Table of contents ■■■■■■■■■■■■■■■■■■■■■■

IV ■■■■■■■■ 940 Professional IC Vario ONE/LPG (2.940.1150)

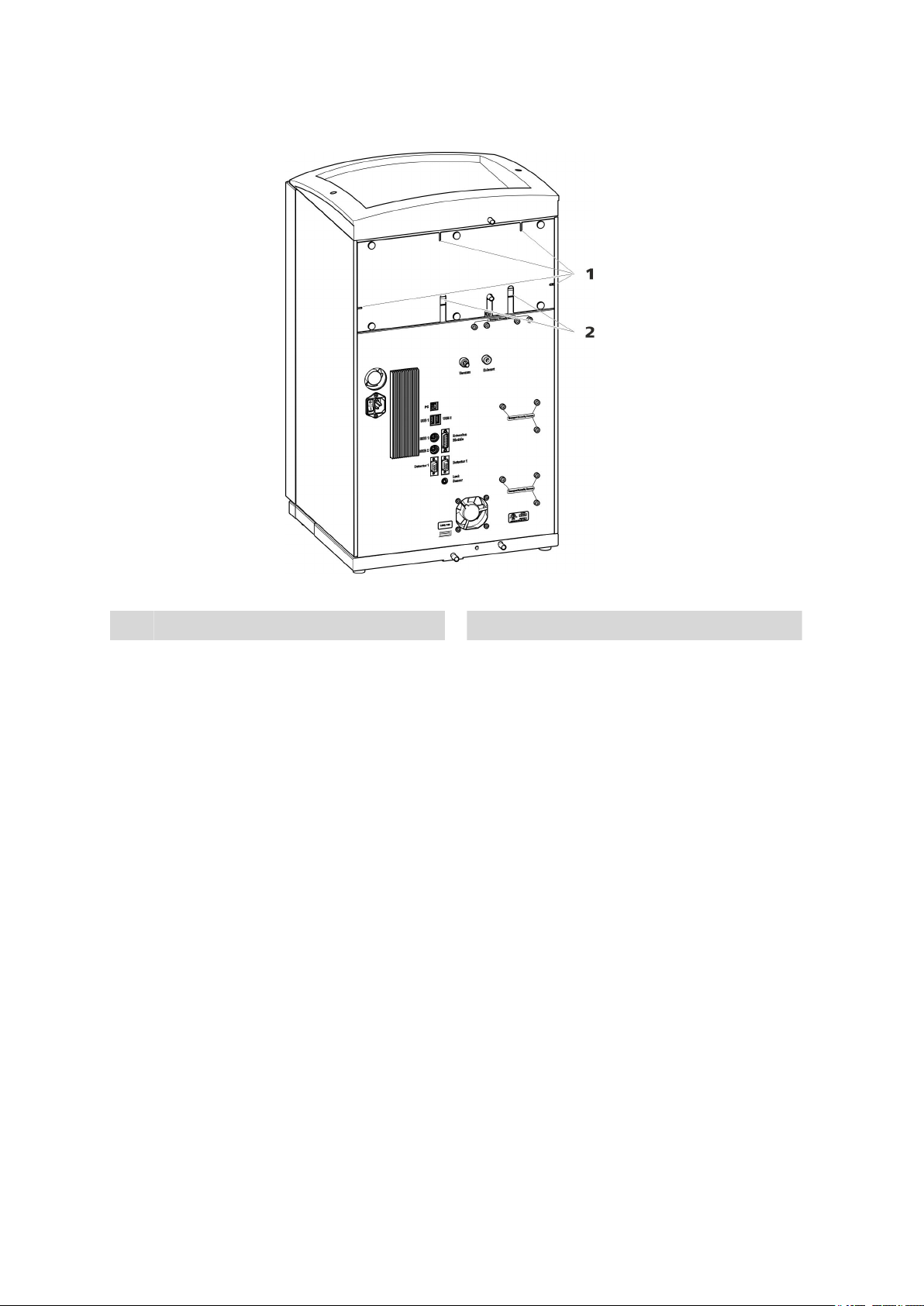

3.15 Connecting the sample degasser (optional) ..................... 31

3.16 Low-pressure gradient ....................................................... 33

3.17 Installing the low-pressure gradient ................................. 35

3.18 Connecting the instrument to a computer ....................... 36

3.19 Connecting the instrument to the power grid ................. 37

3.20 Initial start-up ..................................................................... 38

3.21 Connecting and rinsing the guard column ....................... 40

3.22 Connecting the separation column ................................... 42

3.23 Conditioning ........................................................................ 46

4 Operation 48

5 Operation and maintenance 49

5.1 IC system ............................................................................. 49

5.1.1 Operation .............................................................................. 49

5.1.2 Care ...................................................................................... 49

5.1.3 Maintenance by Metrohm Service .......................................... 49

5.1.4 Shutting down and recommissioning ..................................... 50

5.2 Capillary connections ......................................................... 51

5.3 Servicing the door .............................................................. 51

5.4 Column thermostat – Replacing the capillaries ............... 51

5.5 Handling the eluent ............................................................ 53

5.5.1 Manufacturing eluent ............................................................ 53

5.5.2 Changing the eluent .............................................................. 54

5.6 Servicing the eluent degasser ........................................... 54

5.7 Notes on operating the high-pressure pump ................... 55

5.8 Servicing the high-pressure pump .................................... 56

5.9 Servicing the inline filter .................................................... 69

5.10 Servicing the pulsation absorber ...................................... 72

5.11 Injection valve ..................................................................... 72

5.12 Servicing the detector ........................................................ 72

5.13 Rinsing the sample path .................................................... 72

5.14 Separation column ............................................................. 74

5.14.1 Separating efficiency .............................................................. 74

5.14.2 Protecting the separation column .......................................... 74

5.14.3 Storing the separation column ............................................... 74

5.14.4 Regenerating the separation column ...................................... 74

5.15 Quality management and qualification with Metrohm ... 75