1

Product Specifications 1 Inspection & Maintenance 30

Installation 3 Trouble Shooting 32

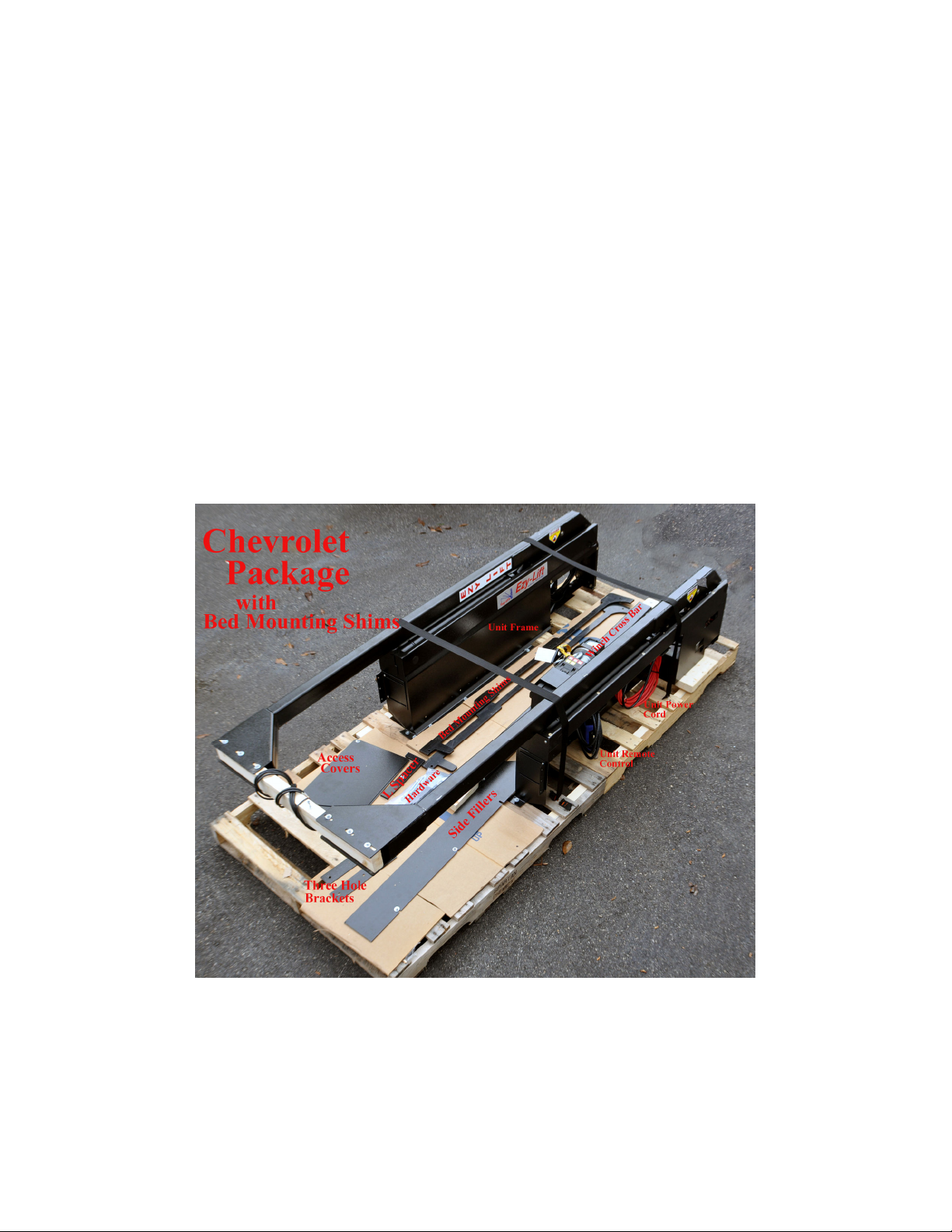

Chevrolet Unit Frame Installation 7 Warranty 33

Frame Installation-All Non Chevrolet Trucks 14 Hydraulic Diagram 34

Install Hydraulic & Power-All Truck Units 19 Electrical Diagram 35

Know Your Ezy-Lift 26 Replacement Parts List 36

Operation 28

Installation of the Ezylift must only be performed by qualified personnel with the proper tools in a prop-

erly equipped facility.

TABLE OF CONTENTS

The Ezy-Lift model 2000 lifting systems have a rated lift capacity of 2000 lbs.

Overloading your vehicle can create safety hazards!

Read and obey all Danger, Warning, Caution, and Operating Instructions on the Ezy-Lift and in this manual.

Make sure that all placards are in place and legible. Failure to comply with safety precautions in this manual and

on the Ezy-Lift is a safety violation that may result in serious injury, death, or property damage.

Read this entire manual before beginning work. Always wear safety glasses and use care when

working with power tools. Safety is a primary concern in the design and manufacturing of our

products. But remember that all efforts to provide safe equipment can be totally negated by a single careless act of

an installer or operator. Accident prevention and safety are dependent upon the awareness and proper training of

the personnel who operate and maintain this equipment. The best safety device is a careful and informed owner/

operator. Taking precedence over any specific rule, however, is the most important rule of all: SAFETY

INTRODUCTION

Throughout the manual you will see advisory signs that indicate special attention to various procedures in installa-

tion and operation.

The DANGER sign indicates an imminently hazardous situation which, if not avoided, will result

in serious injury or death.

The WARNING sign indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

The CAUTION sign indicates a potentially hazardous situation which, if not avoided could result

in minor or moderate injury.