FCI ST51 Operating instructions

This page is subject to proprietary rights statement on last page

Pre-Installation

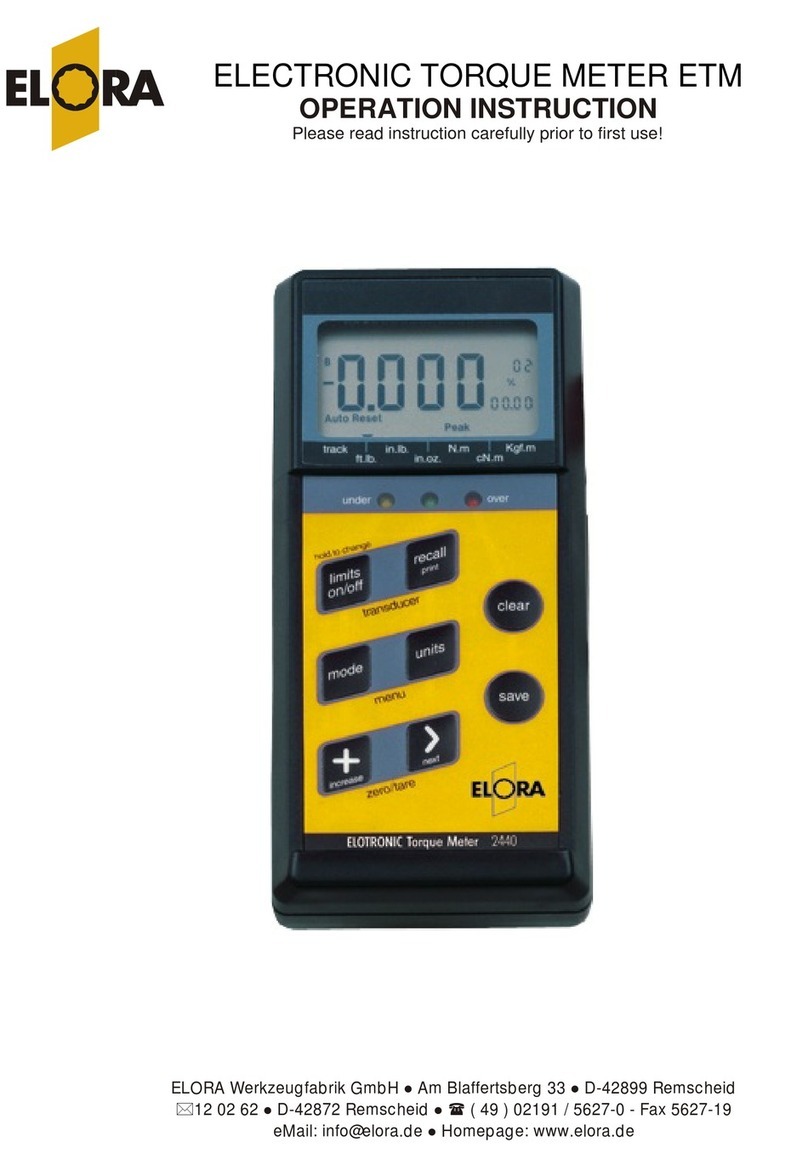

The ST51 can be specified with integral or remote electronics. The flow element has a serial number etched into the side of the

extension pipe as shown on figure A. The transmitter circuit card has a serial number noted on the board as shown in figure B. The

flow sensor and transmitter circuit have been calibrated as a matched set and should be paired together in service unless otherwise

approved by a factory technician.

Flow Direction Alignment

All sensor elements have a flow arrow indicator marked on the element assembly at the reference flat. These flow elements have

been calibrated in a particular direction and are designed to be used in service with the flow arrow facing in the same direction as

flow in the pipe stream. See Appendix C for orientation and factory calibration details.

ST51 MASS FLOW METER

Installation and Operation Guide

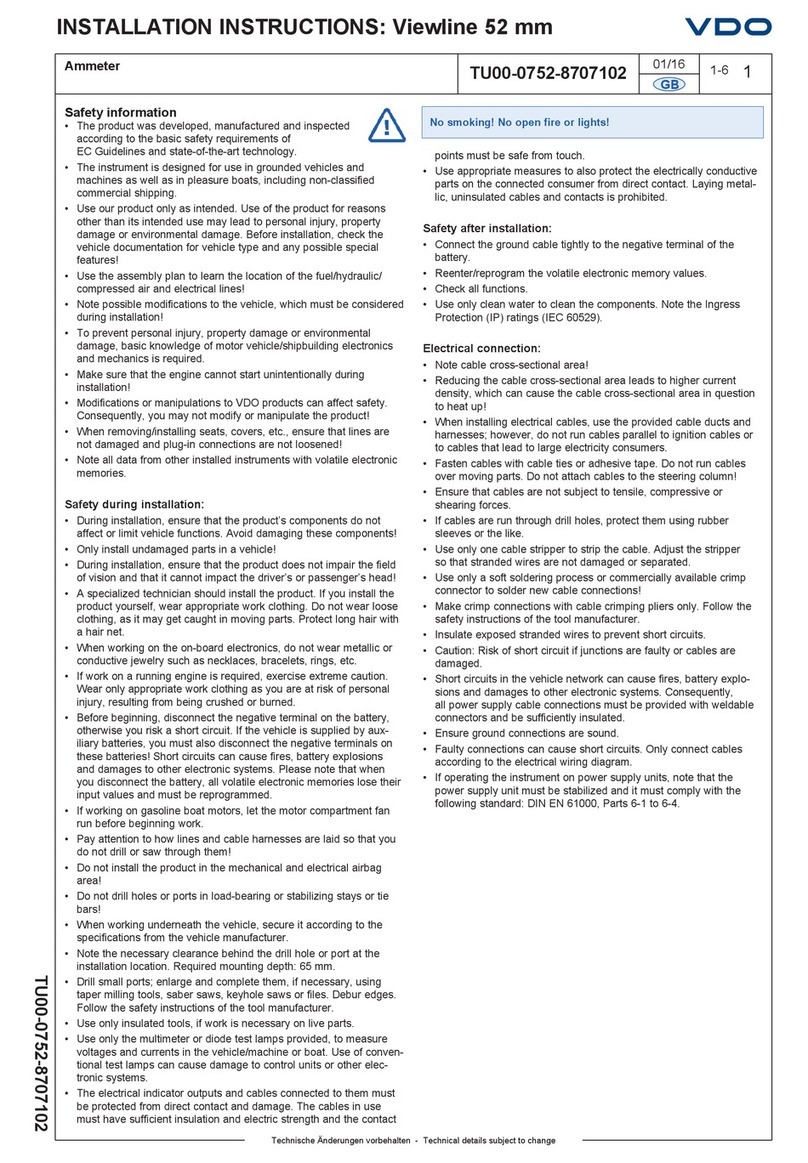

Recommended Straight Run

To optimize flow meter system performance, FCI recommends installation with a minimum of 20 pipe diameters upstream straight run

and 10 pipe diameters of downstream straight run. Where straight run limitations significantly reduce the available pipe diameters, FCI

utilizes Vortab flow conditioners to produce a transferable flow profile from the calibration installation to actual field installations.

FCI’s proprietary AVAL software is available to make flow meter installation evaluations where straight run limitations are considered.

See Fig C for recommended installation.

FCI Flow Meters may be installed with less than the recommended straight run, but may have performance limitations. FCI offers

Vortab flow conditioners for use in applications that have significant straight run limitations. FCI uses the AVAL application model-

ing software to predict meter performance in each installation. AVAL outputs are available to review prior to order placement and

will indicate performance expectations both with and without Vortab Flow Conditioning.

Figure C

Figure A Figure B

Flow Direction

Serial Number

FLOW

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

2 Doc. No. 06EN003389 Rev. -

Instrument

Media Compatibility:

Biogas, Digester Gas, Methane, Natural

Gas, Air, Compressed Air, Nitrogen

Pipe/Line Size Compatibility:

2" to 24" [51 mm to 610 mm]

Flow Range:

0.3 sfps to 400 sfps [0,08 mps to 122 mps]

Accuracy: (at >0.75 sfps [>0,21 nmps]

)

Standard: ± 2% reading ± 0.5% full scale

Optional: ± 1% reading ± 0.5% full scale

Repeatability:

± 0.5% reading

Temperature Compensation:

Standard: 40 °F to 100 °F [4 °C to 38 °C]

Optional: 0 °F to 250 °F [-18 °C to 121 °C]

Turndown Ratio:

3:1 to 100:1

Agency Approvals:

ATEX/IEC Ex: II 2 G Ex d IIC T6...T3

II 2 D Ex tD A21 IP67 T90°C...T121°C

FM, CSA:

Class I, Div. 1, Groups B, C, D (Enclosure only)

Class I, Div. 2 Pending

CRN No.: 0F0303

Warranty:

1 year

Flow Element

Installation:

Insertion, variable length with 1/2" or 3/4" NPT(M)

compression fitting.

Type:

Thermal Dispersion

Material of Construction:

316L stainless steel body with

Hastelloy-C22 thermowell sensors, 316 stainless steel

compression fitting with Teflon or stainless steel ferrule.

Pressure (Maximum Operating without Damage):

Stainless steel ferrule: 500 psig [34 bar(g)]

Teflon ferrule: 150 psig [10 bar(g)]

Operating Temperature:

Stainless steel ferrule: 0 °F to 250 °F [-18 °C to 121 °C]

Teflon ferrule: 0 °F to 200 °F [-18 °C to 93 °C]

Process Connection:

1/2" MNPT or 3/4" MNPT with stainless

steel or Teflon ferrule.

Insertion Length (Field Adjustable):

1" to 6" [25 mm to 152 mm]

1" to 12" [25 mm to 305 mm]

1" to 18" [25 mm to 457 mm]

Flow Transmitter

Enclosure:

NEMA 4X [IP67], aluminum, dual conduit

ports with either 1/2" Female NPT or M20x1.5 entries.

Epoxy coated.

Operating Temperature:

0 °F to 140 °F [-18 °C to 60 °C]

Input Power:

DC: 18 Vdc to 36 Vdc (6 watts max.)

AC:

85 Vac to 265 Vac (12 watts max.; CE Mark Approval

for 100 Vac to 240 Vac)

Analog Output Signals:

Dual 4-20 mA, configurable to

flow rate and/or temperature (500 ohm max impedance)

and a pulse output for total flow.

Output Pulse Source:

Totalized flow or alarm set point.

15VDC. Pulse width at 50% duty cycle for rates 1 to

500Hz, 0.5 second pulse width for pulse rates below 1Hz.

25mA maximum load pulsed, 10mA maximum load if state

set to normally on.

Output Pulse Sink:

Totalized flow or alarm set point. Pulse

width at 50% duty cycle for rates 1 to 500Hz, 0.5 second

pulse width for rates below 1Hz. Customer power source

and load not to exceed 40VDC and 150mA.

Communication Port:

RS-232C. Wireless IR to PDA with

optional digital display models.

Digital Display:

Two-line x 16 character LCD; displays

measured value and engineering units. Top line assigned to

flow rate, second line user assignable to temperature

reading, flow totalizer or alternating. Display can be

rotated in 90° increments for optimum viewing orientation.

Installation and Mounting:

Integral with sensor element

or remote mountable

up to 50' [15 m].

Specifications

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

3 Doc. No. 06EN003389 Rev. -

Installing Flow Element

Insertion Depth

The ST51 is available with both Teflon compression fitting ferrules and metal ferrules. While the Teflon ferrule configuration can be

readjusted, it is possible that over tightening may result in permanent positioning or damage to the extension pipe and will make

future adjustment difficult. While Teflon provides for some adjustability, it has a lower process pressure rating and is not designed

for continuous adjustments. The metal ferrule version can only be tightened down once and it becomes permanently positioned. The

Ferrule type is indicated in the instrument part number displayed on the instrument tag. This can be cross referenced to the ordering

information sheet.

All flow meters have been calibrated with the flow element located at the centerline of the pipe and flow stream as indicated in Figure

D. Couplings and threadolets come in various dimensions. Proper installation requires that the element be measured with consider-

ation to process connection dimensions and pipe centerline. FCI recommends that the element be first installed in the line with the

compression fitting lightly tightened around the extension, then slowly move the pipe extension forward until the element is at

centerline as shown.

Warning: The element is shipped with a protective sleeve surrounding the flow element. After removing the sleeve,

take care to prevent the element from sliding through the compression fitting and contacting the opposing wall with any

force as it may cause damage to the element and potentially upset the calibration.

FLOW ELEMENT INSTALLATION & “U” LENGTH ADJUSTMENT

Figure D

Note: For proper performance, element shall be installed so that tip of probe is .25 inches [ 6mm] past pipe centerline. Instrument is

specifically calibrated for centerline referenced installation. Critical for line sizes 4" [ 25mm] and smaller.

Warning: On top mount installations, particularly, take care to prevent the element from sliding through the compres-

sion fitting and contacting the opposing wall with any force as it may cause damage to the element and potentially upset

the calibration.

0.000 SFPS

32.2 DEGREES F

FLUID COMPONENTS

INTERNATIONAL LLC

~

~

~

~

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

4 Doc. No. 06EN003389 Rev. -

To assist in final installation, FCI suggests making a readable mark on the extension pipe to indicate the final desired compression

fitting position that will place the element at the centerline reference once the system is tightened down into place. With the compres-

sion fitting lightly tightened , hold the element assembly along the outside of the installation, or directly above, to visually verify the

compression fitting location will ensure centerline installation. To calculate the actual “U” length dimension, take the inside diameter

of the pipe or duct divide by 2 , then add 0.25", then add for the pipe wall thickness and the process fitting offset that allows the

compression fitting to securely seat in the process port. See Figure D above.

Align the flat parellel to flow and adjust the instrument depth. Upon determination of the final compression fitting location on the

extension pipe, apply the proper thread sealant to the NPT threads, firmly tighten the compression fitting into the mating process

connection. Torque varies per application. Tighten the compression nut to the torque indicated with the corresponding ferrule

material. Manufacturer recommends 1-1/4 turns from hand tight baseline.

Instrument Wiring

Before the instrument is opened to connect power and signal, FCI recommends that the following ESD precautions be observed:

Use a wrist band or heel strap with a 1 megaohm resistor connected to ground. If the instrument is in the shop setting, there should be

a static conductive mat on the work table or floor with a 1 megaohm resistor connected to ground. Connect the instrument to ground.

Apply antistatic agents such as Static free made by Chemtronics (or equivalent) to hand tools to be used on the instrument. Keep

high static producing items away from the instrument.

The above precautions are minimum requirements. The complete use of ESD precautions can be found in the U.S. Dept of defense

handbook 263.

Warning: Only Qualified personnel are to wire or test this instrument. The operator assumes all responsibility for safe

practices while wiring and trouble shooting.

FCI recommends installing and input power disconnect switch and fuse near the instrument to interrupt power during

installation and maintenance. Operator must have power disconnected before wiring.

See Safety instructions in Appendix A for the use of the ST51 series (AC and DC versions) in Hazardous Areas

Category II (Zone 1). Approval, KEMA 08ATEX0045/IECEx KEMA08.0012 for Category 2 GD protection Ex d IIC

T6..T1, Ex tD A21 IP67 T 90°C...Τ 121°C.

Ferrule Torque

Teflon 65 in – lbs

316 SST 65 ft – lbs

Input Power

The ST51 is available with both VDC and VAC input power configurations. Customers selecting VDC input power will have a VDC

input board only. Similarly, the VAC power board is supplied only with VAC powered units. In addition, both boards are marked for

either AC or DC power. Only connect the power specified on the wiring module as shown on Figures E and F respectively. Both

VAC and VDC inputs require a Gnd wire to be connected. Input power terminal blocks are rated for 14-26 AWG.

To wire the instrument, ensure that the power is off. Pull the power and signal output wires through the port, using care not to

damage wires. FCI recommends using crimp lugs on the output wires to ensure proper connection with the terminal strip. Connect

the output wires as shown on figures E and F. Note that when the 4-20mA outputs are used simultaneously, a single return lead is

used.

Analog Output

4-20mA: The instrument is provided with a standard set up, of two 4-20mA outputs. Output 1 configured for flow and Output 2

configured for temperature. Terminal blocks rated for 14-28 AWG., 500 ohm max load per output.

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

5 Doc. No. 06EN003389 Rev. -

Pulse Output Activation

The ST51 provides a pulse output feature. Instruments ordered with volumetric or mass flow units will be factory set with totalizer

and pulse output activated. The mode can be changed in the field. Wiring either sink or source mode is shown in Figures E and F

below. Though only one configuration is shown with the VAC and VDC power supplies, the source or sink can be utilized with either

power input.

Sink Mode: 40 VDC Max, 150 mA max. Customer supplied power source

Source Mode: 15 VDC output, 50 mA max

Figure E

VDC Power Connection

Figure F

VAC Power Connection

RS 232 Connection

VAC Power

As Shown:

85-265 VAC power connected with gnd

4-20mA connected for flow and temperature

Pulse Out in sink mode

Note: In sink mode, 40VDC max, 150mA max customer

supplied power source.

Power Disspation

AC Version

Power dissipation values under nominal conditions:

Instrument (Electronics + Sensor): 11.6 Watts

Sensor only: 0.25 Watts

Power dissipation values under maximum load conditions:

Instrument (Electronics + Sensor): 12 Watts

Sensor only: 0.30 Watts

DC Version

Power dissipation values under nominal conditions:

Instrument (Electronics + Sensor): 4.5 Watts

Sensor only: 0.25 Watts

Power dissipation values under maximum load conditions:

Instrument (Electronics + Sensor): 6 Watts

Sensor only: 0.30 Watts

RS 232 Connection

VDC Power

As Shown:

18-36VDC power connected with gnd

4-20mA connected for flow and temperature

Pulse Out in source mode

Note: In source mode, 15VDC Output max, 50mA max.

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

6 Doc. No. 06EN003389 Rev. -

Setup Interface

All parameters on this meter are set through the RS232 interface connection (P3 plug) or PDA IR interface. A jumper selection

determines which communication mode is active. The factory default communication mode is set for the RS232 interface. This

setting allows the instrument to be setup with either a FC88 hand held communicator or a computer. The FC88 is powered through the

meter and comes with the serial interface cable. If a computer interface is used, an adapter (RJ to 9 pin Computer Serial Port) is

required and may be obtained from FCI: Part No. 014108-02.

Using Windows Terminal (usually located in Accessories) execute the program by double-clicking on the Terminal Icon.

1. Go to Settings.

2. Click on Communication.

3. Set for COM1 or COM2, 9600 Baud, 8 Bit, and No Parity. Press OK

4. Press the ENTER key to see the Input Mode? prompt.

5. Enter any of the meters single letter commands to execute a function (reference complete function menu in Appendix B).

If the PDA IR interface is used for communication, then jumper JP5 needs to be moved to the alternate position, see Figure G and H.

See PDA IR Communication Interface section for more details.

An additional command line interface (CLI) is available through the RS232 port. This interface is accessed with the “Y” command

using a computer or FC88. The command line password is “357”. See Appendix B - Table 6 for command line details.

Infra Red Communications Window

Flow Rate, Total and Temperature Indicator

JP5

Figure G

JP5 factory set for RS232 interface

Figure H

JP5 set for PDA IR interface

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

7 Doc. No. 06EN003389 Rev. -

If the instrument is installed, and the process flow is zero, the instrument should indicate 0.000.

Flow Unit Modification

Example: SCFM Flow Units and 3 inch Sch 40 round pipe size set up:

Start up and Commissioning

1. Verify all Input power and output signal wiring is correct and ready for initial power start up.

2. Apply power to instrument. The instrument will initialize in the Normal Operation Mode. All outputs will be active and instru-

ments with the display option will indicate flow with the factory set flow unit. Allow 10 minutes for the instrument to warm up

and come to the thermal equilibrium.

The following FC88 commands are typical commands that are used during start up and commissioning:

Command Name Description

T Normal Operation Mode All outputs are active

Z Flow Unit Set-Up Select Flow Units(4 English, 4

Metric)Pipe Dimensions

W Totalizer Enable/Disable

V Output Configuration Select one of 4 Configurations:

Pulse and/or AlarmPulse factor and/or

setpoint

F K-Factor (default=1) Flow factor

N Warm Re-set Re-initialize C/B

S Totalizer Menu Enables W menu (Option)

Enter Display Description

Enter menu: > From Normal Operation Mode

Z E for English M for Metric > Flow Unit Set-Up menu

E0=SFPS, 1=SCFM, 2=SCFH, 3=LB/H,

4=GPM # English units

1 R round duct or S rectangular> Select Standard Ft3/Min (SCFM)

Dia.: 4.0260000

Change? (Y/N)>

YEntervalue:#

area: 7.3926572 CMinflow: 0.0000000

Change? (Y/N)>

Maximum flow: 462.04

Enter to continue

Cmaxflow: 462.04

Change? (Y/N)>

Y#

CMintemp (F): -40.00000

Change? (Y/N)>

CMaxtemp (F): 250.00000

Change? (Y/N)>

Percent of Range is: OFF

Change to ON?>

LCD Mult Factor x1

Change? (Y/N)>

N 100.0 SCFM Instrument will end up in Normal

Operation Mode

R Select Round Duct

3.068 3 inch Sch. 40 pipe I.D.

N

Y

462.04

N

N

N

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

8 Doc. No. 06EN003389 Rev. -

RS232 / FC88

Menu Control and Organization

Most entries require at least two key strokes; a Capital letter and the [ENTER] key, or one or more numbers and the [ENTER] key. All

user entries begin at the input mode prompt “>”,except when the instrument is in the Main Function Mode (just press the desired

function letter and [ENTER] to make an entry).

Backspaces are made using the backspace [BKSP] key. Some entries are case sensitive between numbers and letters. Be sure the

SHIFT key is pressed to indicate the correct case. A square after the prompt caret indicates the FC88 is in lower case. A slightly

raised rectangle in the same spot indicates the FC88 is in the upper case.

It is recommended that the FC88 be plugged into the instrument before power is applied. If the FC88 is plugged in while the

instrument power is on and the FC88 does not respond, press [ENTER], if there is still no response Press [N] or cycle the power.

Note: The Zero and Span may be changed from the original calibration, provided the new values are within the original calibrated

range. i.e. If the original calibration was 1 to 100 SCFM (4-20mA), the new zero (4mA) must be equal to or greater than 1

SCFM, the new span (20mA) must be equal to or less than 100 SCFM.

Some entries require a Factory pass code. If this occurs contact FCI Field Service to continue programming the instrument. The

instrument will prompt the user when this is necessary. Do not change any parameters that require this code unless there is an absolute

understanding of the instrument's operation. The user can not exit some routines unless all entries are completed or the power is

recycled.

The top level of the menu is shown in Appendix B - Table 5. Enter the large letter in the tables below to activate a command. The user

may exit a command at any time entering “Q” [ENTER] in the menus: D, K, V, W, or Z.

Units

Select E=English M=Metric

Select 0= SFPS 5 = SMPS

or 1 = SCFM 6 = NCMH

or 2 = SCFH 7 = NCMM

or 3 = LBS/H 8 = KG/H

or 4 = GPM 9 = LPM

For Volumetric or Mass Flow

Select R = Round pipe or duct

or S = Square duct

Set Diameter or Wide X High (in inches or mm)

Set CMaxflow = Maximum flow rate (span)

Set CMinflow = Minimum flow rate (zero)

Table 2. “Z” Flow Units Set-Up and Scaling

Note: Changing units requires rescaling the unit (set new zero and span).

Analog out

Select 1 2 3 4

4-20mA out 1 Flow Flow Temp Temp

4-20mA out 2 Temp Flow Flow Temp

Pulse out

Select 1 2 3 4

Source out Pulse Pulse Alarm0 Alarm0

Set Factor Factor Set pt.0 Set pt.0

Set Period Period State0 State0

Set State0 State0

Sink Pulse Alarm1 Pulse Alarm1

Set Set pt.1 Factor Set pt.1

Set State1 State1 Period State1

State1

Table 3. “V” Output Configuration Set-Up

Table 1. Diagnostics and Factory Settings

C Calibration Information

Display only: A/D, Delta-R, Ref-R data values

D Diagnostics

Display only: List of unit prameters.

K Factory Calibration Settings

Display only: Cal. parameters, i.e. linearization

and temperature compensation coefficients.

R Factory Reset

Replaces user data with factory calibration data

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

9 Doc. No. 06EN003389 Rev. -

Example: COMMAND V (Reference Table 3)

Case: 4-20mA #1 = flow, 4-20mA #2 = Temperature, Source Out = Pulse, Sink = Alarm

Pressing [V] [ENTER] will display “Output Mode Selected” followed by:

“4-20mA #1 = Flow” “ 4-20mA #2 = Temp” followed by

“Change? (Y/N)”

Press [ENTER] (no change).

The last saved mode will display at this point. i.e.,

“Source: Pulse” “Sink: Pulse” followed by,

“Change? (Y/N)” Select Y [Enter]. The display reads,

“Source: Pulse” “Sink: Pulse” followed by,

“Enter 1 to make the selction #.” Select [ENTER]. The next display reads,

“Source: Pulse” “Sink: Alarm” followed by,

“Enter 2 to make the selction #.” Select 2 and [ENTER]. The next prompt reads,

“PFactor: 1.000” “Change? (Y/N)>” (this factor can be anywhere from 0.001 to 1000 - A

pulse factor of 1.000 will output 1 pulse per unit of

flow.)

If no change, select N and/or [ENTER] to continue.

The next prompt is, “Sample Period”

“Change? (Y/N)>” (this value may be set from 0.5 to 5 seconds)

If no change, select N and/or [ENTER] to continue.

The next prompt is, “Source state: ”“High to Low” Change to “Low to High?>” (this selection toggles the pulse

signal normally high or normally

low).

[ENTER] to read display.

“Switchpt1” “0.0000000” the current set point.

“Change? (Y/N)>” enter Y [ENTER] and enter #______ . Set Point Value , i.e. 50 (value is in same units as the flow and

must be within the calibrated range). [ENTER]. The next prompt is,

“Sink state: ”“High to Low” Change to “Low to High?>”. Set the output signal to be normally “High” or

normally “Low.” Pressing [Y] [ENTER] toggles the current setting. Pressing [ENTER] resumes normal operation.

NOTE: The display comes up to the last setting saved and stays for 2 seconds. If Nor [ENTER] is entered, the menu

proceeds to the Pulse out. If Yis entered, the display moves to the selection options and/or asks for confirmation. If you

miss the option, select [Enter] repeatedly to loop around.

“V” Menu Output Configuration Set Up

Analog out

Output Mode

Selected

4-20mA #1: Flow

4-20mA #2: Temp

Change? (Y/N)>

4-20mA #1: Flow

4-20mA #2: Temp

Enter 1 to make

the selection__

4-20mA #1:

4-20mA #2: Flow

Enter 2 to make

the selection__

4-20mA #1: Temp

4-20mA #2: Flow

Enter 3 to make

the selection__

4-20mA #1: Temp

4-20mA #2: Temp

Enter 4 to make

the selection__

Pulse out

Pulse Out

Selected

Source: Pulse

Sink: Pulse

Change? (Y/N)>

Source: Pulse

Sink: Pulse

Enter 1 to make

the selection #__

Source: Pulse

Sink: Alarm1

Enter 2 to make

the selection #__

Source: Alarm0

Sink: Pulse

Enter 3 to make

the selection #__

Source: Alarm0

Sink: Alarm1

Enter 4 to make

the selection #__

PFactor: 1.000

Change? (Y/N)>

if yes

Enter new factor: ____

Sample Period: 1 second

Change? (Y/N)>

if yes

Enter new Sample Period: ____

If alarm is a selected output

Set point1: 000 Set points are in the

same units as the flow

or temp.

Change? (Y/N)>

if yes

Enter new set point: ____

Resume normal operation

Source state:

High to Low

Change to Low to High?>

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

10 Doc. No. 06EN003389 Rev. -

PDA IR Communication Interface

The IR interface software is an optional accessory kit and can ordered using FCI part number 019819-01. The software is compatible

with PALM OS 4.1 or greater. If the software was ordered with the instrument, a CD should be located with the instrument documen-

tation.

The factory has verified the following 3 PDA models. All commands meet their intended purpose and function properly.

1. Palm, Tungsten E, E2:Palm OS 5.2.1, 5.4.7

2. Palm, Zire 71, Palm OS 5.2.1

3. ecom instruments, m 515-EX, Intrinsically-safe. Palm OS 4.1

Procedure:

1. Down load the software into the target PDA. When complete, a yellow and blue FCI icon will be available.

2. Verify JP5 jumper is set in the PDA IR interface position, see Figure H.

3. Select FCI icon on PDA device.

4. The opening menu is displayed, select start.

5. Five menu groups are displayed.

Process: displays current process variables (Flow and Temperature)

ID-Unit: displays model, firmware version, serial no. …

Set-up: allows access to the following areas

Units K Factor

Line size Temp/Flow min/max

Totalizer Output Cal

LCD Output Config

Diagnostics: A/D values

Utilities: allows access to the following areas

Reset

Parameter memory

Calibration coefficients

Factory restore

Process and System Faults

6. After entering into specific menu areas, point the PDA IR port towards the Instrument display. Begin with the PDA device within

5 feet of the instrument display. Select the “Get All” or “Get” button to retrieve information from the instrument. If a value needs

to be changed, the value must first be retrieved.

Example: reading standard process variable information

1. Verify instrument and PDA are functioning.

2. Select FCI icon on the PDA.

3. Select the start button on the opening screen.

4. Select the “Process” button.

5. Point the PDA at the instrument display, start with the PDA no futher that 5 feet from the instrument.

6. Select the “Get Data” button.

7. Flow and temperature Data will begin streaming to the PDA.

8. If the IR link is interrupted, a “Command response timed out” message will be displayed.

9. Repeat the process if the link is interrupted.

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

11 Doc. No. 06EN003389 Rev. -

The FCI instrument requires little maintenance. There are no moving parts or mechanical parts subject to wear in the instrument. The

sensor assembly which is exposed to the process media is composed of 316 SS and Hastelloy C.

Without detailed knowledge of the environmental parameters of the application surroundings and process media, FCI cannot make

specific recommendations for periodic inspection, cleaning, or testing procedures. However, some suggested general guidelines for

maintenance steps are offered below. Use operating experience to establish the frequency of each type of maintenance.

Calibration

Periodically verify the calibration of the output and recalibrate if necessary. FCI recommends every 18 months at a minimum.

Electrical Connections

Periodically inspect cable connections on terminal strips and terminal blocks. Verify that terminal connections are tight and physically

sound with no sign of corrosion.

Remote Enclosure

Verify that the moisture barriers and seals protecting the electronics in the local enclosure is adequate and that no moisture is entering

the enclosure.

Electrical Wiring

FCI recommends occasional inspection of the system’s interconnecting cable, power wiring and flow element wiring on a “common

sense” basis related to the application environment. Periodically the conductors should be inspected for corrosion and the cable

insulation checked for signs of deterioration.

Flow Element Connections

Verify that all seals are performing properly and that there is no leakage of the process media. Check for deterioration of the gaskets

and environmental seals used.

Insertion Type Flow Element Assembly

Periodically remove the flow element for inspection based on historical evidence of debris, foreign matter, or scale build-up and

appropriate plant shutdown schedules and procedures. Check for corrosion, stress cracking, and/or build-up of oxides, salts, or foreign

substances. The thermowells must be free of excessive contaminants and be physically intact. Any debris or residue build-up could

cause inaccurate flow indication. Clean the flow element, as necessary, with a soft brush and available solvents (compatible with

Stainless Steel).

Maintenance

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

12 Doc. No. 06EN003389 Rev. -

Application Verification

After verifying that the flow meter is functioning, review the application parameters as shown below to verify the calibration matches

the process media.

Equipment Needed

Flow Instrument Calibration Data

Process Parameters and Limits

Check Serial Numbers

Verify that the serial number of the flow element and the flow transmitter electronics are the same. The flow element and the flow

transmitter are a matched set and cannot be operated independently of each other.

Check the Instrument Installation

Verify correct mechanical and electrical installation. Verify the flow element is mounted at least 20 diameters downstream and 10

diameters upstream from any bends or interference in the process pipe or duct.

Check for Moisture

Check for moisture on the flow transmitter. Moisture may cause intermittent operation. Check for moisture on the flow element. If a

component of the process media is near its saturation temperature it may condense on the flow element. Place the flow element where

the process media is well above the saturation temperature of any of the process gases.

Check Application Design Requirements

Application design problems may occur with first time application instruments, although the design should also be checked on

instruments that have been in operation for some time. If the application design does not match field conditions, errors occur.

1. Review the application design with plant operation personnel and plant engineers.

2. Ensure that plant equipment such as pressure and temperature instruments conform to the actual conditions.

3. Verify operating temperature, operating pressure, line size, and gas medium.

Verify Standard Versus Actual Process Conditions

The flowmeter measures the mass flow rate. The mass flow rate is the mass of the gas flowing through a pipe per time. Other flow

meters, such as an orifice plate or a pitot tube, measure the volumetric flow rate. The volumetric flow rate is the volume of gas per

time. If the readings displayed do not agree with another instrument, some calculations may be necessary before comparing them. To

calculate the mass flow rate, the volumetric flow rate, and the pressure and temperature, the point of measurement must be known. Use

the following equation to calculate the mass flow rate (Standard Volumetric Flow rate) for the other instrument:

Equation:

QQ

SA

=× ×P

T

T

P

A

A

S

S

(Metric: Where bar(a) and °K are

Where: used for pressure and temperature.)

QA= Volumetric Flow QS= Standard Volumetric Flow

PA= Actual Pressure TA= Actual Temperature

PS= Standard Pressure TS=Standard Temperature

PSIA and °R are used for pressure and temperature units.

Troubleshooting

Example: (Metric: PS= 1.01325 bar(a)

QA= 1212.7 ACFM QS= 1485 SCFM TS =21.1°C (294.1K))

PA= 19.7 PSIA TA= 120°F (580°R)

PS= 14.7 PSIA TS=70°F (530°R)

(1212.7 ACFM

1)(19.7 PSIA

580° R )(530° R_

14.7 PSIA

)=1485 SCFM

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

13 Doc. No. 06EN003389 Rev. -

Calibration Parameters Verification

The instrument uses a set of predetermined calibration parameters to process flow signals. Most of these parameters should not

change. A data package located with this manual contains the “ST51 Delta R Data Sheet”. This contains the calibration parameters

stored in the flow transmitter at the factory. To verify that these parameters have not changed, complete the following:

1. Identify the appropriate Delta R Data sheets by serial number of the instrument.

2. Press [D] [ENTER] to examine each of the parameters. The [ENTER] key allows scrolling one message at a time. Use Table

4 to verify parameters with the Delta R Data sheet ST51 Parameters.

Table 4. Diagnostic Test Sequence on Display

S/W Version: dR Min: T SpanIDAC 0:

Flow Factor: dR Max: T ZeroIDAC 0:

Cmin Flow: Cal Ref: T SpanIDAC 1:

Cmax Flow: Tcslp: T ZeroIDAC 1:

Eng Units: Tcslp 0: State 0:

Line Size 0: Tcslp 2: Switch Pt 0:

Line Size 1: Tot Menu: State 1:

Cmin Temp: Tot Flag: Switch Pt 1:

Cmax Temp: Totalizer: K factor 1:

Min Flow: Rollover Cnt: K factor 2:

Max Flow: Fix Pt Flag: K factor 3:

Density: Pulse Factor: K factor 4:

*C1 [1]: Pulse Out: I factor:

*C1 [2]: Hours: Temp Flag:

*C1 [3]: Sample Period: Out Mode:

*C1 [4]: dR Slope: Boxcar Max:

*C1 [5]: dr Off Set: RTD-SLP-385:

Break Pt: Refr Slope: % of Range:

*C2 [1]: Refr Off Set: Us er Name:

*C2 [2]: SpanIDAC 0: Shop Order #:

*C2 [3]: Zero IDA C 0: Serial No .:

*C2 [4]: SpanIDAC 1: Model#:

*C2 [5]: Zero IDA C 1:

If parameters that have an asterisk (*) have changed, this may indicate a problem. Customer Service should be contacted. If the

parameters have not changed, continue with the next section.

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

14 Doc. No. 06EN003389 Rev. -

Hardware Verification

Equipment Required:

Digital Multimeter

Screw Driver

The ST51 Flowmeter is comprised of 4 basic components:

1. Sensor element.

2. Customer interface circuit board

3. Control circuit assembly circuit board module.

4. Electronics enclosure.

Step 1

Verify fuse (F1) located on the customer interface circuit board is in normal working condition.

Remove power from the instrument. Open the electronics enclosure exposing the customer interface circuit board. This circuit board

is located under the shorter enclosure lid along with all of the power and input/output connections. Unscrew the clear cover on the

fuse and pull the fuse out of the fuse holder. Check the fuse for continuity. If fuse reads open, replace with equivalent component

(FCI part no. 019933-01), Wickmann Inc. series 374, amp code 1160, package 41.

Ac power customer interface circuit board shown. Fuse (F1) on DC power customer interface circuit board located in similar

position.

Step 2

Verify interconnecting cable from the customer interface board and the control circuit board assembly module are correctly seated

into the appropriate header.

Remove power from the instrument. Open the electronics enclosure exposing the customer interface circuit board. This circuit board

is located under the shorter enclosure lid along with all of the power and input/output connections. Remove the 2 screws securing the

interface circuit board to the electronics enclosure. Carefully lift the interface face board exposing the interconnecting cable between

the interface board and the control circuit assembly. Verify cable is seated firmly at both ends of the cable header.

Fuse (F1)

Cable Header

Interface Board

Control Circuit

Assembly

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

15 Doc. No. 06EN003389 Rev. -

Step 3

Verify sensor element continuity and resistance.

Remove sensor element cable from the bottom of the control circuit assembly. Note that 2 of the wires have a red stripe and are

located closest to the interconnecting cable header. Using an ohm meter verify that resistance between the 2 red striped wires is

approximately 1100 ohms +/- 20. This resistance is temperature dependant. The resistance at 70 degrees F should be 1082 ohms.

Verify the resistance between the 2 natural colored wires are approximately the same.

FCI provides full in-house technical support. Additional technical representation is also provided by FCI field representatives. Before

contacting a field or in-house representative, please perform the troubleshooting techniques outlined in this document. If problems

persist, contact the FCI Customer Service department at 1-800-854-1993 or 1-760-744-6950.

If the instrument is to be returned to FCI, please obtain an Return Authorization. The form contains a declaration of decontamination

cleaning information that the instrument must comply with before it is shipped to FCI.

Sensor Element Cable

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

16 Doc. No. 06EN003389 Rev. -

Transmitter Circuit Calibration Check (Delta R Verification)

References

Delta ‘R’ Data Sheet

Equipment

FC88 Communicator or equivalent.©

DMV

Delta R Data Sheet-Match by serial numbers

2 Precision Decade Resistance boxes, 0.1% (Largest steps: 1K Ohm, smallest steps 0.01 Ohms)

Small flat Blade Screwdriver, 3/32 inches wide blade

FCI Normalization Cable, FCI part number 006407

Procedure

1. Verify all “D” mode calibration parameters are correct according to the meters Delta R Data Sheet, before starting verification.

2. Turn power off

3. Mark all sensor element wires connected to the circuit board, so they may be reconnected to the proper terminals. Disconnect the

wires.

4. Connect the resistance decade box to the electronics as per the appropriate diagram for the ST51.

NOTE: Interconnector wiring (resistance decade box to electronics) must be 24 AWG and 45 inches long, to avoid any

inaccuracies in the Delta R verification, caused by improper wire lengths or wire gauges.

5. Set both decade boxes for the nominal resistance value (1000 ohms) +/- .01%

6. Connect DVM to the meters output termination and monitor the meter output.

7. Turn the power ON and allow the instrument 5 mins. To stabilize

8. With the FC88 connected, Press [T] [Enter] to view the Normal Operating Mode.

9. Adjust the Active Decade Box (Reference decade box remains fixed @ 1000 ohms) to achieve the appropriated Delta R for the

displayed flow value and output, noted on the meters Delta R Data Sheet.

10. Note the [C] mode and verify the meters displayed TCDR and REFR values corresponding to the displayed flow rate as per the

meters Delta R Data Sheet.

11. Return to the [T] mode to continue the verification.

REFERENCE

NORMALIZATION CABLE

FCI P/N 006407

BLACK

BLACK

ORANGE

ORANGE

1433-W DECADE R ISISTOR GENERAL RADIO USA

9

8

7

6

X

G

23mA MAX

1K STEPS

H

L

10 K

2

0

1

4

5

3

ACTIVE

6

8

9

X

6

7

100 STEPS

80mAMA X

2

1

0

4

3

5

2

1

4

5

3

1433-W DECADE R ISISTOR GENERAL RADIO USA

X

6

7

8

9

G

1K STEPS

23mA MAX

H

L

10 K

1

0

2

4

5

3

7

6

X

9

8

6

100 STEPS

80mAMA X

0

1

2

5

3

4

1

2

4

5

3

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

17 Doc. No. 06EN003389 Rev. -

Appendix A - Approval Information

EC

Information

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

18 Doc. No. 06EN003389 Rev. -

Safety Instructions for the use the ST51/75 flowmeter in Hazardous Areas

Approval KEMA 08ATEX0045/IEC KEM08.0012 for:

Category II 2 G for Gas protection Ex d IIC T6…T3

Category II 2 D for Dust protection Ex tD A21 IP67 T90ºC…T121ºC

The ST51/75 series consist of a sensing element and associated integral or remote mounted electronics mounted

in a type “d” flameproof enclosure.

Relation between ambient temperature, process temperature and temperature class is as follows:

Ambient temperature range (Ta): T6 [85ºC] for : -40ºC <Ta< + 65ºC

Process temperature range (Tp): T6 [85ºC] for : -40ºC <Tp< + 65ºC

T5 [100ºC] for : -40ºC <Tp< + 100ºC

T4 [135ºC] for : -40ºC <Tp< + 135ºC

T3 [200ºC] for : -40ºC <Tp< + 200ºC

Electrical data: Power supply: 85 to 265 VAC, 50/60 Hz, 12 Watt max; 24 VDC, 12 VA Max

Dansk Sikkerhedsforskrifter Italiano Normative di sicurezza

Deutsch Sicherheitshinweise Nederlands Veiligheidsinstructies

English Safety instructions Português Normas de segurança

Υπ Υπ_δεί_εις ασφαλείας Español Instrucciones de seguridad

Suomi Turvallisuusohjeet Svenska Säkerhetsanvisningar

Français Consignes de sécurité

DK Dansk- Sikkerhedsforskrifter

Disse sikkerhedsforskrifter gælder for Fluid Components, ST51/75 EF-typeafprøvningsattest-nr. KEMA 08ATEX0045/IEC KEM08.0012

(attestens nummer på typeskiltet) er egnet til at blive benyttet i eksplosiv atmosfære kategori II 2 GD.

1) Ex-anlæg skal principielt opstilles af specialiseret personale.

2) ST51/75 skal jordforbindes.

3) Klemmerne og elektronikken er monteret i et hus, som er beskyttet af en eksplosionssikker kapsling med følgende noter:

• Gevindspalten mellem huset og låget er på en sådan måde, at ild ikke kan brede sig inden i det.

• Ex-„d“ tilslutningshuset er forsynet med et 1/2" NPT og/eller M20x1.5 gevind for montering af en Ex-„d“ kabelindføring, der er attesteret iht.

IEC/EN 60079-1

• Det er vigtigt at sørge for, at forsyningsledningen er uden spænding eller eksplosiv

atmosfære ikke er til stede, før låget åbnes og når låget er åbent på „d” huset (f.eks. ved tilslutning eller servicearbejde).

• Låget på „d” huset skal være skruet helt ind, når apparatet er i brug. Det skal sikres ved at dreje en af låseskruerne på låget ud.

D A Deutsch-Sicherheitshinweise

Diese Sicherheitshinweise gelten für die Fluid Components, ST51/75 flowmeter gemäß der EG-Baumusterprüfbescheinigung Nr. KEMA

08ATEX0045/IEC KEM08.0012 (Bescheinigungsnummer auf dem Typschild) der Kategorie II 2 GD.

1) Die Errichtung von Ex-Anlagen muss grundsätzlich durch Fachpersonal vorgenommen werden.

2) Der ST51/75 muß geerdet werden.

3) Die Klemmen und Elektroniken sind in einem Gehäuse in der Zündschutzart druckfeste Kapselung („d“ ) eingebaut.

• Der Gewindespalt zwischen dem Gehäuse und dem Deckel ist ein zünddurchschlagsicherer Spalt.

• Das Ex-“d“ Anschlussgehäuse besitzt ein 1/2“ NPT und/oder M20x1.5 Gewinde für den Einbau einer nach IEC/EN 60079-1 bescheinigten

Ex-“d“ Kabeleinführung.

• Es ist sicherzustellen, dass vor dem Öffnen und bei geöffnetem Deckel des „d“ Gehäuses (z.B. bei Anschluss oder Service- Arbeiten)

entweder die Versorgungsleitung spannungsfrei oder keine explosionsfähige Atmosphäre vorhanden ist.

• Der Deckel des „d“ Gehäuses muss im Betrieb bis zum Anschlag hineingedreht sein. Er ist durch eine der Deckelarretierungsschrauben zu

sichern.

ST51 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

19 Doc. No. 06EN003389 Rev. -

GB IRL English- Safety instructions

These safety instructions are valid for the Fluid Components, ST51/75 flowmeter to the EC type approval certificate no KEMA 08ATEX0045/IEC

KEM08.0012 (certificate number on the type label) for use in potentially explosive atmospheres in Category II 2 GD.

1) The installation of Ex-instruments must be made by trained personnel.

2) The ST51/75 must be grounded.

3) The terminals and electronics are installed in a flame proof and pressure-tight housing with following notes:

• The gap between the housing and cover is an ignition-proof gap.

• The Ex-“d“ housing connection has a 1/2” NPT and/or M20x1.5 cable entry for mounting an Ex-d cable entry certified acc. to IEC/EN 60079-1.

• Make sure that before opening the cover of the Ex”d“ housing, the power supply is disconnected or there is no explosive atmosphere present (e.g.

during connection or service work).

• During normal operation: The cover of the “d“ housing must be screwed in completely and locked by tightening one of the cover locking screws.

GR Υπ_δεί_εις ασφαλείας

Αυτές οι οδηγίες ασφαλείας ισχύουν για τα Ροόµετρα της Fluid Components τύπου ST51/75 που φέρουν Πιστοποιητικό Εγκρίσεως Ευρωπαϊκής

Ένωσης, µεαριθµόπιστοποίησης KEMA 08ATEX0045/IEC KEM08.0012 (οαριθµός πιστοποίησης βρίσκεται πάνω στην ετικέτα τύπου του

οργάνου) για χρήση σε εκρηκτικές ατµόσφαιρες της κατηγορίας II 2 GD.

1) Ηεγκατάσταση των οργάνων µεαντιεκρηκτική προστασία πρέπει να γίνει από εξειδικευµένο προσωπικό.

2) Το όργανο τύπου ST51/75 πρέπει να είναι γειωµένο.

3) Τα τερµατικά ηλεκτρικών συνδέσεων (κλέµες) και τα ηλεκτρονικά κυκλώµατα είναι εγκατεστηµένα σε περίβληµααντιεκρηκτικό και αεροστεγές

σύµφωνα µετις ακόλουθες παρατηρήσεις:

• Το κενό ανάµεσα στο περίβληµακαι στο κάλυµµαείναι τέτοιο που αποτρέπει την διάδοση σπινθήρα.

• Το “Ex-d” αντιεκρηκτικό περίβληµα, έχει ανοίγµατα εισόδου καλωδίου µεδιάµετρο ½” NPT ή/και M20x1.5, κατάλληλα για τοποθέτηση υποδοχής

αντιεκρηκτικού καλωδίου πιστοποιηµένης κατά IEC/EN 60079-1

• Βεβαιωθείτε ότι πριν το άνοιγµακαλύµµατος του του “Ex-d” αντιεκρηκτικού περιβλήµατος, ητάση τροφοδοσίας είναι

αποσυνδεδεµένη ήότι δεν υφίσταται στη περιοχή εκρηκτική ατµόσφαιρα (π.χ. κατά τη διάρκεια της σύνδεσης ήεργασιών

συντήρησης)

• Κατά τη διάρκεια οµαλής λειτουργίας: Το κάλυµατου “d” καλύµµατος αντιεκρηκτικού περιβλήµατος πρέπει να είναι εντελώς βιδωµένο και

ασφαλισµένο, σφίγγοντας µία από τις βίδες ασφαλείας του περιβλήµατος.

FIN Suomi - Turvallisuusohjeet

Nämä turvallisuusohjeet koskevat Flud Components, ST51/75 EY-tyyppitarkastustodistuksen nro. KEMA 08ATEX0045/IEC KEM08.0012

(todistuksen numero näkyy tyyppikilvestä) käytettäessä räjähdysvaarallisissa tiloissa luokassa II 2GD.

1) Ex-laitteet on aina asennettava ammattihenkilökunnan toimesta.

2) ST51/75 on maadoitettava.

3) Syöttöjännitteen kytkemisessä tarvittavat liittimet ja elektroniikka on asennettu koteloon jonka rakenne kestää räjähdyspaineen seuraavin

lisäyksin :

• Kotelon ja kannen välissä on räjähdyksen purkausväli.

• Ex-d liitäntäkotelossa on 1/2“ NPT ja/tai M20x1.5 kierre IEC/EN 60079-1 mukaisen Ex-d kaapeliläpiviennin asennusta varten

• Kun “d“-kotelon kansi avataan (esim. liitännän tai huollon yhteydessä), on varmistettava, että joko syöttöjohto on jännitteetön tai ympäristössä ei

ole räjähtäviä aineita.

• “d“ -kotelon kansi on kierrettävä aivan kiinni käytön yhteydessä ja on varmistettava kiertämällä yksi kannen lukitusruuveista kiinni.

FLUID COMPONENTS INTERNATIONAL LLC ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

20 Doc. No. 06EN003389 Rev. -

F B L Consignes de sécurité

Ces consignes de sécurité sont valables pour le modèle ST51/75 de la société Fluid Components (FCI) conforme au certificat d’épreuves de type

KEMA 08ATEX0045/IEC KEM08.0012 (numéro du certificat sur l’étiquette signalétique) conçu pour les applications dans lesquelles un matériel

de la catégorie II2GD est nécessaire.

1) Seul un personnel spécialisé et qualifié est autorisé à installer le matériel Ex.

2) Les ST51/75 doivent être reliés à la terre.

3) Les bornes pour le branchement de la tension d’alimentation et l’électronique sont logées dans un boîtier à enveloppe antidéflagrante

avec les notes suivantes :

• Le volume entre le boîtier et le couvercle est protégé en cas d’amorçage.

• Le boîtier de raccordement Ex-d dispose d’un filetage1/2’’ NPT et/ou M20x1.5 pour le montage d’un presse-étoupe Ex-d certifié selon la IEC/EN

60079-1.

• Avant d’ouvrir le couvercle du boîtier « d » et pendant toute la durée où il le restera (pour des travaux de raccordement, d’entretien ou de

dépannage par exemple), il faut veiller à ce que la ligne d’alimentation soit hors tension ou à ce qu’il n’y ait pas d’atmosphère explosive.

• Pendant le fonctionnement de l’appareil, le couvercle du boîtier « d » doit être vissé et serré jusqu’en butée. La bonne fixation du couvercle doit

être assurée en serrant une des vis d’arrêt du couvercle.

I Italiano - Normative di sicurezza

Queste normative di sicurezza si riferiscono ai Fluid Components, ST51/75 secondo il certificato CE di prova di omologazione n° KEMA

08ATEX0045/IEC KEM08.0012 (numero del certificato sulla targhetta d’identificazione) sono idonei all’impiego in atmosfere esplosive applicazioni

che richiedono apparecchiature elettriche della Categoria II 2 GD.

1) L’installazione di sistemi Ex deve essere eseguita esclusivamente da personale specializzato.

2) I ST51/75 devono essere collegati a terra.

3) I morsetti per il collegamento e l’elettronica sono incorporati in una custodia a prova di esplosione („d“) con le seguenti note:

• La sicurezza si ottiene grazie ai cosidetti „interstizi sperimentali massimi“, attraverso i quali

una eventuale accensione all’interno della custodia non può propagarsi all’esterno oraggiungere altre parti dell’impianto.

• La scatola di collegamento Ex-d ha una filettatura 3/4“ e/o 1“ NPT per il montaggio di un passacavo omologato Ex-d secondo IEC/EN 60079-1.

• Prima di aprire il coperchio della custodia „d“ (per es. durante operazioni di collegamento o di manutenzione) accertarsi che l’apparecchio sia

disinserito o che non si trovi in presenza di atmosfere esplosive.

• Avvitare il coperchio della custodia „d“ fino all’arresto. Per impedire lo svitamento del coperchio é possibile allentare una delle 2 viti esagonali

poste sul corpo della custodia, incastrandola nella sagoma del coperchio.

NL B Nederlands - Veiligheidsinstructies

Deze veiligheidsinstructies gelden voor de Fluid Components, ST51/75 overeenkomstig de EG-typeverklaring nr. KEMA 08ATEX0045/IEC

KEM08.0012 (nummer van de verklaring op het typeplaatje) voor gebruik in een explosieve atmosfeer volgens Categorie II 2GD.

1) Installatie van Ex-instrumenten dient altijd te geschieden door geschoold personeel.

2) De ST51/75 moet geaard worden.

3) De aansluitklemmen en de electronika zijn ingebouwd in een drukvaste behuizing met de volgende opmerkingen:

• De schroefdraadspleet tussen de behuizing en de deksel is een ontstekingsdoorslagveilige

spleet.

• De Ex-d aansluitbehuizing heeft een 1/2” of een M20x1.5 schroefdraad voor aansluiting van een volgens IEC/EN 60079-1

goedgekeurde Ex- ‘d’ kabelinvoer.

• Er moet worden veilig gesteld dat vóór het openen bij een geopende deksel van de ‘d’ behuizing (bijv. bij aansluit- of servicewerkzaamheden)

hetzij de voedingsleiding spanningsvrij is, hetzij geen explosieve atmosfeer aanwezig is.

• De deksel van de ‘d’ behuizing moet tijdens bedrijf tot aan de aanslag erin geschroefd zijn.

Hij moet door het eruit draaien van een van de dekselborgschroeven worden geborgd.

Table of contents

Other FCI Measuring Instrument manuals

FCI

FCI ST100 series User manual

FCI

FCI FLT93B Instruction manual

FCI

FCI ST100 series User manual

FCI

FCI ST75 Operating instructions

FCI

FCI ST50 Operating instructions

FCI

FCI DM10-FM User manual

FCI

FCI PETROSENSE PHA-100Plus Setup guide

FCI

FCI ST51-1 Operating instructions

FCI

FCI ST80 Series Instruction manual

FCI

FCI ST100 series Owner's manual