E200InstallationManualV2.14

1

Contents

Contents........................................................................................................................................................ 1

SafetyInstruction.......................................................................................................................................... 2

1.Specification........................................................................................................................................... 4

1.1 Display............................................................................................................................................ 4

1.2 Memory.......................................................................................................................................... 4

1.3 Axisprogramming.......................................................................................................................... 4

1.4 Electricalspecification ................................................................................................................... 4

1.5 Ambientrequirements.................................................................................................................... 5

1.6 Encoderspecification ..................................................................................................................... 5

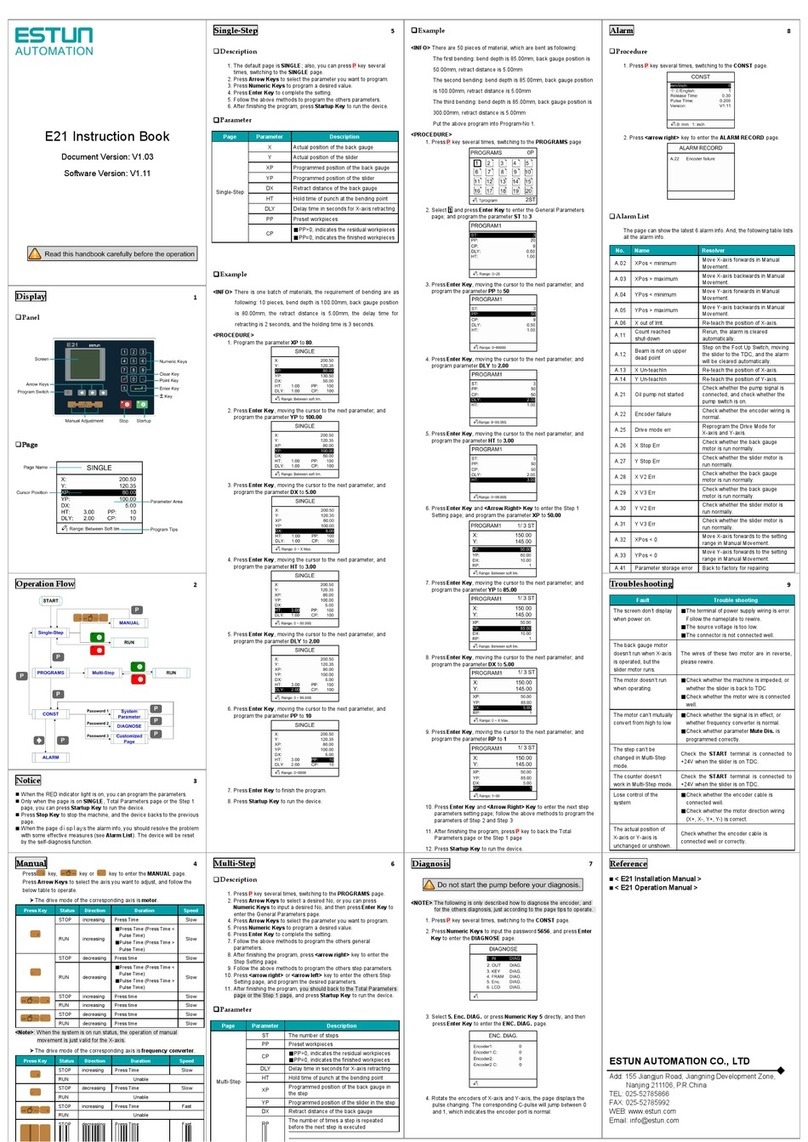

2. Parameterintroduction ............................................................................................................................. 6

2.1 GetintoParameterpage................................................................................................................. 6

2.2 Parametersetup .............................................................................................................................. 7

2.3 Parameterintroduction ................................................................................................................... 8

3. Installation, wiringandcommissioning.................................................................................................. 14

3.1 Outerdimension........................................................................................................................... 14

3.2 Rearpanel..................................................................................................................................... 14

3.3 Commissioningproceduresofcontroller...................................................................................... 17

4.Hardwarediagnosis.............................................................................................................................. 21

4.1 GetintoDiagnosispage................................................................................................................ 21

4.2 Inputdiagnosis.............................................................................................................................. 21

4.3 Outputdiagnosis........................................................................................................................... 23

4.4 Aging............................................................................................................................................ 23

4.5 Encoderdiagnosis......................................................................................................................... 23

4.6 CANdiagnosis.............................................................................................................................. 24

4.7 Keypaddiagnosis.......................................................................................................................... 25

4.8 Restoretofactorysettings............................................................................................................ 26

Appendix 1 MountingMethod ................................................................................................................... 27

Appendix 2 Externalconnectiondiagram.................................................................................................. 28

Appendix 3 FAQ........................................................................................................................................ 30

Appendix 4 EDCparametersschedule....................................................................................................... 32

Appendix 5 E200+EDCalarmsschedule................................................................................................ 33