EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

Revision Number-005 09-01-2021 - Present

4EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

WARNING

Failure to obey the following safety instructions could result in DEATH or

SERIOUS INJURY.

Read and understand entire manual before operating the Roller Compactor.

For your safety and the safety of others, replace any missing or damaged warning decals by contact-

ing the manufacturer at 1-800-417-9272.

Make sure anyone operating the Roller Compactor is thoroughly familiar with its operation. Keep all

unauthorized and untrained personnel, especially children, away from Roller Compactor.

Improper maintenance can be hazardous. Read and understand this section before you

perform any maintenance, service or repairs.

General Safety

• The owner of this machine must observe, and also train the user of the machine to observe, the

eective labour protection laws in the country of application.

• Use suitable lifting equipment to lift the machine.

• This machine is to be used for is intended application only.

• This machine must only be operated by well-trained personnel.

• Personal Protective Equipment (PPE) must be worn by the operator whenever the equipment is

being used.

• The machine must be operated on ground where stability is guaranteed. When working near the

rim of excavated trenches, keep a sensible distance from the edge so that there is no danger of the

machine falling down or the trench collapsing.

• Cordon o the work area and keep members of the public and unauthorised personnel at a safe

distance.

• Make sure you know how to safely switch this machine OFF before you switch it ON in case you

run into any diculties.

• Always switch OFF the engine before servicing it.

• During use, the engine becomes very hot. Always allow the engine to cool down before touching it.

• Never leave the engine running and unattended.

• Never remove or tamper with any tted guards; they are there for your own protection. If they are

damaged or missing, DO NOT USE THE MACHINE until the guard has been replaced or repaired.

• Always switch OFF the engine before transporting it, moving it around site or servicing it.

• Do not operate the machine when you are ill, feeling tired or when under the inuence of alcohol or

drugs.

• If the surface to be compacted is on a slope, take great care when controlling the Roller

Compactor’s direction of travel. Always work up and down a slope; not across.

• This machine is designed to eliminate the possible risks arising from the use of it. However, risks

DO reside, and these residual risks are not clearly recognisable and may cause personal injury or

property damage, and possibly death. If such unpredictable and unrecognisable risks become

apparent, the machine must be stopped immediately, and operator or his supervisor must take

appropriate measure to eliminate such risks. It is sometimes necessary that the manufacturer must

be informed of such event for future counter measuring.

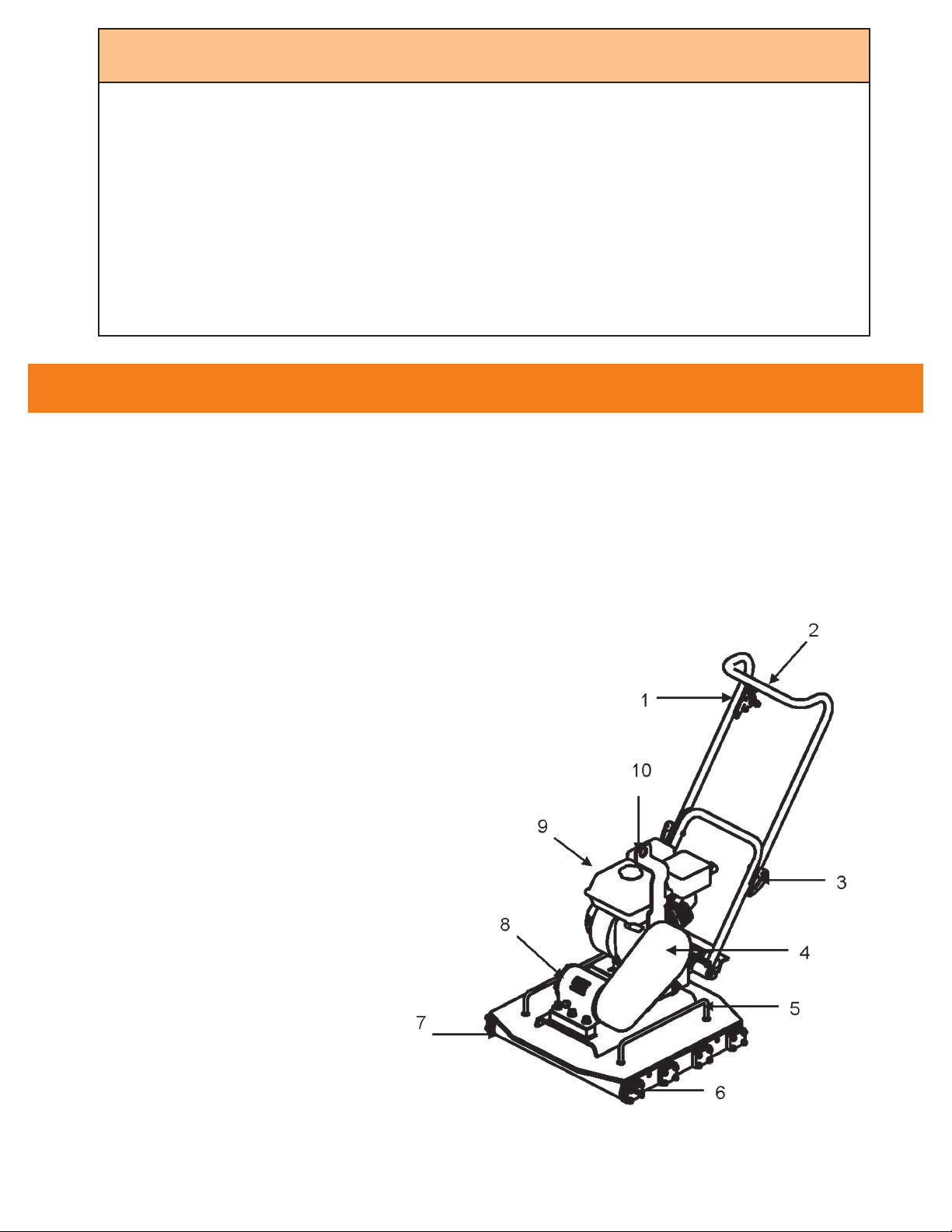

SAFETY PRECAUTIONS