Westward Hydraulic Quick Lifting

Jacks

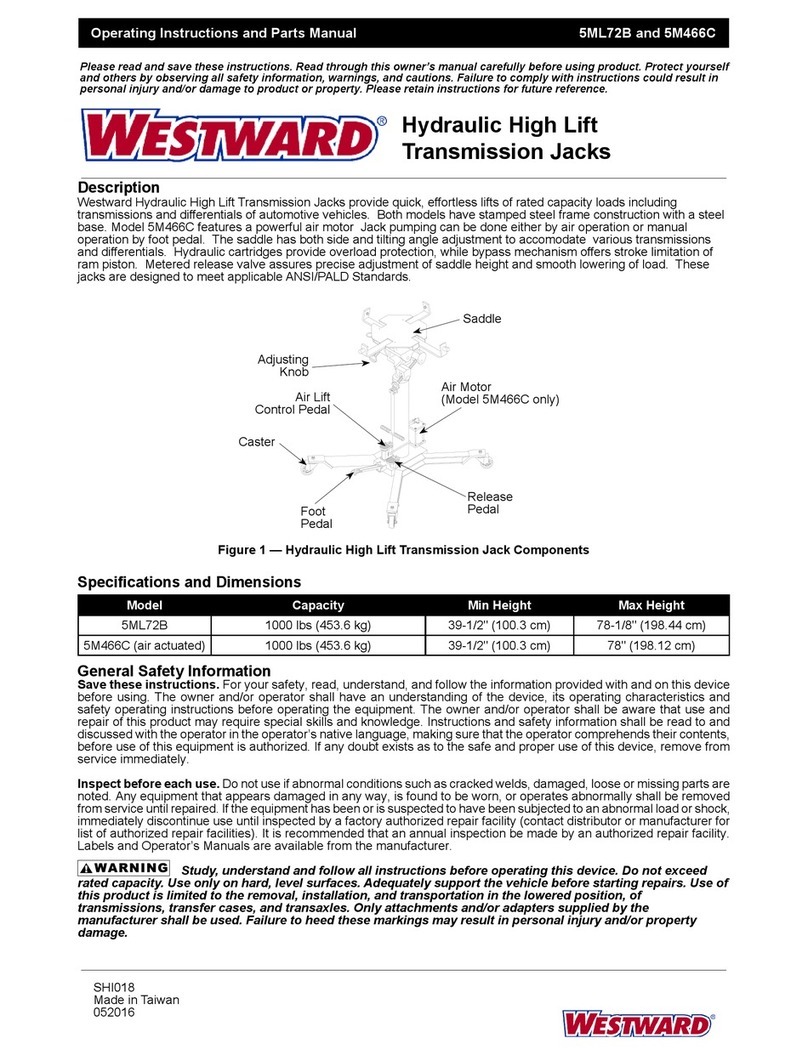

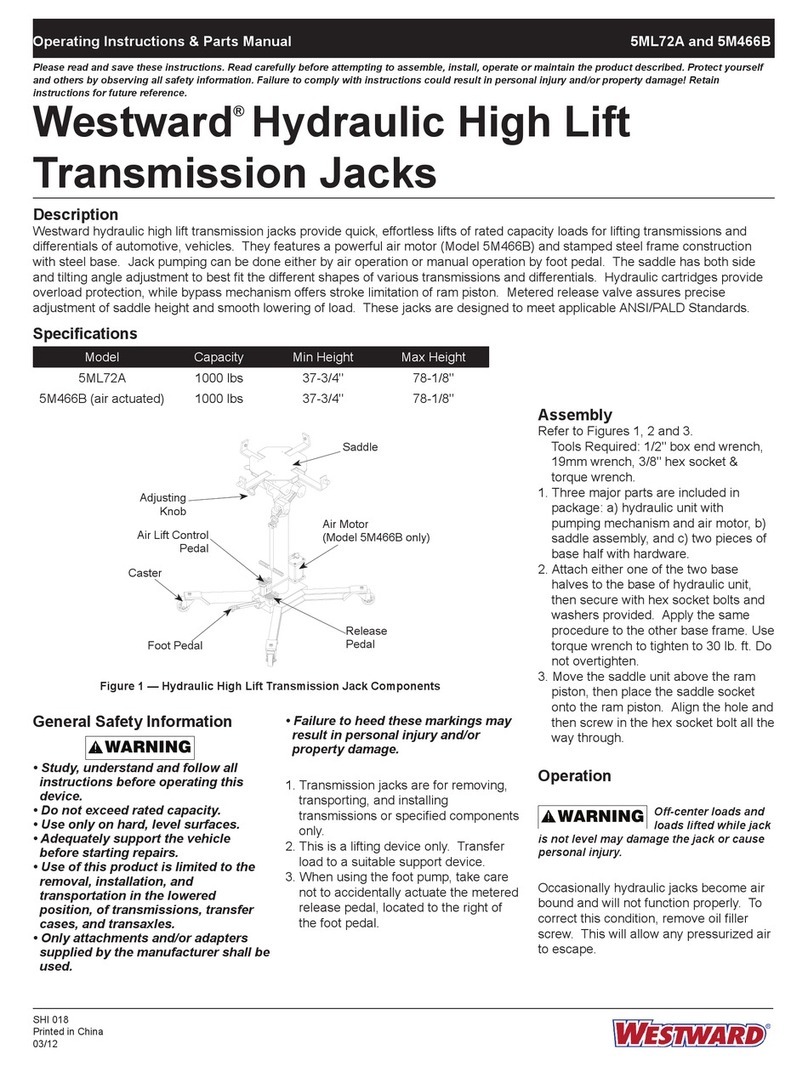

Operating Instructions & Parts Manual 5ML68A, 5ML69A and 5ML70A

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

®

Description

Westward hydraulic Quick Lifting jacks are used for lifting part of a total vehicle (i.e.,

one wheel). Jacks are equipped with a built-in by-pass device to prevent damage

to jack from overpumping. An internal safety valve prevents damage to jack from

overloading. Applications include automotive, truck, farm, industrial and construction.

These jacks are designed to meet applicable ASME/ANSI Standards.

Specifications

Min. Max.

Model Capacity Length Height Height

5ML68A 4 Ton 48 13/16" 5" 24"

5ML69A 5 Ton 52 3/4" 6 1/2" 22 1/4"

5ML70A 10 Ton 51 1/2" 6 7/8" 27"

General Safety Information

Study, understand,

and follow all

instructions before operating this device.

Lifting device only. Intended use is for

lifting part of a total vehicle, only one

wheel or axle at a time. Immediately after

lifting, support vehicle with appropriate

means. Do not exceed rated capacity. Use

only on hard, level surfaces capable of

sustaining rated capacity loads. Lift only

on those areas of the vehicle as specified

by the vehicle manufacturer. Ensure that

the lift point is properly centered on the

jack saddle. Always wear safety glasses

when using this equipment. Inspect

jack before each use. Do not use if bent,

broken, leaking, or damaged components

are noted. No alteration of this product

is allowed. Do not use this device for

any purpose other than that for which it

was intended. Failure to heed any one or

combination of these warnings may result

in severe personal injury and/or property

damage.

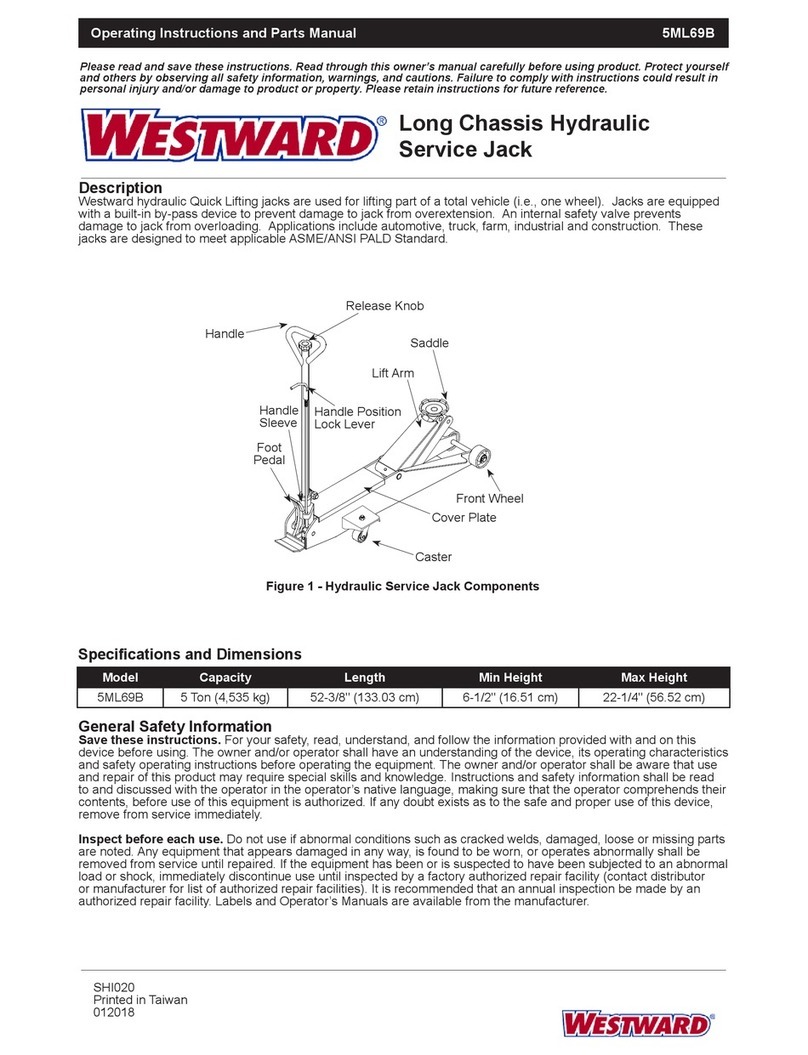

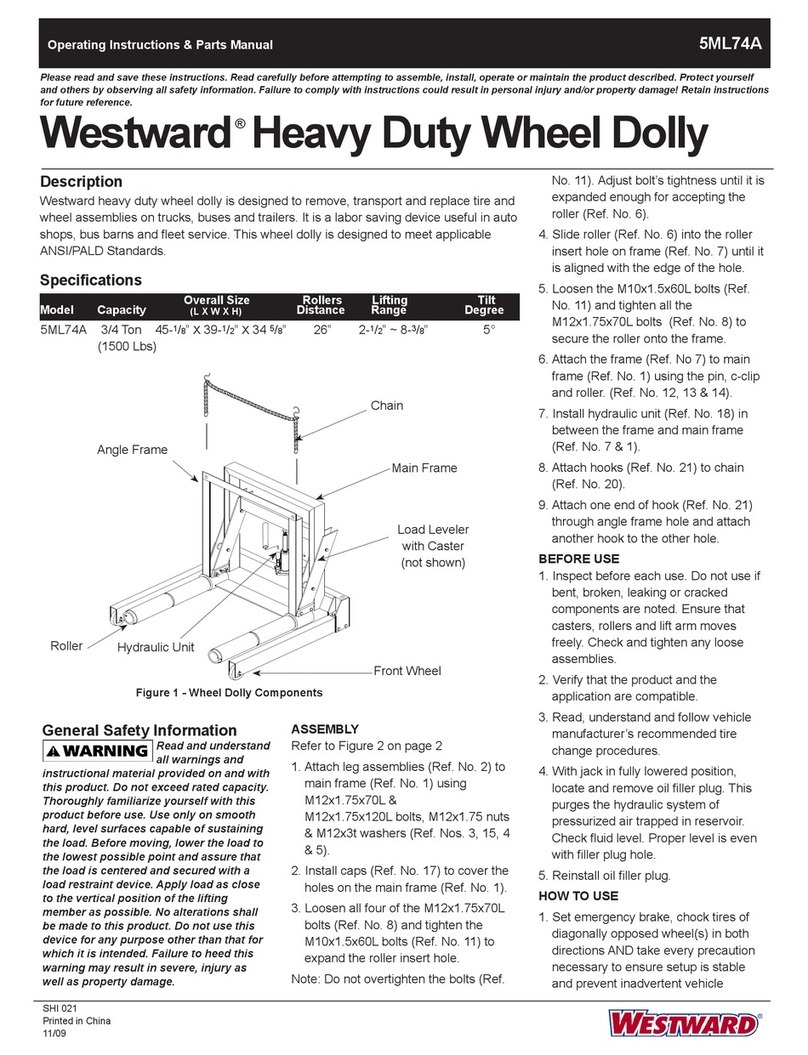

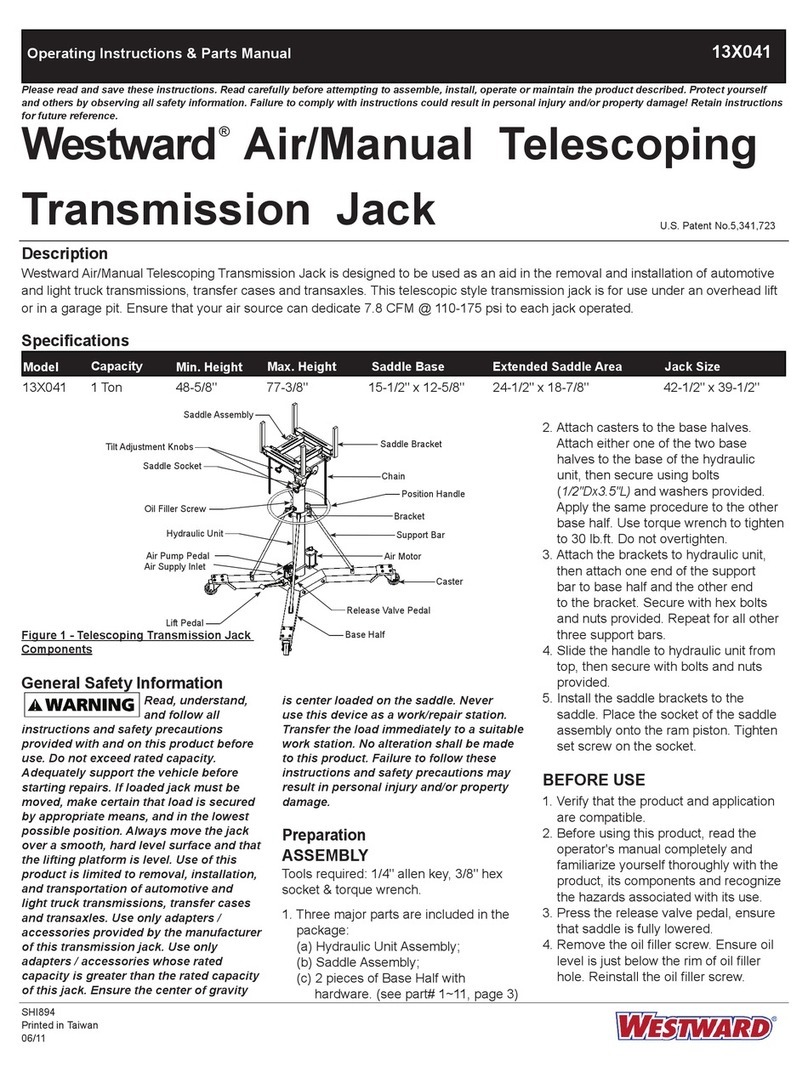

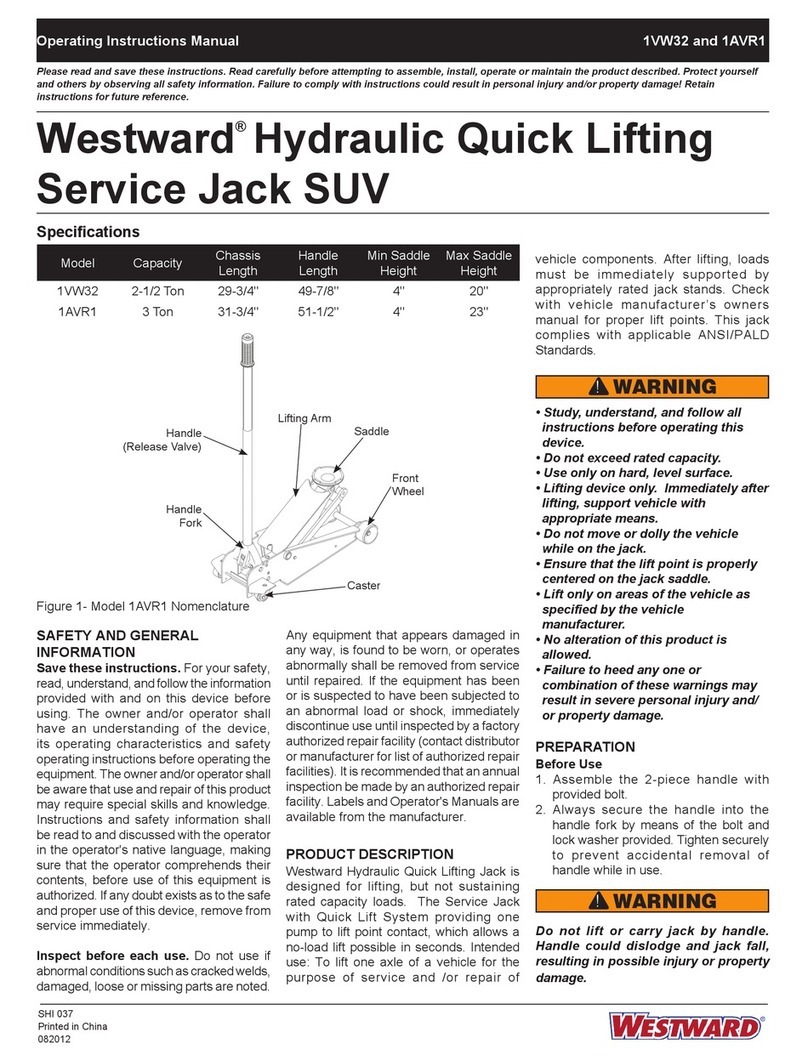

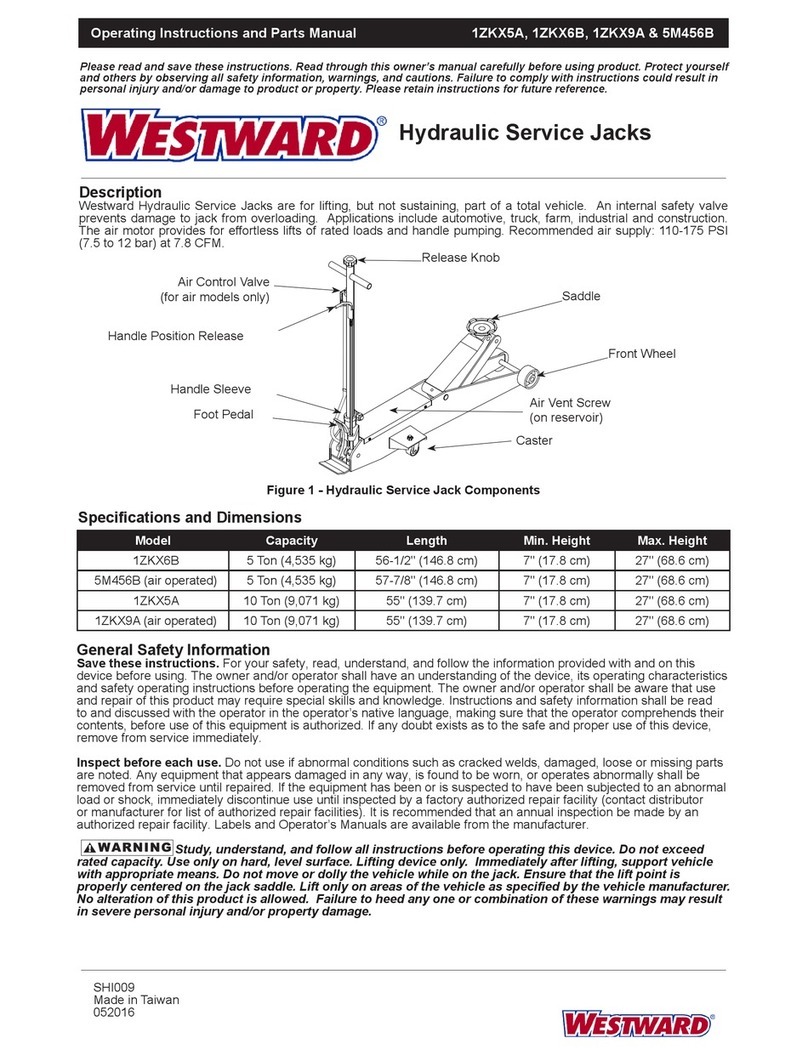

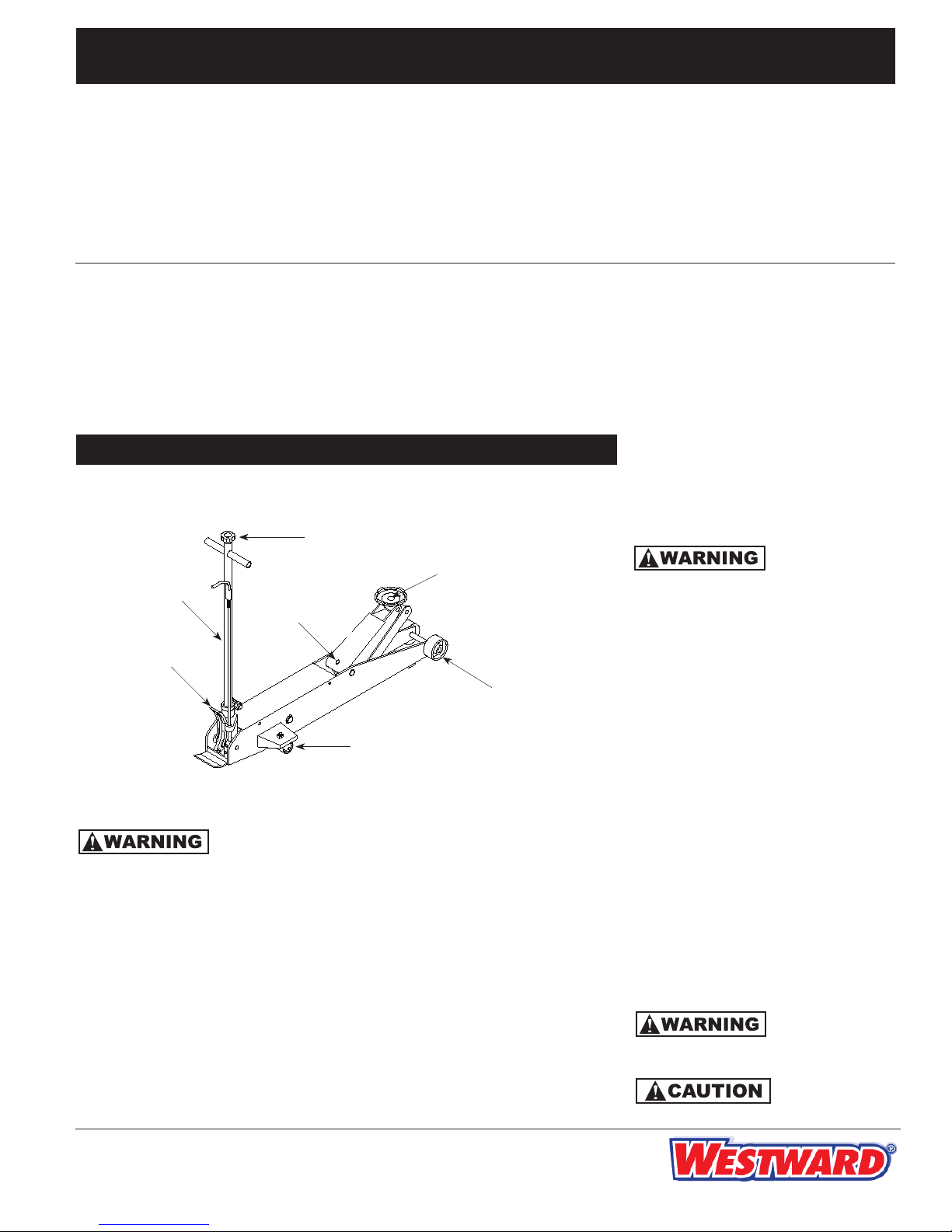

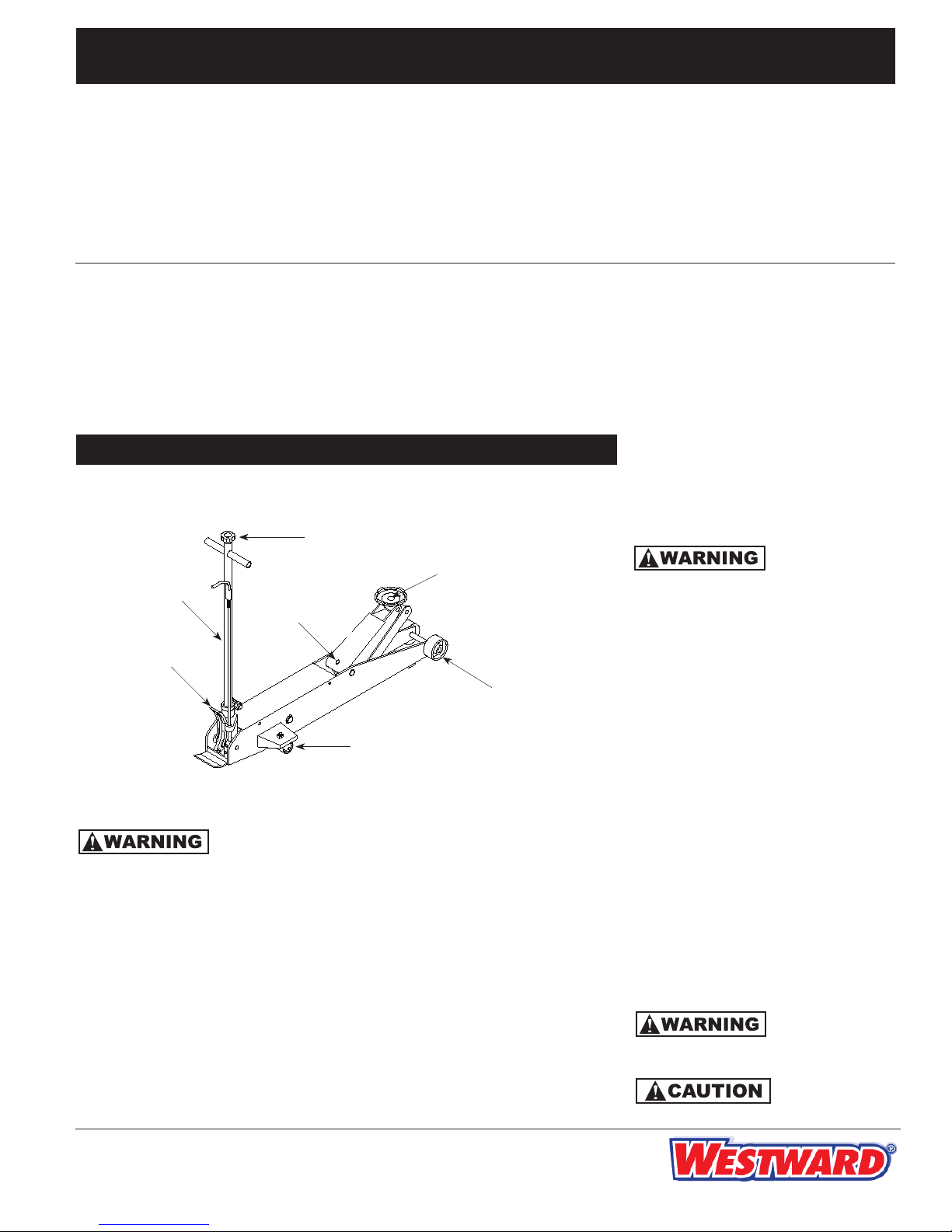

Assembly

Use figure 1 as reference.

1. Assemble the handle to handle socket

by inserting the handle piece into

the socket; align the handle with jack

chassis, then tighten the hexagon nut

securely.

2. Try to operate the release mechanism

by turning the release knob located

on top of the handle clockwise and

counterclockwise to see if release shaft

fits together well.

3. Occasionally, hydraulic jacks become

air bound and will not function

properly. To correct this condition,

remove oil filler/vent plug. This will

allow any pressurized air to escape.

Check for proper oil level (see Adding

Oil, page 2), adjust as needed.

DO NOT OVERFILL! Reinstall oil filler/

vent plug.

4. Squirt a small amount of hydraulic jack

oil on pistons and lightly lubricate all

moving parts of jack.

Operation

Off-centered loads

and loads lifted while

jack is not level may damage the jack or

cause personal injury.

LIFTING

1. Prevent inadvertent vehicle movement

by fully engaging emergency brake,

putting transmission in park. Use

wheel chocks in pairs on the wheel

diagonally opposed to the wheel or

axle lifted.

2. Close release valve by turning

the release knob on top of handle

clockwise until it is firmly closed.

3. Position jack under load and align

to the lift point suggested by vehicle

manufacturer.

4. Operate jack by pumping the handle,

foot pedal until saddle contacts load

point. Ensure load is centered on

saddle. Then operate jack until load

reaches desired height.

NOTE: Never use foot pedal to raise

load.

This is a lifting

device only. The

load must be supported immediately by

other appropriate means.

Keep hands, feet,

and clutter clear of

ground area when lowering the load.

Figure 1 — Hydraulic Service Jack Components

Release Knob

Foot Pedal

Saddle

Front Wheel

Caster

Grease Fitting

Nipple

Handle

SHI 020

Printed in China

11/07