Beamer R2 Rev 1.0 Page 2 of 56 6/13/2007

Table of Contents

1. INFORMATION..................................................................................................................................... 4

1.1 SAFETY ........................................................................................................................................... 4

1.2 NOTES.............................................................................................................................................. 4

1.3 Specifications.................................................................................................................................... 5

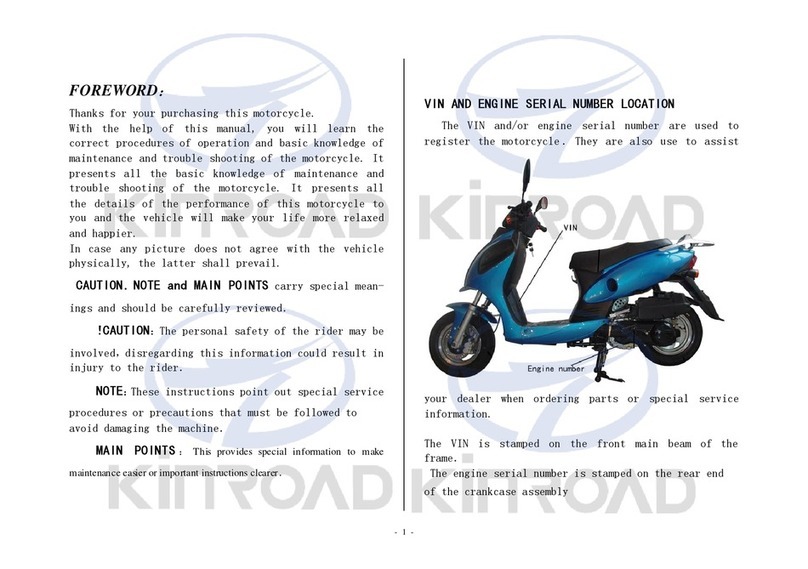

1.4 SERIAL NUMBER .......................................................................................................................... 6

1.5 Standard Torque Values.................................................................................................................... 7

2. MAINTENANCE ................................................................................................................................... 8

2.1 MAINTENANCE DATA ................................................................................................................. 8

2.2 MAINTENANCE SCHEDULE ....................................................................................................... 9

2.3 FUEL TUBE ..................................................................................................................................... 9

2.4 THROTTLE OPERATION .............................................................................................................. 9

2.5 THROTTLE CABLE ADJUSTMENT .......................................................................................... 10

2.6 AIR CLEANER .............................................................................................................................. 10

2.7 SPARK PLUG ................................................................................................................................ 10

2.8 IDLE SPEED .................................................................................................................................. 11

2.9 BRAKE SYSTEM .......................................................................................................................... 11

2.10 WHEELS AND TIRES................................................................................................................. 12

2.11 GEAR OIL .................................................................................................................................... 12

2.12 ENGINE STOP SWITCH............................................................................................................. 12

2.13 HIGH-LOW BEAM CONTROLLER .......................................................................................... 13

3. ENGINE REMOVAL AND INSTALLATION ................................................................................... 14

3.1 ENGINE REMOVAL..................................................................................................................... 14

3.2 ENGINE INSTALLATION............................................................................................................ 16

4. ENGINE FUEL SYSTEM.................................................................................................................... 17

4.1 TROUBLESHOOTING.................................................................................................................. 17

4.2 CARBURETOR.............................................................................................................................. 18

5. ENGINE LUBRICATION AND COOLING SYSTEM ...................................................................... 21

5.1 TROUBLESHOOTING.................................................................................................................. 21

5.2 ENGINE LUBRICATION SYSTEM............................................................................................. 21

5.3 CAUTION: Fuel/Oil Ratio ............................................................................................................. 21

5.4 OIL PUMP...................................................................................................................................... 22

5.5 COOLING SYSTEM...................................................................................................................... 23

6. ENGINE COMBUSTION SYSTEM ................................................................................................... 23

6. ENGINE COMBUSTION SYSTEM ................................................................................................... 24

6.1 TROUBLESHOOTING.................................................................................................................. 24

6.2 CYLINDER AND PISTON REMOVAL....................................................................................... 25

6.3 CYLINDER AND PISTON INSPECTION ................................................................................... 25

6.4 INSTALLATION ........................................................................................................................... 27

7. TRANSMISSION SYSTEM ................................................................................................................ 29

7.1 TROUBLESHOOTING.................................................................................................................. 29

7.2 THE PARTS DRAWING OF TRANSMISSION SYSTEM.......................................................... 29

7.3 TRANSMISSION POWER PATH ................................................................................................ 30

7.4 AUTOMATIC CONTINUOUS VARIABLE TRANSMISSION.................................................. 31

7.5 CONTINUOUS VARIABLE TRANSMISSION........................................................................... 31

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com