Excillum MetalJet D2+ User manual

Revision 19, November 2016

MetalJet D2+ Operating manual

METALJET D2+

Revision 19, November 2016 ii

Disclaimer

The information provided herein is supplied under a non-exclusive license authorizing its use solely for and in

conjunction with Excillum Aktiebolag’s (Excillum) products. Although diligent care has been used to ensure that

the information is accurate, nothing contained herein can be construed to imply any representation or warranty

as to the accuracy or completeness of this information. Excillum reserves the right to alter this information at

our own discretion at anytime. The warranty and product documentation remains valid as long as the customer

does not make any changes to the product.

Acknowledgement

All registered and unregistered trademarks, domain names and copyrights herein are the property of their

respective owners.

Excillum, MetalJet, MetalJet D1, MetalJet D2 and MetalJet D2+ are registered trademarks or trademarks of

Excillum AB. Excillum

’

s MetalJet sources are protected by several patents including, but not limited to, US

Patents No. US 6 711 233, US8 170 179, US 8 681 943, US 8 837 679, US 9 171 693, US 9 245 707, and Chinese

Patents No. CN 01 816396.3, ZL200780026317.0, ZL200980155094.7, ZL 200980158566.4, ZL 201080070417.5,

and other corresponding national patents and patent applications pending.

Copyright notice

© Excillum Aktiebolag 2016, Stockholm, Sweden. All rights reserved worldwide.

Contact information

The MetalJet D2+ source described in this operating manual has been produced by Excillum Aktiebolag. Excillum

may be contacted in several different ways.

Mailing and visiting address

Excillum Aktiebolag

Torshamnsgatan 35

SE-164 40 Kista

SWEDEN

Phone

+46 (0)8-750 96 60

Fax

+46 (0)8-750 96 65

E-mail

Website

www.excillum.com

METALJET D2+

Revision 19, November 2016 iii

Please fill in the serial numbers and the manufacturing year for the sub-assembly units of your MetalJet D2+ x-

ray source in the table below, and have them readily available when contacting Excillum for assistance,

additional information, or purchase of spare parts.

The serial numbers and the manufacturing year may be found on the identification tag on the rear of each sub-

assembly unit, close to the electrical power connector.

System article number: G-020-0037 rev 02

Sub-assembly unit

Article number

Serial number

Manufacturing year

Electron gun/x-ray head

G-020-0020

EXH-

Pump box

G-035-0033

PBO-

X-ray system controller

G-010-0000

SCO-

X-ray high-voltage controller

G-010-0001

HVC-

METALJET D2+ TABLE OF CONTENTS

Revision 19, November 2016 iv

Table of Contents

1INTRODUCTION.............................................................................................................................1-1

1.1 Validity................................................................................................................................................ 1-1

1.2 Instructions and conventions ............................................................................................................. 1-1

1.3 Product information ........................................................................................................................... 1-2

1.3.1 Product identification..................................................................................................................... 1-2

1.3.2 Design and function ....................................................................................................................... 1-2

1.3.2.1 Liquid-metal circulation loop................................................................................................. 1-2

1.3.2.2 Electron gun/x-ray head........................................................................................................ 1-2

1.3.3 X-ray output options ...................................................................................................................... 1-6

1.3.3.1 With x-ray shutter ................................................................................................................. 1-7

1.3.3.2 Without x-ray shutter using standard exit window............................................................... 1-8

1.3.3.3 Without x-ray shutter using increased cone angle exit window ........................................... 1-9

2SAFETY..........................................................................................................................................2-1

2.1 Safety precautions.............................................................................................................................. 2-1

2.1.1 Qualified personnel........................................................................................................................ 2-1

2.1.2 Partly completed machinery .......................................................................................................... 2-1

2.1.3 Operating manual .......................................................................................................................... 2-1

2.1.4 X-ray radiation................................................................................................................................ 2-2

2.1.5 Electricity and high voltage ............................................................................................................ 2-2

2.1.6 High pressure ................................................................................................................................. 2-3

2.1.7 Heat................................................................................................................................................ 2-4

2.1.8 Magnetic fields............................................................................................................................... 2-4

2.1.9 Poisoning hazard ............................................................................................................................ 2-5

2.2 Proper use .......................................................................................................................................... 2-6

2.3 Improper use ...................................................................................................................................... 2-6

3TRANSPORT AND STORAGE ...........................................................................................................3-1

3.1 Transport ............................................................................................................................................ 3-1

3.1.1 Lifting.............................................................................................................................................. 3-1

3.2 Storage................................................................................................................................................ 3-2

4INSTALLATION...............................................................................................................................4-1

4.1 Initial Installation Checklist................................................................................................................. 4-1

4.2 Unpacking........................................................................................................................................... 4-2

4.3 Setting up the MetalJet D2+ source ................................................................................................... 4-2

METALJET D2+ TABLE OF CONTENTS

Revision 19, November 2016 v

4.3.1 Mounting of sub-assembly units.................................................................................................... 4-2

4.3.2 Connecting tubing and cables ........................................................................................................ 4-8

4.3.2.1 Tighten inlet and outlet check valve housings ...................................................................... 4-8

4.3.2.2 Flex-hose assembly and jet-exit port..................................................................................... 4-8

4.3.2.3 Cooling water supply and return........................................................................................... 4-9

4.3.2.4 High-pressure tubing and nozzle assembly ......................................................................... 4-13

4.3.2.5 Vacuum hose ....................................................................................................................... 4-13

4.3.2.6 Cooling water ...................................................................................................................... 4-14

4.3.2.7 Interconnecting cables ........................................................................................................ 4-15

4.3.2.8 MetalJet D2+ 70 kV.............................................................................................................. 4-16

4.3.2.9 MetalJet D2+ 160 kV............................................................................................................ 4-19

4.3.2.10 Mains supply........................................................................................................................ 4-23

4.4 Safety system.................................................................................................................................... 4-25

4.4.1 High voltage controller................................................................................................................. 4-25

4.4.2 Electron gun ................................................................................................................................. 4-25

4.5 Operating conditions ........................................................................................................................ 4-27

4.5.1 Ambient conditions...................................................................................................................... 4-27

4.5.2 Ventilation.................................................................................................................................... 4-27

4.5.3 Cooling water ............................................................................................................................... 4-27

4.6 System integration............................................................................................................................ 4-28

4.6.1 System accessibility...................................................................................................................... 4-28

4.6.2 Network connectivity................................................................................................................... 4-30

5OPERATION...................................................................................................................................5-1

5.1 Introductory notes on source operation ............................................................................................ 5-1

5.1.1 Starting jet pump ........................................................................................................................... 5-1

5.1.2 Leave MetalJet D2+ system in On or Ready................................................................................... 5-1

5.1.3 Expected time between service ..................................................................................................... 5-1

5.1.4 Electron beam power vs. spot size................................................................................................. 5-2

5.2 Starting the MetalJet D2+ system ...................................................................................................... 5-3

5.3 Capabilities of the software................................................................................................................ 5-4

5.4 Starting the software and GUI............................................................................................................ 5-4

5.4.1 GUI layout ...................................................................................................................................... 5-6

5.5 The states of the software.................................................................................................................. 5-6

5.5.1 Standard states .............................................................................................................................. 5-6

5.5.2 Advanced states ............................................................................................................................. 5-7

5.5.3 State indicators .............................................................................................................................. 5-8

METALJET D2+ TABLE OF CONTENTS

Revision 19, November 2016 vi

5.6 User levels .......................................................................................................................................... 5-8

5.7 Error messages ................................................................................................................................... 5-8

5.8 Parametrization .................................................................................................................................. 5-9

5.8.1 Prepare system for parametrization .............................................................................................. 5-9

5.8.2 Align electron beam to optical axis .............................................................................................. 5-10

5.8.3 Determine jet size and position ................................................................................................... 5-10

5.8.4 Characterize focus lens and verify jet stability............................................................................. 5-11

5.8.5 Characterize linefocus coils.......................................................................................................... 5-12

5.9 Set emission power and spot size..................................................................................................... 5-13

5.9.1 Recalibrate spot size .................................................................................................................... 5-14

5.9.2 Validate spot size ......................................................................................................................... 5-14

5.10 Normal operation ............................................................................................................................. 5-14

5.10.1 Turning on x-ray generation .................................................................................................... 5-14

5.10.2 Change emission power and spot size..................................................................................... 5-14

5.10.3 Turning off x-ray generation.................................................................................................... 5-14

5.10.4 Turning off the MetalJet D2+ source ....................................................................................... 5-14

5.11 System Settings................................................................................................................................. 5-16

5.12 Software API ..................................................................................................................................... 5-17

6MAINTENANCE AND SERVICE ........................................................................................................6-1

6.1 Vacuum system................................................................................................................................... 6-2

6.1.1 Roughing pump .............................................................................................................................. 6-2

6.1.2 Turbopump..................................................................................................................................... 6-2

6.2 Jet system ........................................................................................................................................... 6-2

6.2.1 Jet pump lubricants........................................................................................................................ 6-2

6.2.2 Jet pump diaphragm ...................................................................................................................... 6-3

6.2.3 Jet pump check valves.................................................................................................................... 6-3

6.2.4 Nozzle assembly............................................................................................................................. 6-4

6.2.5 Particle filter................................................................................................................................... 6-6

6.2.6 Exit window.................................................................................................................................... 6-6

6.2.7 Liquid metal spillage....................................................................................................................... 6-7

6.3 Electron gun........................................................................................................................................ 6-7

6.3.1 Cathode assembly .......................................................................................................................... 6-7

6.4 Climate system ................................................................................................................................... 6-9

6.4.1 Fan filters........................................................................................................................................ 6-9

6.4.2 Cooling water ................................................................................................................................. 6-9

7SHUTDOWN ..................................................................................................................................7-1

METALJET D2+ TABLE OF CONTENTS

Revision 19, November 2016 vii

7.1 Shutting down for shorter periods ..................................................................................................... 7-1

7.2 Shutting down for longer periods....................................................................................................... 7-1

7.3 Restarting after longer shutdown ...................................................................................................... 7-1

7.4 Disposal .............................................................................................................................................. 7-1

8MALFUNCTION AND TROUBLESHOOTING ......................................................................................8-1

9CUSTOMER SUPPORT ....................................................................................................................9-1

9.1 System log files ................................................................................................................................... 9-1

9.2 Remote support.................................................................................................................................. 9-2

10 SPARE PARTS...............................................................................................................................10-1

11 TECHNICAL DATA ........................................................................................................................11-1

METALJET D2+ INTRODUCTION

Revision 19, November 2016 Page 1-1

1INTRODUCTION

1.1 Validity

This operating manual is for customers of Excillum. It describes the functioning of the MetalJet D2+ source and

provides the most important information for safe use of the unit. The description follows applicable EU

guidelines. Up-to-date operating instructions may be obtained by contacting Excillum, see page ii for contact

information.

1.2 Instructions and conventions

The safety instructions in this operating manual are the result of a risk assessment in accordance with SS EN

12100:2010 (Safety of Machinery - General principles for design - Risk assessment and risk reduction) formerly

SS-EN ISO 14121 (Safety of Machinery –Risk Assessment)).

In this document, the following hazard levels and information are considered:

DANGER

Immediate danger: Death or very severe injuries may occur.

WARNING/ATTENTION

Possible danger: Severe injuries may occur.

CAUTION

Possible danger: Medium to slight injuries may occur.

NOTE

Command or note: Command to perform an action or information about properties. If ignored, this may

result in damage to the product.

METALJET D2+ INTRODUCTION

Revision 19, November 2016 Page 1-2

1.3 Product information

1.3.1 Product identification

To correctly identify the product when communicating with Excillum, always provide the following information

from the identification tag(s):

Model number

Article number

Serial number

Manufacturing year

Anode alloy

The identification tag on each of the four sub-assembly units (see table below) is located on its backside, close

to the electrical power connector.

The article number of this MetalJet D2+ source is G-020-0037. The x-ray source consists of the following four

sub-assembly units.

Sub-assembly unit

Article number

Electron gun/x-ray head

G-020-0020

Pump box

G-035-0033

X-ray system controller

G-010-0000

X-ray high-voltage controller

G-010-0001

1.3.2 Design and function

The MetalJet D2+ x-ray source is based on a metal-jet anode. It is not a stand-alone x-ray source, but a

component in a complete x-ray system (for more information, see Section 2.1).

Basically, the MetalJet D2+ source consists of a recirculating metal-jet loop and an electron gun, as well as

electronics modules for operation control. The electron gun generates an electron beam, which strikes the

metal jet and produces x-rays. This x-ray source is suitable for use in any x-ray application where increased x-

ray source brightness is desired. Increased source brightness can be used in order to decease the exposure

time or increase the resolution of the x-ray image.

1.3.2.1 Liquid-metal circulation loop

The jet pump displaces liquid metal from the reservoir in the low-pressure flex-hose assembly to the high-

pressure side. The pressure in the high-pressure tubing is stabilized by a pulsation dampener. When the liquid

metal reaches the nozzle assembly, a metal jet is ejected. This metal jet is the target for the electron beam

generated in the electron gun. After interaction with the electron beam, the metal jet ends up in the reservoir

in the low-pressure flex-hose assembly, and a closed circulation loop is completed.

1.3.2.2 Electron gun/x-ray head

A potential difference between the cathode and the plate with the anode hole generates an electric field. The

cathode is heated in order to emit electrons into the electric field. When free electrons enter the electric field

they are accelerated towards the plate with the anode hole. The electron beam passes through the anode hole

into the flight tube. The electron optics and the focusing lens manipulate the electron beam in order to focus it

onto the metal jet. When the electron beam strikes the metal jet x-rays are produced and emitted through the

x-ray window.

METALJET D2+ INTRODUCTION

Revision 19, November 2016 Page 1-3

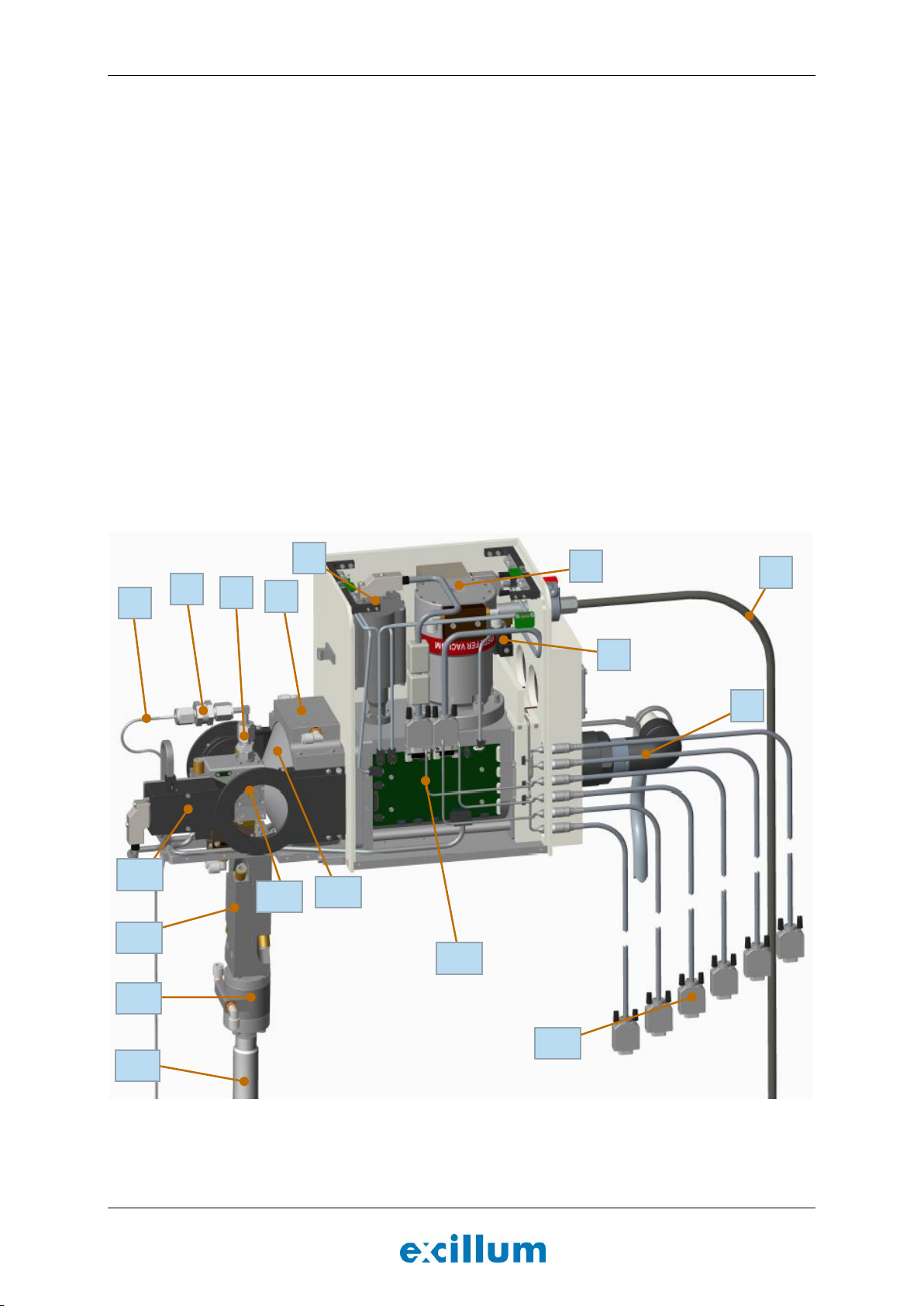

The electron gun/x-ray head consists of the following parts, see Figure 1-1 below:

1. High-pressure tubing

2. Particle filter

3. Nozzle assembly

4. Lens cooling block

5. High-vacuum gauge

6. High-vacuum pump (turbopump)

7. Ventilation valve

8. Fore-vacuum hose

9. High-voltage cable connected to high-voltage feedthrough

10. Interconnecting cables

11. X-ray head PCB (cross connect board)

12. Electron optics

13. Exit window (not visible, it is underneath the shutter)

14. Flex-hose assembly

15. Jet brake

16. Upper cooling block

17. Shutter

Figure 1-1. The main components of the electron gun/x-ray head.

1

2

3

8

7

9

6

5

4

10

0

11

0

12

0

13

0

14

0

16

17

0

15

0

METALJET D2+ INTRODUCTION

Revision 19, November 2016 Page 1-4

The main components of the pump box are the following parts (see Figure 1-2):

1. High-pressure tubing

2. Upper cooling block

3. Jet brake

4. Flex-hose assembly

5. Fore-vacuum hose

6. Cooling water inlet

7. Cooling water outlet

8. Pulsation dampener

9. Diaphragm guard

10. Jet pump

11. Outlet check valve

12. Pump head

13. Inlet check valve

14. Liquid-metal filling valve

15. Filling valve adapter

16. Lower cooling block

17. Roughing pump

18. Heater fan

19. Pump box electronics

METALJET D2+ INTRODUCTION

Revision 19, November 2016 Page 1-6

Figure 1-2. The main components inside the pump box.

1.3.3 X-ray output options

MetalJet D2+ systems can be configured to operate with the x-ray output either on the left-hand side (left-

handed), the right-hand side (right-handed) or both sides (dual port). The definition of left and right is indicated

in Figure 1-3 using a red arrow for the left-handed system and a green arrow for the right-handed system.

Figure 1-3. MetalJet D2+ system configured with the x-ray output on both sides (dual port). Red arrow indicate

output direction of left-handed system and green arrow indicate output direction of a right-handed system.

The output direction can be reconfigured in field, but we strongly suggest that the output direction is specified

when placing the order.

Left side

Right side

METALJET D2+ INTRODUCTION

Revision 19, November 2016 Page 1-7

The system can also be configured to operate either with or without an x-ray shutter. When operated without a

shutter it can be configured with a standard exit window or an exit window with an increased cone angle. The

figures in Sections 1.3.3.1-1.3.3.3 show minimum source-to-object distance, exit window diameter and x-ray

emission cone angle for each of these configurations.

1.3.3.1 With x-ray shutter

Figure 1-4. Schematic of the x-ray head with x-ray shutter mounted.

METALJET D2+ SAFETY

Revision 19, November 2016 Page 2-1

2SAFETY

2.1 Safety precautions

2.1.1 Qualified personnel

Installation work, commissioning and operation of the MetalJet D2+ source must only be done by qualified and

skilled personnel. Installation work shall only be done by qualified personnel who are skilled because of

technical education, expertise and schooling about:

Safety regulations

X-ray radiation

Accident prevention regulations

Standards and approved rules of technique

The qualified and skilled personnel must have the ability to assess the assigned job, identify possible dangers

and avoid them. The qualified personnel must be authorized by the person in charge for security of the plant to

carry out the necessary work and tasks.

2.1.2 Partly completed machinery

The MetalJet D2+ source is a partly completed machinery (as defined by the Machinery Directive 2006/42/EC)

and is therefore intended to be incorporated into or assembled with other machinery or partly completed

machinery in order to function properly. It is the responsibility of the machinery integrator to make sure that

the final machinery meets all local safety regulations such as radiation protection, and all other applicable

regulations such as CE compliance, Machinery Directive, EMC Directive, etc.

NOTE

Partly completed machinery

Excillum is not responsible for the installation, use, or application of the MetalJet D2+ source.

If the MetalJet D2+ source is used in a manner not specified by Excillum, then protection built into the

MetalJet D2+ source may be impaired.

It is the sole responsibility of the machinery integrator that the final machinery including the MetalJet D2+

is safe to use.

2.1.3 Operating manual

This operating manual contains important information regarding the workings, operation, maintenance, and

safety of the MetalJet D2+ source. All persons involved in operation or service must have thoroughly read and

understood the operating manual beforehand.

METALJET D2+ SAFETY

Revision 19, November 2016 Page 2-2

ATTENTION

Operating manual must be read and understood

This operating manual contains necessary information to ensure safe operation of the MetalJet D2+ source.

Each person involved in the installation, operation or maintenance must have read and understood this

operating manual.

Keep this manual handy and in a safe place for future reference. In case of this manual being lost or

damaged, please contact Excillum for a replacement copy (see Page ii for contact information).

In case the MetalJet D2+ source is moved to another location, make sure not to leave the manual behind.

2.1.4 X-ray radiation

In its original design the MetalJet D2+ source provides a high degree of protection from unnecessary radiation.

Therefore, do not modify, remove, or otherwise change any part of the MetalJet D2+ source unless this action

has been approved of by Excillum beforehand. However, no practical design can provide complete protection

nor prevent operators from exposing themselves or others to unnecessary radiation.

Personal radiation monitoring and protective devices are available. Operators are urged to use them to protect

against unnecessary radiation exposure.

DANGER

X-ray radiation can be a health hazard

X-ray equipment may cause injury, or even death, if improperly used.

The MetalJet D2+ apparatus is a source of x-ray radiation, which is harmful to the human body. To avoid

health problems arising from exposure to x-rays, exercise the greatest possible caution when using this x-

ray source.

This x-ray source may be operated by, or under supervision of, authorized and trained personnel only.

All applicable local safety regulations must be strictly complied with.

2.1.5 Electricity and high voltage

Make sure electrical power is switched off, or other appropriate safety precautions are followed, before

maintenance or service work is performed.

The MetalJet D2+ source contains a high voltage generator. Proper high voltage precautions and grounding

techniques must be observed during installation and operation of the MetalJet D2+ apparatus.

The high-voltage decay time when power is shut down can be significant.

Read the document “AN-05 aka "No, you touch it". HVPS output fall and discharge times explained” from

Spellman which gives an estimation of the decay time http://www.spellmanhv.com/Technical-

Resources/Application-Notes/AN-05.aspx.

In no event should the safety interlocks on the MetalJet D2+ source be disconnected or bypassed.

METALJET D2+ SAFETY

Revision 19, November 2016 Page 2-3

DANGER

High voltage is potentially lethal

High voltage can cause electric shock or burn.

All sub-units of the MetalJet D2+ source must be properly grounded before being energized. Use high

voltage precautions.

Always ensure complete discharge of the high-voltage cable when removing it from the system by letting

the circled metal connectors touch ground, see Figure 2-1.

Figure 2-1. Always ensure complete discharge of the high-voltage cable when removing it from the system by

letting the circled metal connectors touch ground.

2.1.6 High pressure

The MetalJet D2+ source has, unlike conventional x-ray sources, a liquid-metal-jet anode. The metal jet is

generated by forcing a liquid metal through a small orifice. The pressure generated by the metal pump is 190

bar. Therefore, only properly trained service personnel should be permitted to service the diaphragm pump or

any part of the tubing system connected to the pump.

WARNING

High liquid-metal pressure

Under no circumstances should any kind of service, maintenance, or adjustments to the jet pump, or the

equipment and tubing connected to it, be done while the MetalJet D2+ source is in operation.

Service, maintenance, or any kind of adjustments of the jet pump, or the equipment and tubing connected

to it, may only be performed by properly trained service personnel.

METALJET D2+ SAFETY

Revision 19, November 2016 Page 2-4

2.1.7 Heat

During operation of the MetalJet D2+ source the surfaces of the x-ray head, the vacuum pumps, and the low-

pressure tubing may become hot. Depending on the operating and ambient conditions these surfaces may

reach temperatures above 50°C (122°F). Use suitable finger guards if necessary.

CAUTION

Hot surfaces

The x-ray head, the vacuum pumps, and the low-pressure tubing may become hot during operation of the

MetalJet D2+ source.

2.1.8 Magnetic fields

The electron gun/x-ray head of the MetalJet D2+ source is sensitive to external magnetic fields, which may

cause severe loss of x-ray output performance, since the electron beam may be affected.

The MetalJet D2+ source may also be sensitive to ferromagnetic materials (and other materials with a high

relative magnetic permeability) close to the electron gun/x-ray head. These may affect the magnetic fields

generated by the electron optics and the focusing lens and thus cause a severe loss of x-ray output

performance.

As a consequence of the influence of materials with a high relative permeability and external magnetic fields,

the MetalJet D2+ source may be damaged and in need of service to exchange parts and recalibrate settings.

Permanent magnets, energized electro-magnets, or ferromagnetic materials must not be placed close to the

MetalJet D2+ source.

CAUTION

External magnetic fields and ferromagnetic materials

The MetalJet D2+ source may experience loss of performance as well as damage if exposed to external

magnetic fields or ferromagnetic materials close to the electron gun/x-ray head.

Table of contents

Popular Laboratory Equipment manuals by other brands

Sartorius Stedim Biotech

Sartorius Stedim Biotech 16249 Directions for use

Agilent Technologies

Agilent Technologies 1290 Infinity II user manual

Metrohm

Metrohm 800 Dosino manual

Labcyte

Labcyte Echo 650 Series quick start guide

Agilent Technologies

Agilent Technologies 1260 Infinity user manual

Olympus

Olympus OER-Elite Operation manual