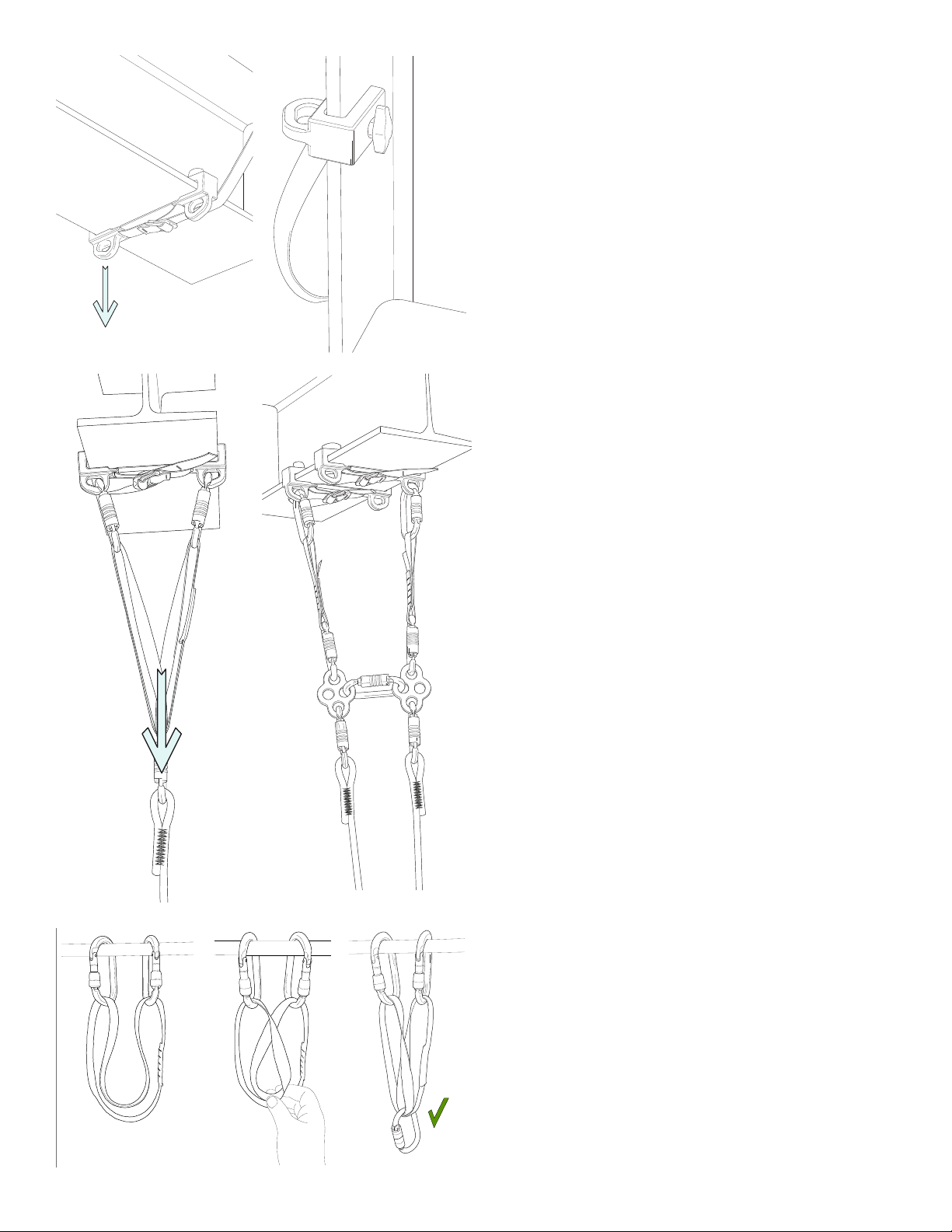

Compatibility

Make sure that each item in an assembly can be used together and work as a system. Compatibility

needs to be checked prior to use. Check individual manuals for each item and see if they can be used

together.

Safe use

When working at height or other related activities such as rope access: never rely on a single piece of

equipment always make sure you have an equal redundant back-up system.

Do not fall into the beam clamp directly without any energy absorbance.

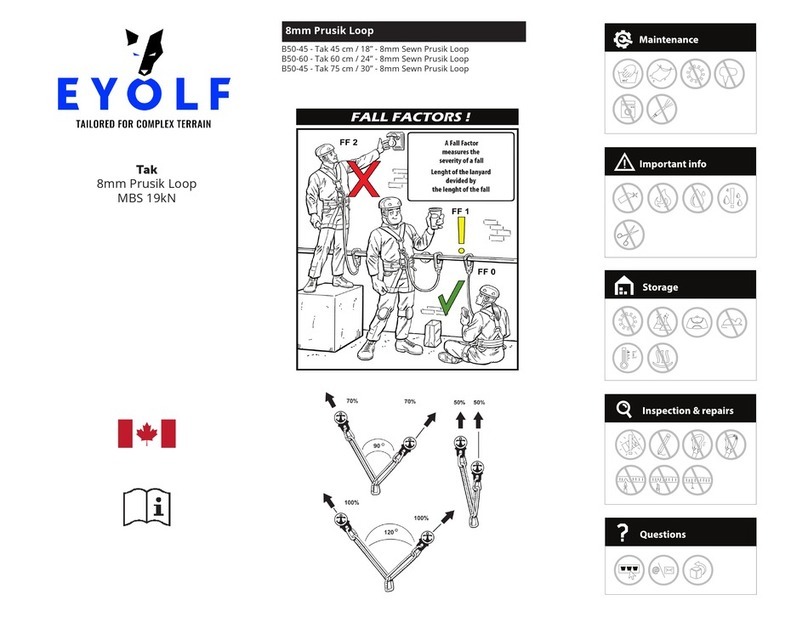

Minimize a fall at all times, check your fall factors and the equipment your using to see if it can survive

the impact. See drawing on fall factors.

Use in extreme environment

Use of any PPE in extreme environments can be dangerous. It is important to do appropriate testing

before the use of our products in environments such as extreme cold or high temperatures (working

temperatures are -30 degrees up to 60 degree Celsius), chemicals, dust, sand and other foreign materials,

electrical power, grinding and chang should be avoided, if you have any questions contact us and we

can help you determine the eects.

Inspection

An examination should be carried out before the product is put into service.

Periodic examinations should takes place at least once a year, taking into account factors such as legisla-

tion, equipment type, frequency of use, and environmental conditions.

A periodic exam should be carried out by a competent person.

Before each use visually inspect to ensure the product is in serviceable condition and operates correctly.

If any compromises are found do not use the product and retire it.

If the product has been used to arrest a fall, withdrawn from use immediately! Do not use again until, in

writing, a competent person says it is acceptable for use.

A pre-use check by the user may not be applicable if the user is under supervision of a competent person

or in the case it is used for emergency use which have been pre-packed or sealed by a competent person.

When carrying out an inspection pay attention to the following items:

Check the label / marking (visible, legible, age)

Check webbing (cuts, burns, wear, chemical marks, crushed, other damage)

Check stitching (cut, worn, coloured or disordered threads)

Check aluminium components (deformation, cracks, wear, corrosion, marks)

Check compatibility of connector

Check condition of protective components

Safety of users depends upon the continued eciency and durability of the equipment.

Maintenance

Always keep the product clean and dry. Any excess moisture should be removed with a clean, dry cloth

and then allowed to dry naturally in a warm room away from direct heat.

Rinse in clean cold water. If still soiled wash in clean warm water (max. 40°C) with a soft detergent (with-

in pH range of 5.5 to 8.5). You can use a front loading washing machine but rst place the product in a

washing bag to protect against mechanical damage. Rinse properly in clean cold water and if needed to

disinfect use a solution of water with alcohol. Do not use bleach!

Follow these instructions, if in doubt about the disinfecting method please contact us for further details.