EsiWelma Sensigas URS20SE User manual

EsiWelma Srl

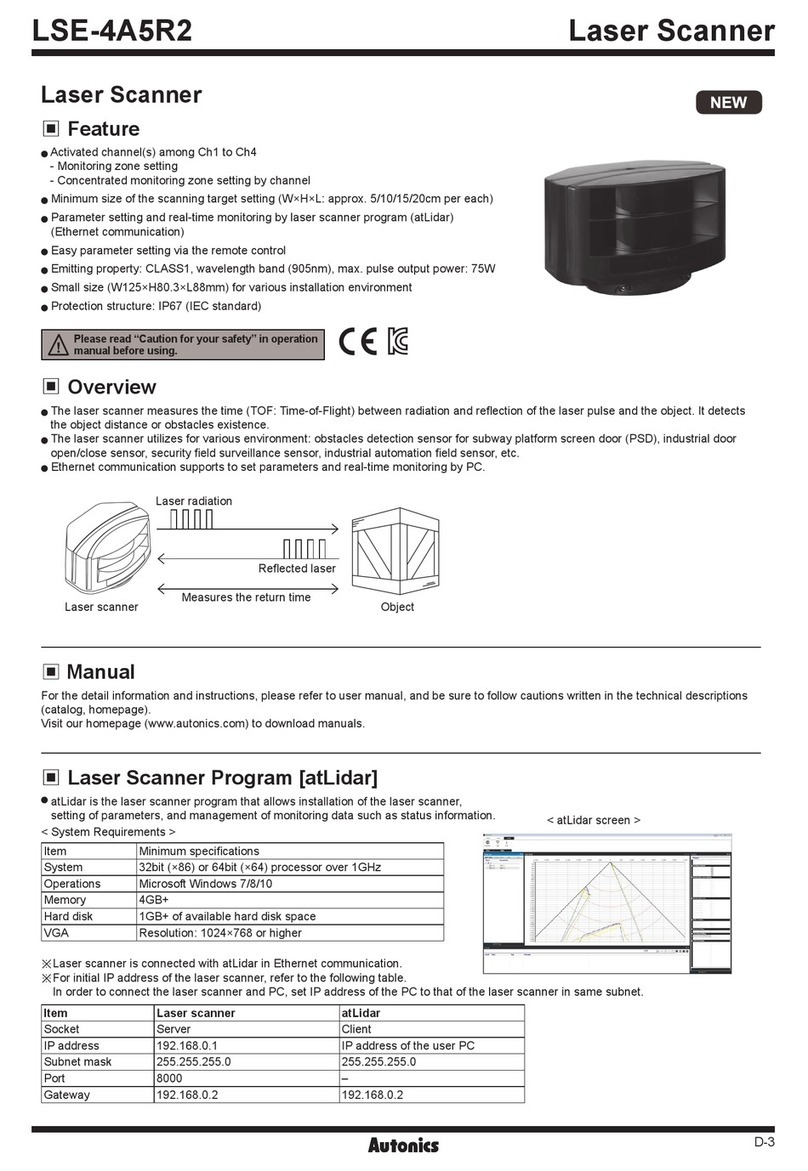

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

1/8

Oxygen detectors

ATEX certified (II 2G Ex d IIC T6)

URS20SE

Sssssss

11…28Vdc power supply.

Electrochemical cell sensor designed for the detection of oxygen (O2).

Up to three alarm thresholds plus sensing element fail.

LED on sensing element body to indicate operating status.

Automatic countdown of sensor life.

Use

The URS20SE detectors are used to detect the presence of oxygen (O2), in areas

classified as Zone 1.

An Oxygen excess forms if it leaks in hospitals, laboratories, welding centres and,

more in general, where oxygen is stored.

Oxygen deficiency is an indirect measurement of the presence of other explosive or

asphyxiant gases that deplete the oxygen in the air.

URS20SE sensors can be used in stand-alone mode with 4…20mA output or with an

optional voltage-free contact relay card having the following four digital outputs:

Pre-alarm, 1st alarm threshold, 2nd alarm threshold, sensor fail.

Operation

If there is an oxygen leak or an absence of oxygen, the detector compares the

measured concentration value with the threshold limit setpoints and energises the

associated relays. Information on the measured concentration value is always at the

4…20mA output.

Ordering

To order, simply state the part number: URS20SE.

For special versions, on request, please contact Customer Service.

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

2/8

Technical

characteristics

Type of sensor

Electrochemical cell

Detectable Gas

O2 excess

O2deficiency

Power supply

11÷28Vdc

Max power consumption

2.5W

Measuring range

0…30% O2

Precision

2,5% of full scale range (in air)

Repeatability

2,5% of full scale range

Measurement resolution

0.1% O2

Microprocessor resolution

1024 points (10 bit)

Digital filter system

Kalman Filter

Watchdog

Internal

Warm-up time

< 2m

Stabilization time

< 2m

Response time

< 10s (T20), < 45s (T90)

Average Sensor life (in air)

120 weeks

Sensor type settings

(O2excess or deficiency)

S1.7 DIP switch

OFF (O2excess)

S1.7 DIP switch

ON (O2deficiency)

Threshold limit settings

(S1.8 = OFF, default): Pre-alarm

1st threshold alarm

2nd threshold alarm

23% O2

25% O2

27% O2

19% O2

17% O2

15% O2

Threshold limit settings

(S1.8 = ON): Pre-alarm

1st threshold alarm

2nd threshold alarm

22% O2

23% O2

24% O2

20% O2

19% O2

18% O2

4..20mA Output

Proportional mode

(default)

Consumption mode

(applications at 1 or 2

thresholds)

4…20mA Output reference

selection:

-4mA = 0% O2

- 20mA = 30% O2

-0mA = no alarm

- 10mA = 1st threshold alarm

- 20mA = 2nd threshold alarm

by jumper selectable polarity

4…20mA output load resistor

- up to 200at 12Vdc power supply

- 200700at 24Vdc power supply

Operating Temperature

Storage Temperature

-20 50 °C

-20 70 °C

Relative Humidity (without condensing)

-Operation

-Storage

15 90 %RH

45 75 %RH

Operating pressure (KPa)

80 110

Air speed (m/s)

6

Visual warnings

Red LED visible with detector energized

Dimensions and weight

See dedicated section

Options & Accessories

Card with 4 SPDT relays UZR20.4

NO or NC contacts available, jumper

selectable

See threshold limit settings

Maximum relay capacity:

50mA at 24Vac/dc, 100mA at 12Vac/dc

Relay operating mode:

-direct: relay ON when an event is

detected

-reverse: relay ON when no event is

detected

TUL40.. Gas calibration kit

See installation and commissioning chapter

TUS40 Handheld terminal

for service and maintenance

See installation and commissioning chapter

CRG40 Gas collecting cone

See dedicated data sheet

PAP40 Powerful jets protection

See dedicated data sheet

ATEX markings

1370 II 2G Ex d IIC T6

BVI 07 ATEX 0032

-20°C TA+50°C

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

3/8

Sensors lifetime

Sensor average lifetime (see technical characteristics) is referred to a typical usage

in a pollution-free environment. Presence of a high concentration of pollutants can

shorten the lifetime of the sensing element.

Once the detection system starts up, it has to be supplied with energy during all the

lifetime of its sensors.

Seasonal use of the detection system is not recommended.

Installation

Oxygen excess

Since oxygen weighs more or less the same as air, unless there is forced or natural air

circulation, it tends to spread at the point of the leak.

So, the excess oxygen detectors must be installed near any likely leakage points, in

order to detect the excess oxygen as quickly as possible.

Oxygen deficiency

Detection of oxygen deficiency has the purpose of indirectly detecting the presence of

other gases that deplete the oxygen in the air, therefore causing asphyxiation problems,

for example.

In this case, the detectors must be located at the breathing height of the occupants in the

premises.

Take into consideration the following specific installation guidelines, as well as the above

instructions, for location of the detectors.

The detectors must be installed:

1. where accidental gas leakages are possible

2. at least 1.5m away from heat sources or from vent holes

3. not in spaces where ventilation is poor and where gas pockets may form

4. away from hindrances to natural gas flow

5. away from equipment that may leak gas during normal operations

6. in environments with a temperature range of -20°C to 50°C and relative humidity

below 90% (non-condensing)

7. Disconnect equipment from the power supply when mounting and dismantling

detectors.

Special

recommendations

CAUTION: safety is guaranteed only if cover is screwed on tight.

-Tighten the cover clockwise, and when it is screwed on, make sure that there is no

more than 0.5 mm between housing and cover. This guarantees that it is screwed on

tight. Remember to tighten the hexagon locking grub screw that fits into the end of

the cover.

-Ensure compliance with the words << DO NOT OPEN WHEN ENERGISED >>,

clearly indicated on the cover. Alternatively, make the area safe before opening the

sensor cover.

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

4/8

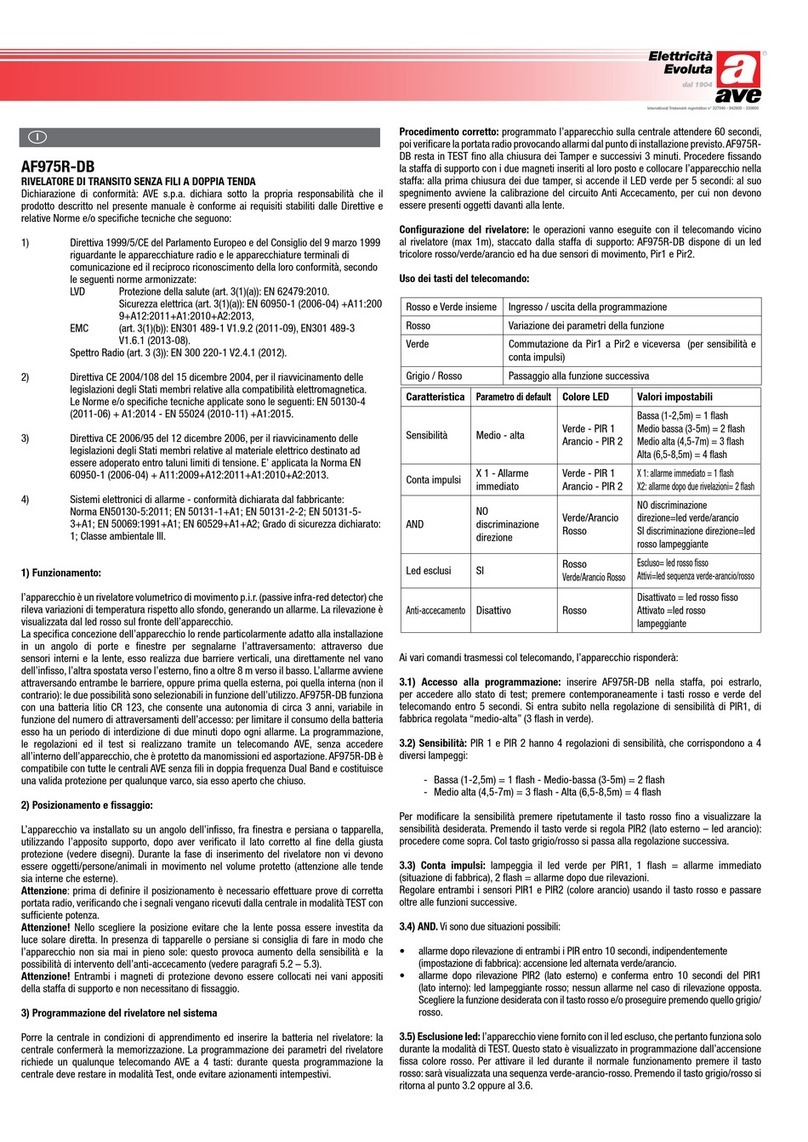

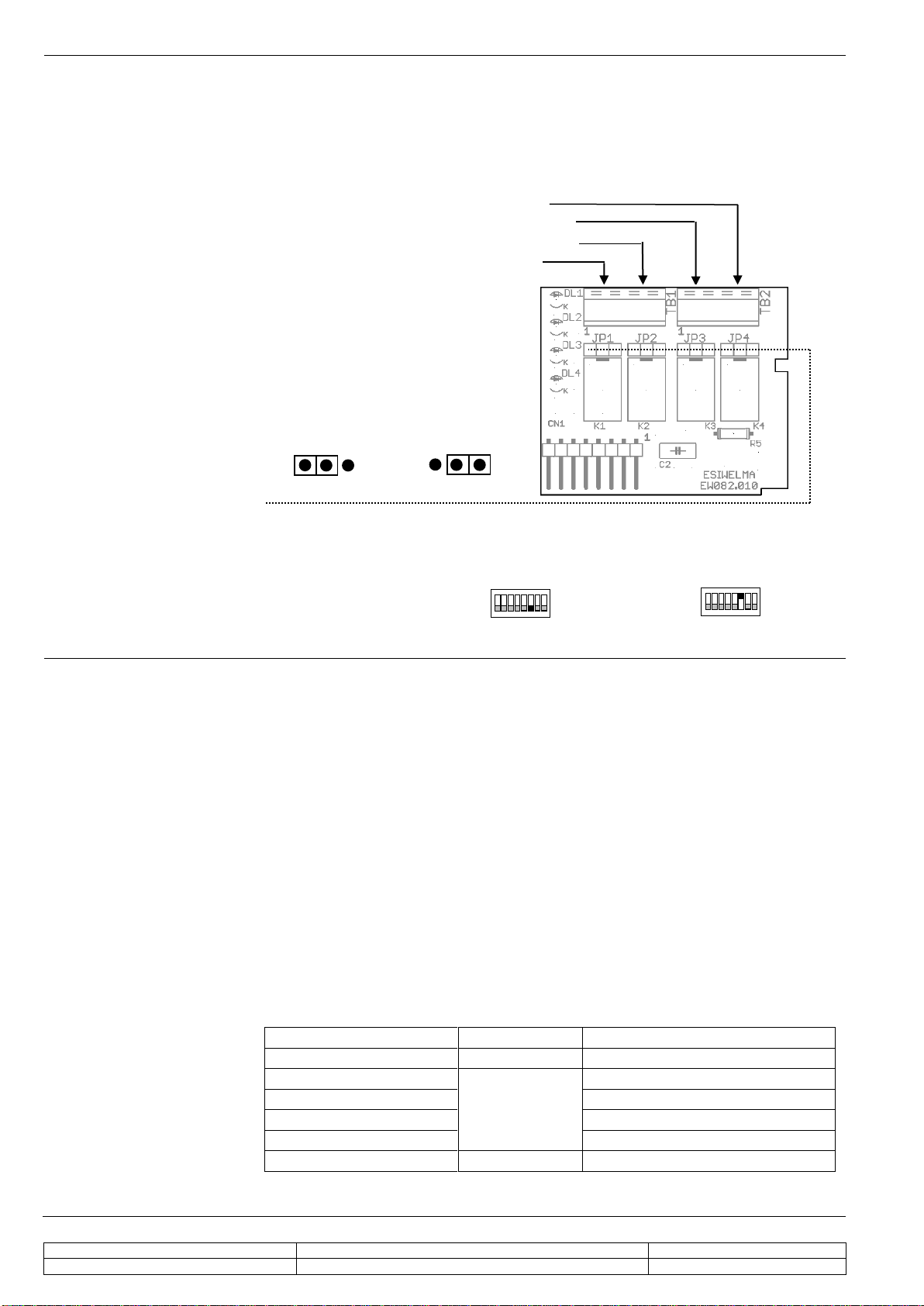

Electrical Installation

Terminal board and

electrical connections

Cabling:

Configuration:

4…20mA Output

reference selection:

4...20mA signal

operating mode

configuration:

Setting threshold limit

values:

CAUTION: Make the area safe and make sure that the device power supply is

off before cabling and configuration operations.

Install the sensor in compliance with EN 60079-14.

ATEX certified 1“ NPT cable glands are used for cable entry, in compliance with

standards EN 60079-0 and EN 60079-1 (Ex d protection mode).

Ground the sensor using the internal grounding system.

Relay card

(on connector

CN3)

Terminal Board TB1

12…24Vdc

+

-

4…20mA

-

+

JP2 jumper circuit Sensor card

S1 DIP switch

CN4 connector for

Handheld terminal

Depending on the connecting distance, use at least 3-core cable, min. diameter

0.75mm2up to 100m, 1mm2up to 200m, 1.5mm2up to 500m.

Use shielded cable where there is a risk of electromagnetic interference.

If a relay card is used, use multi-core cable suitable for the number of connections.

Make sure that the cable sheath is no larger than the diameter of the cable gland.

Default settings of the sensor are shown in the “Technical Specifications” chapter.

In order to change the default settings, switch off the power supply, input the new

settings at the JP2 jumper circuit or at the S1 DIP switch as shown in the diagram,

then power-up again; in particular:

The default setting for the 4-20mA signal is the negative power signal. Output

reference selection should be made by JP2 triple of jumpers; to change this setting,

operator has to move JP2 jumpers as shown in the figure:

Caution: if the default settings are changed,

the connections on the TB1 terminal board

will be inverted.

Ref. at -(default) Ref. at

To set the operating mode of the 4...20mA signal, it is necessary to use the 5th

selector of the DIP switch at S1; in particular:

Proportional Threshold mode

To set the threshold limit values of the optional relay card, or of the threshold

operating mode of the 4...20mA signal, it is necessary to use the last selector of the

DIP switch at S1 (ignore the first four selectors); in particular, the thresholds, given in

percentage of O2, will be:

(S1.8 = OFF, default): Pre-alarm

1st threshold alarm

2nd threshold alarm

O2excess

23% O2

25% O2

27% O2

O2deficiency

19% O2

17% O2

15% O2

(S1.8 = ON): Pre-alarm

1st threshold alarm

2nd threshold alarm

22% O2

23% O2

24% O2

20% O2

19% O2

18% O2

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

Connection slot

for relay card

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

5/8

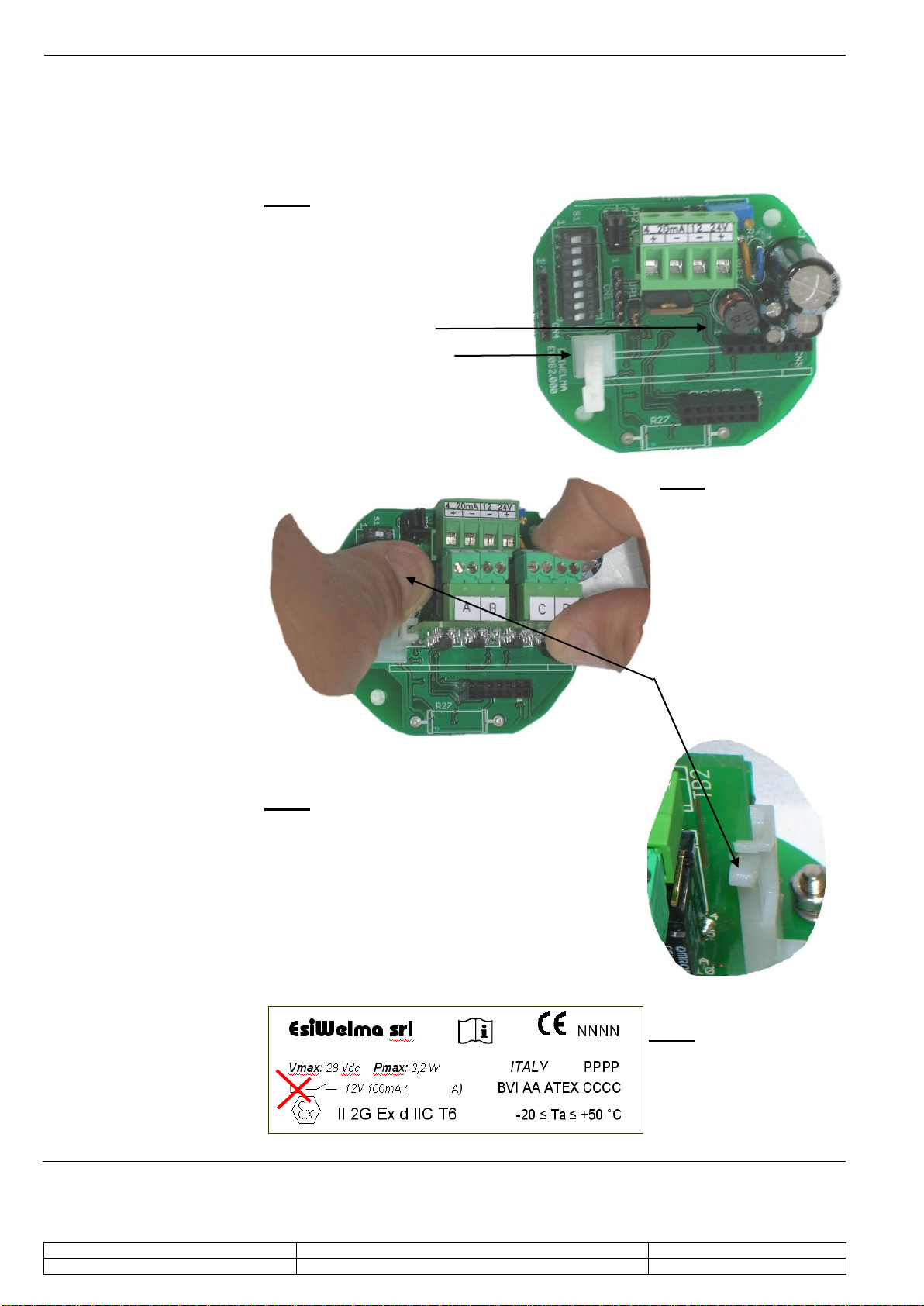

Mechanical installation

of the optional relay

card

The control card can be expanded with a relay card inserted into a dedicated

connector CN3 with four SPDT relays that will be activated under the following

conditions: pre-alarm, 1st threshold alarm 2nd threshold alarm and sensor fail, and

relative LED alerts.

To install the card, follow the instructions below:

Step 1:

Insert the connection slot provided

with the relay card into the control

card, making sure the flexible tab is

towards the main terminal board.

Find CN3 connector.

CN3 connector

Connection slot

(flexible tab)

Step 2:

Fit the relay card snugly

and pull the flexible tab

of the connection slot

towards the main

terminal board.

Flexible tab

Step 3:

Check the position of the card. Make sure

that all the card pins fit into the CN3

connector and push slightly upwards to

check that the flexible tab on the connection

slot keeps the card in place.

Step 4:

Tick the check box with a

permanent marker to

indicate the presence of

the relay card in the device

2.5 W

TYPE URS20SE

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

6/8

Electrical installation of

the optional relay card

Selecting the type of

contact on the terminal

board:

Configuring the relay

operating mode:

After mechanically installing the relay card, it is necessary to configure it electrically,

selecting the relay operating mode and the type of contact desired on the terminal

board (NC or NO).

A pair of extractable terminals is available for each relay; the type of contact (NC or

NO) to be associated with them can be selected using the JP1…JP4 jumpers.

NC or NO contact of pre-alarm relay

NC or NO contact of 1st THRESHOLD relay

NC or NO contact of 2nd THRESHOLD relay

NC or NO contact of FAIL relay

DL1 (yellow), Sensor FAIL

DL2 (red), 2nd alarm THRESHOLD

DL3 (red), 1st alarm THRESHOLD

DL4 (red), Pre-alarm

Selecting the terminal contact:

NC NO

To set the operating mode of the relays: for direct (relay energized by event) or

reverse (relay energized with no event), it is necessary to use the 6th selector of the

DIP switch at S1; in particular:

direct operating mode reverse operating mode

Checklist after

mechanical and

electrical installation

The sensors are factory calibrated so they normally do not require any other

calibration once installed. Still, after installation, an operational check of the sensors

is recommended.

The detector will enter a 2-minute warm-up phase after power-up.

After this time, the sensor will switch to normal operating mode, but it will take about

2 hours before it reaches top performance level.

When the detector is operating, a gas response check should be carried out using

the TUL40.. gas calibration kit. This kit contains:

-1 calibration gas cylinder: 4% of O2; (see kit part numbers on the specific

technical data sheet)

-pressure valve and flow regulator

-sensor body adapter

-about 2 metres of hose between cylinder and adapter.

During the test, check the output current, the status of the LED outside the

enclosure on the sensor body and, if present, the status of the LEDs on the relay

card before closing the housing.

The LED on the sensor body and the 4...20mA output have the following operating

meaning:

Sensor status

4...20mA Output

Status LED on sensor body

WARM-UP

2mA

Flashing at 2Hz frequency

OPERATING

4...20mA

0,10,20mA for

threshold

applications

1 flash about every 10 sec.

PRE-ALARM

2 flashes about every 5 sec.

1st ALARM THRESHOLD

3 flashes about every 5 sec.

2nd ALARM THRESHOLD

4 flashes about every 5 sec.

SENSOR FAIL

22mA

Steady

Since the sensor scale is between 0…...30% O2, in air (20.9% O2) the 4…...20mA

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

D | C

B | A

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

7/8

Checklist after

mechanical and

electrical installation

(continued)

output must be set between 14 and 16mA (theoretic value 15.1mA).

Use the calibration kit to apply the gas mixture at 4% of CO2, making sure the

4...20mA output is between 5 and 7mA (theoretic value 6.1mA); the status LED and

the pre-alarm, 1st and 2nd alarm threshold relays on the optional relay card switch on

according to the thresholds and the alarm mode settings.

Maintenance

Routine

Corrective

Decommissioning

A sensor functional test should be carried out every three-six months.

Routine maintenance involves repeating the same tests as set forth in “checklist

after mechanical and electrical installation”.

If any abnormalities are found during routine sensor maintenance, return the sensor

concerned to the supplier / installer, who in turn will send it back to the

manufacturer.

Sensors may need to be re-calibrated, using the TUL40.. calibration kit and the

TUS40-20 handheld terminal, which must be connected to the sensor via the

communication interface integrated in the cable (on the connector CN4).

For the re-calibration procedure, see the instructions supplied with the handheld

terminal.

Remove power from the detector, disconnect all wiring and conduits and dismount

the housing from all the blocking systems.

Warranty

Warranty on EsiWelma products is valid for 12 months from installation date and

no longer than 24 months from manufacturing date on the product. Installation

data, stamp and signature on the data sheet filled in by the installer will be

considered proof for warranty.

A copy of the warranty data sheet must be sent when returning the product under

warranty.

Accessories

UZR20.4 Four-relay card

TUL40.. Gas calibration Kit

TUS40 Handheld terminal

CRG40 Gas collecting cone

PAP40 Powerful jets protection

Dimensions and weight

Dimensions (HxWxD): 164x100x82mm. Weight: 0.8Kg

EsiWelma Srl

URS20SE - EW0826A1_en.docx

Oxygen detectors –URS20SE

16/06/2017

Gas detection systems for industrial environments

8/8

Key to marking

information

Marking in conformity with all applicable EC Directives

1370 Identification number of Notified Body involved in production control

Marking for all equipment in conformity with Directive ATEX 2014/34/EC

II Equipment group for surface industry

2 Equipment category 2 for use in Zone 1

G Equipment intended for use in explosive gas atmosphere, caused by mixture of air

and gas, vapours, flammable mist

Ex d IIC T6 Type of protection complying with EN60079-0 and EN60079-1

BVI 07 ATEX 0032 EC-type examination certificate

-20°C TA +50°C Operating temperature range

Installation data

To be filled in by Installer

Installer's stamp and

signature

Installation site:

Product order number:

Part Number:

Manufacturing date:

Installation date:

Replacement date:

Routine checks

To be filled in by Installer / Service Personnel

Signature

Remarks

……………………………………………………………………………………………………………..

……………………………………………………………………………………………………………..

……………………………………………………………………………………………………………..

……………………………………………………………………………………………………………..

……………………………………………………………………………………………………………..

Other EsiWelma Security Sensor manuals

Popular Security Sensor manuals by other brands

Alert-it Care Systems

Alert-it Care Systems P162B User/installer handbook

PCB Piezotronics

PCB Piezotronics IMI SENSORS HTTO640B31 Installation and operating manual

logika

logika WL-ZSPWBPWBPW-PI11-04 product manual

Autonics

Autonics LSE-4A5R2 manual

SOR

SOR 102 manual

Superior

Superior AccuTrak VPE-1000 user manual