URD40SE - EW0526D1_en.docx

CO2gas detectors –URD40SE

Gas detection systems for industrial environments

The relative density of carbon dioxide is about one and a half times that of air, so it

tends to collect at floor level in closed, unventilated environments.

Therefore, the sensor must be installed about 30 cm above the floor level.

Take into consideration the following specific installation guidelines, as well as the

above instructions, for location of the detectors.

The detectors must be installed:

1. where accidental gas leakages are possible

2. at least 1.5m away from heat sources or from vent holes

3. not in spaces where ventilation is poor and where gas pockets may form

4. away from hindrances to natural gas flow

5. away from equipment that may leak gas during normal operations

6. in environments with a temperature range of -20°C to 50°C and relative

humidity below 90% (non-condensing)

7. Disconnect equipment from the power supply when mounting and dismantling

detectors.

CAUTION: safety is guaranteed only if cover is screwed on tight.

-Tighten the cover clockwise, and when it is screwed on, make sure that there is

no more than 0.5 mm between housing and cover. This guarantees that it is

screwed on tight. Remember to tighten the hexagon locking grub screw that fits

into the end of the cover

-Ensure compliance with the words << DO NOT OPEN WHEN ENERGISED >>,

clearly indicated on the cover. Alternatively, make the area safe before opening

the sensor cover.

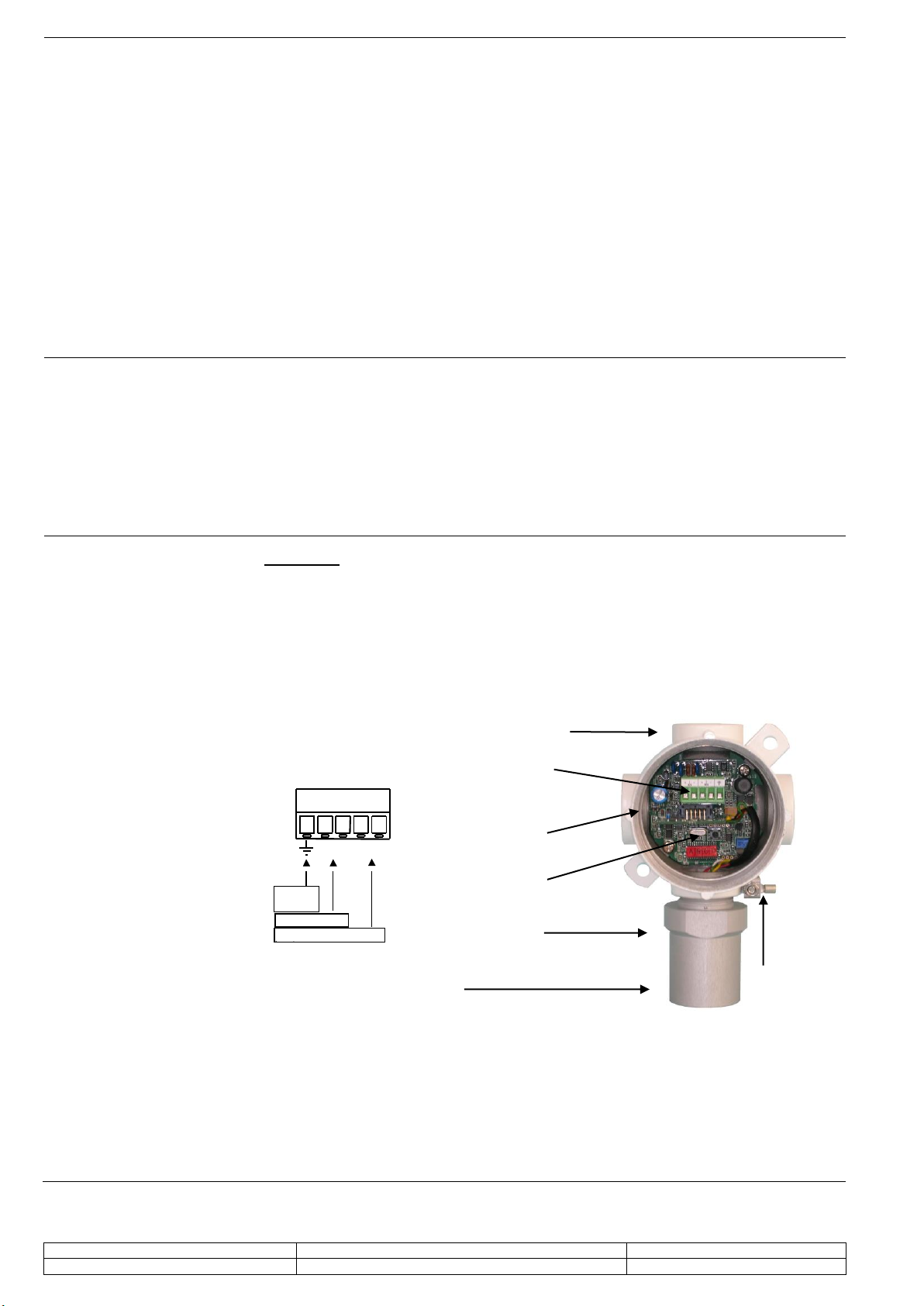

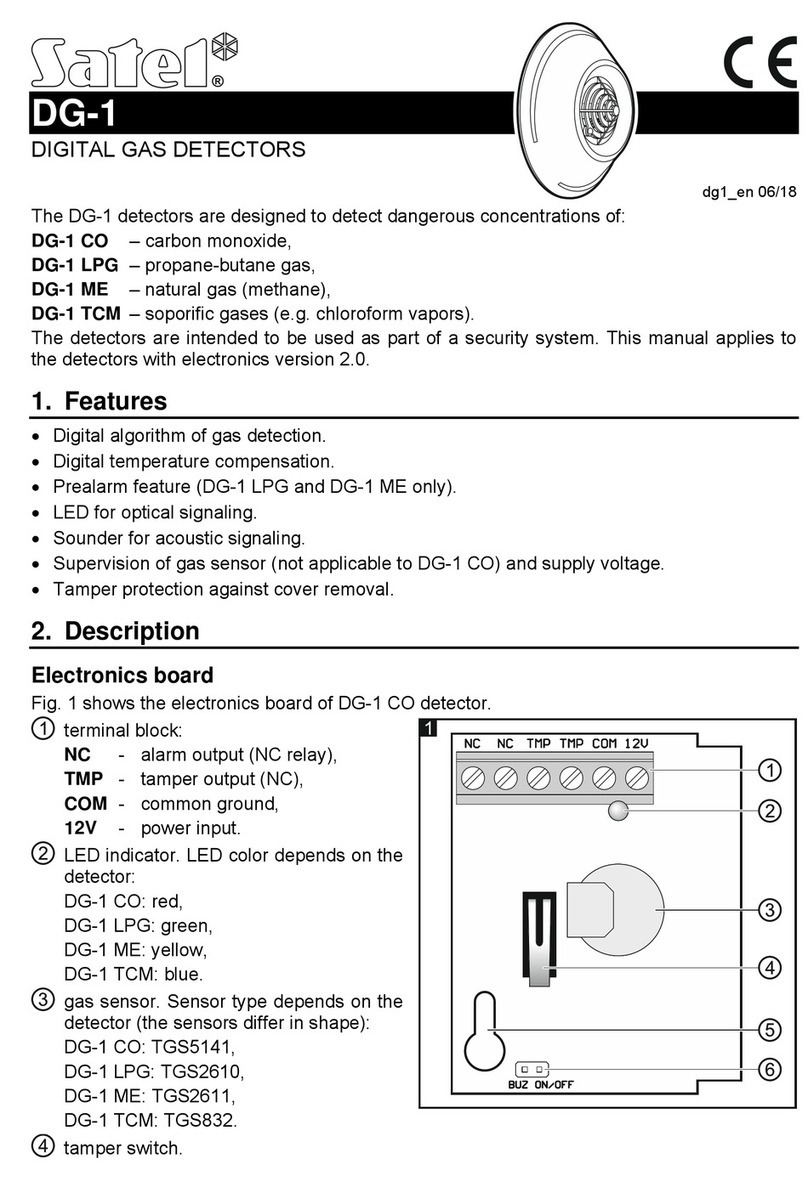

Electrical installation

and configuration

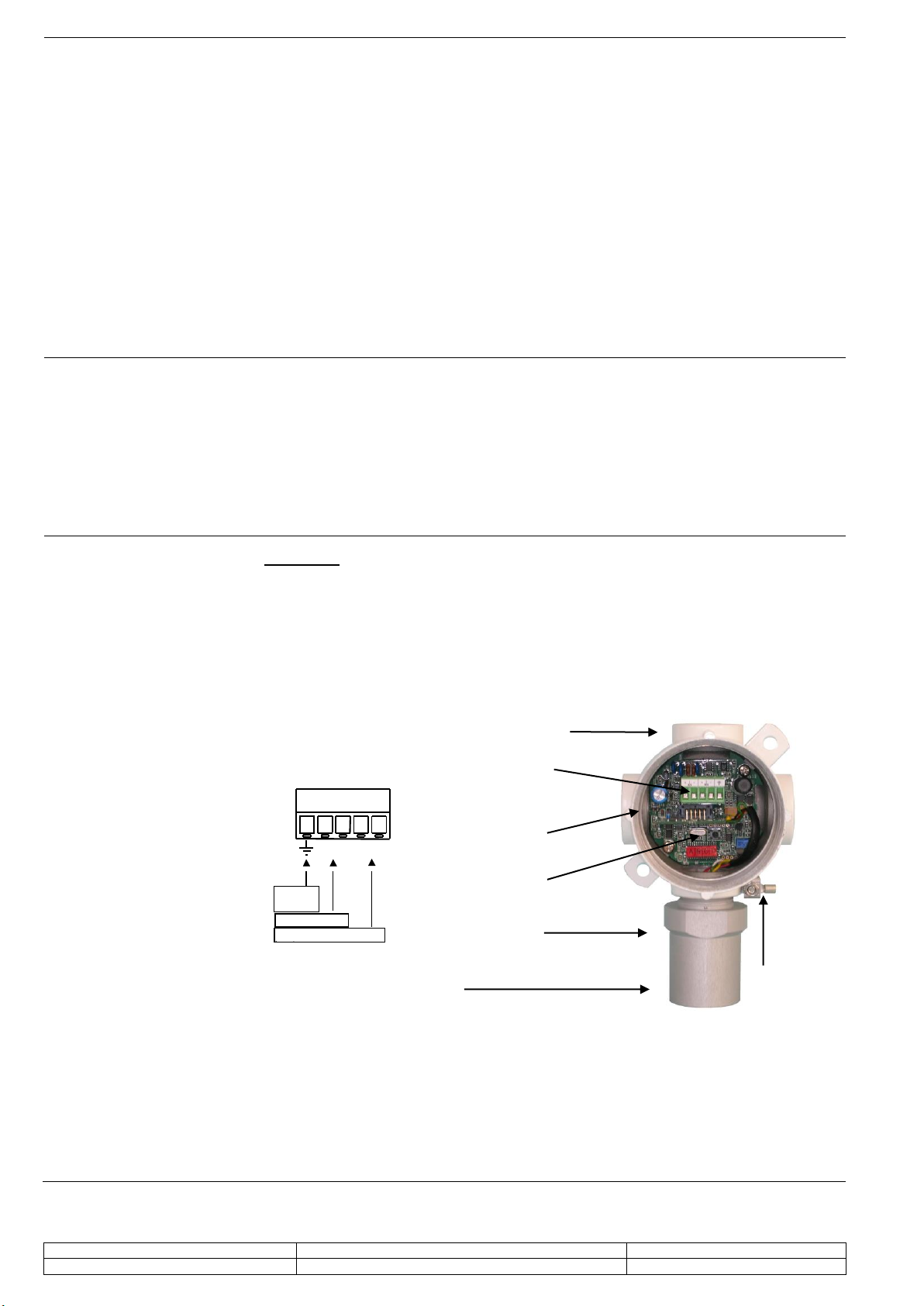

Terminal board and

electrical connections

Cabling:

CAUTION: Make the area safe and ensure that the device power supply is off

before cabling and configuration operations.

Install the sensor in compliance with EN 60079-14.

ATEX certified 1“ NPT cable glands are used for cable entry, in compliance with

standards EN 60079-0 and EN 60079-1 (Ex d protection mode).

Ground the sensor using the internal grounding system.

Refer to the Control Unit manual for all cabling information (cable type and

specifications, bus topology, length of connections etc.) and configuration.

Depending on the connecting distance, use at least 4-core cable, min. diameter

0.75mm2up to 100m, 1mm2up to 200m, 1.5mm2up to 500m.

Use shielded cable where there is a risk of electromagnetic interference.

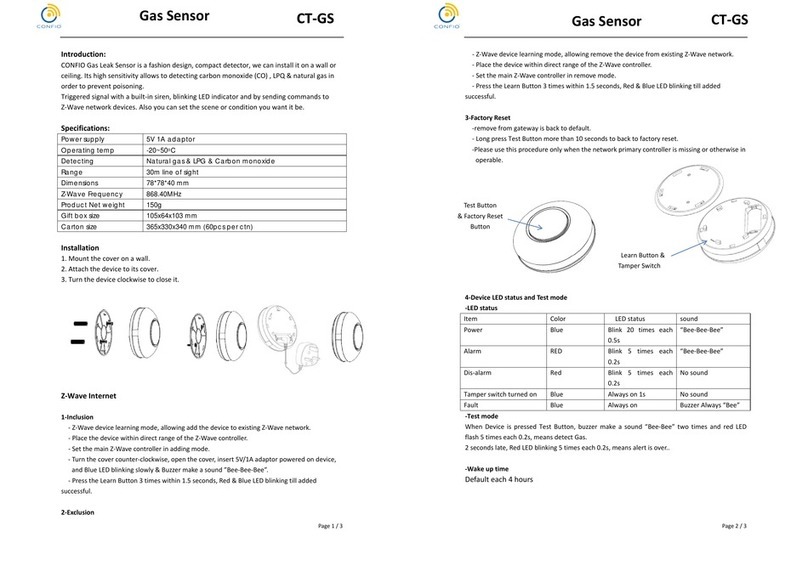

12 Vdc power supply

input

Power supply

and BUS

connector