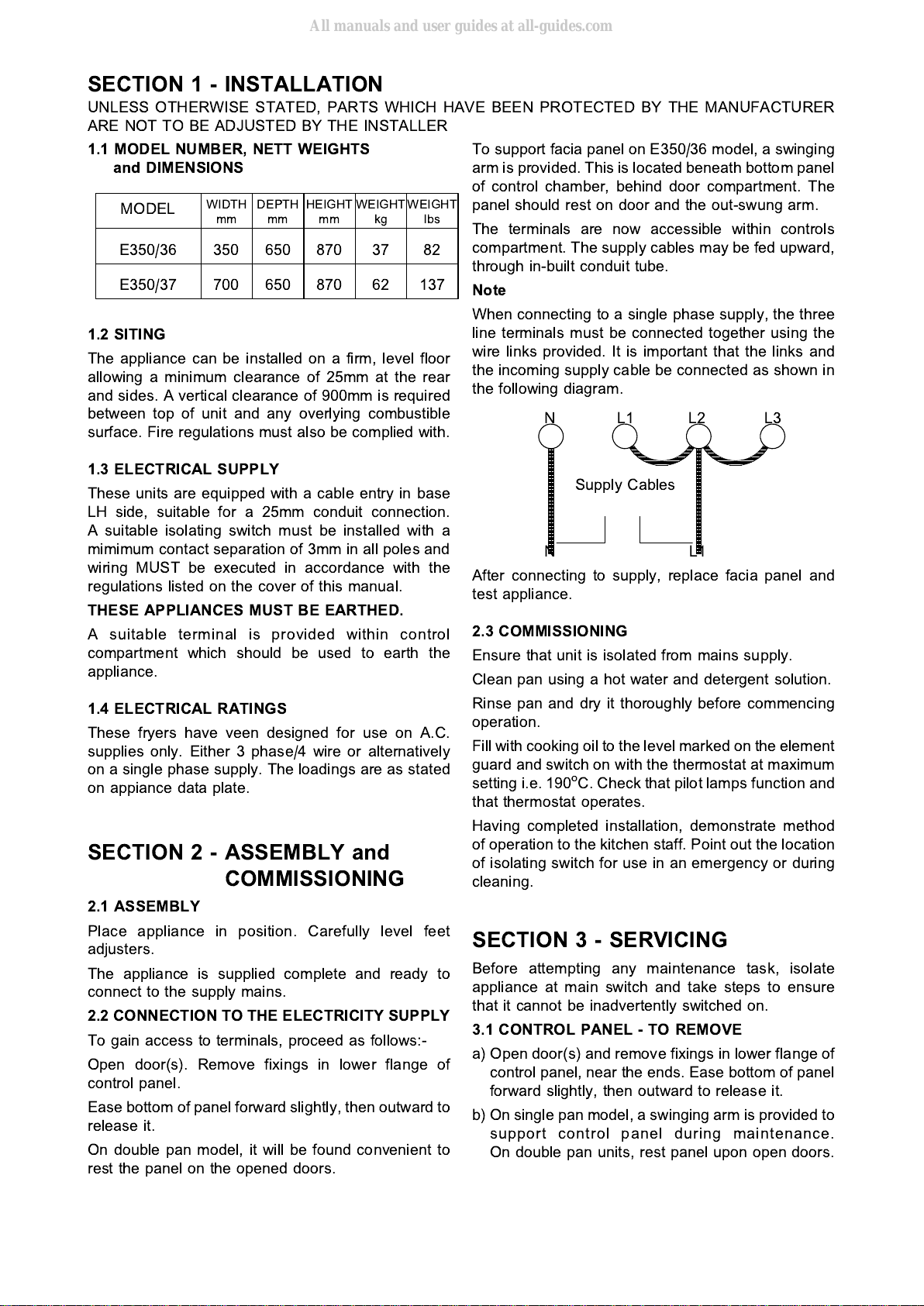

3.2 CONTROL THERMOSTAT

Should this co ponent prove to be faulty, it is not

nor ally repairable. It ust be replaced, using the

following procedure:-

a) Drain pan.

b) Re ove control panel. (Refer to Section 3.1)

c) Identify control ther ostat and re ove push-on

connections. First note their locations.

d) Using a stubby pozidriv screwdriver, re ove

ther ostat fro control panel.

e) Re ove heating ele ent as detailed in Section

3.4.

f) Re ove cover plate on ele ent hinge block

through which capillary tube passes. Manoeuvre

capillary tube and phial through oving hinge tube.

g) Feed capillary tube and phial through hole in base

of hinge block. Re ove ther ostat.

h) Replace ther ostat in reverse order, taking care

that capillary tube is well clear of ele ent

ter inals.

Not

When fitting a new ther ostat, fit existing insulating

sleeving over capillary tubing. Ensure that no tubing

is left exposed to possible contact with live parts.

Coil the excess capillary tube by wrapping it round a

suitable andrel of approxi ately 1

1

/

2

" dia eter.

When fitting gland, ensure it is tightened fir ly but do

not overtighten. Always check fitting for leaks by

re-filling with oil and heating to axi u

te perature.

When fitting ther ostat to control panel, ensure that

earth bonding wire is replaced below one of the

ther ostat fixing lugs. Take care that coiled capillary

tubing is clear of any live parts when control panel is

replaced.

Re-fit the ther ostat in reverse order to re oval.

3.3 PILOT LAMPS - TO REPLACE

a) Re ove control panel. (Refer to Section 3.1)

b) Pull off la p connections.

c) Undo hex nut at rear of la p and re ove la p.

Replace in reverse order.

3.4 HEATING ELEMENT - TO REPLACE

To replace ele ent, proceed as follows:-

a) Drain pan.

b) Re ove basket support bar fro ele ent and fully

raise ele ent.

c) Re ove fixings on underside of ele ent ter inal

box.

d) Re ove ele ent ter inal box cover plate by

prising up lower edge with a screwdriver.

e) Lower ele ent and re ove guard (4 fixings).

f) Re ove ele ent push on connections. First note

their locations.

g) Re ove fixings which secure ele ent to ter inal

box. Re ove ele ent.

Replace in reverse order and ensure that oil

resistant gasket is fitted below ele ent ounting

plate.

Important

Earth bonding connections are provided with

shakeproof or spring washers. It is i portant that

these be correctly replaced during re-asse bly.

3.5 SAFETY THERMOSTAT

3.5.1 To R -s t

In event of control ther ostat failure resulting in

overheating of the oil, the safety ther ostat will

operate and will switch off all power to ele ents.

To re-establish circuit, it will be necessary to re-set

the safety ther ostat.

Allow fryer to cool and re ove control panel (refer to

Section 3.1). This will reveal safety ther ostat which

is ounted on rear of controls co part ent.

To re-set, fir ly press red button.

On double pan odels, LH and RH ther ostats are

appropriate to LH and RH pans respectively.

3.5.2 Saf ty Th rmostat - To R plac

a) Drain pan.

b) Re ove control panel. (Refer to Section 3.1)

c) Identify safety stat and re ove push-on

connections. First note their locations.

d) Using a stubby pozi screwdriver, re ove stat fro

ounting bracket.

e) Re ove heating ele ent as detailed in Section

3.4.

f) Re ove cover plate on ele ent hinge block,

through which capillary tube passes. Manoeuvre

capillary tube and phial through oving hinge

tube.

g) Feed capillary tube and phial through hole in base

of hinge block. Re ove ther ostat.

h) Replace ther ostat in reverse order. Ensure

capillary tube is well clear of ele ent ter inals.

After replacing ther ostat, press red button fir ly to

ensure contacts are in closed condition.

3.7 TILT SWITCH

Located in ele ent re inal box, this should require

no aintenance.

All manuals and user guides at all-guides.com