8

When the down button is pressed in the operating

mode menu, the cursor is moved to the "With stop

float" line and the "Confirm" button is pressed, the

"Stop Float" operating mode becomes active.

This mode is used in applications where the pump is

desired to run until all deep reservoirs are drained.

In stop float mode, 1 each, 2 operating floats in total

are used to start the pumps, and 1 common stop float

is used to stop the pumps. Start floats are positioned at

the upper water level and the stop float is positioned at

the lower water level. Pumps that are activated with the

help of floaters connected to pressure switch terminals

are stopped with a stop command coming from the

float located at the bottom level in the reservoir

and descends with a decrease in the water level and

"No Water" alarm is not given. It is not suitable for

booster applications. Since the water in the chamber is

discharged, the suction part makes air and the air must

be taken from the system.

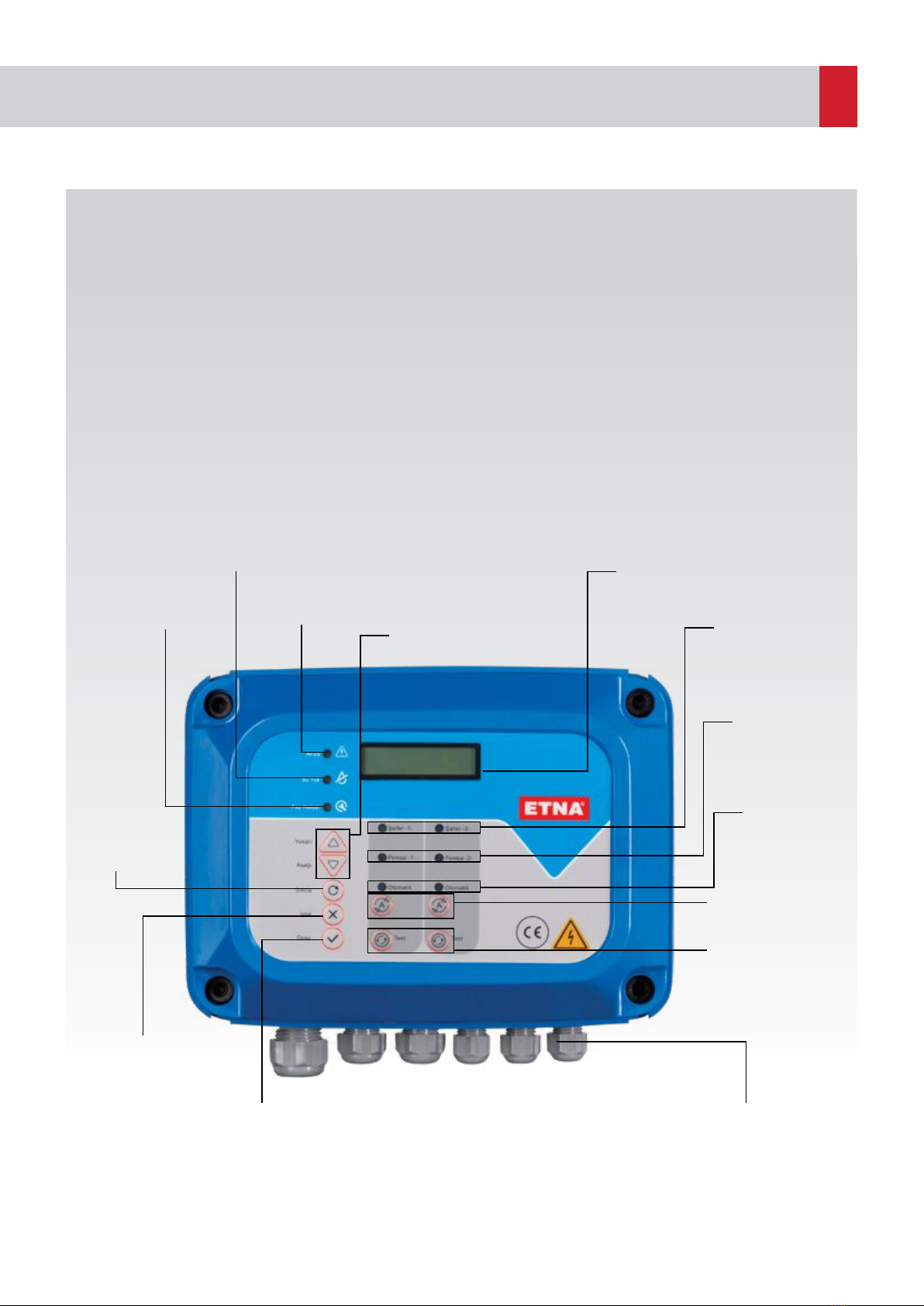

Figure 24. Running Mode Menu

Figure 23. Running Mode Menu

When the "Confirm" button is pressed while the cursor

is on the "Running Mode" line on the Settings main

screen, the screen shown in Figure 23 is displayed.

The "Booster" mode with the cursor is active. In booster

mode, the pumps are switched on and o with the start

or stop command coming from the pressure switches.

In booster mode, the reservoir water level is controlled

with the help of a floater.

Figure 22. Running Mode MainMenu

i. Runnig Mode

Figure 25. PTC Protection Menu

Hydropan full version has a ptc protection menu to

enable or disable PTC protection.

PTC protection Submenu is entered when the

“Approval” button is pressed while cursor is in

the PTC protection line as Figure 25.

When the PTC protection Submenu is entered, as

shown in Figure 26, the cursor is placed in front of the

relevant pump by using the up and down arrow keys

and the Confirm button is pressed.

In the PTC Protection Submenu as shown in Figure

27, select PTC protection or no PTC protection for the

relevant pump and press Approval button.

j. PTC Protection

Figure 26. PTC Protection Submenu

Figure 27. PTC Protection Submenu