5

4138

Drwg. No.

GB

SINGLE-/THREE-PHASE FOR SLIDING GATE OPERATORS MEC 200

PLUS

70/3

®

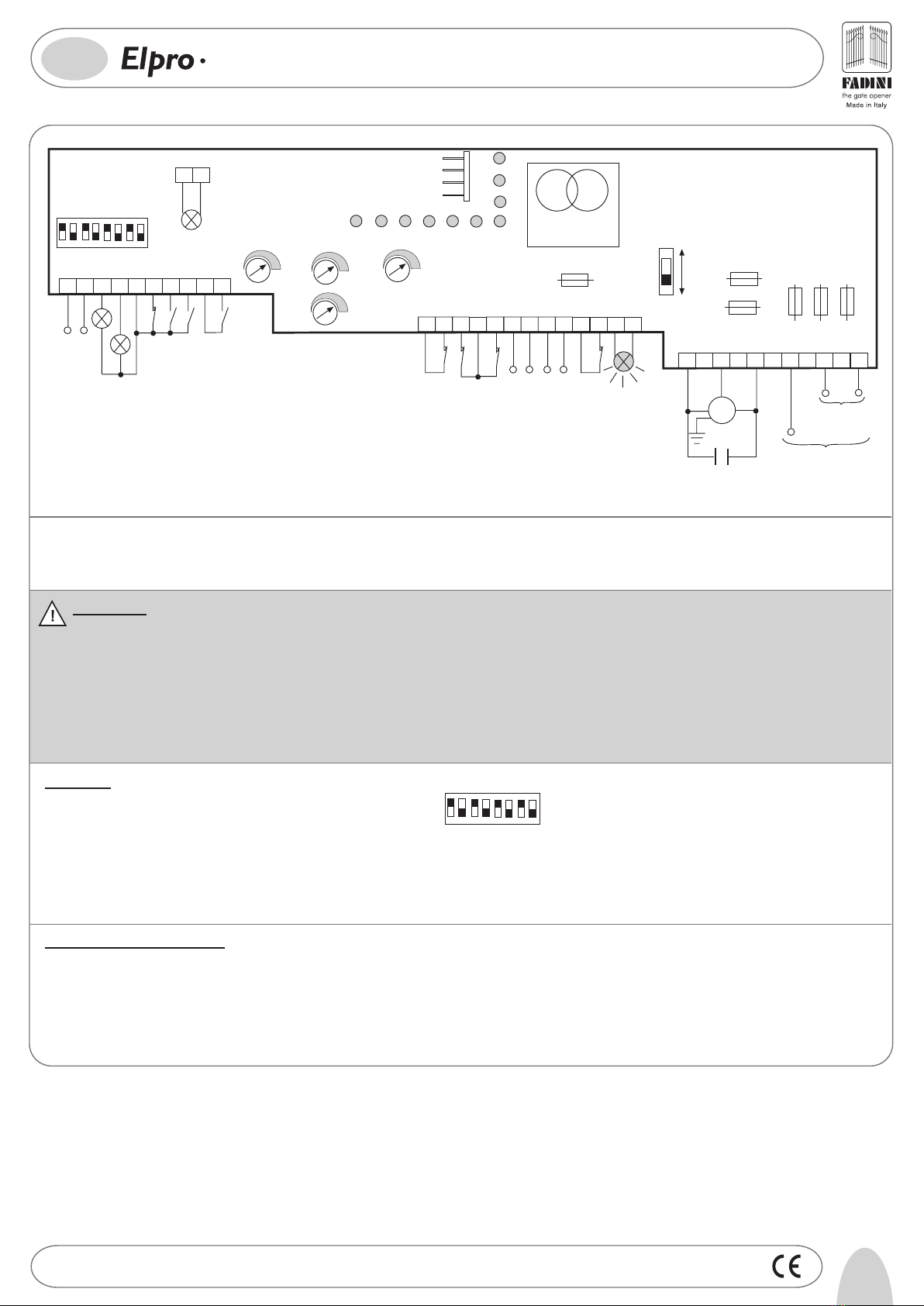

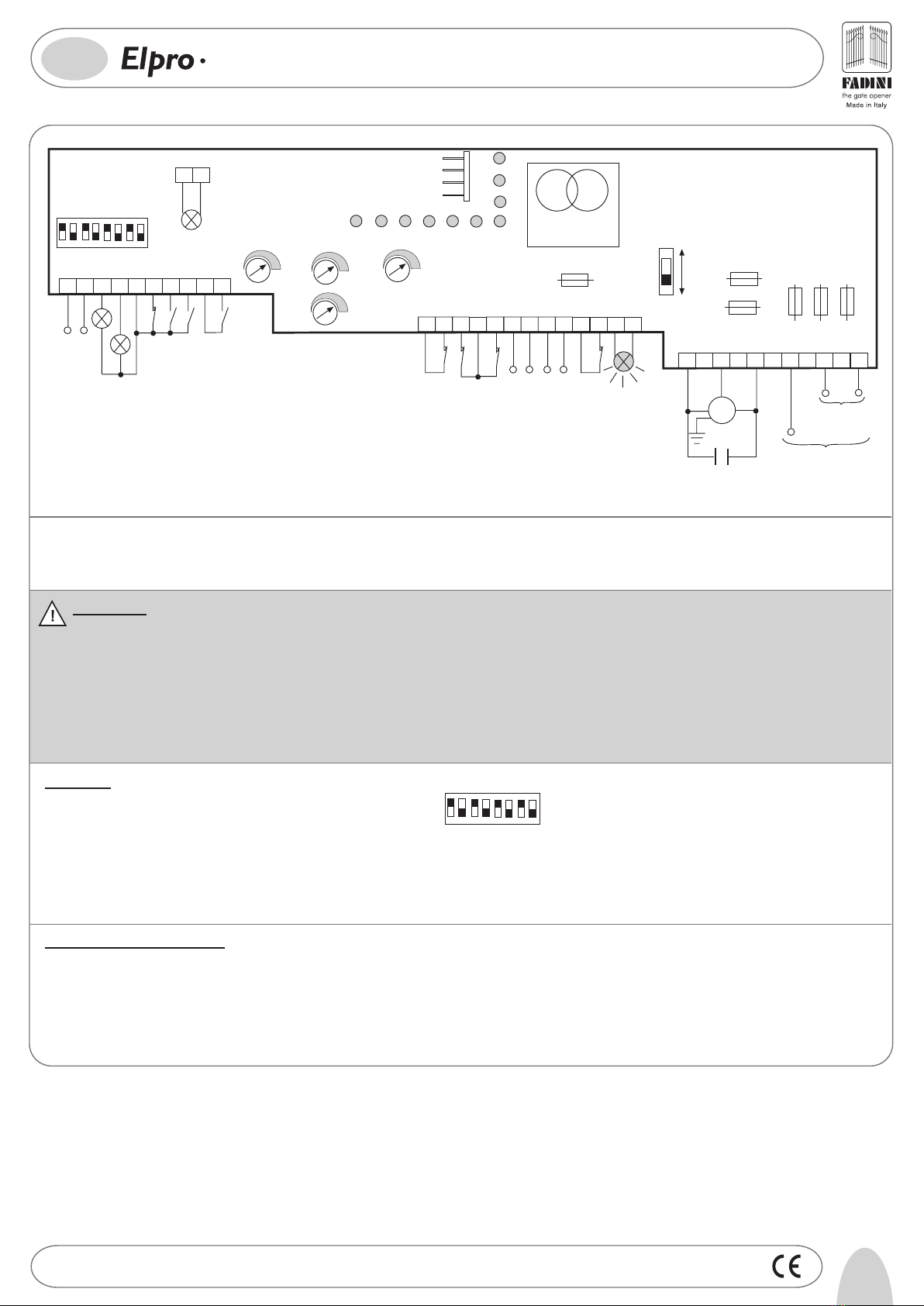

General description: The electronic control panel Elpro 70/3 Plus, new generation, is designed to operate the sliding gate operators MEC 200. Power supply is 230-400V single- and

three-phase. It is built in full compliance with the Low Voltage 2006/95/CE and Electro-Magnetic Compatibility Regulations 2004/108/EEC - 92/31/EEC. Fitting operations are recommended

to be carried out by a qualified technician in conformity to the existing safety standards. The manufacturing company declines any responsability for incorrect handling and applications;

also, it reserves the right to change or update the control panel any time. Failure to follow the installation regalations may result in serious damages to properties and persons.

PLEASE NOTE:

- The control panel is fitted inside Mec 200.

- Make sure that the power supply to the electronic programmer is 230V ±10% or 400V ±10%.

- Make sure that the power supply to the Electric Motor is 230V ±10% or 400V ±10%.

- For distances of over 50 metres we recommend using electric cables with bigger sections.

- Fit the mains to the control panel with a 0.03A high performance circuit breaker.

- Use 1.5 mm2section wires for voltage supply, electric motor and flashing lamp. Maximum recommended distance 50 m.Use 1 mm2section wires for

limit switches, photocells, push-buttons/key-switch and accessories.

- Bridge terminals 11 and 12 if no photocells are required.

- Bridge terminals 5 and 6 if no key- or push-button switches are required.

N.W: To fit extra accessories such as lights, CCTV etc. use only solid state relays to prevent damages to the microprocessor.

Dip-Switch:

1= ON Photocells. Stop on opening

2= ON Radio. No reversing on opening

3= ON Automatic closing

4= ON Preflashing activated

5= ON Radio.Step by step, stop in between

6= ON Deadman Control (Dip 4=OFF n Dip 3=OFF)

7= ON No light during dwell time

8= OFF. Blank

DIP-SWITCH

145678

2

ON

OFF

3

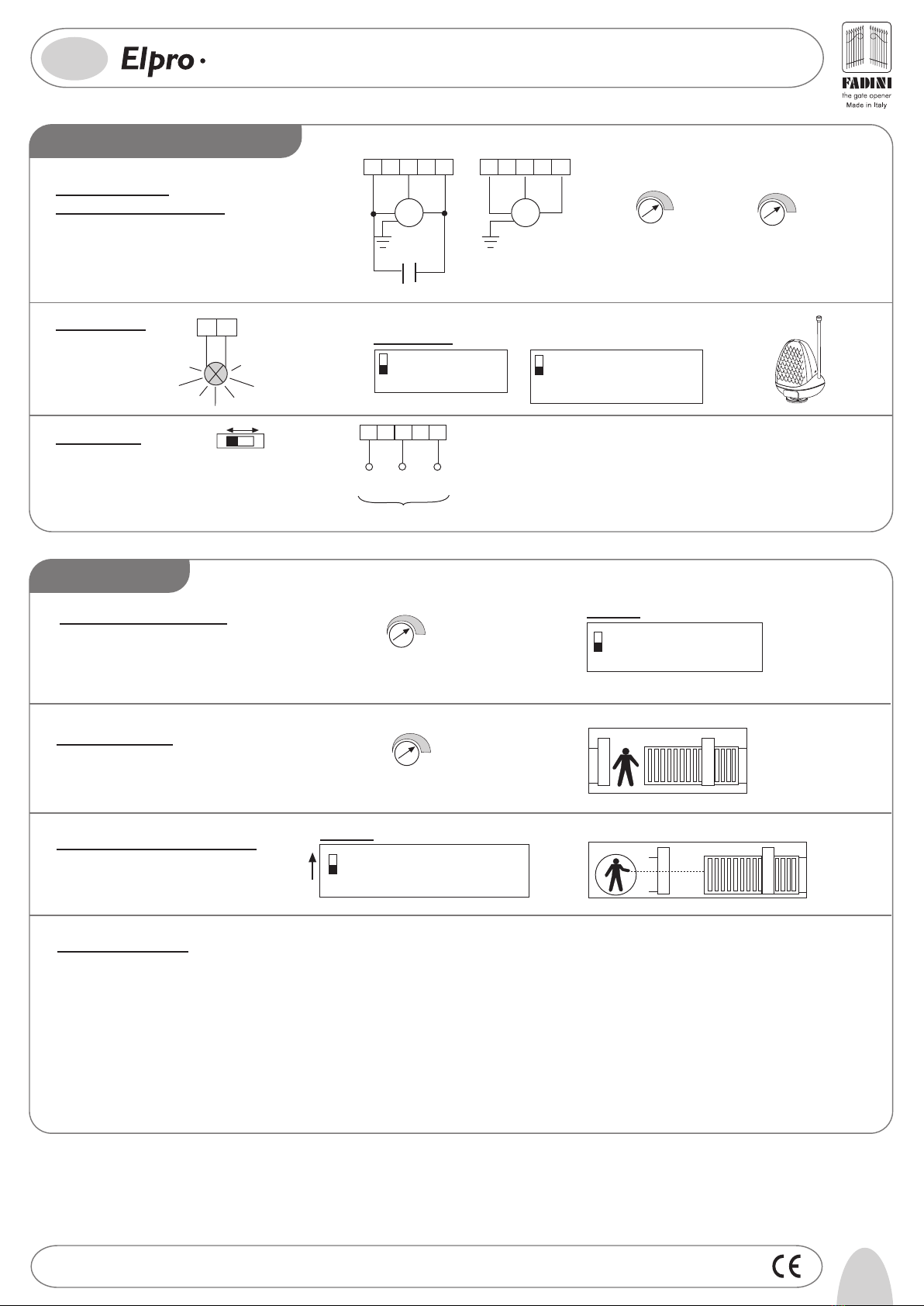

In case of failure of the panel:

- Make sure that the power supply to the electronic programmer is 230V ±10% or 400V ±10%

- Make sure that the power supply to the Electric Motor is 230V ±10% or 400 V ±10%

- For distances of over 50 metres we recommend using electric cables with bigger sections.

- Check fuses

- Check photocells if contacts are normally closed

- Check all NC contacts

- Check that no voltage drop has occurred from the control panel to the electric motor

DIP-SWITCH ON

OFF

145678

23

L2

L3 L4

L5 L6 L7

400V

F1=8A Mains

F2=8A Mains

F3=8A Mains

F5=1A Flashing

Lamp Protection

F4=630mA

Transformer

Protection

F6=630mA for 24V

protection

TRANSFORMER

MOTOR RUN TIME

from 5 to 150s

DWELL TIME

from 5 to 150s PEDESTRIAN TIME

from 3 to 30s

-

+

-

+

-

+

T3

T2

T1

T

NEUTRAL

S

LIVE

MOTOR

M

U

WV

16µF CAPACITOR for

single-phase application

1410

25

39

24V RADIO

POWER SUPPLY

INDICATION LAMP CLOSE

COMMON

78

6

STOP

CLOSE

OPEN

RADIO CONTACT

FLASHING LAMP

230V 25W max

191816 17 2322

11 12

PHOTOCELL CONTACT

13 1514

LIMIT SWITCH CLOSE

LIMIT SWITCH OPEN

COMMON

24V PHOTOCELL

SUPPLY

20 21

SAFETY SWITCH

25 2624 292827

230V

±10%

50Hz

SINGLE-PHASE

POWER SUPPLY

L9

L8

L1

L10

R

LIVE

230/400V

±10%

50Hz

THREE-PHASE

POWER SUPPLY

INDICATION

LIGHT

24V max 3W

230V

COM.

+24 SPIA

ELECTRIC LOCK

OR 12V AC RELAY FOR 230V

COURTESY LIGHT

-

+

T4

EXT TIME (Electric lock &

Courtesy Light) from 2 to 255s

INDICATION LAMP OPEN

RADIO

PLUG-IN

CARD CONNECTOR