FCI ST100A Series User manual

06EN003480 Rev. A ST100A Series Flow Meter

Fluid Components International LLC

Notice of Proprietary Rights

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components

International LLC (FCI). Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company

only (and does not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

©Copyright2020byFluidComponents International LLC.All rightsreserved. FCIis aregistered trademark ofFluid Components InternationalLLC.Information subjectto changewithout notice.

ST100A Series Flow Meter 06EN003480 Rev. A

Fluid Components International LLC iii

Table of Contents

Table of Contents......................................................................................................................................................................................iii

List of Figures ...........................................................................................................................................................................................v

List of Tables............................................................................................................................................................................................vii

Typographical Conventions ....................................................................................................................................................................viii

1GENERAL.........................................................................................................................................................................................1

Product Description...........................................................................................................................................................................1

Theory of Operation..........................................................................................................................................................................1

Safety Instructions.............................................................................................................................................................................1

Order Verification..............................................................................................................................................................................1

Technical Specifications....................................................................................................................................................................3

2INSTALLATION.................................................................................................................................................................................7

Specific Conditions of Use................................................................................................................................................................7

Instrument Identificationand Outline Dimensions.............................................................................................................................7

ST100A Insertion Sensor Installation................................................................................................................................................7

STP100A Flow Element Installation................................................................................................................................................14

ST102AA and ST112AA Flow Element Installation ........................................................................................................................14

ST100AL In-Line Process Connection............................................................................................................................................16

Flow Transmitter Electronics Installation.........................................................................................................................................16

Instrument Wiring............................................................................................................................................................................21

Post Installation Check....................................................................................................................................................................33

3OPERATION...................................................................................................................................................................................35

Basic Commissioning and Start-Up................................................................................................................................................35

Configuring the ST100A Series.......................................................................................................................................................35

Verify Engineering Units..................................................................................................................................................................39

System Faults, Alarms and Logging Indication...............................................................................................................................39

ST100A Series ConfigurationSoftware Application (User Password: 2772)..................................................................................40

Real Time Clock..............................................................................................................................................................................41

Totalizer Setup................................................................................................................................................................................42

Process Data Logging.....................................................................................................................................................................43

Configuring for AST™ or Constant Power Measurement Methods ................................................................................................46

Flow Filtering...................................................................................................................................................................................47

NAMUR Setup.................................................................................................................................................................................48

Internal Delta-R Resistor (idR) Check.............................................................................................................................................50

Using Digital Outputs......................................................................................................................................................................53

HART Operation..............................................................................................................................................................................54

Service Data Operation...........................................................................................................................................................55

HART Command List Reference.....................................................................................................................................................59

Modbus Operation...........................................................................................................................................................................77

Extended Operation Modes............................................................................................................................................................84

06EN003480 Rev. A ST100A Series Flow Meter

iv Fluid Components International LLC

4MAINTENANCE..............................................................................................................................................................................89

Introduction.....................................................................................................................................................................................89

General Maintenance......................................................................................................................................................................89

Power Fuse Replacement...............................................................................................................................................................90

Lithium Battery Replacement..........................................................................................................................................................91

5TROUBLESHOOTING....................................................................................................................................................................93

Non-Maintenance Observations......................................................................................................................................................93

General Function Check.................................................................................................................................................................94

Troubleshooting the Flow Element..................................................................................................................................................95

Verification of the Electronics..........................................................................................................................................................97

Constant Power Configuration Troubleshooting .............................................................................................................................99

Defective Parts..............................................................................................................................................................................101

Customer Service..........................................................................................................................................................................101

Reference: Error/Status Register Information...............................................................................................................................102

APPENDIX A DRAWINGS................................................................................................................................................................105

APPENDIX B ADDITIONAL INFORMATION....................................................................................................................................135

Parameters Report from the ST100A Series Configuration Software (Sample)...........................................................................136

HMI Menu Outline.........................................................................................................................................................................145

ST100A Series Configuration Software Menu Outline (v3.2.0.x)..................................................................................................146

Instructions: Installing Sun Shield on ST100A Series Integral Enclosure.....................................................................................147

Instructions: Installing Sun Shield on ST100A Series Remote Enclosure ....................................................................................148

APPENDIX C GLOSSARY................................................................................................................................................................149

Abbreviations................................................................................................................................................................................149

Definitions

.....................................................................................................................................................................................149

APPENDIX D APPROVAL INFORMATION......................................................................................................................................151

Safety Instructions.........................................................................................................................................................................152

APPENDIX E CUSTOMER SERVICE..............................................................................................................................................157

Customer Service/Technical Support....................................................................................................................................157

ST100A Series Flow Meter 06EN003480 Rev. A

Fluid Components International LLC v

List of Figures

Figure 1 – Example Compression Fitting Process Connection.................................................................................................................7

Figure 2 – Compression Fitting Installation, Dimensions..........................................................................................................................8

Figure 3 – Example Flange Mount Installation..........................................................................................................................................9

Figure 4 – Example NPT Pipe Thread Mount Installation.........................................................................................................................9

Figure 5 – Retractable Packing Gland Installation..................................................................................................................................10

Figure 6 – Flow Element Installation Using FCI Retractor Tool 026854-01............................................................................................12

Figure 7 – Packing Gland Locking Collar................................................................................................................................................12

Figure 8 – 2-Point Flow Element Installation (Compression Fitting Shown)...........................................................................................15

Figure 9 – ST100AL Process Connection...............................................................................................................................................16

Figure 10 – Integral Electronics Installation (Compression Fitting Shown).............................................................................................17

Figure 11 – Remote Installation, Mounting Bracket on Wall...................................................................................................................18

Figure 12 – Remote Installation, Mounting Bracket on 1" – 1½" Pipe....................................................................................................19

Figure 13 – Remote Installation, Mounting Bracket on 2" Pipe...............................................................................................................19

Figure 14 – Remote Installation, Optional Stainless Steel Bracket on 2" Pipe.......................................................................................20

Figure 15 – Recommended Wiring Routing, Base Electronics Enclosure..............................................................................................21

Figure 16 – ST100A Series I/O Connector Locations.............................................................................................................................22

Figure 17 – ST100A Series Electronics Enclosure Label.......................................................................................................................23

Figure 18 – Bus Configuration 2 mm Jumper Headers and DIP Switch.................................................................................................24

Figure 19 – Input Power Wiring ..............................................................................................................................................................24

Figure 20 – ST100A Series Ferrite Core Installation (Auxiliary Board Not Shown for Clarity)................................................................25

Figure 21 – Flow Element Connections, TB1 and TB2 (Dual Element Models).....................................................................................26

Figure 22 – HART and Ch. 1 & Ch. 2 4-20 mA Connections, J25..........................................................................................................27

Figure 23 – Single Connection and Multidrop HART Setups..................................................................................................................28

Figure 24 – Ch. 3 4-20 mA Output, J8 (Aux. Board)...............................................................................................................................28

Figure 25 – Modbus/PROFIBUS/Fieldbus Connections, J8...................................................................................................................29

Figure 26 – Modbus Wiring.....................................................................................................................................................................29

Figure 27 – Fieldbus/PROFIBUS Wiring.................................................................................................................................................30

Figure 28 – Source/Sink Outputs, Pressure Input, and Ext. 4-20 mA Input Connections, J9.................................................................31

Figure 29 – Source Output......................................................................................................................................................................32

Figure 30 – Sink Output..........................................................................................................................................................................32

Figure 31 – ST100A Series Service Ports..............................................................................................................................................33

Figure 32 – Hot Key on the Optional HMI Display..................................................................................................................................35

Figure 33 – HMI Display IR Sensor Functions........................................................................................................................................36

Figure 34 – Basic Setup Options, HMI....................................................................................................................................................37

Figure 35 – Instrument Setup Options....................................................................................................................................................37

Figure 36 – Display Setup Options.........................................................................................................................................................38

Figure 37 – Configuration Software Tabs for Basic Setup Functions.....................................................................................................39

Figure38 –ExampleLog, Alarm,andLogging IconsontheOptional Display...............................................................................................40

Figure 39 – The Configurator Welcome Screen .....................................................................................................................................40

06EN003480 Rev. A ST100A Series Flow Meter

vi Fluid Components International LLC

Figure 40 – Example Process Data Screen............................................................................................................................................41

Figure 41 – Example Date and Time Set Screen ...................................................................................................................................41

Figure 42 – Example Totalizer Display Showing Total Flow Value.........................................................................................................42

Figure 43 – Totalizer Setup Screen........................................................................................................................................................42

Figure 44 – SD Card Data Logging Example Screen (Basic Setup).......................................................................................................43

Figure 45 – Example AST Power Mode Tab (Configuration)..................................................................................................................46

Figure 46 – Flow Filtering Setup Screen.................................................................................................................................................47

Figure 47 – Chart: Flow Output Over Time with Various Flow Damping Values....................................................................................48

Figure 48 – NAMUR Fault.......................................................................................................................................................................48

Figure 49 – NAMUR Output Level Selection (4-20 mA User Tab)..........................................................................................................49

Figure 50 – Example idR Check Results Display ...................................................................................................................................50

Figure 51 – Example Internal Delta R Scheduled Screen (After Clicking "Run test now...")..................................................................51

Figure 52 – idR Log and Process Data Log Files on microSD Card Example........................................................................................51

Figure 53 – Example Internal Delta-R Log File Results (Data Formatted and Titles Added using Microsoft Excel)...............................51

Figure 54 – Internal Delta-R Resistor Check (idR) HMI Display Sequence............................................................................................52

Figure 55 – Digital Bus Deactivation Warning When Enabling HART....................................................................................................53

Figure 56 – Field Communicator Easy Upgrade Utility, Import DD.........................................................................................................55

Figure 57 – ST100A Series Configuration Software Output Tab with Modbus Selected........................................................................77

Figure 58 – ST100A Series Configuration Software Modbus Tab, Serial Interface Configuration..........................................................78

Figure 59 – Extended Operating Mode Status on Front Panel Display (EGS Shown) ...........................................................................84

Figure 60 – Auxiliary Input Configuration................................................................................................................................................84

Figure 61 – Example Extended Op. Mode Tab (Configuration)..............................................................................................................85

Figure 62 – Connections for External Flow Input (EFI)...........................................................................................................................85

Figure 63 – External ST100A Series Flow Input (EFI) Setup Screen.....................................................................................................86

Figure 64 – Example Configurator Process Data Screen with EFI Mode Shown...................................................................................86

Figure 65 – External Control Group Switching (EGS) Setup Screen......................................................................................................87

Figure 66 – Example Process Data Screen with EGS Mode Shown......................................................................................................88

Figure 67 – Fuse Location, Power Supply Board ...................................................................................................................................90

Figure 68 – Instrument Disassembly for Lithium Coin Cell Battery (CR2450N) Replacement...............................................................92

Figure 69 – Example Heater Values Tab (Diagnostics)..........................................................................................................................96

Figure 70 – System Status LED, Main Board (Aux. Board Not Shown for Clarity).................................................................................97

Figure 71 – DMM Hookup to Measure 4-20 mA Output .........................................................................................................................99

Figure 72 – Connecting FES-200 to ST100A Series Transmitter.........................................................................................................100

Figure 73 – ST100A Series Decade Box Wiring...................................................................................................................................100

ST100A Series Flow Meter 06EN003480 Rev. A

Fluid Components International LLC vii

List of Tables

Table 1 – Compression Fitting Material....................................................................................................................................................8

Table 2 – Interconnecting Cable Minimum Conductor Size....................................................................................................................21

Table 3 – Modbus Select Jumpers .........................................................................................................................................................30

Table 4 – Modbus Line Configuration Jumpers......................................................................................................................................30

Table 5 – FOUNDATION Fieldbus/PROFIBUS Select Jumpers.................................................................................................................31

Table 6 – Flow Parameters, HMI............................................................................................................................................................38

Table 7 – Log File Filename Format LGabcdxx.csv ...............................................................................................................................44

Table 8 – Log File Entry Example...........................................................................................................................................................44

Table 9 – Fatal Faults that Trigger NAMUR............................................................................................................................................49

Table 10 – ST100A Series HART Process Variables.............................................................................................................................54

Table 11 – ST80/ST80L HART Field Device Registration Information...................................................................................................55

Table 12 – HART Universal Commands.................................................................................................................................................59

Table 13 – HART Common Practice Commands...................................................................................................................................66

Table 14 – ST100A Series HART Device Specific Command Groupings..............................................................................................68

Table 15 – HART Device Specific Commands.......................................................................................................................................68

Table 16 – Command Status Bytes, Bit Assignments ............................................................................................................................74

Table 17 – Command-Specific Response Codes...................................................................................................................................74

Table 18 – Command 48, Additional Device Status Bytes Bit Assignments...........................................................................................75

Table 19 – HART Engineering Units Codes ...........................................................................................................................................76

Table 20 – ST100A Series Modbus Function Codes..............................................................................................................................78

Table 21 – ST100A Series Modbus Process Data .................................................................................................................................79

Table 22 – Modbus Service Data – Service and Setup Functions..........................................................................................................80

Table 23 – ST100A Series Modbus Engineering Unit Codes.................................................................................................................82

Table 24 – ST100A Series Modbus Exception Codes............................................................................................................................83

Table 25 – ST100A Series Modbus Variables and Registers Map.........................................................................................................83

Table 26 – Power Fuse Summary ..........................................................................................................................................................90

Table 27 – Lithium Coin Cell Battery Summary......................................................................................................................................91

Table 28 – Flow Element Resistance Measurements (In Ohms) Taken From Remote/Integral Electronics..........................................95

Table 29 – Flow Element Resistance (In Ohms) at the Local Enclosure................................................................................................95

Table 30 – Nominal Heater Parameter Ranges......................................................................................................................................96

Table 31 – System Status LED D3 States..............................................................................................................................................97

Table 32 – Instrument Power Supply Voltages.......................................................................................................................................98

Table 33 – Basic CORE Fault Register (CORE CY Command)...........................................................................................................102

Table 34 – Detailed CORE Fault Register (CORE 2V Command).......................................................................................................103

Table 35 – FE Fault Register (FE DF Command).................................................................................................................................104

Table 36 – ST100A Series Drawings in Appendix A.............................................................................................................................105

06EN003480 Rev. A ST100A Series Flow Meter

viii Fluid Components International LLC

Typographical Conventions

Important notes or warnings are shown like the following:

Note:

A note is additional information that adds to or supplements the topic.

Caution:

A caution indicates an action that can cause equipment damage, loss of data or software, or minor injury.

Warning:

A warning indicates an action that can cause equipment damage, or serious injury/death, or both.

Caution symbols that may be marked on the product or its packaging are explained below:

Risk of Danger symbol (observe all warnings and cautions in manual).

Hot Surface Caution symbol (risk of burn from probe heater).

ESD (Electrostatic Discharge) Susceptibility symbol (do not touch without

appropriate precautions).

Static-sensitive Devices symbol (use ESD handling procedures).

ST100A Series Flow Meter GENERAL

Fluid Components International LLC 1

1 GENERAL

Product Description

The ST100A Series is a thermal dispersion, industrial process grade air/gas flow meter. It is suitable for all air and gas flow measurement

applications in line sizes from 1" to 100" [25 to 2500 mm] and larger. The instrument provides direct mass flow measuring and measures flow rate,

totalized flow and temperature, and the STP versions add pressure measurement.

The measurements are made available to the user by way of 4-20 mA analog output channels with HART or pre-selected digital bus protocols. The

optional graphics display provides real-time process variable values along with flow range and process description information.

There are no moving parts to clean or maintain. A wide selection of process connections are offered to fit with any process piping. Versions are

available for temperature service from -40 °F [-40 °C] to 850 °F [454 °C].

The ST100A Series electronics/transmitter can be integrally mounted with the flow sensor or remote mounted up to 1000' [300m] from the sensor

element. Additional patented or FCI exclusive features include VeriCal® in-situ calibration verification, AST™ (patent pending) adaptive sensing

technology measuring technique, dual sensor/single transmitter models, and a built-in data logger capable of storing more than 20M readings. All

ST100A Series instruments are precision calibrated in FCI’s world-class, NIST traceable calibration facility on one of our flow stands matched to your

gas application and actual installation conditions.

Theory of Operation

The instrument is functionally based on the thermal dispersion operating principal. With AST™, power to the active RTD sensor’s heater is varied to

maintain a constant Delta T with the reference (unheated) RTD sensor. The flow rate and the heater power needed to maintain Delta T is

proportional. Once the heater current reaches a set maximum, the heater current is maintained as the instrument reads the varying sensor

resistance (Delta R). This resistance is proportional to flow rate. The transition between reading the heater power (constant Delta T) and reading the

sensor resistance (constant power) is seamless and automatic and is the key to the AST™ feature. The differential signal, whether it’s from the

sensor heater power (constant Delta T) or the sensor resistance (constant power) is scaled to drive a 4-20 mA flow output. A second temperature

output, from the unheated reference sensor, drives a second 4-20 mA output. A third 4-20 mA output is optional.

Safety Instructions

Warning:

Explosion Hazard. Do not disconnect equipment when flammable or combustible atmosphere is present.

●Field wiring shall be in accordance with NEC (ANSI-NFPA 70) or CEC (CSA C22.1) locations as applicable.

●Theinstrumentmust beinstalled,commissionedandmaintainedby qualifiedpersonneltrained inprocessautomationand control

instrumentation.Theinstallationpersonnel mustensure the instrument has been wired correctlyaccording tothe applicable wiringdiagram.

●All location specific installation and wiring requirements must be met and maintained. FCI recommends an input power circuit breaker

be installed between the power source and the flow meter. This facilitates easy power disconnection during commissioning and

maintenance procedures. Use a switch or circuit breaker if the instrument is in a hazardous area.

●The flow meter contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling the circuit

board assemblies.

●Hazardous Areas: The instrument is designed for use in hazardous areas. The approved area classification is identified on the

nameplate along with the temperature and pressure limitations. The USB port and the optional Ethernet port do not support the

hazardous area requirements and should only be used when the area is declassified. Remove any non-certified parts such as plastic

protection caps from cable entry ports and replace by suitable wiring and cabling system certified by notified bodies for use in

hazardous areas.

●When mounting the flow element into the process pipe, it is important that a lubricant/sealant is applied to the mating threads. Use a

lubricant/sealant that is compatible with the process media. Tighten all connections firmly. To avoid leaks do not overtighten or cross-

thread connections.

Order Verification

●Verify the received hardware matches the purchased hardware and application requirements. Verify the model/part number on the

instrument I.D. tag (e.g., ST100AL – 43E8000…) matches the purchased model/part number.

●Review the Calibration requirements as specified on the Engineering Data Sheet in the documentation package. Verify the flow,

temperature and pressure limits meet the application requirements.

GENERAL ST100A Series Flow Meter

2 Fluid Components International LLC

Hardware - Model Descriptions

ST100A – Single point insertion element with flow and temperature process output

ST100AL – In Line element with flow and temperature process output

ST102AA – Dual point insertion elements with flow and temperature process output

ST110A – Single point insertion element with flow and temperature process output, VeriCal option

ST112AA – Dual point insertion elements with flow and temperature process output, VeriCal option

STP100A – Single point insertion element with flow, temperature and pressure process output

STP110A – Single point insertion element with flow and temperature process output, VeriCal option

Documentation and Accessories

06EN003480 ST100A Series Installation, Operation, & Maintenance Manual

06EN003481 ST100A Series Configuration Software Manual

Calibration Certification Documentation

PC Configuration Software and USB Cable

Supplemental Manuals, optional

06EN003482 ST100A Series FOUNDATION™ Fieldbus Manual

06EN003483 ST100A Series PROFIBUS PA Manual

Supplemental Software, optional

HART DD Files

FOUNDATION Fieldbus

PROFIBUS DD File

PDM/DTMs

ST100A Series Flow Meter GENERAL

Fluid Components International LLC 3

Technical Specifications

Instrument

■Measuring Capability

ST1XX Models: Flow rate, total flow and temperature

STP1XX Models: Flow rate, total flow, temperature and pressure

■Basic Style

ST100A: Insertion, single-point

ST100AL: In-line (spool piece), single-point

ST102AA: Insertion, dual-element system

ST110A: Insertion, single-point with VeriCal™ capability

ST112AA: Insertion, dual-element system with VeriCal capability

STP100A: Insertion, single-point with pressure measurement

STP110A: Insertion, single-point with pressure measurement and

VeriCal capability

■Flow Measurement Range

InsertionStyle: 0.25SFPS to1000 SFPS[0,07 NMPSto 305NMPS]

ST100AL In-line: 0.0062 SCFM to 1850 SCFM

[0.01 NMCH to 3,140 NMCH]

– Air at standard conditions; 70 °F and 14.7 psia [21 °C and

1,01325 bar(a)]

■Temperature Measurement Range

Up to 850 °F [454 °C] commensurate with element; see

Operating Temperature in Flow Element specification

■Pressure Measurement Range (STP Models)

Available Ranges:

0 psig to 50 psig [0 bar(g) to 3,4 bar(g)]

0 psig to 160 psig [0 bar(g) to 11 bar(g)]

0 psig to 500 psig [0 bar(g) to 34 bar(g)]

0 psig to 1000 psig [0 barg to 70 bar(g)]

Refer also to STP Models: Additional Specifications on Pressure

Sensor on page 4.

■Environmental Conditions

Maximum Relative Humidity: 93%

Maximum Elevation: 6561’ [2000 m]

OVERVOLTAGE CATEGORY II

POLLUTION DEGREE 2

■Media

All gases that are compatible with the flow element material

■Accuracy

Flow:

Gas Specific Calibration: ±0.75% reading, ±0.5% full scale

Temperature:

±2 °F [±1.1 °C] (display only, flow rate must be greater than 5

SFPS [1,5 m/sec])

Pressure (STP Models):

±0.25% full scale pressure range

■Response Time (Flow)

1 second to 63% of final value (one step change) typical with –FP

or –FPC type flow element operating in AST mode

■Temperature Coefficient

With optional temperature compensation; valid from 10% to

100% of full scale calibration

Flow: Maximum ±0.015% of reading / °F up to 850 °F

[±0.03% of reading / °C up to 454 °C]

■Repeatability

Flow: ±0.5% reading

Temperature: ±1 °F [± 0.6 °C] (flowrate must be greater than 5

SFPS [1,5 NMPS])

■Turndown Ratio

Normally factory set and field adjustable from 2:1 to 100:1 within

calibrated flow range; up to 1000:1 possible with factory

evaluation of application.

■Temperature Compensation

Standard: ±30 °F [±16 °C]

Optional: ±100 °F [±55 °C]

■Agency Approvals

FM, FMc:

FM20US0094X / FM20CA0042X

Class I, Division 1, Groups B, C, D

Class II, III, Division 1, Groups E, F, G

Class I, Division 2, Groups A, B, C, D

Class II, Division 2, Groups E, F, G

Class III, Division 1, 2

Type 4X, IP66/IP67

T6 Ta = –40°C to 42°C

T5 Ta = -40°C to 57°C

T4A Ta = -40°C to 65°C

ATEX/IECEx:

FM20ATEX0022X / IECEx FMG20.0025X

II 2 G Ex db IIC T6...T4 Gb

II 2 D Ex tb IIIC T85°C...T135°C

IP66/67

T6/T85°C: -40°C<Ta<+42°C

T5/T100°C: -40°C<Ta<+57°C

T4/T135°C: -40°C<Ta<+65°C

Other:

CE Marking

Probe complies with Canadian electrical code

requirements of ANSI/ISA 12.27.01-2011 as a single

seal device.

■SIL/IEC 61508: SIL 1 Compliant, SFF 71.1% to 79.1%

■Calibration: Performed on NIST and and ISO/IEC 17025

traceable flowstands and equipment

■Other: Follows best practices and guidelines as set forth in

ISO 14511; complies with ISO 14164

■Storage Temperature

-76 to 150 °F [-60 to 65 °C]

GENERAL ST100A Series Flow Meter

4 Fluid Components International LLC

Flow Element

■Material of Construction

All-welded 316L stainless steel; Hastelloy-C optional

■Operating Pressure

ST100A Insertion Style

Metal ferrule: 1000 psig [69 bar (g)]

Teflon ferrule: 150 psig [10 bar (g)])

Packing gland (low pressure): 50 psig [3.5 bar (g)])

Packing gland (medium pressure): 500 psig [34 bar (g)])

Fixed 1" NPT: 1000 psig [69 bar (g)]

Fixed flange: per flange rating

STP Models: See pressure sensor specifications. Same as ST type above or per

pressure sensor specification, whichever is lower.

ST100AL In-line Style

Pipe Size Pipe Sched. Max. Pressure

Calc. Hydrostatic

Test Pressure

psig

bar(g)

psig

bar(g)

0.7- inch

40

2750

190

4125

284

80

3000

207

4500

310

1-inch

40

2500

172

3750

259

80

3000

207

4500

310

1.5-inch

40

1750

121

2625

181

80

2500

172

3750

259

2-inch

40

1500

103

2250

155

80

2250

155

3375

233

1-inch tube

.065 wall

2400

165

3600

248

Note: Maximum temperature for all: 250 °F (121 °C).

■Operating Temperature (Process)

ST80 Insertion Style (FPC, FP, and Ssensor head types)

Process Connection

Transmitter

Temp. Service

1

Compression Fitting Integral/Remote

Lo: 350 °F [177 °C]

2

Med: 500 °F [260 °C]

Low Pressure Packing

Gland Integral/Remote

Lo: 350 °F [177 °C]

Med: 500 °F [260 °C]

Remote

Hi: 850 °F [454 °C]

Med. Pressure Packing

Gland Integral/Remote

Lo: 350 °F [177 °C]

Med: 500 °F [260 °C]

Hi: 850 °F [454 °C]

Fixed NPT Integral/Remote

Lo: 350 °F [177 °C]

Med: 500 °F [260 °C]

Remote

Hi: 850 °F [454 °C]

Fixed Flange (1" or DN25) Integral/Remote

Lo: 350 °F [177 °C]

Med: 500 °F [260 °C]

Fixed Flange (≥1½" or

≥DN40) Integral/Remote

Lo: 350 °F [177 °C]

Med: 500 °F [260 °C]

Remote

Hi: 850 °F [454 °C]

Notes: 1. Minimum temperature is -40 °F [-40 °C].

2. For Teflon ferrule maximum temperature is 200 °F (93 °C).

ST100AL In-line Style (Fand Ssensor head types)

-40 °F to 257 °F [-40 °C to 125 °C]

■Models ST100A, ST102A, ST110A, ST112A, STP100A,

STP102AA, STP112A, Process Connections and Insertion

Lengths

Compression Fittings: Models ST100A and ST102AA only

¾" or 1" male NPT, stainless steel with adjustable Teflon

ferrule or metal ferrule; or flanged tapped and threaded for ¾"

fitting, ANSI or DIN flanges.

Compression fittings not available with 850 °F [454 °C]

temperature versions of ST100A or ST102AA.

Retractable Packing Glands

Low pressure 50 psig [3,5 bar(g)] or medium pressure 500 psig

[34 bar(g)] with graphite or Teflon packing material; 1¼" male

NPT or ANSI or DIN flange.

Teflon packing required when process media is ozone, chlorine

or bromine. Remote mount required when medium pressure

packing gland is required.

Fixed Fittings / All Welded

1" male NPT, ANSI or DIN flange

Insertion Length

Field adjustable lengths:

1" to 6" [25 mm to 152 mm]

1" to 12" [25 mm to 305 mm]

1" to 21" [25 mm to 533 mm]

1" to 36" [25 mm to 914 mm]

1" to 60" [25 mm to 1524 mm]

Fixed lengths from 2.6" to 60" [66 mm to 1524 mm]

■ST100AL In-line Flow Body and Process Connections

Flow element is calibrated and supplied as a spool-piece; options

include low flow injection tubes and built-in Vortab flow

conditioners for optimum low flow rangeability and performance

Size: 1" diameter tubing; 1”, 1½" or 2" Schedule 40 pipe;

1" Schedule 80 pipe

Length: 9 nominal diameters

Process Connections: female NPT, male NPT, ANSI or DIN

flanges, or butt weld prepared

Option: Flanges sized for flow tube

■Remote Transmitter Configurations

Transmitter maybe mountedremotely fromflow element using

interconnectingcable(up to1000ft[300m]).Remote configuration

requiredwith selectionof mediumpressurepacking gland.

■STP Models: Additional Specifications on Pressure Sensor

Standard Sensor

psig

bar(g)

psig

bar(g)

psig

bar(g)

psig

bar(g)

Pressure Range:

50

3,4

160

11

500

34

1000

70

OverpressureSafety:

100

7

290

20

1000

70

1740

120

Burst Pressure:

250

17,24

500

34

2500

172

7975

550

Wetted Materials

Connection:

316L SS

316L SS

316L SS

316L SS

Pressure Sensor:

PH

13-8 SS

316L SS

316L SS

316L SS

Ex Rated Sensor

psig

bar(g)

psig

bar(g)

psig

bar(g)

psig

bar(g)

Pressure Range:

50

3,4

160

11

500

34

1000

70

OverpressureSafety:

240

16,55

1160

80

1160

80

1740

120

Burst Pressure:

290

20

1390

95,84

5800

400

7970

549,5

Wetted Materials

Connection:

Stainless

Steel

Stainless

Steel

Stainless

Steel

Stainless

Steel

Pressure Sensor:

Stainless

Steel

Stainless

Steel

SS and

Elgiloy

SS and

Elgiloy

ST100A Series Flow Meter GENERAL

Fluid Components International LLC 5

Flow Transmitter/Electronics

■Operating Temperature:

Single Point System: -40 °F to 140 °F [-40 °C to 65 °C]

Two Point System: -40 °F to 100 °F [-40 °C to 60 °C]

■Input Power

AC: 100 VAC to 265 VAC, 50 Hz to 60 Hz

DC: 24 VDC (19.2 – 28.8 volts)

■Power Consumption

AC:

10 W, 1 Flow Element

13.1 W, 2 Flow Elements

DC:

9.6 W, 1 Flow Element

13.2 W, 2 Flow Elements

■Battery Backup (for RTC)

Industrial-spec 3V Lithium coin cell type CR2450N

■Outputs

Analog

Standard: Three (3) 4-20 mA outputs*, 0-1kHz, or 0-10 kHz

pulse/frequency (pulse width = 500 µsec; available multipliers:

0.001, 0.01, 0.1, 1.0, 10.0, and 100.0).

4-20mA outputs are user assignable to flow rate, temperature or

if so equipped, pressure; outputs are user programmable to full

flow range or subsets of full flow range; pulse/frequency output is

user selectable as pulse for external counter/flow totalizer, or as

0-1 kHz or 0-10 kHz frequency representing flow rate.

* Outputs are isolated and have fault indication per NAMUR

NE43 guidelines, user selectable for high (>21.0 mA) or low

(<3.6 mA)

HART (comes standard with analog outputs), V7 compliant.

Digital

Standard: USB, Ethernet (service and configuration ports only),

and Modbus RS-485

Optional: FOUNDATION Fieldbus H1 or PROFIBUS PA

FF Physical Parameters

Maximum Network Input Voltage - Ui (in V) = 32

Maximum Network Input Current - li (in mA) = 13

■Auxiliary Inputs

One 4-20mA inputchannelfor FCI-administeredspecialconfigura-

tions to allow ST100A Seriesto accept inputs from external devices

suchasgasanalyzers, gascomposition,or pressure sensors.

■Enclosures

Main Transmitter/Electronics:

NEMA 4X, IP66/67 polyester powder coated aluminum or

optional 316L stainless steel.

Four (4) cable ports ½"-14 NPT or M20 x 1.5.

Size:5" Wx5.4" Hx7.75"L(127 mmx137mm x197mm)

Local Enclosure (Remote Configuration):

• Singlecableport enclosure(available withpacking gland/low and

med press; ≥1.5" fixed flange; fixed NPT process connections):

NEMA 4X, IP66/67 polyester powder coated aluminum or

optional 316L stainless steel.

One (1) cable port 1"-11.5 NPT

Size: 4.68"W x4.87" H x 5.4" L (119 mm x 124mm x 137 mm)

• Dualcable portenclosure(availablewithcompressionfitting; 1"

fixed flange process connections):

NEMA 4X, IP66/67 polyester powder coated aluminum or

optional 316L stainless steel.

Two (2) cable ports 1/2"-14 NPT or M20 x 1.5

Size:3.27" Wx3.54"H x3.9"L(84mm x90mm x99 mm)

■Data Logger

User programmable for readings per time increment to a maxi-

mum of 1 reading/second; removable, circuit board-mounted

8 GB microSD (secure digital) memory card supplied,

■Readout/Display (Option 1):

•Large backlit 2" x 2" [50 mm x 50 mm] LCD for display of digital

flow rate, analog bar graph of flow rate, total flow, and

temperature; user selectable engineering units, and alarm/fault

status indication.

•User programmable 17 alphanumeric character field

associated with each calibration group.

•Set-Up & Service mode displays text and service codes.

•Display is electronically rotatable in 90° increments to optimize

viewing angle.

Note: For units without the display option, the service port (USB

or Ethernet) lets a PC configure/manage the instrument via the

ST100A Series configurator utility.

■Readout/Display and Optical Touch Buttons (Option 2)

Includes the Readout/Display Option 1 items, plus adds four

keypad/buttons for the user interface.

•Four (4) optical touch buttons for user programming of

instrument set-up and service interrogation.

•User programming and setup via the front panel.

•Optical touch button activation through front window – no need

to open enclosure to access or activate.

•Set and adjust the meter or interrogate diagnostics in-situ,

even in HazEx installation.

GENERAL ST100A Series Flow Meter

6 Fluid Components International LLC

Other Options

■Vortab Flow Conditioners

Available for all line size applications; standard choice with Model

ST100AL (in-line).

■Sun Shield

Shades main transmitter, electronics, and display from direct

sunlight; 316L stainless steel.

FCI P/N 023241-01 Integral transmitter

FCI P/N 023237-01 Remote transmitter

■Ball Valves/Cable Glands

■Certification and Testing Documentation

CMTR, NACE, PMI, 02cleaning, radiography, dye penetrant,

hydrostatic or air pressure test, certificate of origin, certificate of

conformance, wake frequency strength, and more.

■Field Service and Support

Start-up assistance, site commissioning and installation

validation, maintenance agreements, bus communications

integration and validation, and more.

ST100A Series Flow Meter INSTALLATION

Fluid Components International LLC 7

2 INSTALLATION

Specific Conditions of Use

1. Consult the manufacturer if dimensional information on the flameproof joints is necessary.

2. The painted surface of the ST100A Series Flow Meter may store electrostatic charge and become a source of ignition in applications

with a low relative humidity < 30% relative humidity where the painted surface is relatively free of surface contamination such as dirt,

dust, or oil. Cleaning of the painted surface should only be done with a damp cloth.

3. Do not replace internal battery when an explosive gas atmosphere is present.

4. Refer to Appendix D, page 152, for details on the relationship between the temperature class, the maximum surface temperature, the

ambient temperature and the process temperature.

Instrument Identificationand Outline Dimensions

APPENDIX A starting on page 105 provides outline dimensions and mounting bracket dimensions for all integral and remote mounted electronic

configurations. Verify all dimensions meet the application requirements before beginning the installation process.

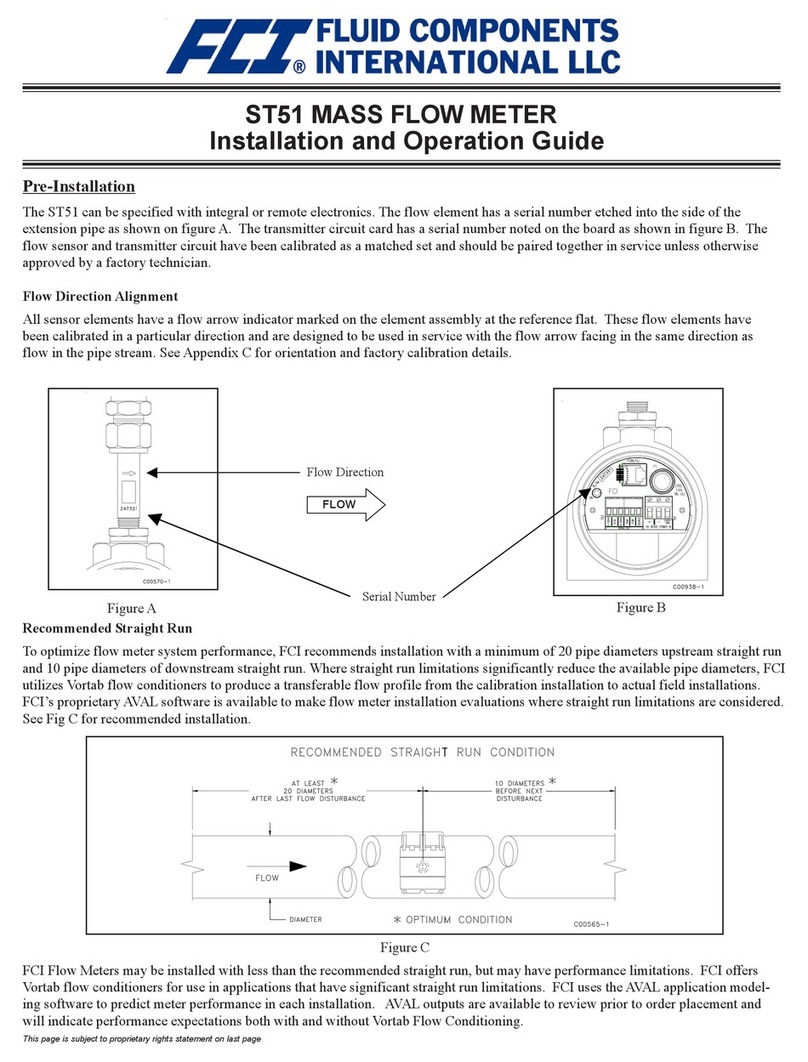

ST100A Insertion Sensor Installation

The proper flow meter location in the process piping configuration is critical to the instrument’s ability to measure the process variables accurately.

FCI recommends 20 nominal pipe diameters upstream and 10 pipe diameters downstream of the instrument installation point for most applications.

These distances can be significantly reduced when the flow meter is combined with FCI’s flow conditioning technology (Vortab).

Insertion flow elements can be mounted into the process using several available customer selectable configurations; compression fitting mounted,

threaded or flanged packing gland mounted, and threaded or flanged fixed “U” length mounted process connections. The specific sensor process

connection is specified by the customer on the order information sheet (OIS).

Mount the flow element to the process piping per the application piping requirements. Orient the instrument so that the flow arrow etched on the

element matches the direction of the process flow with the reference flat parallel to flow within ±3° of rotation. Insert a flow element with variable

insertion length ½” inch past the centerline of the process pipe or tube with the flow direction arrow correctly aligned and leveled. After the flow ele-

ment has been located correctly and tightened into place, verify that the process seal does not leak by slowly applying pressure until the maximum

operation pressure is applied. Check for leaks at the process connection boundary using standard leak detection methods.

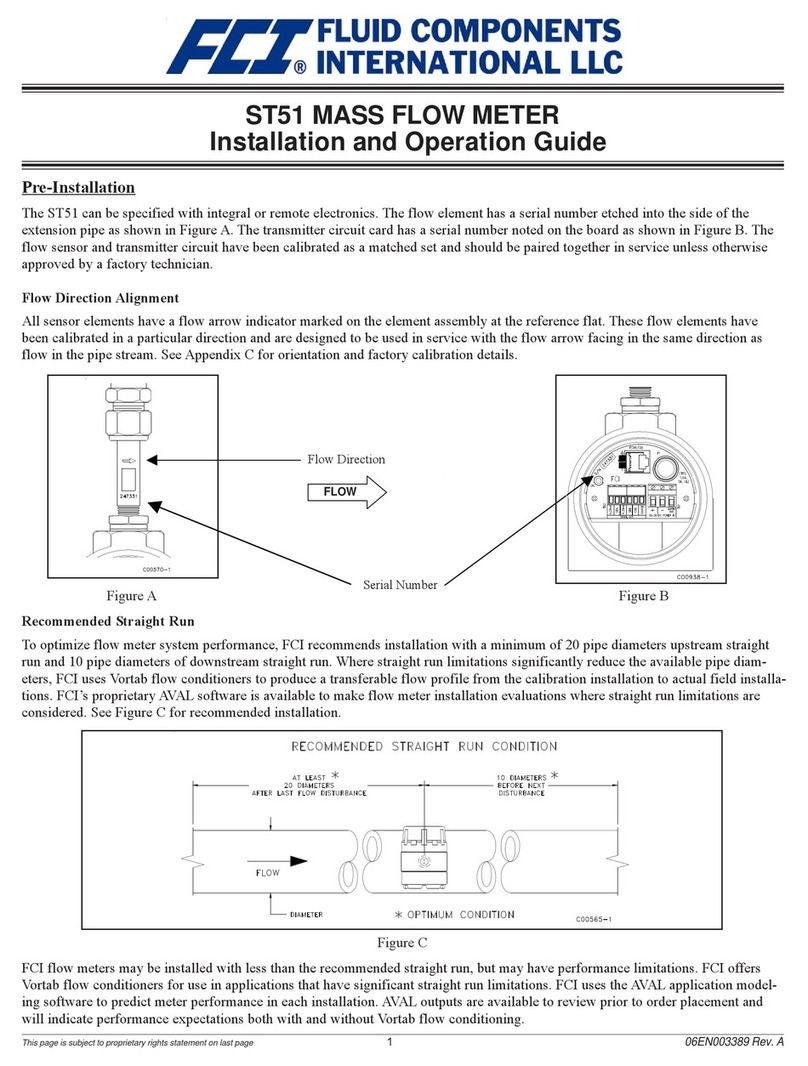

Figure 1below shows a properly mounted compression fitting process connection instrument.

Figure 1 – Example Compression Fitting Process Connection

INSTALLATION ST100A Series Flow Meter

8 Fluid Components International LLC

Compression Fitting

FCI single point insertion flowmeters are calibrated at the centerline of the process pipe. The flowelement is properly mounted when the

tip of the flowelement is located 0.50 inches (13 mm) past the pipe centerline. See Figure 2below. The scale etched on the side of the

insertion pipe indicates the length to the tip of the flow element. Follow the steps below to install the compression fitting flow element.

1. Calculate the insertion depth using the equation below.

I = Insertion depth

I.D. = Pipe inside diameter

T = Pipe wall thickness

C = Pipe mounting coupling and compression fitting (installed length)

= 0.50" + ..

2++

I = __________

2. Mark the insertion pipe at the calculated insertion depth.

Figure 2 – Compression Fitting Installation, Dimensions

3. Apply proper thread sealant to the tapered pipe thread on the compression fitting and secure into pipe mounting coupling.

4. Insert the flow element to the insertion depth mark making sure the orientation flat is aligned parallel to the flow direction. Hand tighten

the compression nut. Compression fitting manufacturer recommends 1¼ turns past hand tight.

5. Tighten the compression nut to the torque specified for the corresponding ferrule material. See Table 1below.

Table 1 – Compression Fitting Material

Ferrule Material

Torque

Teflon

6 ft-lbs

316 SST1

65 ft-lbs1

Note:

The metalferruleconfiguration can onlybe tightened onetime. Once tightened, the insertion length isno longer adjustable.

ST100A Series Flow Meter INSTALLATION

Fluid Components International LLC 9

Flange Mount

The flange mount flow element is shown in Figure 3below. Attach the process mating flange with care. Correctly orient the flow element's

reference flat to ensure the instrument's calibrated accuracy.

●Verify the process media flow matches the flow direction arrow on the flow element.

●Apply appropriate gasket and or sealant to flange mount as required.

●Mate flow element flange to process flange keeping flat oriented properly.

●Secure flanges with appropriate mounting hardware.

Figure 3 – Example Flange Mount Installation

C00991-2-1

REMOTE ENCLOSURE

EXPLOSION PROOF

AGENCY APPROVED

FLANGE,

SIZE AND RATING

CUSTOMER SPECIFIED

FLAT TO SHOW

FLOW ORIENTATION

NPT Pipe Thread Mount

Thepipethreadconfigurationisshownin Figure 4below.Apply sealantcompatiblewith theprocessmedia tomale threads.Carefullyinsertinto

processmounting coupling.Tightenthe flowelement untilsnugand continueuntil flatand flowdirectionarrow arealigned withprocess flow.

Figure 4 – Example NPT Pipe Thread Mount Installation

PIPE

PIPE

C00992-2-1

1" or 1¼" NPT

FLAT TO SHOW

FLOW ORIENTATION

0.50"

[12.6 mm]

INSTALLATION ST100A Series Flow Meter

10 Fluid Components International LLC

Retractable Packing Gland Mounting

A retractable low and medium pressure packing gland, with 1¼" MNPT threads or ANSI/DIN flange, and graphite or Teflon packing, is a

process connection option. FCI single point flow meters are calibrated at the centerline of the process pipe. The flow element is properly

mounted when the tip of the flow element is located .50 inches (13 mm) past the pipe centerline. Follow the below steps to install/retract

instruments with the retractable packing gland option (as applicable to your configuration, also follow the pipe thread or flange mount

procedures as described in previous sections).

Insertion/Installation Procedure

1. The scale etched on the side of the insertion probe indicates the length to the tip of the flow element. Calculate the insertion depth

using the equation, variables, and Figure 5below.

ID

= Inside Diameter of Pipe

T

= Pipe Wall Thickness

C

= Mounting Coupling with Optional Ball Valve and Installed Packing Gland Length

INSERTION DEPTH = ______________

Figure 5 – Retractable Packing Gland Installation

ST100A Series Flow Meter INSTALLATION

Fluid Components International LLC 11

2. Mark the insertion pipe at the calculated insertion depth.

3. Ball Valve Applications Only: If a ball valve is required, install the ball valve to the process mounting coupling. Close the ball valve

to prevent the process media from leaking out when installing the packing gland with the process line pressurized.

4. Apply the proper thread sealant compatible with the process media to the male threads of the packing gland. Fully retract the insertion

probe into the cavity of the packing gland and install the packing gland into the process mounting coupling or ball valve as described

in the previous sections: Flange Mount and NPT Pipe Thread Mount. If a ball valve is not used, make sure to first depressurize

the process line before installing.

5. Tighten the packing nut until the internal packing is tight enough to prevent excess process leakage, but also allow the insertion probe

to be inserted into place. For ball valve applications, open the ball valve after the packing nut has been tightened.

Caution:

For applications where the process media is pressurized to greater than 50 psig (3.5 barg), a medium pressure

packing gland assembly with support rods or FCI retractor tool, part no. 026854-01, must be used to safely insert the

probe into the process. The FCI packing gland and retractor tool are rated to a maximum pressure of 500 psig (35

barg). For instructions on how to install the flow meter using the FCI retractor tool, see step 7.

6. Manual Flow Element Insertion: Insertion by Hand (Pressure: 50 psig [3.5 barg] max.) or Using Med. Pressure Packing Gland

Assembly with Support Rods (Pressure: 500 psig [35 barg] max.)

a. Align the orientation flat and flow arrow parallel to the flow direction and proceed to insert the flow element into the process

media pipe up to the insertion depth mark. For medium pressure packing gland, use the adjusting nuts on the threaded rods to

pull the flow element up to the insertion depth mark, and then tighten the adjustable nuts against the adjustable support beam to

lock the insertion probe into place. Make sure to move the adjustable nuts at the same time (equally) to prevent the probe from

bending and damaging the packing gland.

b. Tighten the packing nut another ½- to 1-turn tight (approximately 65-85 ft-lbs [88-115 N-m]) until the packing has created a full seal.

c. Ensure the locking collar is properly secured to the back of the packing gland. Torque the two ¼"-28 socket head cap screws on

the locking collar to 94 in-lbs [11 N-m} using a 3/16" hex key.

7. Flow Element Insertion Using FCI Retractor Tool 026854-01 (Pressure: 500 psig (35 barg) max.)

a. Place the flow element into the top and bottom brackets of the FCI retractor tool as shown in Figure 6.

b. Align the orientation flat and flow arrow parallel to the flow direction. Position the top bracket close to the orientation flat as

shown in Figure 6.

c. Secure the top and bottom bracket clamps to the flow element using the eight no. 8-32 screws provided as shown in Figure 6.

Torque these screws to 20 in-lbs [2 N-m] minimum.

d. The retractor tool has, on both ends, a 3/8" drive socket that engages the retractor to move the flow element in or out. Once the

flow element has been properly secured, open the ball valve and insert the flow element by using either a hand wrench or a drill

to rotate either drive socket in the appropriate direction for insertion as shown in Figure 6. Observe the Warning below if using

an electric drill. Insert the flow element up to the insertion depth mark and tighten the packing nut another ½ to 1 turn tight

(approximately 65 to 85 ft-lbs [88-115 N-m]) until the packing has created a full seal.

Warning:

Take note of your environment if using an electric drill to operate the retractor. Do not use an electric drill in an

explosive environment as the drill could create a spark and cause an explosion.

e. Ensure the locking collar is properly secured to the back of the packing gland. Torque the two ¼"-28 socket head cap screws on

the locking collar to 94 in-lbs [11 N-m} using a 3/16" Allen wrench (hex key).

Note:

After insertingthe probe, you have theoption to leave the retractor tool inplace to easefuture proberemoval.If theretractor

toolisremoved,make suretoreinstall itbefore retractingthe probeat pressures>50 psig. Sincethe packinggland itself

has a 500 psig rating, the probe remains securely in place with the retractor off.

INSTALLATION ST100A Series Flow Meter

12 Fluid Components International LLC

Figure 6 – Flow Element Installation Using FCI Retractor Tool 026854-01

Retraction/Removal Procedure

Caution: For applications where the process media is pressurized to greater than 50 psig (3.5 barg), FCI retractor tool, part no.

026854-01, must be used to safely retract the probe from the process (does not apply to applications using the

medium pressure packing gland assembly with support rods). For applications where the process media is

pressurized to equal to or less than 50 psig (3.5 barg), the flow element can be safely guided by hand. When using

hands to restrain the retraction, be prepared for a rapid pressure impulse of the flow element. Check first that there

are no objects directly behind the flow element as the insertion probe may retract very quickly.

1. Manual Flow Element Retraction: Retraction by Hand (Pressure: 50 psig [3.5 barg] max.) or Using Med. Pressure Packing

Gland Assembly with Support Rods (Pressure: 500 psig [35 barg] max.)

a. Loosen the socket head cap screw on the side of the locking collar. See Figure 7 below.

Figure 7 – Packing Gland Locking Collar

b. Low Pressure (max. 50 psig [3.5 bar(g)]): Slowly loosen the packing nut until the insertion probe begins to retract. Use hands as

needed to help control the retraction. If the probe does not begin to retract itself, gently shake and pull the insertion probe until

the flow element has been fully retracted into the packing gland.

This manual suits for next models

7

Table of contents

Other FCI Measuring Instrument manuals

FCI

FCI PETROSENSE PHA-100Plus Setup guide

FCI

FCI MT86 Instruction manual

FCI

FCI ST75 Operating instructions

FCI

FCI FLT93B Instruction manual

FCI

FCI ST100 series User manual

FCI

FCI ST50 Operating instructions

FCI

FCI ST50 User manual

FCI

FCI ST100 series User manual

FCI

FCI DM10-FM User manual

FCI

FCI ST100 series Mounting instructions