6

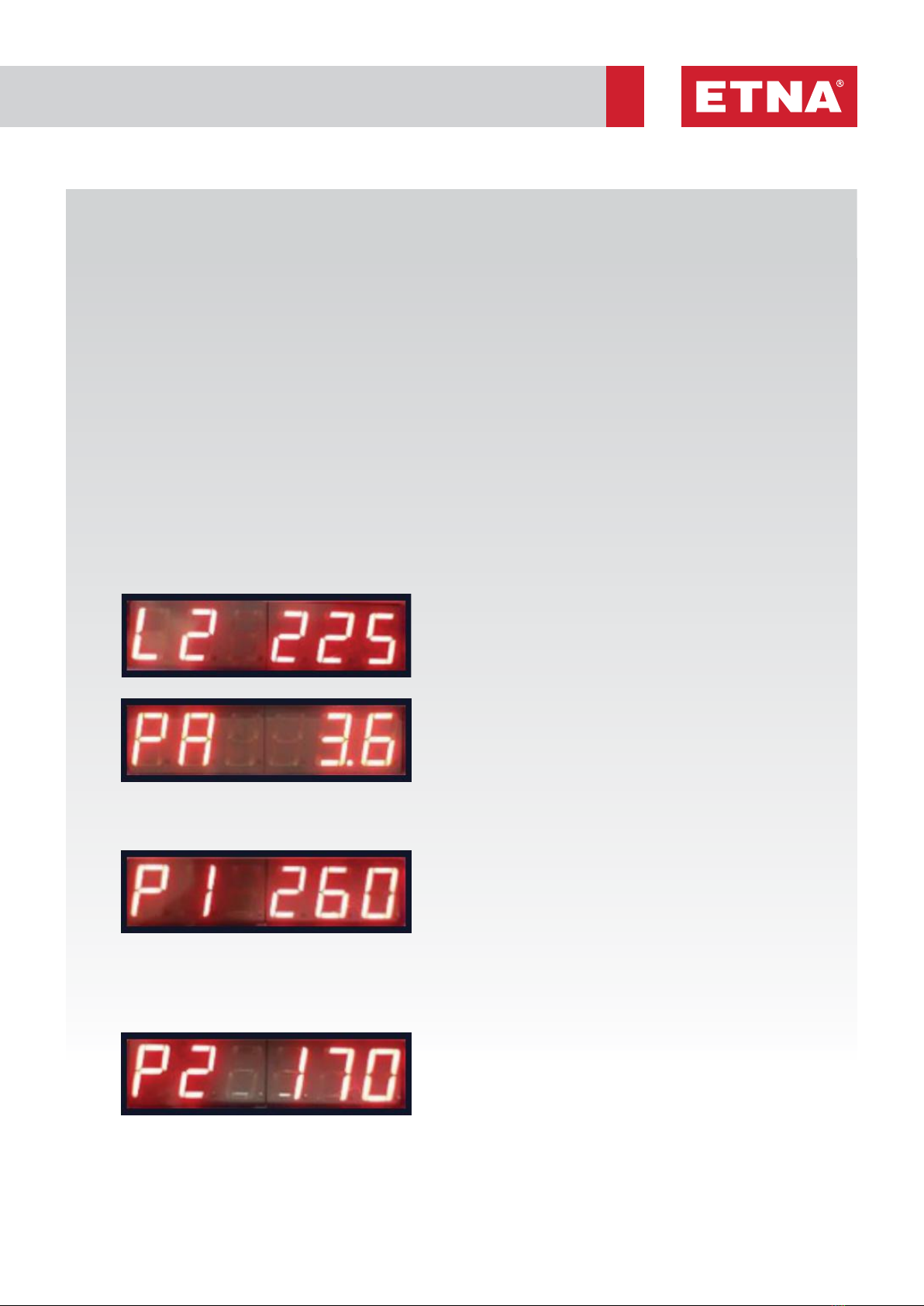

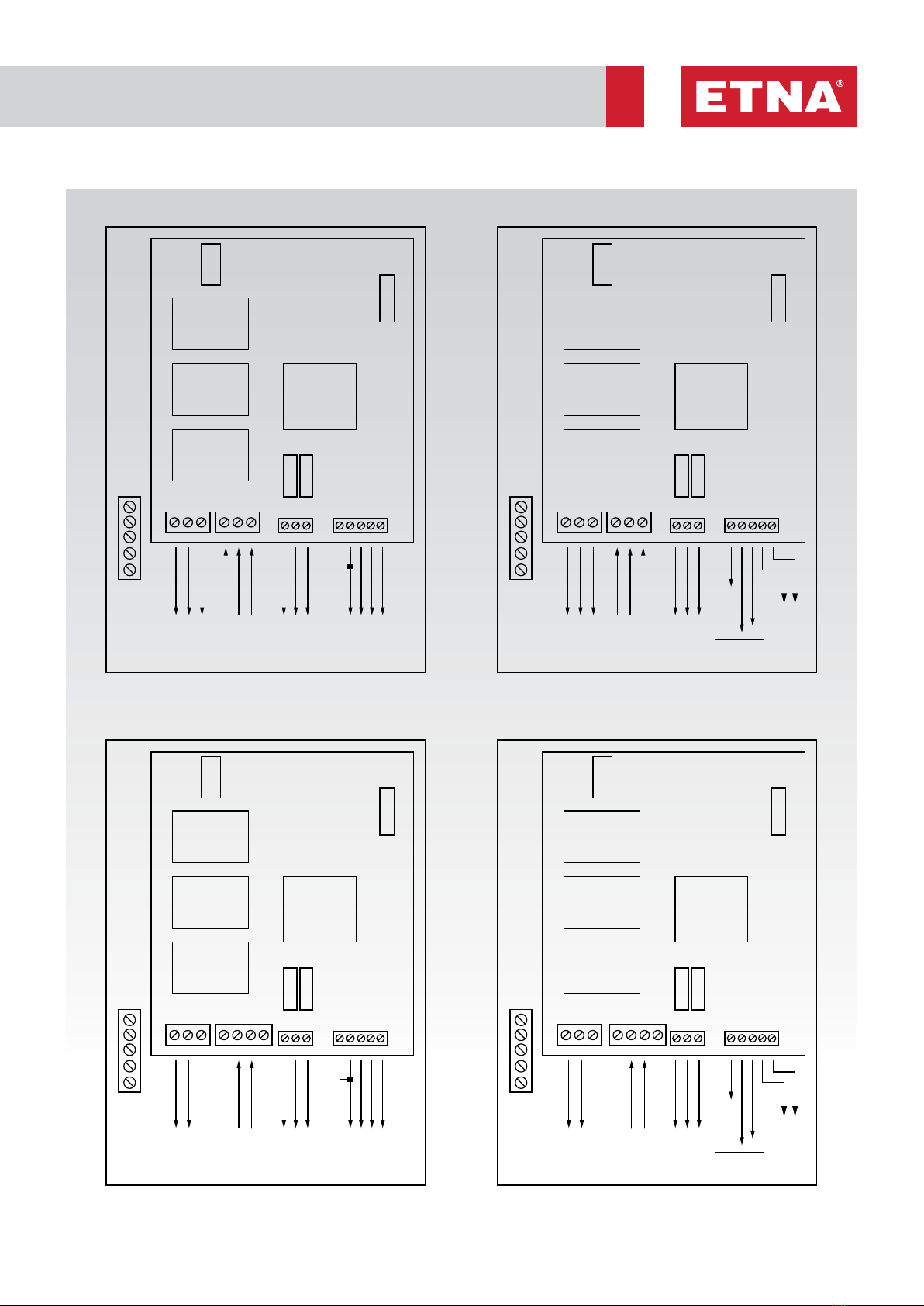

High Current Protection Setting Menu can be

reached by pressing “Approval” button first and

then “Down” button for two times when display is

on main screen. It is possible to enter the submenu

by re-pressing the “Approval” button and high

current protection value can be set by using “Up/

Down” buttons

Low Current Protection Setting Menu can be

reached by pressing “Approval” button first and

then “Down” button for three times when display is

on main screen. It is possible to enter the submenu

by re-pressing the “Approval” button and low

current protection value can be set by using “Up/

Down” buttons

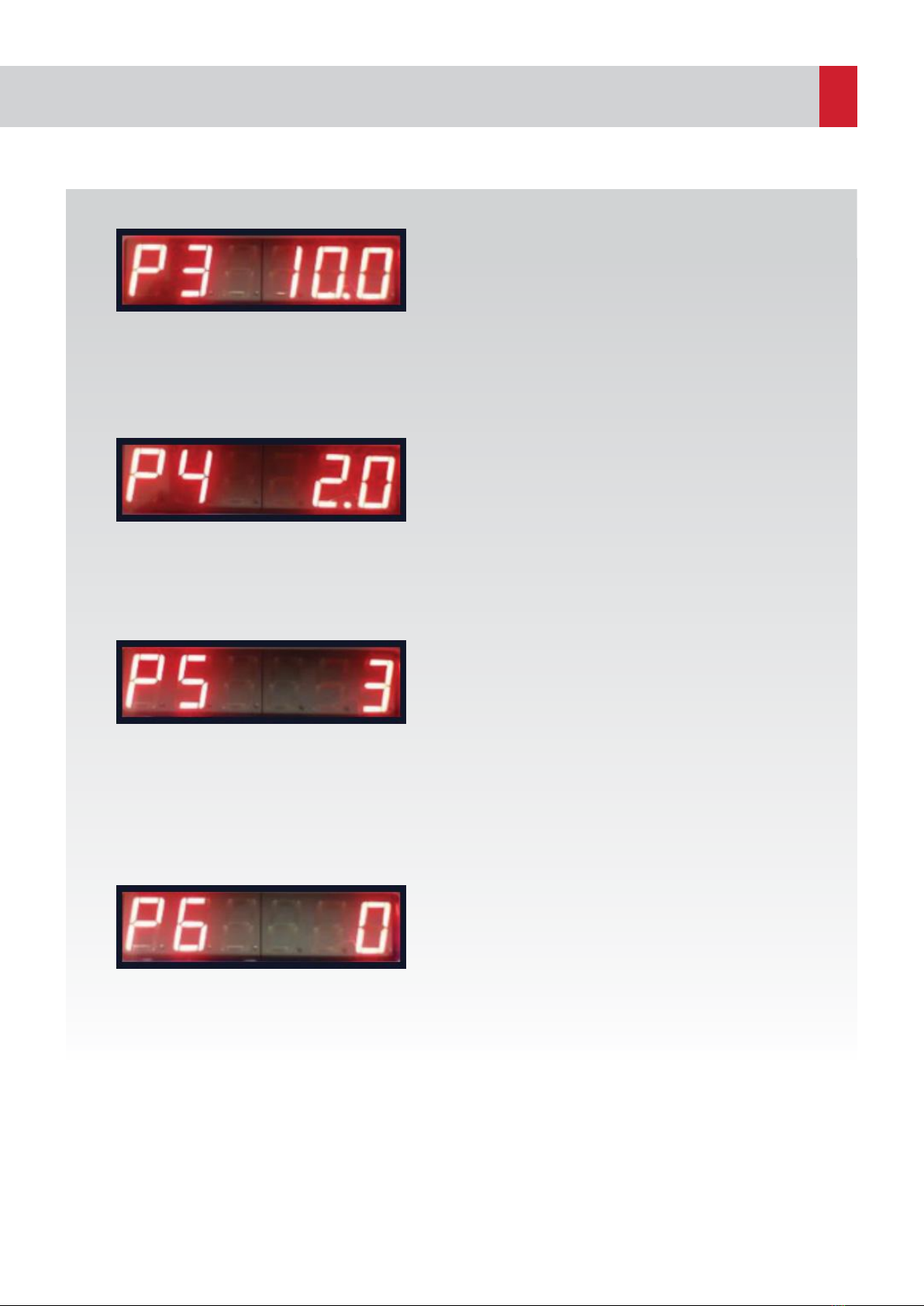

Fault display delay duration means when a

fault detected on the system , warning will be

delayed for this parameter long. Fault Display

Delay Duration Menu can be reached by pressing

“Approval” button first and then “Down” button

for four times when display is on main screen. It is

possible to enter the submenu by re-pressing the

“Approval” button and fault display delay duration

value can be set by using “Up/Down” buttons

Pump Operation Mode Selection Menu as P6

seen on the Figure 10 can be reached by pressing

“Approval” button first and then “Down” button

for five times when display is on main screen. It is

possible to enter the submenu by re-pressing the

“Approval” button and pump operation mode can

be set by using “Up/Down” buttons. By setting the

parameter to “0” the panel can be used in booster,

waste water and deep well applications. When

parameter is set to “1” panel can be used in well

discharging applications. When parameter is set

to “2” panel can be used in well and water storage

tank filling applications.

Figure 7. High Current Settings Menu Menu

Figure 9. Fault Display Delay Duration Menu

Figure 10. Pump Operation Mode Menu

Figure 8.Low Current Settings Menu

c. High Current Protection Setting Menu

d. Low Current Protection Setting Menu

e. Fault Display Delay Duration Menu

f. Pump Operation Mode Selection Menu