EP1000 PLC Quick User Manual

Contents

Chapter 1 Product Overview..................................................................................... 1

1.1 Overview.......................................................................................................... 1

1.2 Module Diagram .............................................................................................. 1

1.3 EPX-Programmer ............................................................................................ 3

Chapter 2 Installation ................................................................................................ 4

2.1 Matters Need Attention.................................................................................... 4

2.2 Assemblage..................................................................................................... 5

2.3 Wiring............................................................................................................... 7

2.3.1 Wiring of CPU Module........................................................................................... 7

2.3.2 Wiring of Communication Module ......................................................................... 8

2.3.3 Wiring of Input Module .......................................................................................... 9

2.3.4 Wiring of Output Module...................................................................................... 11

2.3.5 Wiring of Analog Module ..................................................................................... 16

2.3.6 Wiring of Power Supply Module .......................................................................... 17

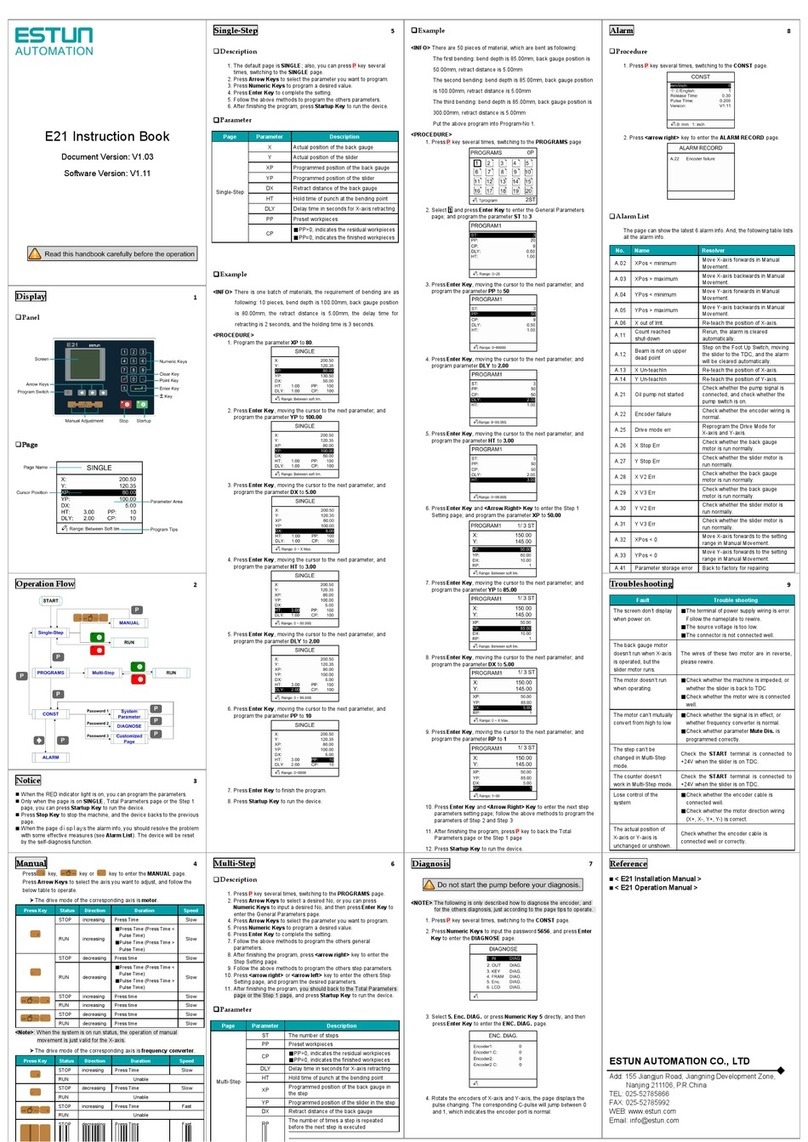

Chapter 3 Basic Operation...................................................................................... 18

3.1 Connect to PC ............................................................................................... 18

3.2 Install and Use EPX-Programmer ................................................................. 18

3.2.1 Installing EPX-Programmer................................................................................. 18

3.2.2 Starting EPX-Programmer................................................................................... 19

3.3 Create a Sample Program............................................................................. 20

3.3.1 Description .......................................................................................................... 20

3.3.2 Procedure............................................................................................................ 21

3.4 Download the Sample Program .................................................................... 22

3.5 Run the Program ........................................................................................... 23

3.6 Status Chart................................................................................................... 23

Appendix A Modules Dimension............................................................................ 25