FCI ST100 series User manual

ST100 Series

Thermal Mass Flow Meter

HART Operation

Manual

Fluid Components International LLC (FCI). All rights reserved.

ST100 Series HART

Fluid Components International LLC

Notice of Proprietary Rights

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components International LLC (FCI).

Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include manufacture or

processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2015 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

Fluid Components International LLC i

ST100 Series HART 06EN003404 Rev. A

Table of Contents

Introduction.......................................................................................................................................................................................................................1

Definition ..........................................................................................................................................................................................................................1

Universal HART Commands ..........................................................................................................................................................................................1

Common Practice HART Commands .............................................................................................................................................................................1

Device Specific Commands...........................................................................................................................................................................................1

EDDL/DD Files...............................................................................................................................................................................................................1

FCI Configurator.............................................................................................................................................................................................................1

Installation........................................................................................................................................................................................................................2

General .........................................................................................................................................................................................................................2

Electrical Wiring............................................................................................................................................................................................................2

Topology and Network Configuration............................................................................................................................................................................4

Operation..........................................................................................................................................................................................................................5

Functional Description...................................................................................................................................................................................................5

Process Data Operation.................................................................................................................................................................................................5

ST100 HART Process Data Organization.......................................................................................................................................................................5

Device Description Files................................................................................................................................................................................................6

Service Data Operation.................................................................................................................................................................................................7

Setting the ST100 for the HART Protocol Operation ....................................................................................................................................................9

ST100 HART Command List ........................................................................................................................................................................................10

ST100 HART Universal Commands.............................................................................................................................................................................10

ST100 HART Common Practice Commands................................................................................................................................................................14

ST100 HART Device Specific Commands....................................................................................................................................................................15

ST100 HART DTM...........................................................................................................................................................................................................20

What is FDT-DTM Technology?...................................................................................................................................................................................20

How it works with the ST100 HART device?..............................................................................................................................................................20

ST100 HART DTM Installation and Setup examples..................................................................................................................................................21

How to get the information through ST100 HART DTM device .................................................................................................................................25

ST100 HART PDM...........................................................................................................................................................................................................28

HART Diagnostics...........................................................................................................................................................................................................32

Technical Characteristics................................................................................................................................................................................................35

Appendix A - Drawings...................................................................................................................................................................................................37

Appendix B - Customer Service / Technical Support .....................................................................................................................................................39

ii Fluid Components International LLC

06EN003404 Rev. A ST100 Series HART

INTENTIONALLY LEFT BLANK

ST100 Series HART

Fluid Components International LLC 1

Introduction

This manual describes the ST100 HART protocol 7.3 features, its operation and configuration. The ST100 can provide up to 4 different process

variables. It provides Flow, Temperature, Flow Totalizer, and Pressure, as outputs. The flow output can be selected as Volumetric, Mass

or Velocity units. The ST102 and ST112 can support up to two flow sensors and provides the average flow of the two sensors in a single output.

This documents is written to be used with all members of the ST100 product family configured with the HART 7.3 communication Protocol.

The HART output is provided through an extension card that is fully integrated into the ST100 instrument.

Denition

Universal HART Commands

A collection of commands that must be supported by all HART compatible devices. The Universal Command Specification establishes the minimum

Application layer support required of all HART devices. The Application layer defines the commands, responses, data types and status reporting sup-

ported by the Protocol.

Common Practice HART Commands

A collection of commands applicable to a wide range of devices. These commands shall be supported by devices whenever possible. The HART Com-

mon Practice Commands enhances interoperability by providing additional standardized, device-independent commands.

Device Specific Commands

Commands defined by the manufacturer according to the need of the Field device. The manufacturer of the Field device controls these commands.

The FCI ST100 family of products has 20 manufacturer specific commands.

EDDL/DD Files

Text files interpreted by the host system. The EDDL file is a file that tells the host what functionality the device (ST100) has, and how the functionality

is invoked. The EDDL also tells the host to do common maintenance functions such as calibration, configuration check status of individual sensors,

change engineering units, etc.

FCI Configurator

A PC software tool that gives access to the ST100 functions and features. It facilitates basic instrument setup and configuration, as well as advance

functions. The FCI configurator can interface through the ST100 USB Service port or the Ethernet Service port.

ST100 Series HART

2 Fluid Components International LLC

Installation

General

For details on the general mounting, placement of sensor head and mounting options see the Basic User Manual, 06EN003400.

Electrical Wiring

Access the wiring terminal block by removing the rear electrical connection cover. This cover can be locked closed by the cover locking screw.

Release the cover locking screw and remove the cover.

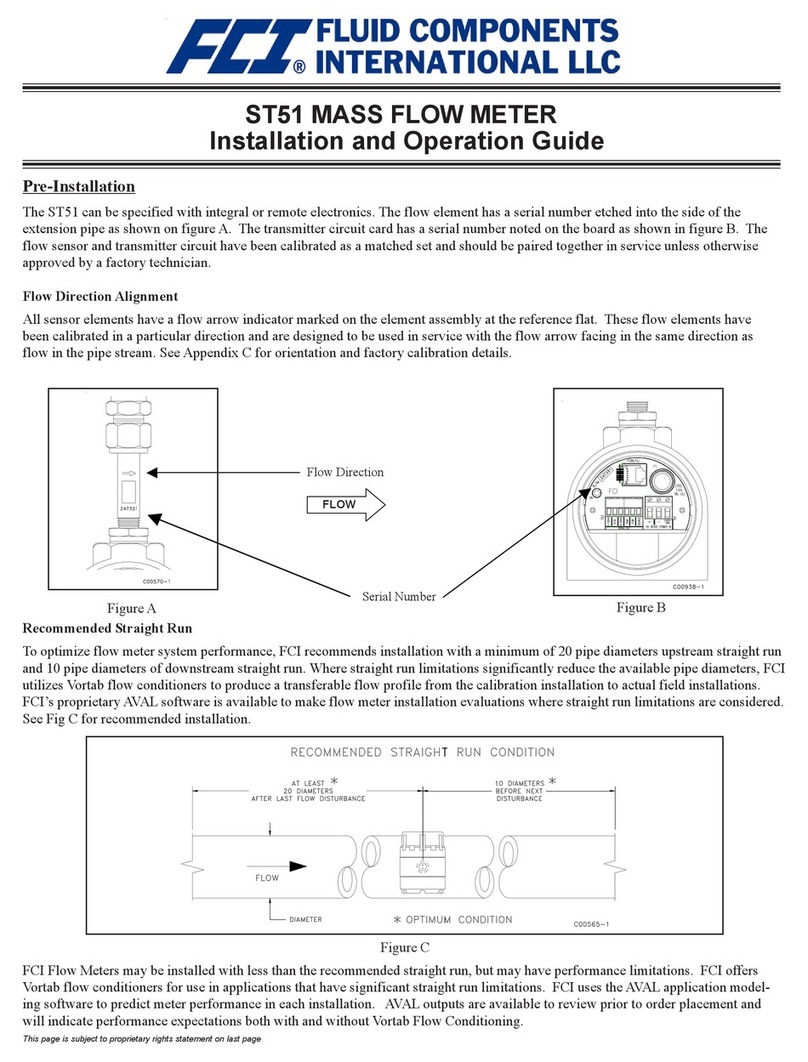

Cable access to wiring connections is obtained through one of the four conduit outlets, see Figure 6 below.

Figure 1 - HART Output Wiring Table

The HART connections for the ST100 are located in the back panel. The connector for the HART is P1A; the pins are labeled “CH1” and “RTN 1/2”.

The ST100 HART connections are non- polarized, but polarity needs to be observed for other manufacturer’s devices. Connect the HART bus cable as

noted below. See Appendix A for Channel 1 HART Connections on instruments shippped before April 2012.

Figure 6 - Instrument Wiring

See Appendix A for Channel 1 HART

Connections on instruments shippped

before April 2012.

ST100 Series HART

Fluid Components International LLC 3

Figure 3 - Detail External Power Supply connection for Non-Network

Figure 2 - Detail Internal Power Supply connection for Non-Network

ST100 Series HART

4 Fluid Components International LLC

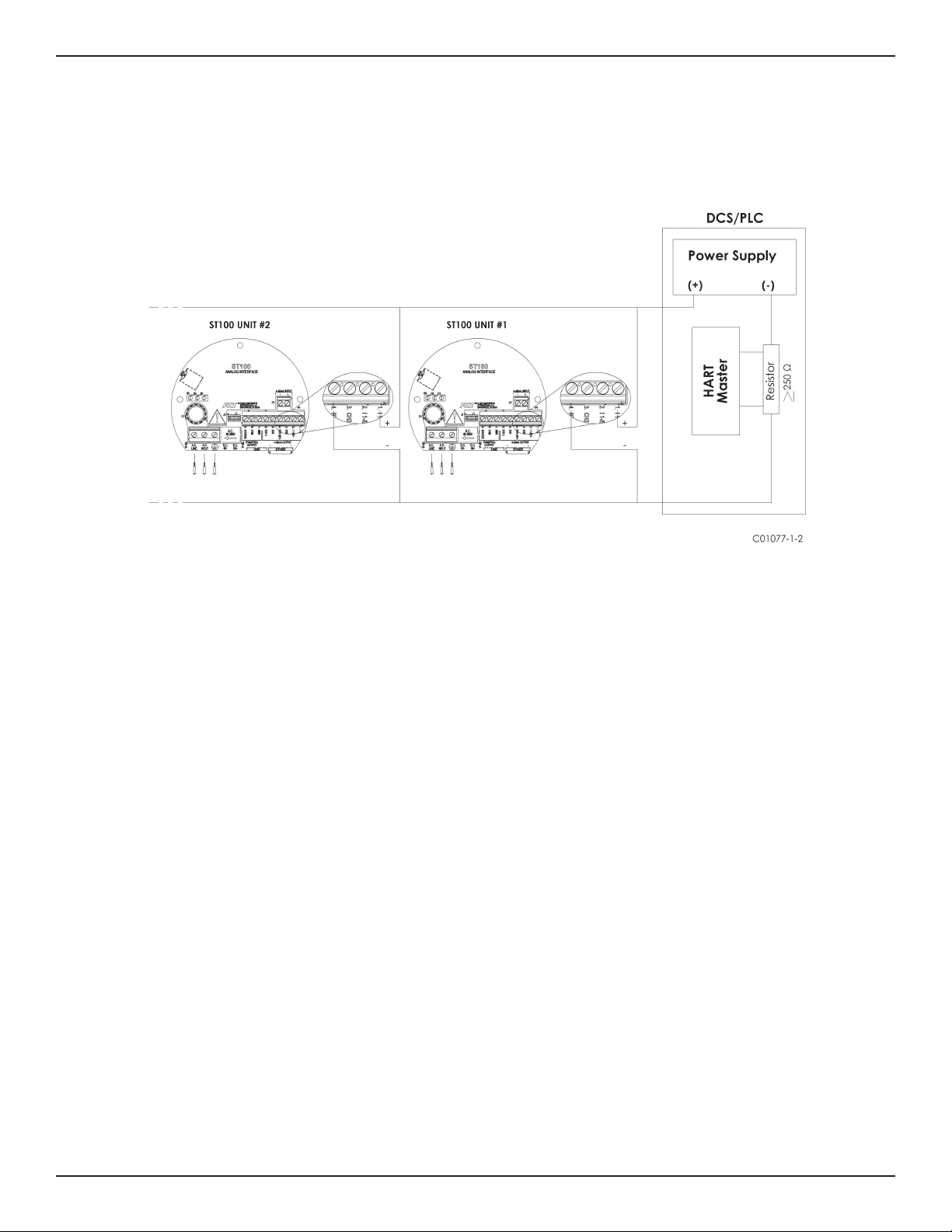

Topology and Network Configuration

The ST100 supports Multidrop topology. In multidrop operation, the devices exchange data and measured values only via the HART protocol/HART

Network. In Network configuration the analog current signal serves just to energize the two-wire devices, providing a current of 4 mA per instrument.

In multidrop mode, up to 15 field devices are connected in parallel to a single wire pair or segment (Figure 4). The host distinguishes the field devices

by their preset addresses that range from 1 to 255. The factory preset address is 0.

Figure 4 - Multidrop Mode with HART Transmitters

ST100 Series HART

Fluid Components International LLC 5

Operation

Functional Description

The primary function of the HART protocol is to present the instruments process data through its process data commands. Command 1, command 3

and command 9.

The ST100 does not implement the HART Burst mode. A HART master that supports HART 7.0 and higher is required. A HART communicator that

supports HART 7.0 and higher is required (e.g., Emerson 475 Communicator.)

Process Data Operation

Even though HART 7.0 is compatible with older versions of the HART protocol, the ST100 HART implementation and commands 1 and 3 are still sup-

ported, they contain the Flow Variable only, for the full set of Dynamic variables it is recommended that the HART master use command 9 to request

process data of dynamic variables and status.

ST100 HART Process Data Organization

It is important to briefly review how the ST100 Process data is organized under the HART command 9. For Details on Command 9 see the HART

Specification “Universal Commands Specification” HCF_SPEC-127, Revision 7.1.

Not all the variables described in this section are available in all configurations of the ST100 flow meter. For example not all configurations have

Process Pressure, and instruments that output Mass Flow or Volumetric flow, the Flow Totalizer may be turned on or off.

The following are the ST100 process variables that are provided through HART command 9.

There are 3 flow classes or types, and these are “Exclusively OR” meaning that only one class of flow is active at a time.

PROCESS VARIABLE SLOT # HART VARIABLE CODE

DESCRIPTION DEVICE VARIABLE CODE DEVICE VARIABLE

CLASSIFICATION

VOLUMETRIC FLOW * 0 PRIMARY VARIABLE 0 66

MASS FLOW * 2 PRIMARY VARIABLE 2 72

VELOCITY FLOW * 4 PRIMARY VARIABLE 4 67

VOLUME (TOTALIZER) 1 SECONDARY VARIABLE 1 68

MASS (TOTALIZER) 3 SECONDARY VARIABLE 3 71

TEMPERATURE 5 TERTIARY VARIABLE 5 64

PRESSURE 6 QUATERNARY VARIABLE 6 65

* Implies an “Exclusive OR” Releationship

Under the “Device Variable Status” parameter, for each process variable, only the four most significant bits are used.

The two most significant bits contain

“Process Data Status”: 11 = good

01 = Poor Accuracy

10 = manual/fixed

00 = bad

The two bits after the two most significant contain

“Limit Status”: 11 = constant

01 = low limited

10 = high limited

00 = not limited

Device variable status example: 1100XXXX.X, variable values indicated in positions represented by an ‘X’ can be ignored.

ST100 Series HART

6 Fluid Components International LLC

Device Description Files

EDDL Files

TThe ST100 EDDL files are support files that provide an extended description of each object in the Virtual Field Device (VFD), and provide information

needed for a control system or host to understand the meaning of the data in the VFD including the human interface. The EDDL file can be thought as

a “driver” for the device.

FCI provides two types of files; first the standard EDDL files located in the folder A67F0101, and the Emerson 375 and 475 files located in the folder

DDP.

A67F0101Folder:

0101.fm8

A67F0101.ddl

DDP Folder:

00A67F0101.hdd

00A67F0101.hhd

0101.fm8

A67F0101.ddl

Loading the DD Files to the 475 Field Communicator

In order to load the DDPs into the Field Communicator the “Easy Upgrade Utility from EMERSON must be used. Below is the procedure for how to

load DD files into the 475-Field communicator.

Open Field Communicator Easy Upgrade Utility program and click Utilities on the left hand menu; select Import DDs from local source. The following

window should pop up:

Select the FCI files and press “OK”.

ST100 Series HART

Fluid Components International LLC 7

Service Data Operation

The Service Data functions are organized into 3 areas:

1. ST100 Basic Setup

2. ST100 Configuration

3. ST100 Factory Calibration Limits

The service information is presented here as seen through the 475 HART communicator, with FCI’s EDDL files loaded. The same information seen by

the 475 is shown in the DCS when the ST100 HART EDDL files are loaded.

ST100 Basic Setup

The Basic Setup function includes the ability to review and change the

engineering units of the process variables, review and change the Plenum or

pipe size, enable or disable the Totalizer, review and change device informa-

tion, reset the operation of the ST100 to the factory settings, enable or disable

the write protect, and PV Setup.

Engineering Units Information

ST100 Series HART

8 Fluid Components International LLC

Factory Reset

WARNING

The factory Reset command re-loads the configuration and calibration

parameters that were loaded into the instrument during the original cal and

setup. Any changes made to the configuration of calibration parameters will be

lost when the Factory Reset command is executed.

ST100 Configuration

The configuration functions facilitate the setup of the individual 4 - 20 mA

current output channels.

ST100 Calibration Limits (example)

The ST100 Calibration Limits function provide you with the ability to review the

limits that have been set for each of the following process parameters: Flow,

Temperature, and Pressure.

ST100 Series HART

Fluid Components International LLC 9

Setting the ST100 for the HART Protocol Operation

Note:

If the ST100 was ordered as a 4-20 mA analog current output or a HART device, the factory will have configured the instrument for

HART operation, and it should not be necessary to do any instrument configuration.

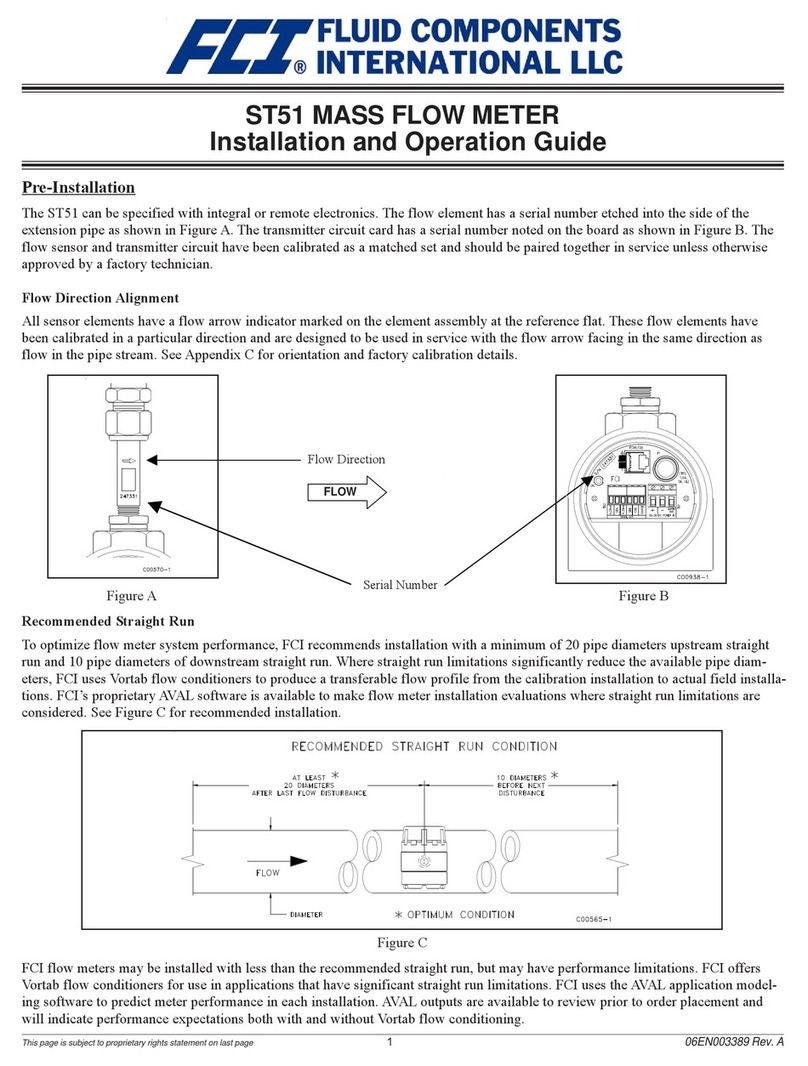

The ST100 PC Configurator tool is used to select the communication protocol with instrument power ON. In normal operating conditions, connect the

PC with the configurator software to the ST100 USB port using FCI’s cable (P/N 022646).

To configure the ST100 for HART open the ST100 Configurator . From the tree menu, on the left side select “Configuration”, and then select the

“Output” tab. In the Output tab select “Analog Output Board” and then select “4-20mA channel #1 as HART”. Verify the 4-20mA range values meet

the process requirements. Then press the “Send to Device” button to download the setting to the ST100 instrument.

Figure 5 - Communication via the USB Port

C01078-1-2

ST100 Series HART

10 Fluid Components International LLC

ST100 HART Command List

The ST100 HART commands are divided into three classes.

• Universal Commands

• Common Practice Commands

• Device Specific Commands

ST100 HART Universal Commands

The ST100 HART supports Universal Commands 0 through 22. Commands 4 and 5 are reserved under Universal Command

Specification Rev. 7.1 (HCF_SPEC-127, Revision 7.1) and not implemented in this specification. There is no HART command 10.

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

0

READ UNIQUE IDENTIFIER -

"254" "254"

UNSIGNED-8

EXPANDED DEVICE TYPE EXPAND DEV TYPE

ENUM (2 BYTE)

MINIMUM PREAMBLES - REQUEST MIN # PREAMBLES

UNSIGNED-8

HART PROTOCOL MAJOR REV HART PROTOCOL REV.

UNSIGNED-8

DEVICE REVISION LEVEL DEV. REV LEVEL

UNSIGNED-8

DEVICE SOFTWARE REVISION LEVEL SOFTWARE REV. LEVEL

UNSIGNED-8

ELECTRONICS REVISION LEVEL (HARDWARE) ELECTRONICS REV. LEVEL

UNSIGNED-8

PHYSICAL SIGNALING CODE STAK SOFT. REV

CODE 0 = BELL 202 CURRENT ENUM (1 BYTE)

FLAGS FLAGS

CODE 01 = MULTI SENSOR ENUM (1 BYTE)

DEVICE ID DEV. ID NUMB.

UNSIGNED-24

MINIMUM PREAMBLES - RESPONSE

UNSIGNED-8

MAXIMUM # OF VARIBLES MAX # VARIABLES

UNSIGNED-8

CONFIGURATION CHANGE COUNTER CONFIG CHANGE COUNT

UNSIGNED-16

EXTENDED FIELD DEVICE STATUS

UNSIGNED-8

MANUFACTURER ID CODE

FCI CODE = 166 DEC (00A6) ENUM (2 BYTES)

PRIVATE LABEL DIST. CODE

ENUM (2 BYTES)

DEVICE PROFILE CODE

ENUM (2 BYTES)

ST100 Series HART

Fluid Components International LLC 11

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

1

READ PV VARIABLE (FLOW PV UNITS CODE

UNITS, & FLOW VALUE) CHAR (1 BYTE)

PV VALUE

FLOAT (4 BYTE)

2

READ PV CURRENT AND % PV I VALUE (mA)

RANGE FLOAT (4 BYTE)

% PV VALUE

FLOAT (4 BYTE)

3

READ PV CURRENT OUT & ALL PV I VALUE (mA)

DYNAMIC VARIABLES FLOAT (4 BYTE)

FLOW UNITS PV UNITS CODE

CHAR (1 BYTE)

FLOW VALUE PV VALUE

(4 BYTE)

6

WRITE NODE ID (WRITE POLLING ADDRS

POLLING ADDRESS) CHAR (1 BYTES)

LOOP CUR MODE

CHAR (1 BYTES)

7

READ LOOP CONFIGURATION POLLING ADDRS

CHAR (1 BYTES)

LOOP CUR MODE

CHAR (1 BYTES)

8 READ DYNAMIC VARIABLE ENUM

CLASSIFICATIONS (4 BYTES)

9

READ DEVICE VARIABLES

WITH STATUS (UP TO 8 SLOTS)

EXTENDED FIELD DEVICE STATUS BITMAP

SLOT X DEV. VARIABLE CODE UNSIGNED-8

(1 BYTE)

SLOT X DEV. VARIABLE CLASS ENUM

(1 BYTE)

SLOT X UNITS COD ENUM

(1 BYTE)

SLOT X DEV. VARIABLE VALUE FLOAT

(4 BYTE)

SLOT X DEV. VARIABLE STATUS BITS

(1 BYTE)

9

SLOT X DATA TIME STAMP UNSIGNED-8

(BYTES 65 - 68) (4 BYTES)

11 READ UNIQUE IDENTIFIER ASSOCIATED W/TAG UNIQ. ID (TAG)

NOTE: SAME AS COMMAND "0" ( SEE COMMAND "0") BITSTRING (12 BYTES)

ST100 Series HART

12 Fluid Components International LLC

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

12 READ USER MESSAGE DEV. ID NUMB.

BITSTRING (12 BYTES)

13

READ TAG TAG

ASCII BIT STRING (6 BYTES)

READ DESCRIPTOR DESCRIPTOR

ASCII BIT STRING (12 BYTES)

READ DATE CODE DATE

ASCII BIT STRING (5 BYTES)

14

READ PV SENSOR INFO

SENSOR SERIAL NUMBER SENSOR S/N

UNSIGNED-24

LIMITS UNITS CODE - PV LIMITS UNITS CODES

ENUM (1BYTE)

UPPER SENSOR LIMIT - PV UPPER SENSOR LIMIT

FLOAT (4 BYTES)

LOWER SENSOR LIMIT - PV LOWER SENS LIMITS

FLOAT (4 BYTES)

MIN SPAN - PV MIN SPAN

FLOAT (4 BYTES)

15

READ OUTPUT INFORMATION

ALARM SELECT CODE ALRM SEL. CODE

ENUM (1BYTE)

TRANSFER FUNCTION CODE TRN. FUNC. CODE

CHAR (1BYTE)

FLOW RANGE UNITS CODE RNG UNITS CODE

CHAR (1BYTE)

FLOW UPPER-RANGE VAL UP RANG VALUE

FLOAT (4 BYTES)

FLOW LOWER-RANGE VAL LO RANG VALUE

FLOAT (4 BYTES)

FLOW DAMPING VALUE DAMPING VALUE

FLOAT (4 BYTES)

WRITE PROTECT CODE W PROTECT CODE

ENUM (1BYTE)

RESERVED (SET TO 250) RESERVED

ENUM (1BYTE)

16

READ FINAL ASSEMBLY NUMBER

ASSEMBLY NUMBER ASSEMB. #

UNSIGNED-24

17

WRITE MESSAGE

MESSAGE BITSTRING (24 BYTES)

ST100 Series HART

Fluid Components International LLC 13

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

18

WRITE TAG, DESCRIPTOR, DATE

TAG TAG

BITSTRING (6 BYTES)

DESCRIPTOR DESCRIPTOR

BITSTRING (12 BYTES)

DATE DATE

CHAR (3 BYTES)

19

WRITE FINAL ASSEMBLY NUMBER

ASSEMBLY NUMBER ASSEMB. #

UNSIGNED-24

20

READ LONG TAG

LONG TAG LONG TAG

BITSTRING (32 BYTES)

21

READ UNIQUE INDENTIFIER ASSOCIATED WITH LONG

TAG

UNIQUE IDENTIFIER

UNIQ. ID

BITSTRING (32 BYTES)

22

WRITE LONG TAG

LONG TAG LONG TAG

BITSTRING (32 BYTES)

ST100 Series HART

14 Fluid Components International LLC

ST100 HART Common Practice Commands

The ST100 HART supports Common Practice commands 35, 38, 40, 42, 44, 45, 46, 48, 50, and 51.

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

35

WRITE PV RANGE VALUES

RNG UNITS CODE

UNSIGNED-8

UPPER RANGE VALUE UPPER-RNG VAL

FLOAT (4 BYTES)

LOWER RANGE VALUE LOWER-RANGE VALUE

FLOAT (4 BYTES)

38 RESET "CONFIGURATION CHANGE" FLAG RESET CONFIG. CHANGE. FLAG

UNSIGNED-8

40 ENTER/EXIT FIXED CURRENT MODE (IN mA) I MODE SELECT

Value =0 means exit fixed current mode FLOAT (4 BYTES)

42

PERFORM DEVICE RESET

RESET INSTRUM.

UNSIGNED-8

44

WRITE PV UNITS

PV UNITS CODE

ENUM (1BYTE)

45

TRIM DAC ZERO - MEASURED CURRENT CHAN #1 IN

(mA)

TRIM_DAC_ZERO

FLOAT (4 BYTES)

46

TRIM DAC GAIN - MEASURED CURRENT CHAN #1 IN

(mA)

TRIM_DAC_GAIN

FLOAT (4 BYTES)

48

READ ADDITIONAL DEVICE STATUS 25 BYTES

DEVICE-SPECIFIC STATUS

6 BYTES

EXTENDED DEVICE STATUS

1 BYTE

DEVICE OPERATING MODE

1 BYTE

STANDARIZED STATUS 0

1 BYTE

STANDARIZED STATUS 1

1 BYTE

ANALOG CHAN SATURATED

1 BYTE

STANDARIZED STATUS 2

1 BYTE

ST100 Series HART

Fluid Components International LLC 15

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

48

STANDARIZED STATUS 3

1 BYTE

ANALOG CHAN FIXED

1 BYTE

DEVICE SPECIFIC STATUS

11 BYTES

50

READ DYNAMIC VARIABLE ASSIGNMENTS

PRIMARY DEVICE VARIABLE 1 BYTE

SECONDARY DEVICE VARIABLE N/A

TERTIARY DEVICE VARIABLE N/A

QUATERNARY DEVICE VARIABLE N/A

51

WRITE DYNAMIC VARIABLE ASSIGNMENTS 1 BYTE

PRIMARY DEVICE VARIABLE 1 BYTE

SECONDARY DEVICE VARIABLE N/A

TERTIARY DEVICE VARIABLE N/A

QUATERNARY DEVICE VARIABLE N/A

ST100 HART Device Specific Commands

The ST100 HART supports 20 Device Specific commands.

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

137

READ TOTALIZER VALUE

READ TOTALIZER

FLOAT (4BYTES)

138

READ TOTALIZER STATE

READ TOT STATE

UNSIGNED-8

139

WRITE TOTALIZER STATE

READ TOT STATE

UNSIGNED-8

140

READ DEVICE INFORMATION

DEVICE CO DEVICE CO

ASCII BITSTRING (10 BYTES)

DEVICE SERIAL NUMBER DEVICE S/N

ASCII BITSTRING (10 BYTES)

DEVICE SOFTWARE VER DEV SOFTW VER

ASCII BITSTRING (4 BYTE)

159 WRITE FACTORY RESTORE FACT_RESTORE

ENUM (1 BYTE)

ST100 Series HART

16 Fluid Components International LLC

HART COMM NUMB. HART COMMAND DESCRIPTION HART DATA TYPE & SIZE

145

READ CUSTOMER ENGINEERING UNITS

FLOW UNITS CODE FLOW CODE

UNSIGNED-8

TEMPERATURE UNITS CODE TEMP CODE

UNSIGNED-8

TOTALIZER UNITS CODE TOTAL CODE

UNSIGNED-8

PRESSURE UNITS CODE PRESS CODE

UNSIGNED-8

146

WRITE CUSTOMER ENGINEERING UNITS

FLOW UNITS CODE FLOW CODE

UNSIGNED-8

TEMPERATURE UNITS CODE TEMP CODE

UNSIGNED-8

TOTALIZER UNITS CODE TOTAL CODE

UNSIGNED-8

PRESSURE UNITS CODE (optional) PRESS CODE

UNSIGNED-8

148

READ PLENUM INFORMATION (PIPE SIZE)

PLENUM HEIGHT VALUE PIPE_HEIGHT

FLOAT (4BYTES)

PLENUM WIDTH (DIAM) VALUE PIPE_WIDTH

FLOAT (4BYTES)

PLENUM UNITS CODE PIPE_CODE

UNSIGNED-8

149

WRITE PLENUM INFORMATION (PIPE SIZE)

PLENUM HEIGHT VALUE PIPE_HEIGHT

FLOAT (4BYTES)

PLENUM WIDTH (DIAM) VALUE PIPE_WIDTH

FLOAT (4BYTES)

PLENUM UNITS CODE PIPE_CODE

UNSIGNED-8

150 WRITE "WRITE PROTECT" MODE WRITE_PROT

UNSIGNED-8

Other manuals for ST100 series

4

Table of contents

Other FCI Measuring Instrument manuals

FCI

FCI ST51 Operating instructions

FCI

FCI ST75 Operating instructions

FCI

FCI FLT93B Instruction manual

FCI

FCI ST51-1 Operating instructions

FCI

FCI ST100 series Mounting instructions

FCI

FCI MT100 User manual

FCI

FCI ST100 series Mounting instructions

FCI

FCI ST100 series Owner's manual

FCI

FCI ST80 Series Instruction manual

FCI

FCI ST50 User manual

Popular Measuring Instrument manuals by other brands

PHYWE

PHYWE Cobra SMARTsense Chloride Ion operating instructions

Endress+Hauser

Endress+Hauser EngyCal RS33 Brief operating instructions

Tegam

Tegam AVM-2000 Instruction and service manual

Sokkia

Sokkia CX-52 Operator's manual

Geometrics

Geometrics G-877 Operation manual

SolarV

SolarV EPEVER MT11 instruction manual