Page 5 of 38

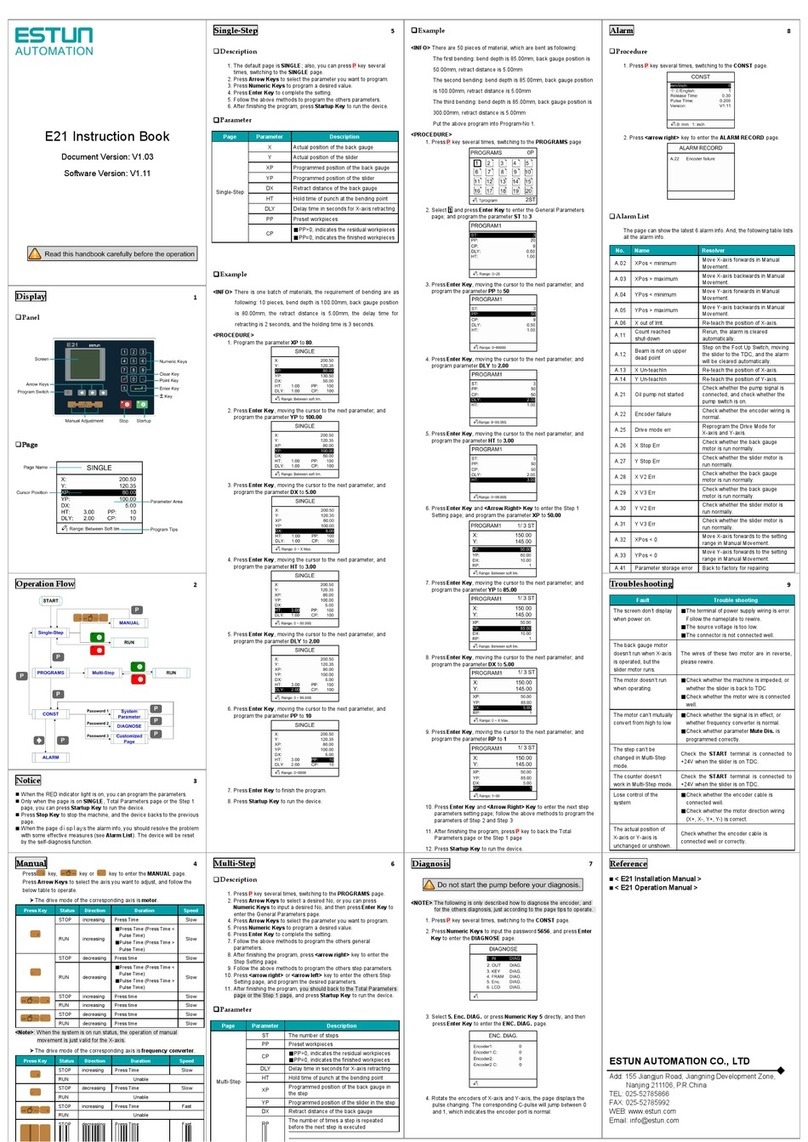

Content

Preface ..........................................................................................................................3

1 Specification.............................................................................................................7

1.1 Display ...................................................................................................................................7

1.2 Internal memory.....................................................................................................................7

1.3 Electrical specification...........................................................................................................7

1.4 Encoder specification.............................................................................................................8

2 Installation ...............................................................................................................9

2.1 Annoucements before installation ..........................................................................................9

2.2 Installation space and direction..............................................................................................9

2.3 Installation environment ........................................................................................................9

2.4 Installation dimension..........................................................................................................10

2.5 Installation layout.................................................................................................................10

2.5.1 Layout of rear panel....................................................................................................10

2.5.2 Rear panel port description ......................................................................................... 11

2.5.3 Overall wiring scheme ................................................................................................12

2.5.4 Electrical wiring scheme.............................................................................................12

2.6 Definition of system interface..............................................................................................13

2.6.1 Definition of power interface......................................................................................13

2.6.2 Definition of input interface .......................................................................................13

2.6.3 Definition of external output interface........................................................................15

2.6.4 Definition of encoder interface ...................................................................................15

2.6.5 Definition of communication interface.......................................................................16

3 Parameter Description of Machine Tool ..........................................................17

3.1 Enter parameter page ...........................................................................................................17

3.2 Parameter specification ........................................................................................................18

4 Debugging..............................................................................................................22

4.1 Preparation before debugging ..............................................................................................22

4.2 Debugging procedure...........................................................................................................22

4.3 Debugging............................................................................................................................22

4.4 Actual processing .................................................................................................................24

5 Diagnosis ................................................................................................................25

5.1 Enter diagnosis page ............................................................................................................25

5.2 Input diagnosis.....................................................................................................................25

5.3 Output diagnosis ..................................................................................................................26

5.4 Keyboard diagnosis..............................................................................................................26

5.5 FRAM diagnosis ..................................................................................................................27

5.6 Encoder diagnosis ................................................................................................................28

5.7 LCD diagosis .......................................................................................................................28