ESTUN AUTOMATION Proprietary

Contents

Preface .......................................................................................................................................ii

Purpose................................................................................................................................................. ii

Audience .............................................................................................................................................. ii

Organization......................................................................................................................................... ii

Conventions ......................................................................................................................................... ii

Chapter 1 Outline .................................................................................................................1-1

1.1 Introduction................................................................................................................................. 1-1

1.2 Features....................................................................................................................................... 1-2

1.3 Appearance.................................................................................................................................. 1-3

1.4 Electrical Specifications.............................................................................................................. 1-5

Chapter 2 Programming ......................................................................................................2-1

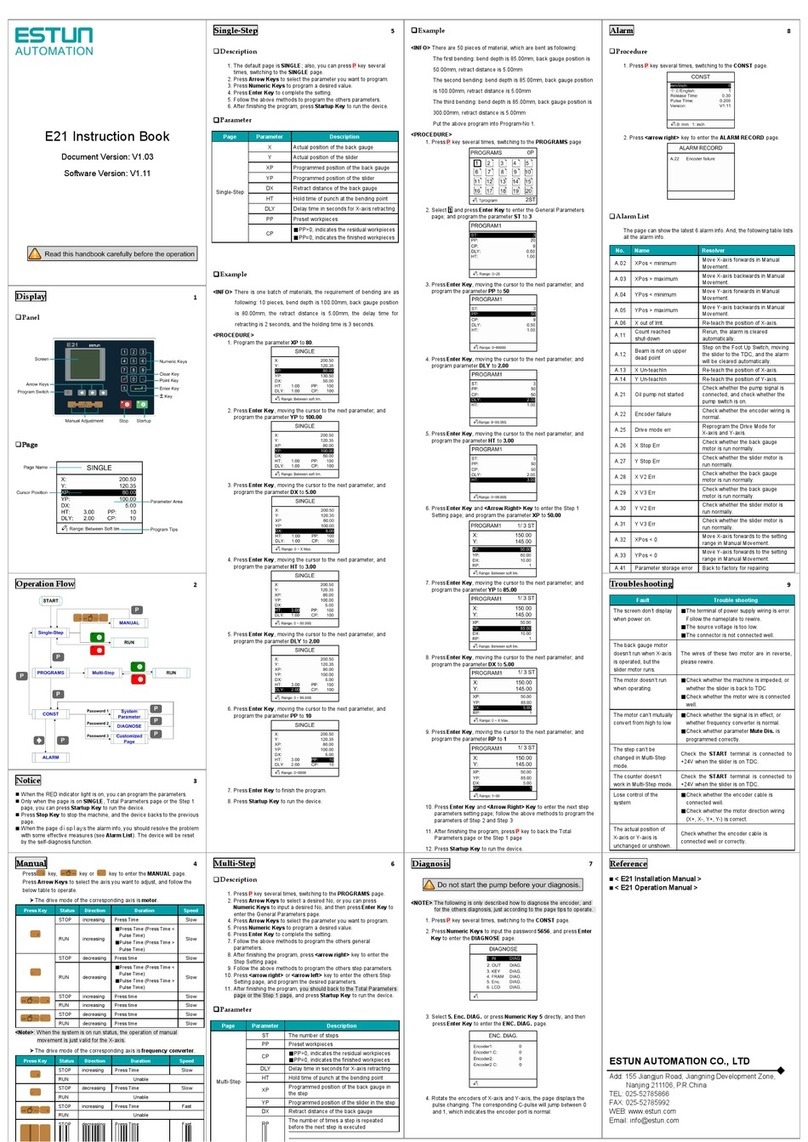

2.1 Page Structure ............................................................................................................................. 2-1

2.2 Operation Flow............................................................................................................................ 2-4

2.3 Single-Step.................................................................................................................................. 2-4

2.4 Multi-Step ................................................................................................................................... 2-7

2.5 Manual Movement.................................................................................................................... 2-11

2.6 Die Settings............................................................................................................................... 2-12

2.7 Bend Correction........................................................................................................................ 2-13

2.8 Program Management............................................................................................................... 2-14

2.8.1 Create a Program................................................................................................................................. 2-14

2.8.2 Edit the Program ................................................................................................................................. 2-15

2.8.3 Delete a Program................................................................................................................................. 2-15

2.9 Teaching.................................................................................................................................... 2-15

Chapter 3 Basic Operation...................................................................................................3-1

3.1 Start............................................................................................................................................. 3-1

3.2 Stop ............................................................................................................................................. 3-1

3.3 Alarm and Reset.......................................................................................................................... 3-2

3.4 Monitor........................................................................................................................................ 3-2

3.5 Constant ...................................................................................................................................... 3-4

Appendix A Glossary...............................................................................................................I

Appendix B Parameters Lists................................................................................................ II

Appendix C Timing Charts..................................................................................................IX

Appendix D Alarm List ........................................................................................................XI