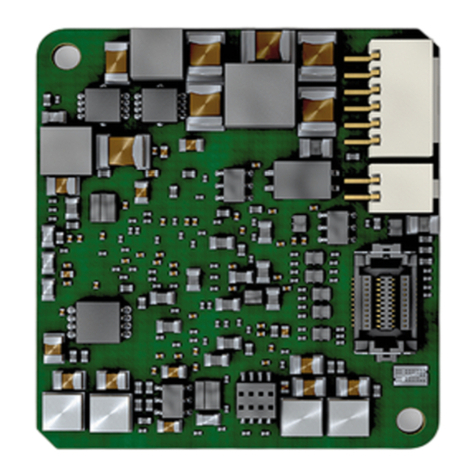

ES4455.1 Load Board - User’s Guide 3

Contents

ETAS Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Load Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Basic Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.1 Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.2 Labeling of Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Taking the Product Back and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

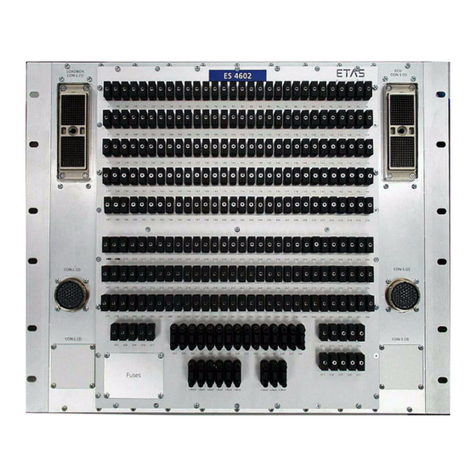

2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Numbering the Loads on an ES4455.1 Load Board . . . . . . . . . . . . . . . . . . . 11

2.1.1 Load Signals to the Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.2 Connecting Loads and Measuring the Signals . . . . . . . . . . . . . . . . 12

2.2 Current Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 Configuring the Current Transducers . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.3 Overcurrent Protection of the Measure Outputs. . . . . . . . . . . . . . . 15

2.3 Digital Current Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Configuring Current Measuring. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.3 Acoustic Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 Settings in LABCAR-RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Pin Assignment and Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 “Threshold Calibration Connection” Connector . . . . . . . . . . . . . . . . . . . . . 19

3.2 LEDs for Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

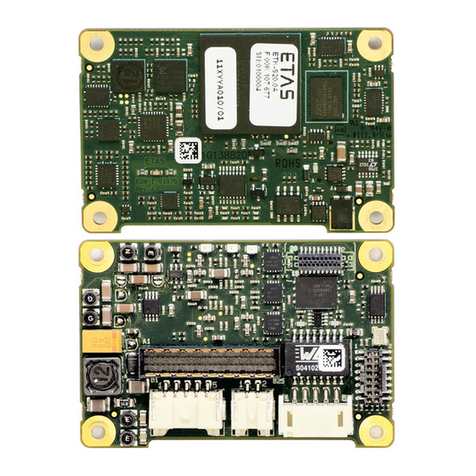

4.1 PB4451CR Piggyback for 2 RB CRS Injectors . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 PB4451GDI Piggyback for 2 RB GDI Injectors . . . . . . . . . . . . . . . . . . . . . . . 22