specified by the vehicle manufacturer.

• Immediately after lifting load, ensure jack mechanical load holding means is engaged.

• Do not move while loaded.

• Secure load with appropriate restraint device.

• Do not adjust safety valve.

• Wear ANSI-approved safety goggles and heavy-duty work gloves during use.

• Keep clear of load while lifting and lowering.

• Lower load slowly.

• Do not use for aircraft purposes.

• Inspect before every use; do not use if parts loose or damaged.

• Keep your work area clean and well lit. Cluttered work areas invite accidents.

• Do not allow anyone on the vehicle while using the jack. Keep bystanders a safe

distance away from the vehicle and jack.

• Stay alert. Watch what you are doing, and use common sense when operating a jack.

Do not use a jack while tired or under the influence of drugs, alcohol, or medication. A

moment of inattention while operating jacks may result in serious personal injury.

model no. 009-1534-6 I contact us 1-888-942-6686