2111628M Revision date: 09.25.18

READ THIS DOCUMENT BEFORE YOU BEGIN

Thank you for purchasing the 111628M FodderPro 2.0 Micro System. When properly assembled and maintained, this product will provide years of reliable

service. This guide includes important information needed to safely assemble and maintain the system. Read these instructions before you begin.

Important Information

REQUIRED TOOLS

The following list identifies the main tools needed to

assemble the fodder system. Additional tools and

supports may be needed.

• Tape measure and marker

• Variable speed drill (cordless with extra batteries

works best) and drill bit set with a 9/32" & 7/16" bit.

• Small hammer and gloves

• PVC Tube Cutting Tool

• Level 2' (or longer)

• Wrench set or adjustable wrenches

• Socket Set with Ratchet

• Straight Screw Driver

• 1-3/8" hole saw bit for the drain manifold—Step Bit

recommended.

• Adjustable pliers

• 5/8" nut driver (or 5/8" socket)

• Ladder or work platform to work at the height of

the fodder system frame.

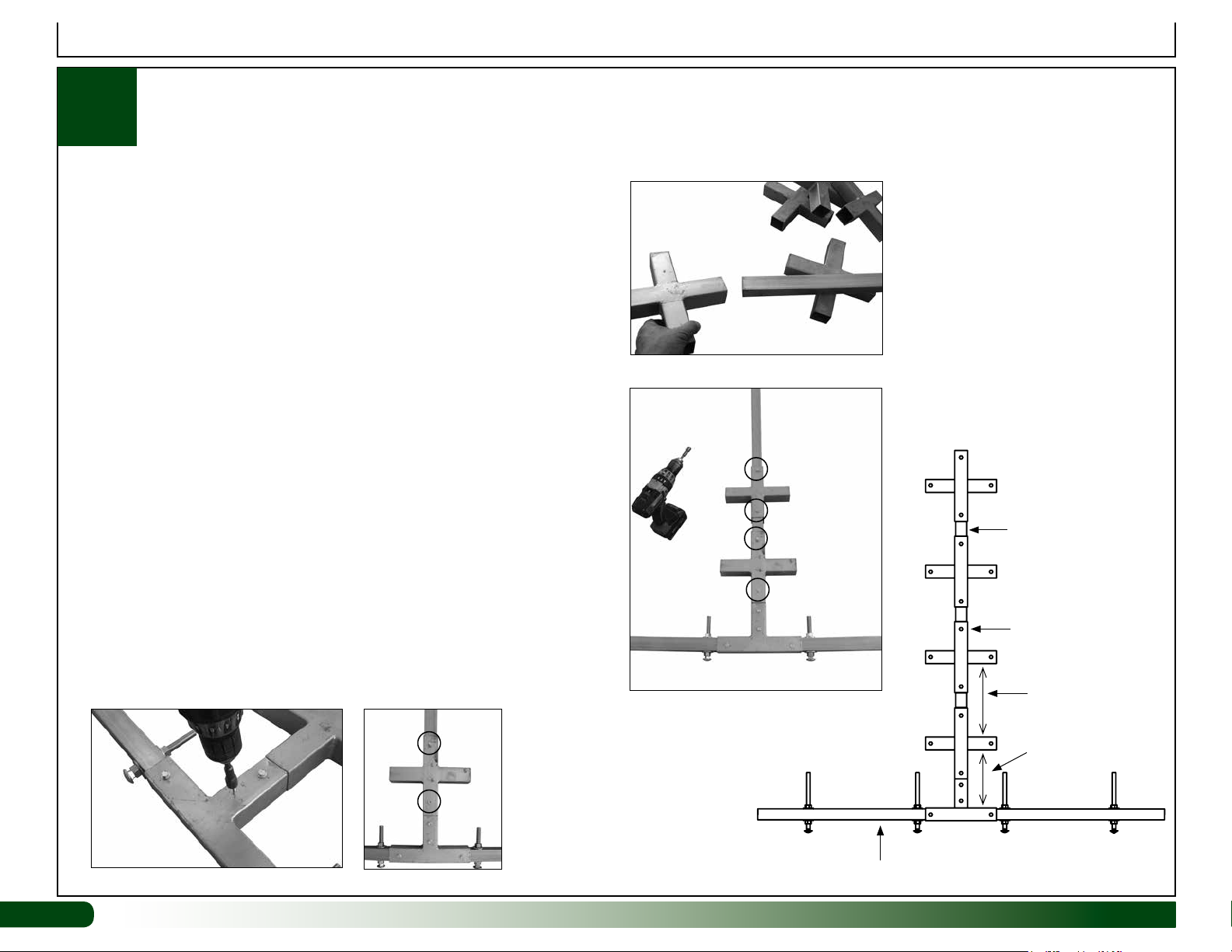

ASSEMBLY PROCEDURE

Following the instructions as presented will

help ensure the proper assembly of your fodder

system. This manual describes how to assemble a

single 111628M FodderPro 2.0 Micro System.

The steps outlining the assembly process are as

follows:

1. Verify that all parts are included in the

shipment. Notify customer service for

questions or concerns.

2. Read these instructions and all additional

documentation included with the shipment

before you begin.

3. Gather the tools and assistants.

4. For best results, assemble the components

in the order they are presented in these

instructions.

SAFETY PRECAUTIONS

• Wear eye protection.

• Wear gloves when handling metal tubes.

• Use a portable GFCI (Ground Fault Circuit

Interrupter) when working with electric power tools

and cords.

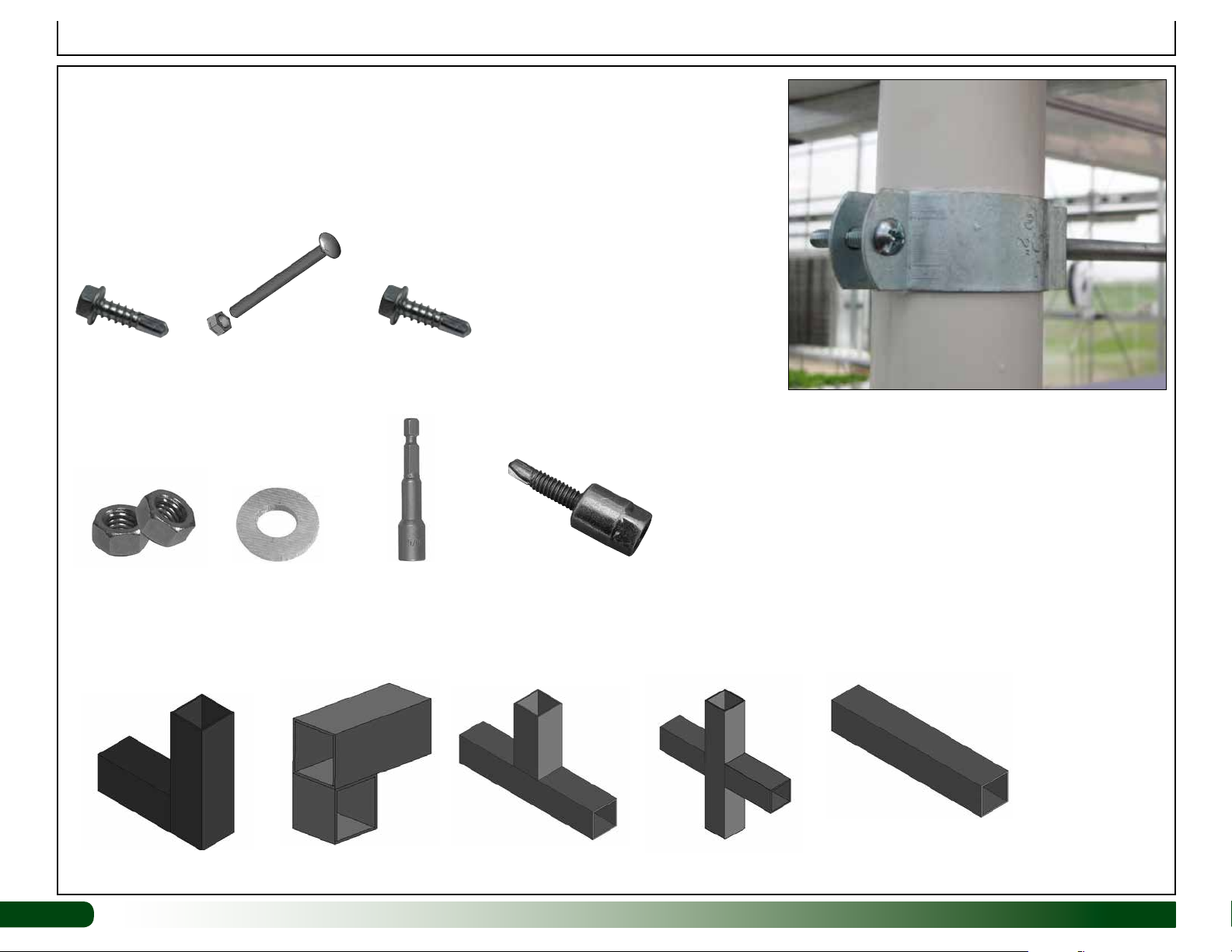

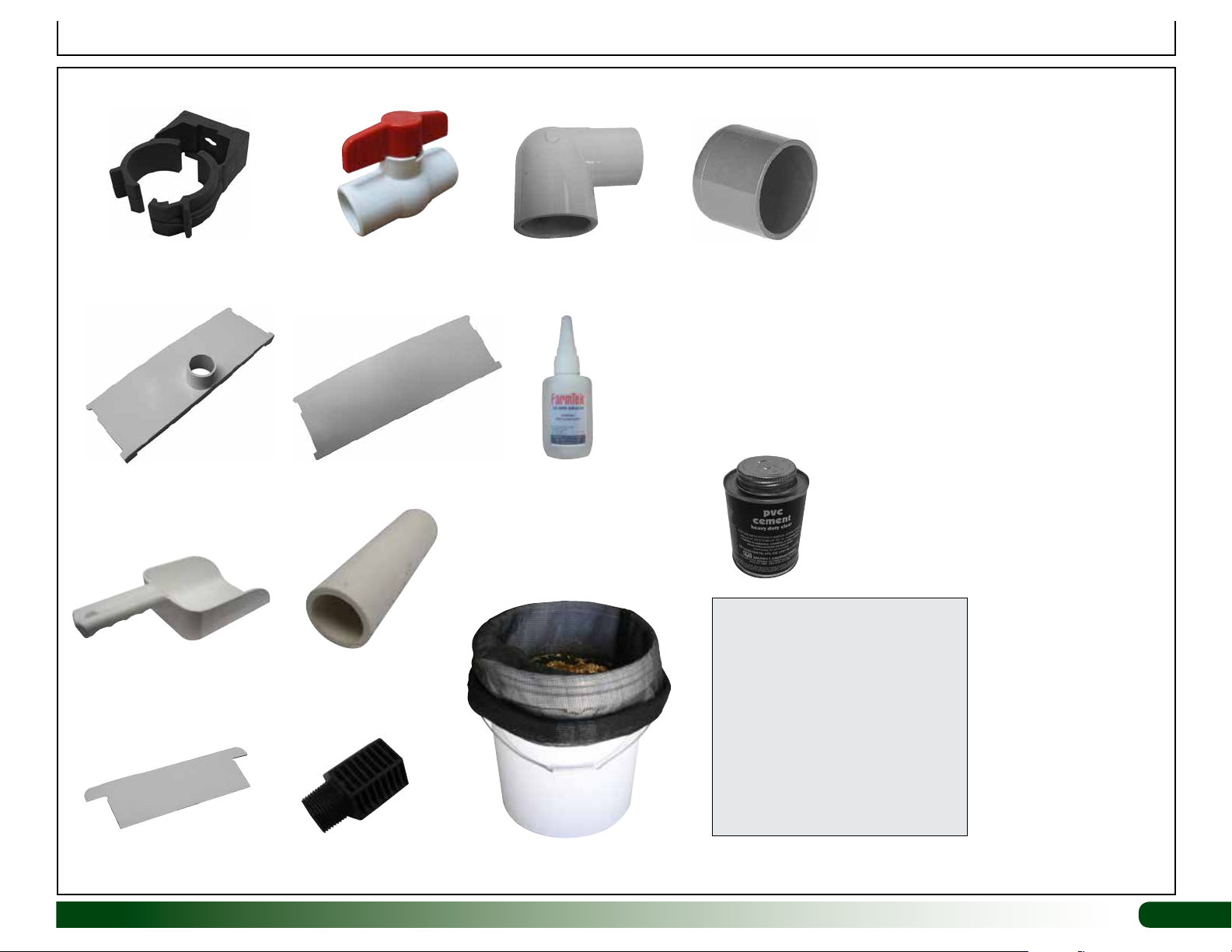

UNPACK AND IDENTIFY PARTS

The following steps will ensure that you have all

the necessary parts before you begin assembly.

1. Unpack the contents of the shipment and

place where you can easily inventory the

parts. Refer to the Bill of Materials/Spec

Sheets.

2. Verify that all parts listed on the Bill of

Materials/Spec Sheets are present. If anything

is missing or you have questions, consult

the Pictorial Parts Guide and all diagrams for

clarification, or contact Customer Service.

QUICK START GUIDE

For a quick overview of this product and its

components, consult the Quick Start Guide at the

back of these instructions.

ELECTRICAL WARNING

Fodder frame is metal and will conduct electricity!

Exercise caution if working around or on the

frame with electric power tools. Use cordless,

battery-power tools.

CONSULT THE SERVICES OF A QUALIFIED

ELECTRICAL TECHNICIAN WHEN INSTALLING

ANY PUMPS, ARTIFICIAL LIGHTING,

OR OTHER ELECTRICALLY POWERED

ACCESSORIES.

OPEN SYSTEM

The 111628M FodderPro 2.0 Micro System is

an open system, which means that the water

is not recycled for use in the fodder system.

Unlike a closed system where the water is

stored in a reservoir and recycled, the open

system requires a water source and a drain to

accept the unused water. The unused water can

be recycled for use in other applications such

as watering other plants; however, to promote

healthy fodder growth, it is not recommended

for reuse in the fodder system.