4 Module programming

In order to operate electric FAKRO accessories equipped with the Z-WAVE system by means of

the ZWMA adapti e module, it is necessary to:

1. Add the de ice to be operated by means of the module to the “Z-Wa e” system – see ZWP10 remote

control and ZWK10, ZWK1 keyboards manuals, chapter “Adding de ice to the network (INCLUDE

function)” or other controller working in the Z-Wa e system. If the de ice is already operated with one

of the controllers, proceed to section 2.

2. Add the module to the Z-Wa e network as a SECONDARY controller, chapter 4.1 (LEARN MODE

function).

and

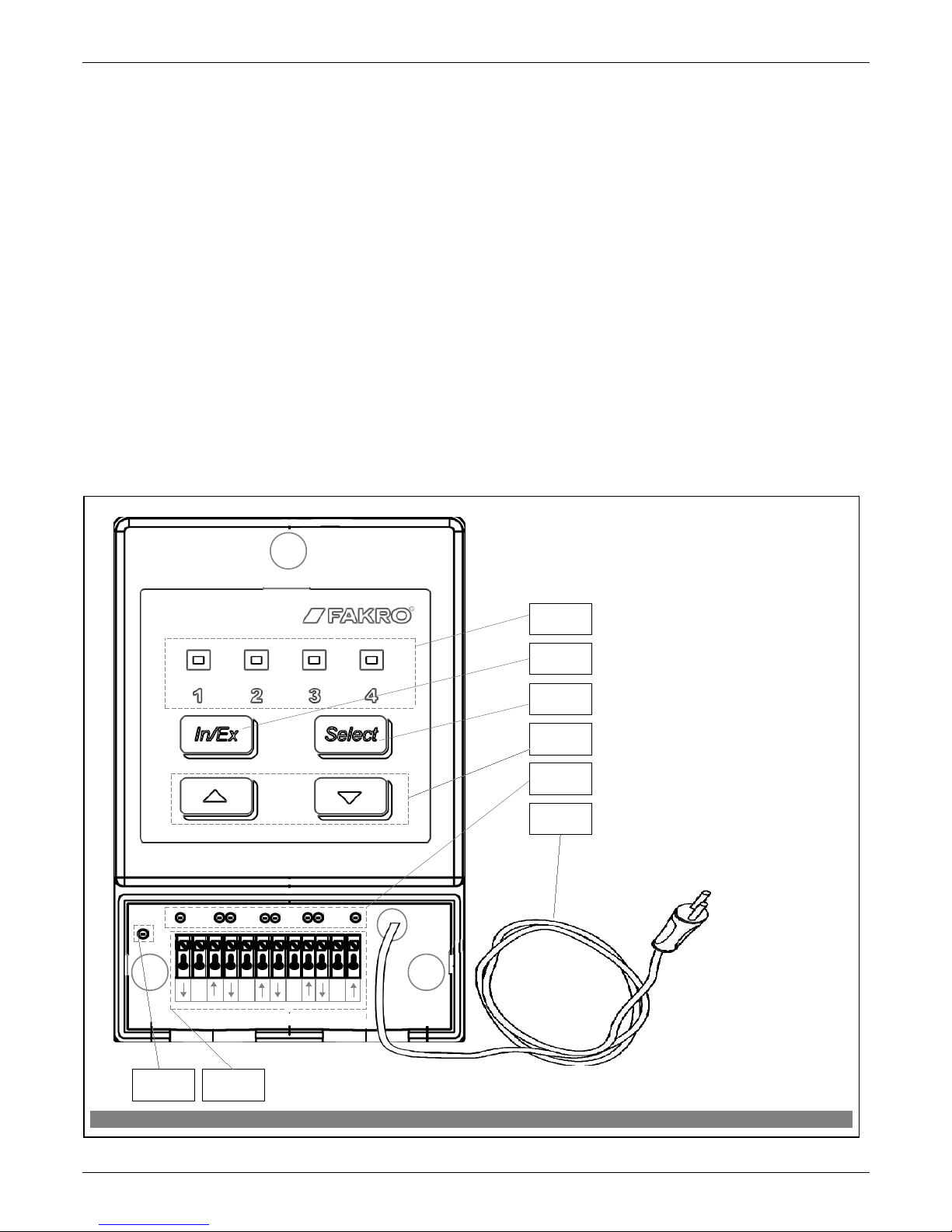

3. Associate the de ice with a selected channel in the module (No. 1, Figure 1) specifying the task to be

performed by it (chapter 4.2, ASSOCIATE function).

Note!!! Any de ice which is physically remo ed from the network (e.g. damaged) should be deleted from the

memory of the controller (PRIMARY, SECONDARY), that is first deleted from the pair of buttons (section

3.4) and then remo ed from the network (section 3.5). The correct implementation of the procedures is to

ensure optimal communication between de ices. Unplugging the de ice without remo ing it from the controller

memory will result in a prolonged reaction time to commands and faster depletion of the controller battery. If it

is necessary to remo e the damaged equipment, whose remo al from the controller memory is not possible, it is

desirable to reconfigure the whole network (all de ices). Start a new network configuration from restoring the

controller to the factory settings (DEFAULT function), then call the EXCLUDE function of de ices working

correctly and continue to the section 3, "Controller Programming".

Note!!! Mo ing the de ice within the network (e.g. socket module) it is recommended to delete it from the

controller memory (delete it from the pair of buttons first (section 3.4) and then remo e from the network

(section 3.5) and then add it again after installation in new place of work.

13.11.21 NC825-GB 5/16 ©2013, FAKRO