CO2gas detectors –URD20SE

Gas detection systems for industrial environments

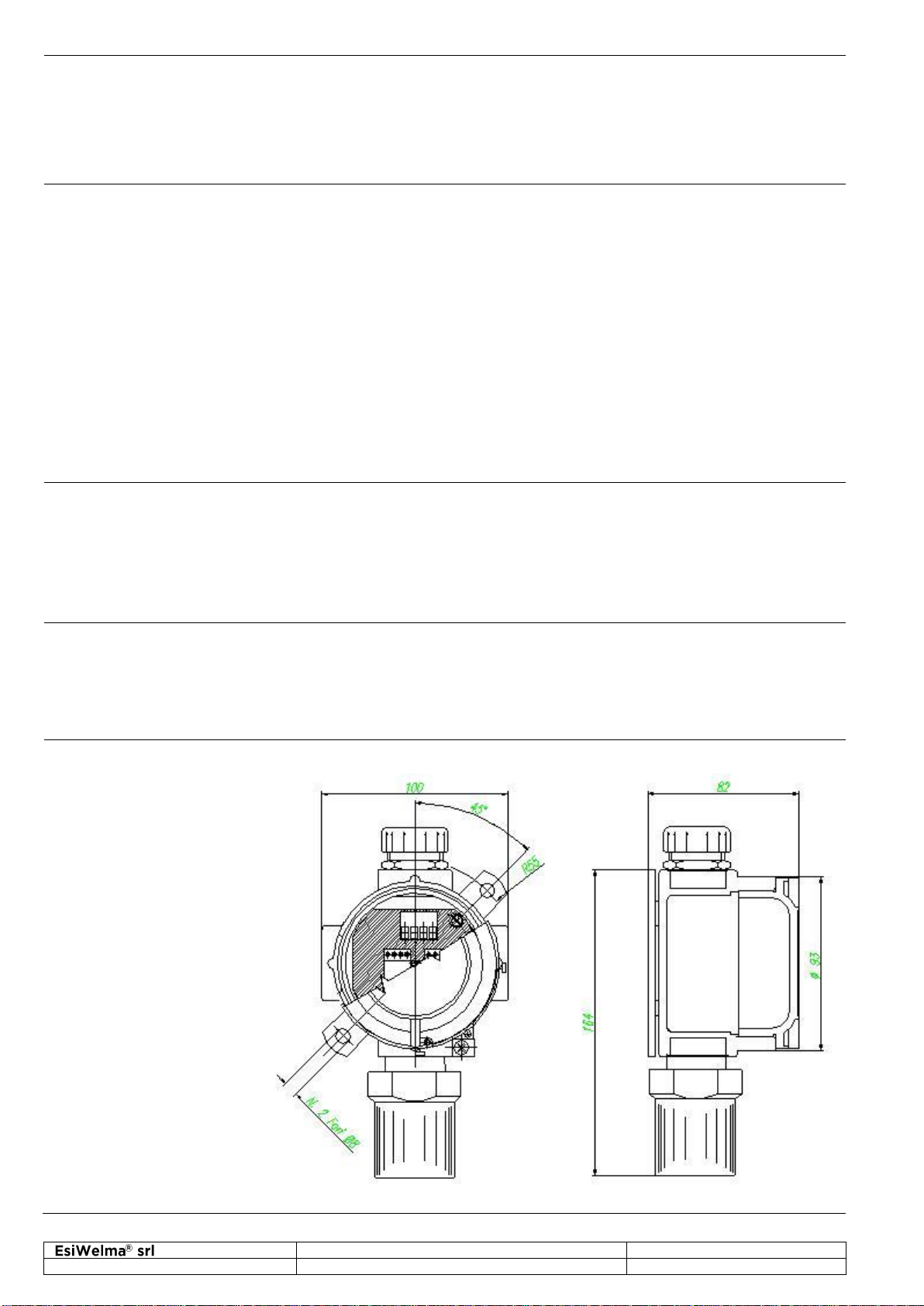

Electrical Installation

Terminal board and

electrical connections

Cabling:

Configuration:

4…20mA Output

reference selection:

4...20mA signal

operating mode

configuration:

Setting threshold limit

values:

CAUTION: Make the area safe and make sure that the device power supply is

off before cabling and configuration operations.

Install the sensor in compliance with EN 60079-14 Standard.

ATEX certified 1“ NPT cable glands are used for cable entry, in compliance with

standards EN 60079-0 and EN 60079-1 (Ex d protection mode).

Ground the sensor using the internal grounding system.

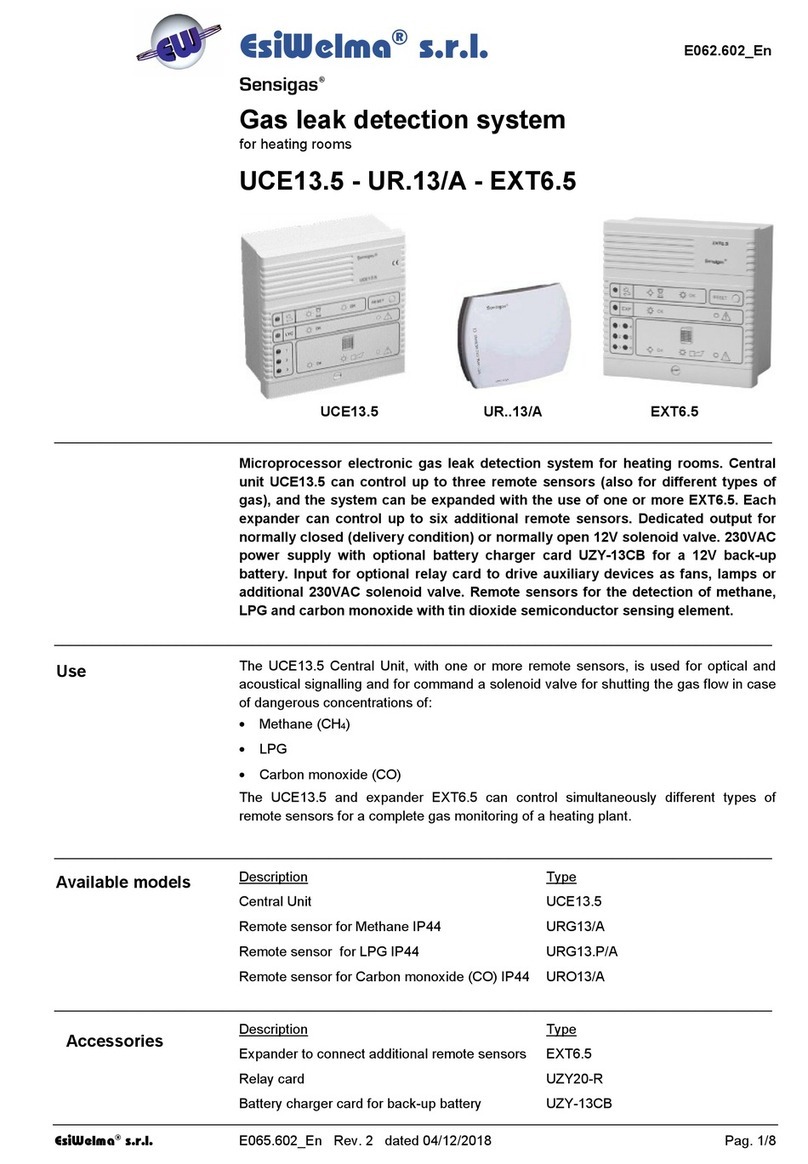

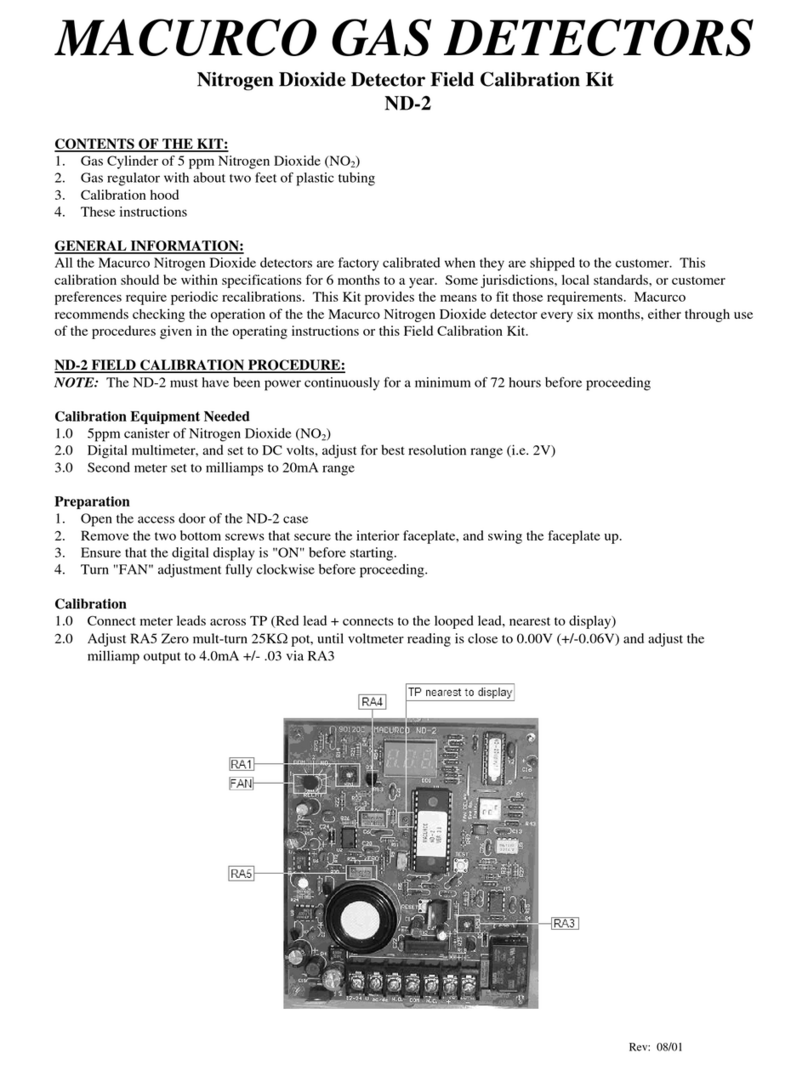

Relay card

(on connector

CN3)

Terminal Board TB1

JP2 jumper circuit Sensor card

S1 DIP switch

CN4 connector for

handheld terminal

Depending on the connecting distance, use at least 3-core cable, min. diameter

0.75mm2up to 100m, 1mm2up to 200m, 1.5mm2up to 500m.

Use shielded cable where there is a risk of electromagnetic interference.

If a relay card is used, use multi-core cable suitable for the number of connections.

Make sure that the cable sheath is no larger than the diameter of the cable gland.

Default settings of the sensor are shown in the “Technical Specifications” chapter.

In order to change the default settings, switch off the power supply, input the new

settings at the JP2 jumper circuit or at the S1 DIP switch as shown in the diagram,

then power-up again; in particular:

The default setting for the 4-20mA signal is the negative power signal. Output

reference selection should be made by JP2 triple of jumpers; to change this setting,

operator has to move JP2 jumpers as shown in the figure:

Caution: if the default settings are changed,

the connections on the TB1 terminal board

will be inverted.

Ref. at -(default) Ref. at +

To set the operating mode of the 4...20mA signal, it is necessary to use the 5th

selector of the DIP switch at S1; in particular:

Proportional Threshold mode

To set the threshold limit values of the optional relay card, or of the threshold

operating mode of the 4...20mA signal, it is necessary to use the first four selectors

of the DIP switch at S1; in particular, the thresholds, given in full scale percentage,

will be:

CUSTOM (*) 3, 5, 10% 5, 10, 15% 5, 10, 20% 10, 15, 25% 10, 15, 30%

10, 20, 40% 10, 25, 35% 15, 25, 40% 15, 30, 45% 25, 35, 50% 20, 40, 60%

(DEFAULT)

20, 40, 80% -----------------Future implementations------------------

(*) When the first four selectors

of the DIP switch are in OFF

position, the threshold limit

values can only be set by the

TUS40handheld terminal.

If this is selected without using

the handheld terminal, the

detector will automatically set

the default threshold limit

values. To set the detector

with the handheld terminal, see

the dedicated instruction

manual.

Connection slot

for relay card