The instrument cluster provides you with

operating conditions of your vehicle. To the

left is the fuel gauge which indicates the fuel

level in the fuel tank. When the needle

reaches the red zone on the gauge, you are

running Iow on fuel and the tank should be

refilled. This gauge is controlled by a fuel

level sending unit located inside the fuel tank.

The center speedometer indicates the

current speed of your vehicle. The

speedometer is calibrated in both MPH,

(Miles per hour) and KPH, (Kilometers per

hour). This gauge is controlled by a cable

attached to the front wheel of the vehicle.

The right side is a series of three indicator

lamps. The top most lamps in the cluster will

indicate that the turn signals have been

activated and also indicates which signal

lamps are illuminated.

The right indicator lamp indicates the head

light controller is in the Hi-Beam, 100%,

position when illuminated.

The left lamp indicates the 2 cycle oil level in

the oil tank. When illuminated your oil tank is

Iow and needs to be refilled. Continued

operation of the engine with a Iow oil

condition will cause sever damage to the

engine and potentially unsafe operating

condition. Refill your oil tank with High grade

JASO FC 2 cycle injector oil.

Instrument Cluster

Throttle Control

The throttle control is the right-hand handle grip.

Throttle is controlled by twisting the grip.

The throttle control is spring loaded and set

at the factory to return to the idle position

when pressure is released.

Page 5

Ignition Switch

Ignition Switch

and stops the engine. The "OPEN" position can open

the seat when you want to use the storage compart-

ment under the seat. The "LOCK" Position locks the

In order to turn the key to the "LOCK" Position

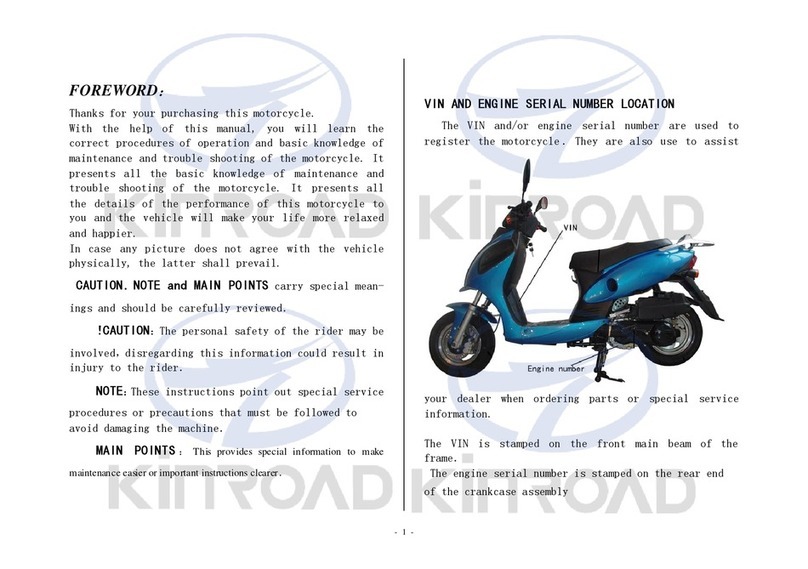

The ignition switch is located on the control

column's right side below the handlebars. A key

is required to work the switch. This switch has

three positions,"ON", "OFF", "OPEN" and "LOCK".

The switch must be in the "ON" position for the

engine to start and run. The "OFF" position

disconnects power to the ignition and light circuits

steering column and allows the key to be removed.

position you must press down on the key with

the steering column turned slightly to the left.

NOTE: Always lock your vehicle when leaving it

unattended and take your keys for additional

security against theft of your vehicle.