SAFETY INSTRUCTION- QUICK GUIDE

SIKKERHEDS INSTRUKTIONER- Forkortet udgave

SICHERHEITSINSTRUKTIONEN- Kurzausgabe

VEILIGHEIDSINSTRUKTIES- Korte uitgave

INSTRUCCIONES DE SEGURIDAD - GUIA RAPIDA

•Laws governing safety aspects on machinery may vary between countries but the following guides will useful to all operators:

•Before starting, carefully read the machine maintenance and operating manual and follow all the instructions.

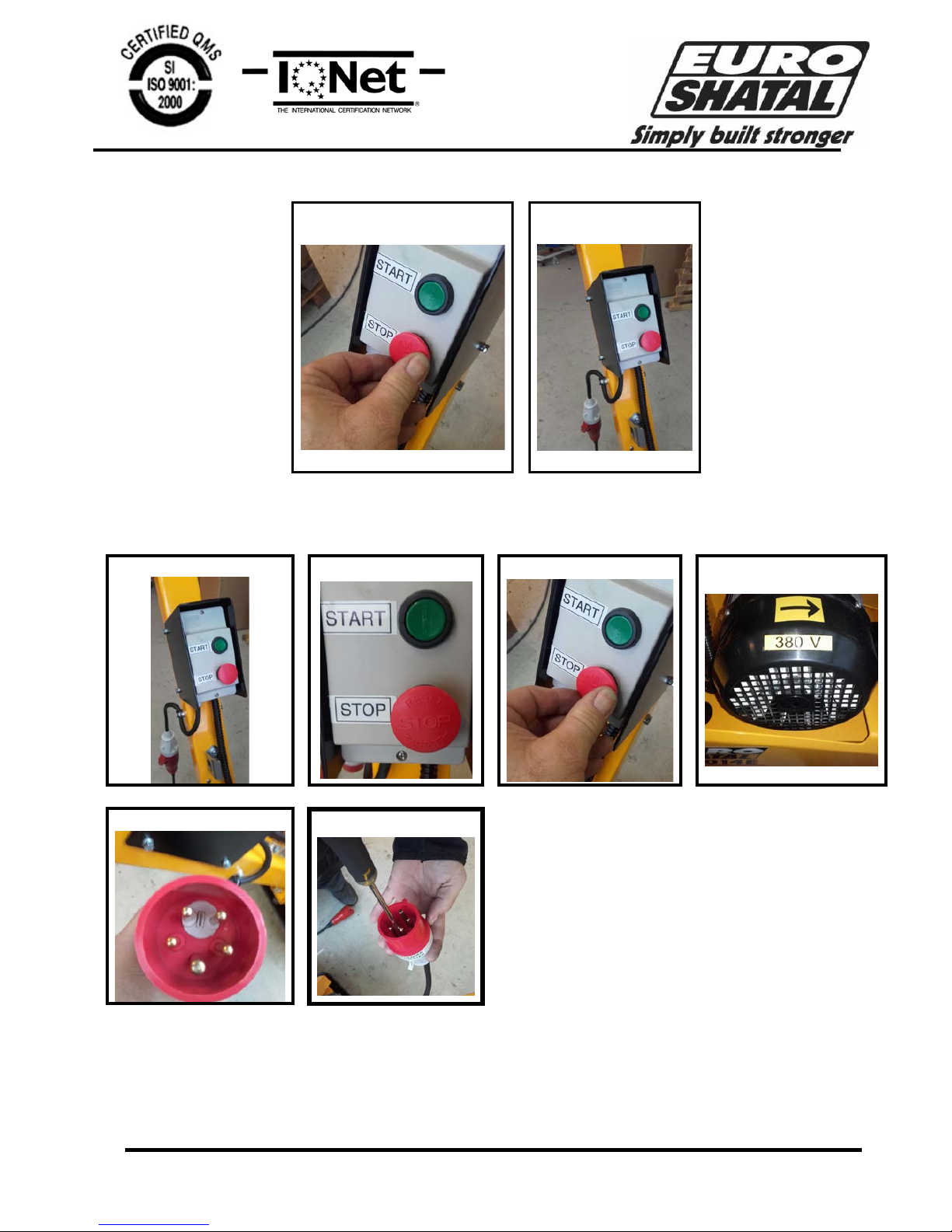

•Connect to three phase electric power socket, with 16 A, 380 V.

•In case of electrical outage, turn the operation switch off before further operation.

•Turn the operation switch off, after all machine use.

•Never operate the machine without the belt guard.

•Keep hand and feet away from moving parts while the machine is running.

•Operating the machine is advisable only with good lighting conditions.

•Hearing protection must be worn.

•Foot protection must be worn.

•Do not touch hot surfaces.

•Sikkerhedslovgivningen på maskiner kan være forskellige landene imellem, men de følgende retningslinier er nyttige for alle operatører.

•Før start, venligst læs maskinens service og brugsanvisning, følg alle instruktioner nøje.

•Brug aldrig maskinen uden remskive beskyttelse.

•Hænder og fødder skal holdes væk fra alle bevæglige dele når maskinen kører.

•Brug ikke maskinen i lukkede rum, eller ved brandfarlige områder.

•Anvend maskinen kun når der er god belysning.

•Høreværn er altid påbudt.

•Sikkerhedssko er altid påbudt.

•Rør aldrig ved varme flader.

•Die Sicherheitsgesetze für Maschinen kønnen verschiden sein, aber die folgende anleitungen sind für alle operatoren verwändlich.

•Vor Arbeitsbeginn bitte Bedienungs – und Wartungsanleitung sorgfältig lesen und allen Empfehlungen folgen.

•Bitte die Maschine nie ohne Keilriemengehäuse benutzen.

•Bitte Hände und Füsse entfernt halten von allen beweglichen Teilen während die Maschine läuft.

•Bitte die Maschine nicht in feuergefährlichen oder geschlossenen Räumen benutzen.

•Bitte nur die Maschine benutzen wenn eine gute Beleuchtung vorhanden ist.

•Gehörschutz muss immer getragen werden.

•Sicherheitsschuhe müssen immer getragen werden.

•Heisse Flächen bitte nicht berühren.

•Wetgeving inzake veiligheidsaspecten van machines kunnen verschillen naargelang het land. Volgende gids kan door iedere gebruiker

gebruikt worden.

•Voor het starten zorgvuldig de instruktiehandleiding doorlezen, alle instrukties moeten gevolgd worden.

•Nooit de machine gebruiken zonder V-snaarbescherming.

•Houd altijd handen en voeten weg van bewegende delen terwijl de machine loopt.

•Gebruik de machine niet in gesloten en brandgevaarlijke ruimtes.

•Gebruik alleen de machine bij goede verlichting.

•Gehoorbescherming moet altijd gedragen worden.

•Veiligheidsschoenen moeten altijd gedragen worden.

•Nooit warme vlakken aanraken.

•Antes do arranque, leia com atenção o manual de operação e manutenção do motor e siga todas as

Instruções.

•Nunca opera a máquina sem a guarda da correia.

•Não utilize o aparelho em locais fechados e ambientes inflamáveis.

•Use gasolina sem chumbo.

•Pare o motor antes de encher o tanque de combustível. Nunca reabastecer perto de uma chama, ou faíscas, que poderiam

começar um incêndio. Não fume. Use somente combustível puro e limpo no enchimento dos equipamentos. Tome cuidado de

não derramar combustível.

•Antes de arrancar o motor certifique-se que não está ninguém na area perigosa próximo do motor ou equipamento, e que as

guardas de protecção estão colocadas.

•É aconselhável operar a máquina em boas condições de iluminação.

•Protecção auricular deve ser usada.

•Protecção aos pés deve ser usada.