E2608-series detectors-transmitters belong to the new PluraSens® family of

multifunctional measurement instruments. The instruments utilise gas sensors of

various types with excellent repeatability, stability and long lifetime

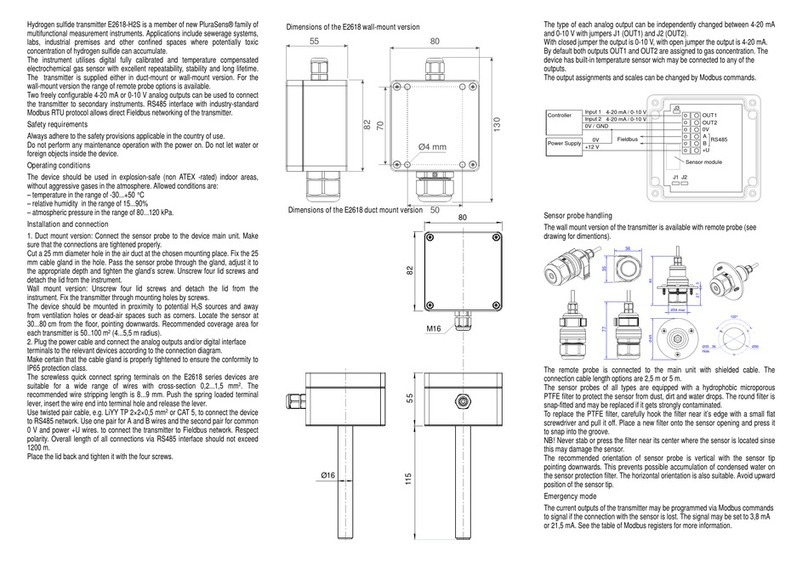

The devices are supplied either in duct-mount or wall-mount version. The wall mount

version of the device is available with remote probe. The remote probe is connected to

the main unit with shielded cable. Default connection cable length is m.

E2608 series provides two independent analog outputs OUT1 and OUT2, user-

selectable to 4-20 mA or 0-10 V, proportional either to gas concentration or temperature.

RS485 Modbus RTU digital communication interface allows easy instrument

configuration and integration into various automation systems.

Two relays RE1 and RE2 with closing contacts can be used to switch 24 V or 2 0 V

powered alarm sirens, ventilation fans, shut-off valves or other actuators.

The version of your detector is marked on the package.

Safety requirements

Always adhere to the safety provisions applicable in the country of use.

Do not perform any maintenance operation with the power on. Do not let water or

foreign objects inside the device.

Operating conditions

The device should be used in explosion-safe (non ATEX -rated) indoor areas, without

aggressive gases in the atmosphere. See Specification table for more details.

Installation and connections

There are no precise rules or standards to follow when installing the gas detectors. The

following points must be taken into account:

application (air quality control or leakage detection),

properties of the space under investigation (room geometry, direction and velocity of

air flows etc),

detected gas (relative density to air, whether the gas is flammable, or toxiс, or oxygen

displacing),

safety: strong vibrations, mechanical shock, and the sources of strong

electromagnetic interference should be avoided,

the device should be accessible for maintenance and repair.

For early leakage detection install the sensor as close as possible to the potential

leakage sources (flanges, valves, pressure reducers, pumps, etc), taking into

consideration other points listed above. For general area monitoring without definite

leakage sources, the detectors should be distributed evenly in the room. For personal

safety control the detectors are installed in the breathing zone (at the height of the head

of people or animals). Recommended sensor position is vertical, pointing downwards.

See Installation guidelines section for more information.

1. Wall mount version:Fix the detector on a wall by screws, using cross-shaped

mounting lugs supplied with the instrument (see dimensional drawing above).

Duct mount version: Cut hole with a diameter of 6...45 mm in the air duct at the chosen

mounting place. Place the rubber flange aligning the holes in the flange and the air-duct

and fix the flange with four self-tapping screws. Pass the sensor probe through the

flange and adjust it to the appropriate depth.

2. Unscrew four lid screws and detach the lid from the detector. Plug the power cable

and connect the analog / relay outputs and / or digital interface terminals to the relevant

devices according to the connection diagram below.

The screwless quick connect spring terminals on the E2608 series devices are suitable

for a wide range of wires with cross-section 0,2...1,5 mm2. We recommend to strip the

wire end by 8...9 mm and tin it, or to use the wire end sleeves.

To connect the wire, insert the wire end into terminal hole. To disconnect, push the

spring loaded terminal lever, pull the wire out, and release the lever

Use twisted pair cable, e.g. LiYY TP 2×2×0,5 mm2 or CAT 5, to connect the device to

RS485 network. Use one pair for A and B wires and the second pair for common 0 V

and power +U wires to connect the transmitter to Fieldbus network. Respect polarity.

Overall length of all connections via RS485 interface should not exceed 1200 m.

Note The outputs are not galvanically isolated from 24 V power supply and share

common 0V. Allowed load resistance limits are stated in Specifications table. To power

the instrument from an external 24 VDC source, connect terminals 0V and + to the

source. If the integrated mains power supply module is used, connect terminals L and N

to the mains.

Note Actuator short-circuits should be avoided, to protect the instrument relays use

external fuses or safety switches.

The type of each analog output can be independently selected with the appropriate

jumper (J1 for OUT1 and J2 for OUT2). With jumper open, the output type is 4-20 mA.

With jumper closed, the output type is 0-10 V.

By default both outputs OUT1 and OUT2 are assigned to gas concentration. The device

has built-in temperature sensor which may be tied to any of the outputs.

The output assignments and scales can be changed by Modbus commands

. Turn on the power. The sensor heating up may take up to five minutes after switching

on. A LED placed on the PCB of the device allows to control the connection process.

The LED response to different processes is presented in the table below.

Process LED mode

Sensor heating period Blinking 0.5 Hz (50% on, 50% off)

Sensor absence or malfunction Blinking 0.5 Hz (90% off, 10% on)

Relay1 turned on Blinking 1 Hz (50% on, 50% off)

Relay2 turned on Blinking 2 Hz (50% on, 50% off)

Modbus response The signal is modulated with short on-off pulses,

even single Modbus cycle is traceable

Normal measurement Continuous light

4. Make sure that the detector is properly fixed, the external devices connected, power

on and control LED is constantly lit. Make certain that the cable glands are properly

tightened to ensure the conformity to IP65 protection class. Place the lid back and fix it

with the screws. The device is ready to use.

It is recommended to keep the device powered constantly, except for periods of

maintenance and calibration, deplacement etc.

Sensor probe handling

The wall mount version of the transmitter is available with remote probe (see drawing

below for dimensions). The remote probe is connected to the main unit with shielded

cable. Default connection cable length is m.

The sensor probes of all types are equipped with a hydrophobic microporous PTFE filter

to protect the sensor from dust, dirt and water drops. The filter may be replaced if it gets

strongly contaminated. To replace the PTFE filter, unscrew the M25 nut and remove

the old filter. Place a new filter into the nut and tighten it again.

NB! Never stab or press the filter near its centre where the sensor is located since this

may damage the sensor.

The recommended orientation of sensor probe is vertical with the sensor tip pointing

downwards. This prevents possible accumulation of condensed water on the sensor

protection filter. The horizontal orientation is also suitable. Avoid upward position of the

sensor tip.

Configuring

Gas detectors E2608 share all functionalities of the PluraSens® multifunctional

transmitter platform. The features and options include:

- digital output change rate limiting filter

- digital integrating (averaging) filter

- temperature measurement channel with internal sensor

- free assignment of each analog output to chosen parameter

- flexible setting of analog output scales for each output

- output shift and slope adjustment for calibration

- free assignment of each of two relays to chosen parameter

- several relay control logic modes (HI or LO with hysteresis, U or П)

- switch delays and minimum on/off state durations for each relay

- Modbus controlled forced state option for analog outputs and relays.

E2608 can be configured through its RS485 interface by Modbus RTU commands. A

standard configuration kit includes Model E1087 USB-EIA485 converter and a software

pack. Please contact your Seller or the Manufacturer for more information.

Return to default settings

To reset the device’s Slave ID, baudrate and sbit number to factory settings, proceed as

follows:

1. De-energize the device 2. Connect the J jumper

. Turn on the device 4. De-energize the device

5. Disconnect the J jumper 6. Turn on the device

RS485 communication interface

See Annex 1

36

77

Ø35...36 Ø50

120°

Ø 65 80

32 7

Ø34 max

Hole

35

4-20 mA / 0-10 V

4-20 mA /0-10 V

0V / GND

OU T1

OU T2

0V

A

BS485

+U = 11...30 VDC

E1

E2

Fieldbus

24VDC

S

N

L90 ... 265 VAC

J2 - OUT2 ty peJ1 - OUT1 type

J3 - return to factory sett ings

Control L ED

J1 J2

55

200

M16

Ø35

2 03

M25

35

8287

82 55

8727

M25

Wall mount version

Duct mount version

94

99

73

68

With mounting lugs