READ THIS FIRST:

Check the pack and make sure you have all of the

parts listed on the front of this booklet. If not,

contact the outlet where you bought this product.

This product must be installed by a competent

person in accordance with the current building and

IEE wiring regulations.

As the buyer, installer and/or user of this product it

is your own responsibility to ensure that this tting

is t for the purpose for which you have intended

it. Eterna Lighting cannot accept any liability for

loss, damage or premature failure resulting from

inappropriate use.

This product is designed and constructed according

to the principles of the appropriate British Standard

and is intended for normal service. Using this tting

in any other environments may result in a shortened

working life, for example where there is prolonged

periods of use or higher than normal ambient

temperatures.

Switch o the mains before commencing installation

and remove the appropriate circuit fuse or lock o

MCB.

Disconnect the Driver / dimmer from the electrical

supply before ash or high voltage testing.

Do not connect to a circuit which also has inductive

loads connected; switching of inductive loads will

generate spikes which may damage electronic

components within your driver / dimmer.

This unit is suitable for outdoor use.

This product is designed for permanent connection

to xed wiring: this must be a suitable circuit

(protected with the appropriate MCB or fuse).

Before making xing hole(s), check that there are no

obstructions hidden beneath the mounting surface

such as pipes or cables.

Make sure that the xings are strong enough to

support the considerable weight of the tting and

hold it rigidly.

The chosen location of your new tting should

allow for the product to be securely mounted (e.g.

to a ceiling joist) and safely connected to the mains

supply (lighting circuit).

When making connections ensure that the terminals

are tightened securely and that no strands of wire

protrude. Check that the terminals are tightened

onto the bared conductors and not onto any

insulation.

This product must be connected to earth

termination.

This product is not intended to be used by children

and persons with sensory, physical and/or mental

impairments that would prevent them from using it

safely.

You are advised at every stage of your installation to

double-check any electrical connections you have

made. After you have completed your installation

there are electrical tests that should be carried out,

these tests are specied in the current IEE wiring and

building regulations.

OPERATION CHECKS:

Periodic testing should be carried out to ensure

emergency lighting is operating correctly.

Interruption of the supply, causing the tting to be

energised from the battery, should be carried out by

the operation of a local keyswitch or other isolation

device. During this period all ttings should be

examined visually to ensure that they are functioning

correctly. At the end of the test period the supply

shall be restored and all indicator lamps or devices

checked to ensure that the normal supply has been

restored.

DAILY:

Visual inspection of the battery charge LED.

EACH MONTH:

Isolate the power supply for a period sucient to

ensure that each lamp is illuminated. Endorse the

test record form supplied.

ONCE EACH YEAR:

Isolate the power supply and check that the light is

still illuminated after 3 hours. Endorse the test record

form.

Because of the possibility of a failure of the normal

lighting supply occurring shortly after a period of

testing of the emergency lighting system or during

the subsequent recharge period, all full duration

tests shall wherever possible be undertaken

preceding time of low risk to allow for battery

recharge.

NOTE: please keep this instruction booklet and

the test record in a safe place. A re ocer or

other authorised person may want to see your

record of inspection and testing.

INSTALLATION:

01) Choose the location of your new tting giving

consideration to all of the conditions listed above

and the position of the entry points for the mains

supply cable.

02) Put nger in the hole on top of the clip and pull

outwards to release the diuser clips to open up

the tting.

03) Press together the tops of the clips protruding

through the middle of the gear tray and lift the

tray out of the tting.

04) If xing direct to a mounting surface, clear

through the mounting holes on the back of the

tting, visible from the outside, using a 5mm drill.

05) Using the back of the tting as a template, mark

the location of the xing holes on your mounting

surface.

06) If xing directly to a solid surface, drill holes and

insert the plastic plugs supplied.

07) Secure your tting in position using the screws

and washers supplied. Put the washer onto the

screw before xing. If the xings supplied are

not appropriate to your installation, please select

suitable alternatives. Take care not to over tighten

xing screws to prevent damaging the case.

08) Hanging clips are supplied to allow you to

suspend the tting from chains (not supplied).

09) Ensure that the chain is strong enough to support

the weight of the tting and that the tops of the

chains are xed securely to the mounting surface.

10) Pierce the centre of the grommet at the end of

the tting adjacent to the supply wiring. Take

care not to make the hole too large as the tight

t of the gland to the cable is essential for it to

retain its IP rating. Alternatively, t a gland/nut

assembly.

11) Thread the supply cable through the gland.

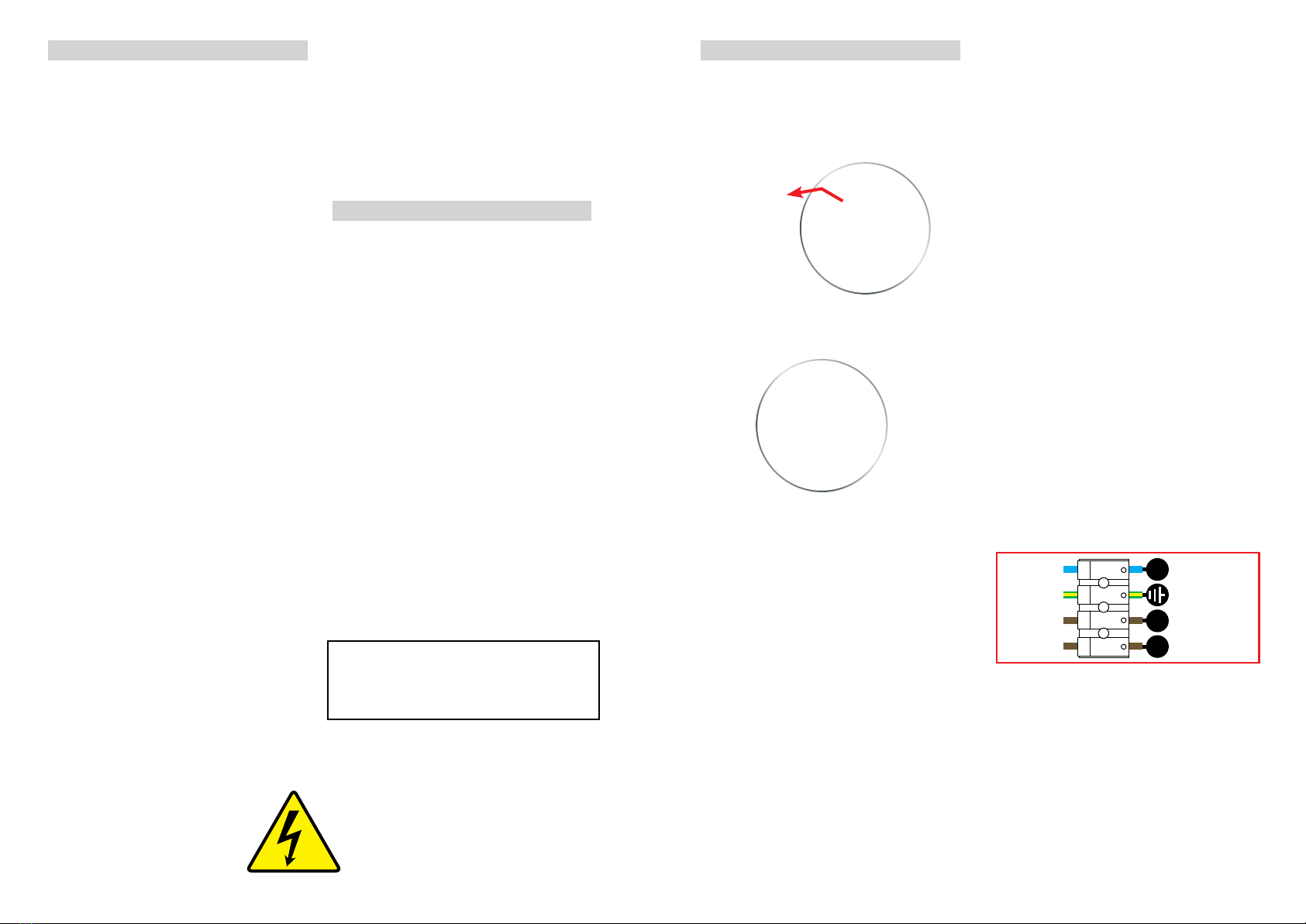

12) Make connections to the terminal block on the

back of the white metal gear tray according to the

following colour code:

Neutral - Blue or Black

Earth - Green and Yellow

PL (Permanent Live) - Brown/Red

SL - (Switch Live) - Brown/Red

13) Adjust the microwave sensor settings as required.

14) Locate the gear tray over the metal clips

protruding from the case and press the gear tray

into position. Ensure that all clips have latched

securely.

15) Hold the diuser in position on the tting so that

it is seated on the soft foam gasket all the way

around.

16) Position the bottom of each clip hook in the lip of

the diuser and press the thumb catches up and

over to lock rmly in position.

17) Restore the power supply and switch on.

NOTE: this unit has a permanent live mains supply,

please ensure you isolate before removing cover.

There may also be a seperate switched supply that

controls the emergency light tting - this also needs

to be isolated.

Yellow/Green EARTH

PL

N

Blue/Black

Brown/Red

Brown/Red

SL

NEUTRAL

PERMANENT LIVE

SWITCH LIVE