GENERAL ST80/ST80L Flow Meter

4 Fluid Components International LLC

■Operating Temperature (Process)

ST80 Insertion Style (FPC, FP, and Ssensor head types)

CompressionFitting Integral/Remote

LowPressurePackingGland Integral/Remote

Med. Pressure PackingGland Integral/Remote

FixedNPT Integral/Remote

FixedFlange(1"orDN25) Integral/Remote

Fixed Flange (≥1½" or ≥DN40) Integral/Remote

Notes: 1. Minimum temperature is -40 °F [-40 °C].

2. For Teflon ferrule max. temperature is 200 °F (93 °C).

ST80L In-line Style ( Fand Ssensor head types)

-40 °F to 257 °F [-40 °C to 125 °C]

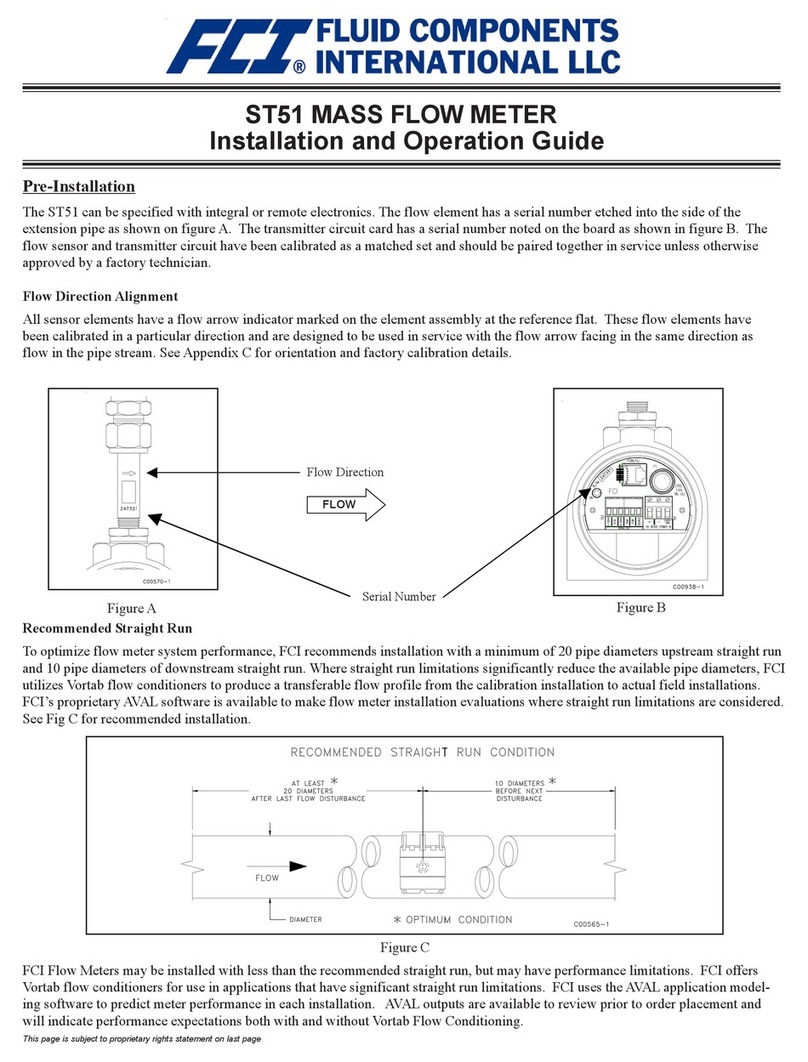

■Model ST80, Process Connections and Insertion Lengths

Compression Fittings: Model ST80 only

¾" or 1" male NPT, stainless steel with adjustable Teflon

ferrule or metal ferrule; or flanged tapped and threaded for ¾"

fitting, ANSI or DIN flanges.

Compression fittings not available with 850 °F [454 °C]

temperature versions of ST80.

Retractable Packing Glands

Low pressure 50 psig [3,5 bar (g)] or medium pressure 500

psig [34 bar (g)] with graphite or Teflon packing material; 1¼"

male NPT or ANSI or DIN flange.

Teflon packing required when process media is ozone, chlorine

or bromine. Remote mount required when medium pressure

packing gland is required.

Fixed Fittings/All Welded

1" male NPT, ANSI or DIN flange

Insertion Length

Field adjustable lengths:

1" to 6"[25 mm to 152 mm]

1" to 12"[25 mm to 305 mm]

1" to 21"[25 mm to 533 mm]

1" to 36"[25 mm to 914 mm]

1" to 60"[25 mm to 1524 mm]

Fixed lengths from 2.6" to 60" [66 mm to 1524 mm]

■Model ST80L, In-line Flow Body and Process Connections

Flow element is calibrated and supplied as a spool-piece; options

include low flow injection tubes and built-in Vortab flow

conditioners for optimum low flow rangeability and performance

Size: 1" diameter tubing; 1", 1½", or 2" Schedule 40 pipe;

1" Schedule 80 pipe

Length: 9 nominal diameters

Process Connections: female NPT, male NPT, ANSI or DIN

flanges, or butt weld prepared

Option: Flanges sized for flow tube

■Remote Transmitter Configurations

Transmitter may be mounted remotely from flow element using

interconnecting cable (up to 1000 ft [300 m]). Remote configura-

tion required with selection of medium pressure packing gland.

Flow Transmitter/Electronics

■Operating Temperature

-40 °F to 140 °F [-40 ° C to 60 °C]

■Input Power

AC: 100 VAC to 240 VAC, 50 Hz to 60 Hz

DC: 24 VDC (19.2 – 28.8 volts)

■Power Consumption

■Battery Backup (for RTC)

Industrial-spec 3V Lithium coin cell type CR2450N

■Outputs

Analog

Standard: Two (2) 4-20 mA outputs*.

4-20 mA outputs are user assignable to flow rate and tempera-

ture; outputs are user programmable to full flow range or subsets

of full flow range.

* Outputs are isolated and have fault indication per NAMUR

NE43 guidelines, user selectable for high (>21.0 mA) or low

(<3.6 mA)

HART (comes standard with analog outputs), V7 compliant.

Digital

Standard: USB (service and configuration port only); Modbus

RS-485

Optional: FOUNDATION Fieldbus H1, PROFIBUS PA, or

PROFIBUS DP.

FF Physical Parameters

Maximum Network Input Voltage - Ui (in V) = 32

Maximum Network Input Current - li (in mA) = 13

■Enclosures

Main Transmitter/Electronics:

NEMA 4X, IP66/67 polyester powder coated aluminum or

optional 316L stainless steel.

Four (4) cable ports ½"-14 NPT or M20 x 1.5

Size: 5" W x 5.40"Hx7.75"L(127mmx137 mmx197mm)

Local Enclosure (Remote Configuration):

•Single cable port enclosure (available with packing gland/low and

med press; ≥1.5" fixed flange; fixed NPT process connections):

NEMA 4X, IP66/67 polyester powder coated aluminum or

optional 316L stainless steel.

One (1) cable port 1"-11.5 NPT

Size:4.68" W x 4.87" H x 5.4" L (119 mm x 124mm x 137 mm)

•Dual cable port enclosure (available with compression fitting;

1" fixed flange process connections):