-3-

6.3.7 Permissible overhung load and permissible thrust load............................................................ 33

6.4 Installing the combination hollow shaft gearhead ............................................................. 34

6.4.1 Checking the parts....................................................................................................................................... 34

6.4.2 Cautions on operations ............................................................................................................................. 35

6.4.3 Mounting motor and gearhead............................................................................................................. 36

6.4.4 Installing............................................................................................................................................................ 37

6.4.5 Rotation direction of gearhead and transmission efficiency.................................................... 42

6.4.6 Maximum permissible torque of gearhead ...................................................................................... 42

6.4.7 Permissible overhung load and permissible thrust load............................................................ 43

7. Setting and Operation............................................................................................................................. 44

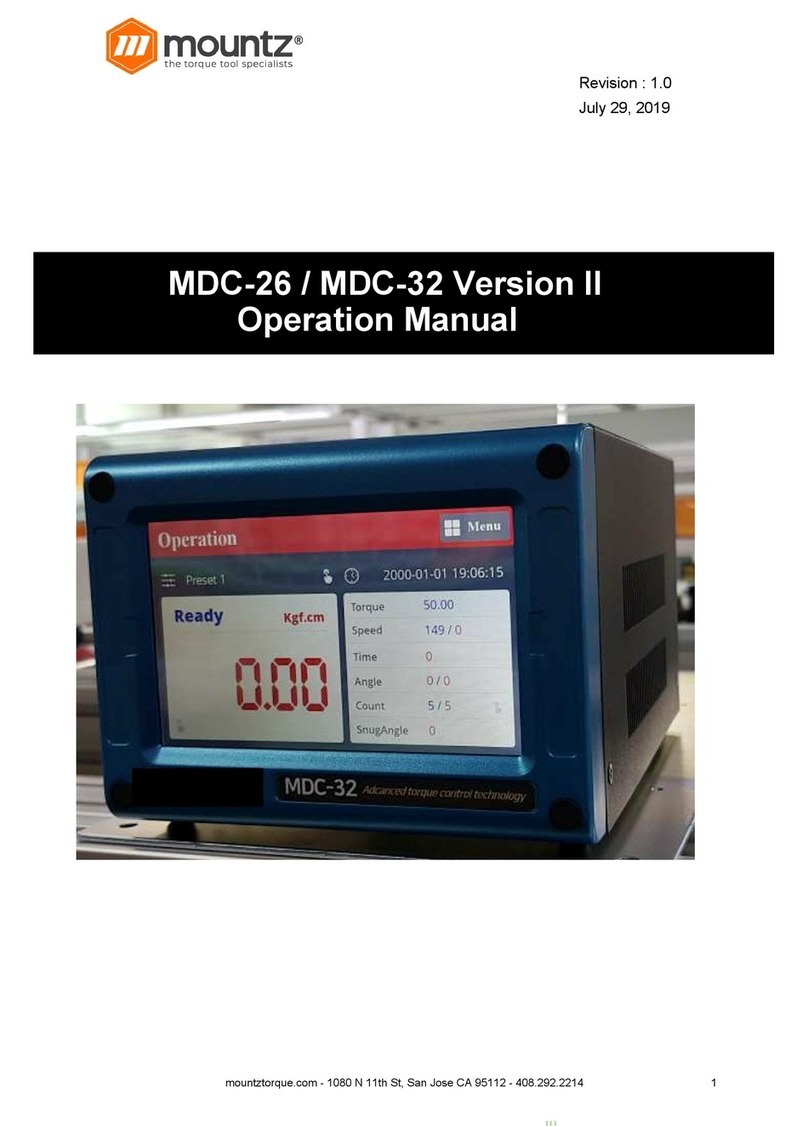

7.1 Exterior and names ........................................................................................................................... 44

7.2 Rotation direction switch................................................................................................................ 45

7.3 Connecting............................................................................................................................................ 46

7.3.1 Connection the power supply ................................................................................................................ 46

7.3.2 Connecting the motor................................................................................................................................ 48

7.3.3 Ground connection...................................................................................................................................... 48

7.3.4 Connecting the I/O signals ...................................................................................................................... 49

7.4 Operating............................................................................................................................................... 54

7.4.1 Connecting ...................................................................................................................................................... 54

7.4.2 Inputting the power .................................................................................................................................... 55

7.4.3 Operating ......................................................................................................................................................... 55

7.4.4 Reading of 7-Segment............................................................................................................................... 56

7.5 Operating by I/O signals ................................................................................................................ 57

7.5.1 Operating ......................................................................................................................................................... 57

7.5.2 Operating with multiple speeds ............................................................................................................ 58

8. Convenient functions ............................................................................................................................... 61

8.1 Function list .......................................................................................................................................... 61

8.2 Setting and 7-segments display.................................................................................................. 63

8.3 Parameter list....................................................................................................................................... 70