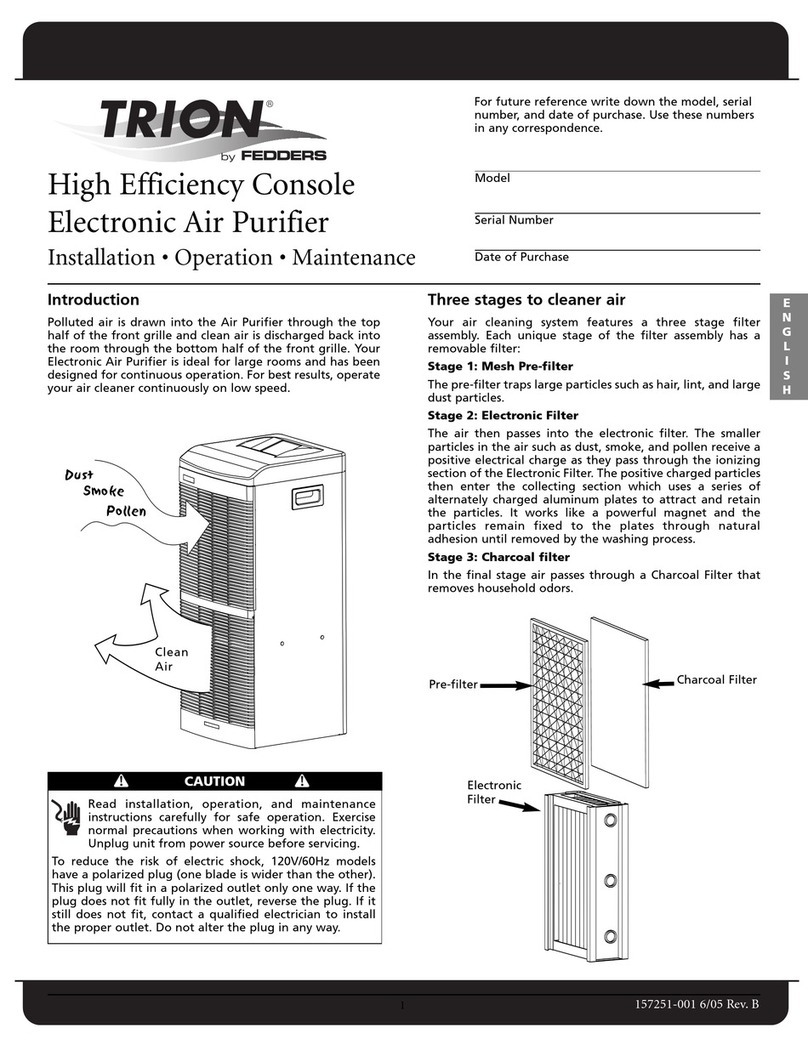

Fedders Trion PORT-A-CART Operation manual

PORT-A-CART™

Portable Cartridge Air Cleaner

•INSTALLATION

•OPERATION

•SERVICE

For Industrial Applications

www.trioninc.com

Manual Part Number 157199-001· March 2004

2

Table of Contents

Specifications....................................................................................3

System Design..................................................................................3

Installation.........................................................................................3

Unpack and Inspect................................................................3

Installing Source Capture Arm ...............................................3

Positioning the Unit ................................................................4

Electrical Power Requirements.........................................................4

Operation ..........................................................................................4

Maintenance......................................................................................5

Cleaning Filter........................................................................5

Manual Cleaning ....................................................................5

Optional Pulse Cleaning.........................................................5

Recommended Operating Range...........................................5

The Cartridge Filter...........................................................................6

To Remove and Replace Filter...............................................6

Warranty............................................................................................6

Troubleshooting Guide......................................................................7

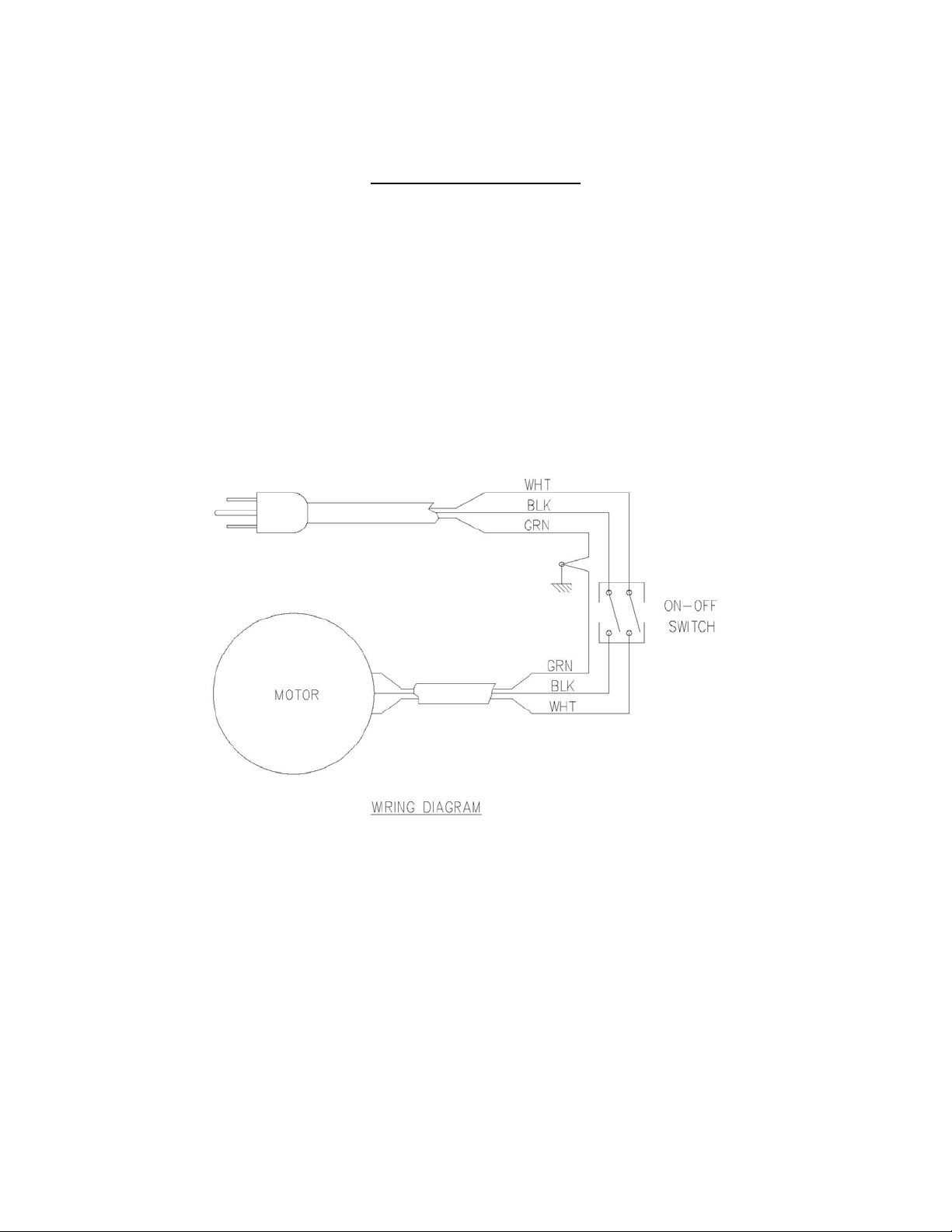

Figure 1 Wiring Diagram...................................................................8

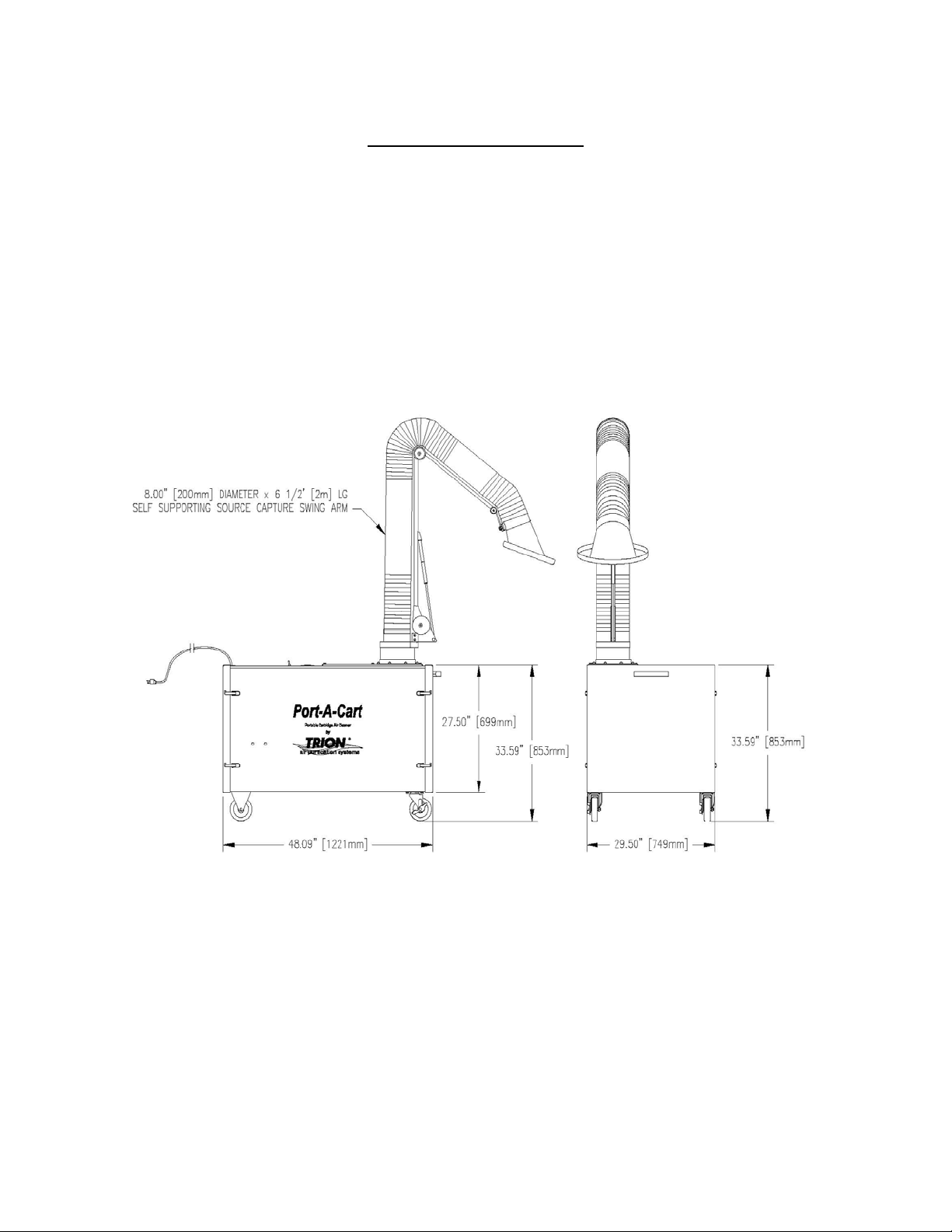

Figure 2 Outline Diagram..................................................................9

Parts List.........................................................................................10

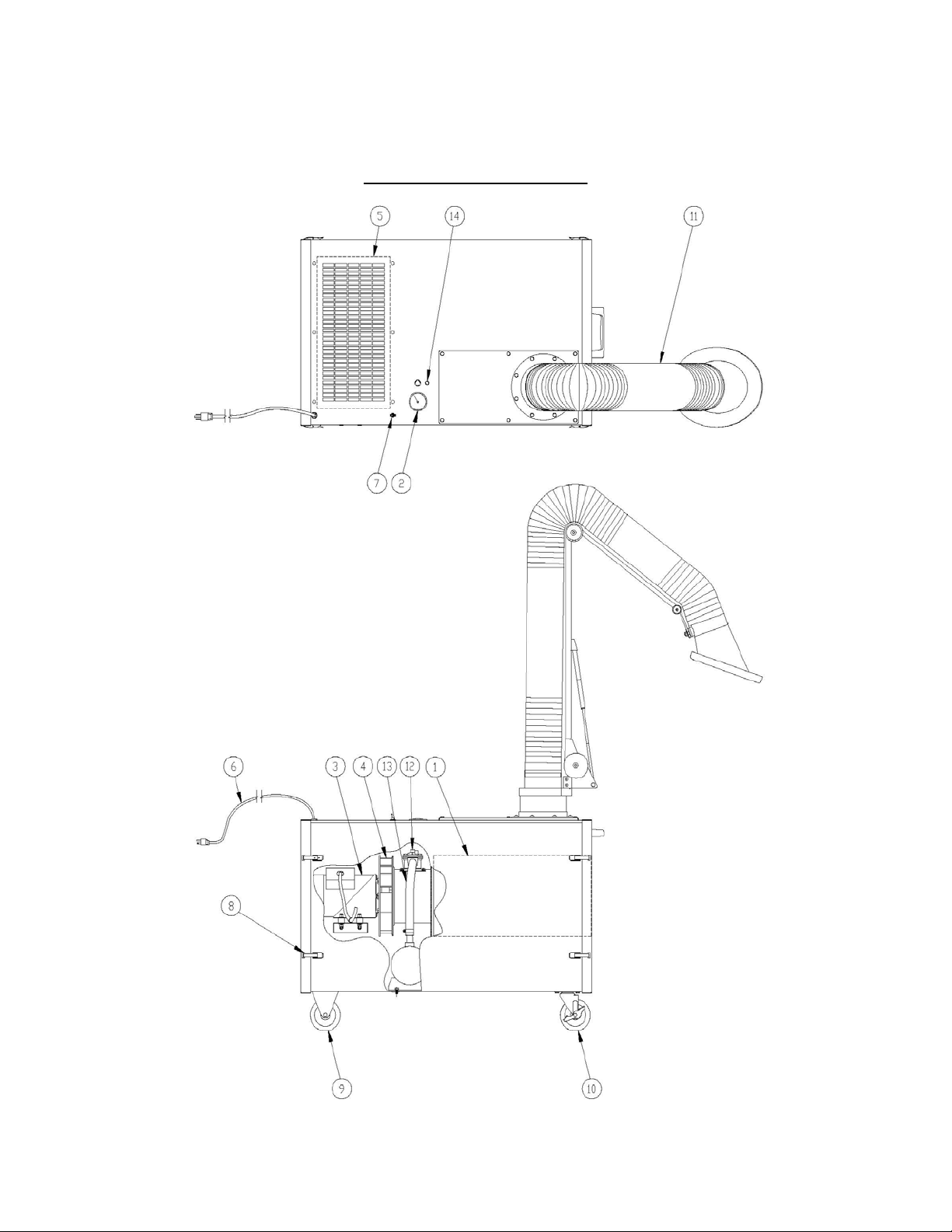

Figure 3 Parts List Diagram ............................................................11

Contact Information.........................................................................12

CAUTION:

READ INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS CARE-

FULLY FOR SAFE OPERATION

EXERCISE EXTREME CAUTION WHEN WORKING WITH ELECTRICITY

3

SPECIFICATIONS: PORT-A-CART™

Power Requirement: 120 volts, 60 Hz,

1 Phase, 17 amps,

1612 watts

Weight: 400 lbs. (180 kg)

Dimensions: 48.1”L x 29.5” W x 33.5” H

(1222 x 749 x 851 mm)

Filter Area: 190 Sq. Ft. (17.7 Sq. m)

Backflush Air Pressure: 80-120PSI(1/4” shop hose

or larger)

5.5-8.3 Pascals (6mm

shop hose or larger)

Arm: 6.5’ L, 8” diameter

externally supported

with 360 rotation

(2m x 200mm)

Pick-Up Velocity: 2000 FPM (10 MPS)

Duct Velocity: 2900 FPM (15 MPS)

Capture Zone: 12” to 18”

(300 to 450mm)

Filtered Air: 1000 CFM (1700 M3H)

SYSTEM DESIGN

SYSTEM DESIGN AND LAYOUT

WARNING!

The Port-A-Cart is NOT designed to collect

wet or oily particulate and should not be in-

stalled in applications collecting coolants,

grease, processing fluids or other types of

liquid aerosols. Contact the Trion sales de-

partment for special units for these type in-

stallations at 800-884-0002.

The Port-A-Cart Cartridge Air Cleaner is de-

signed to pick-up and collect dry solid particu-

late such as weld fumes and industrial dust.

Clean air is then discharged back into the

work space. The unit is equipped with cast-

ers, a source capture arm, a filtration compart-

ment, and a blower compartment. Simply roll

the unit to a level location near the source of

pollutants, adjust the arm, and place the cast-

ers in the locked position. Then connect the

electrical power and the unit is ready for op-

eration.

In operation, the pick-up arm delivers the con-

taminated air to the cartridge filter for collec-

tion. A Minihelic gauge monitors the pressure

across the cartridge filter and indicates when

cleaning should take place.

INSTALLATION

1. UNPACK AND INSPECT

Upon receipt, all shipping containers and their

contents should be examined for damage. Any

damage occurring in shipment must be imme-

diately reported to the carrier, an inspection

report completed and a claim filed with the

carrier at the receiving point.

The Port-A-Cart cabinet is shipped assem-

bled. Please check to ensure all components

are included:

• Painted steel cabinet with integral car-

tridge filter, casters, and power cord

• Minihelic gauge

• Drop-Out tray

• Source capture arm, hood, and mounting

hardware (shipped loose)

• Impregnated carbon filter (odor control)

2. INSTALLING SOURCE CAPTURE ARM

To simplify packaging and reduce the possibil-

ity of shipping damage, the source capture

arm is shipped separately. The necessary

mounting hardware is included with the arm.

Using washers and bolts provided, secure the

arm to the cabinet. The mounting holes are

pre-drilled. The tension is adjustable at each

arm elbow (five places). The hood tension

adjustment is located outside the hood.

4

3. POSITIONING THE UNIT

Roll the unit to a level floor space in the area in

which it is to be used. When the unit has been

properly positioned, lock the two swivel casters to

prevent movement during operation.

WARNING !

Combustible Materials Hazard

Can Cause Personal Injury, Death or

Equipment Damage

1. Due to potential fire hazards, do not mix

combustible materials with those that

would be a potential source of ignition.

Examples of combustible materials in-

clude but are not limited to: wood dust,

paper dust, lint from fabrics or buffing

wheels, grinding dust from painted sur-

faces and aluminum or magnesium

dusts. Examples of potential ignition

sources include but are not limited to:

grinding dust from ferrous metals or

sparks from any source.

2. This equipment should not be used for

the collection of any materials where

there is a risk of explosion. Pressure

relief or explosion vents should not be

applied to the equipment or any adjoin-

ing system.

3. Equipment location, installation and op-

eration should comply with all national

and local fire codes. When in doubt,

consult the proper authorities.

4. Workers and machine operators should

be instructed to keep any burning ob-

jects, such as cigarettes, safely away

from air inlets leading to the equipment.

5. All those involved with the use of this

equipment should comply with the

statements pertaining to worker safety

as noted in this manual.

WARNING !

Electric Shock Hazard

Can Cause Electrical or Equipment

Damage

Do not connect power before the installa-

tion is complete.

ELECTRICAL POWER REQUIREMENTS

The blower motor is 1 1/2 HP requiring a 120

volt, 60 Hz, 1 ph (17 amp) source of power.

The unit is supplied with a 10’ (4.7 m) power

cord.

OPERATION

Plug the power cord into a 120 volt, 60 hertz

outlet. Turn the power switch on.

5

MAINTENANCE

WARNING !

Sharp Edges Can Cause

Personal Injury

Wear protective gloves to prevent cuts from sharp

edges.

CLEANING FILTER

Quality equipment, such as your Trion Port-A-

Cart cartridge air cleaner, will require minimum

maintenance to keep it in good operating condi-

tion. The motor is a totally enclosed, fan-cooled

type with permanently lubricated bearings. No

maintenance is required other than to routinely

check for foreign debris in the arm hood, the

drop-out tray and the motor blower compart-

ments. Rubber gaskets should be checked twice

a year. Aging occurs primarily due to ozone pre-

sent in ambient air and eventually hardens the

rubber and causes cracking and loss of seal.

Contact Trion for replacement parts at

800-884-0002.

MANUAL CLEANING

The Minihelic gauge, located on the top surface

of the unit, monitors static pressure across the

cartridge filter. Note the gage reading on initial

start-up. As contaminants collect, the static pres-

sure will increase until the pick-up or capture

zone becomes ineffective. Filter cleaning is re-

quired at this point. Again, note the static pres-

sure gage reading. The clean filter and dirty filter

readings may be used for future reference in de-

termining the cleaning cycle.

To clean the filter cartridge, turn the unit blower

off and close the damper in the pick-up arm. Re-

move the filter access cover. Using a com-

pressed air gun or nozzle, backflush contami-

nants from the cartridge filter by directing the air

through the filter from the center of the cartridge.

The particulate blown from the cartridge is col-

lected in the dust tray located below the filter.

When the filter cleaning is complete, the dust tray

may need to be emptied.

Return the unit to operation by reattaching the

filter access cover and opening the damper in the

pick-up arm.

OPTIONAL PULSE CLEANING

A backflush pulse cleaning system is avail-

able. It consists of an air tank, a pulse valve

and a manual switch. The air tank is located

inside the blower compartment. The pulse

valve is located to direct a blast of air into the

center of the cartridge from the blower end.

The actuator switch is located on the top sur-

face of the unit.

To clean the cartridge, turn the unit off and

close the damper in the pick-up arm. Connect

a dry/ clean compressed air source (80-120

PSI, 5.5-8.3 Pascals) to the air inlet on the

top surface of the unit. The built-in air tank will

fill from the connected air supply. When the

tank is full, the air flow stops. Initiate back-

flushing by pushing the pulse switch. Repeat

the pulse cycle several times for best results.

When the filter cleaning is complete, the dust

tray may need to be emptied.

Return the unit to operation by reattaching the

filter access cover and opening the damper in

the pick-up arm.

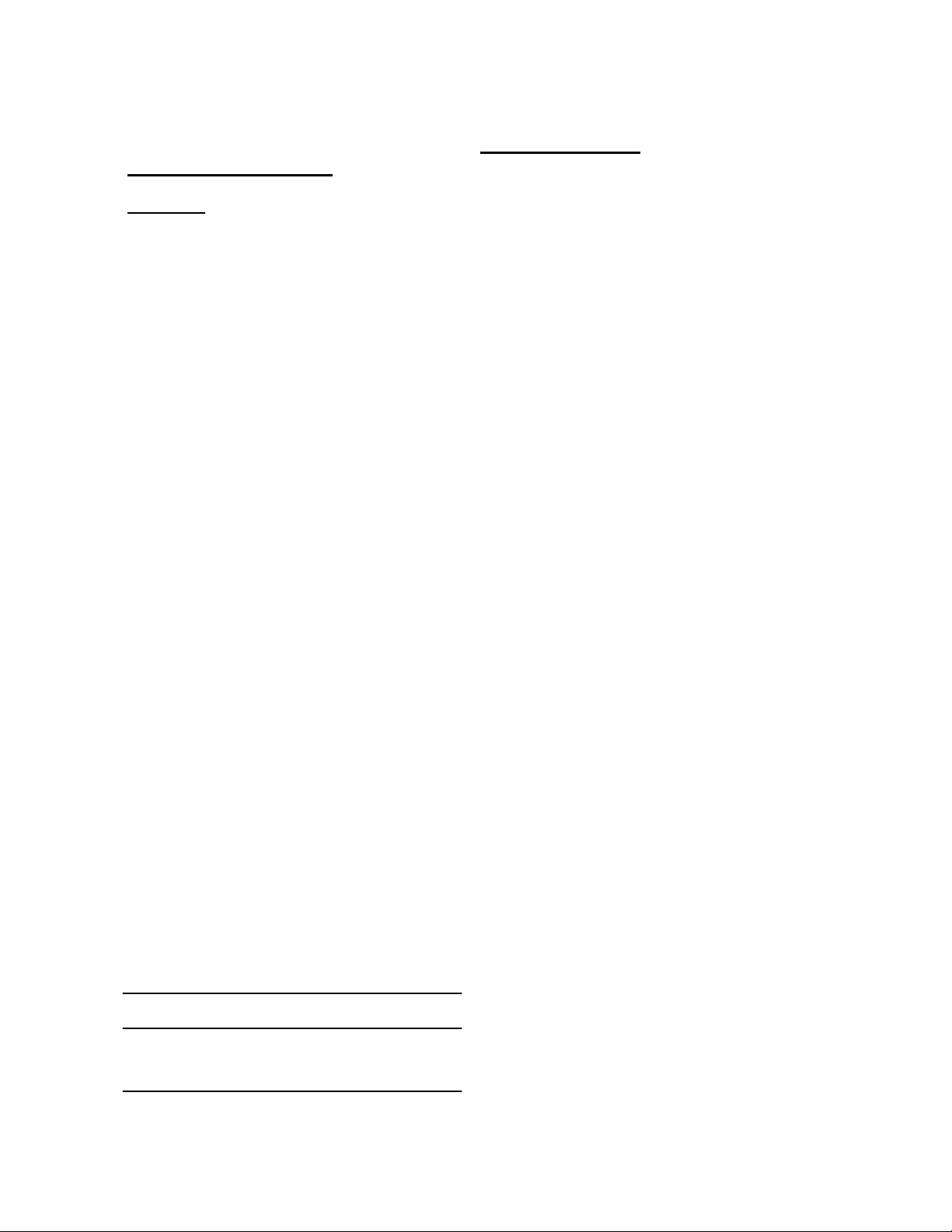

RECOMMENDED OPERATING RANGE

* Resistance across the filter will increase

over time as contaminants become embedded

in the filter fibers. A reduction of 0.15” - 0.25”

after pulsing 5-10 times is common.

** When repeated pulsing and manual

cleaning does not reduce the gauge reading

below this range, airflow is typically insufficient

and the cartridge should be replaced.

Condition Gauge Reading Air Flow

New Filter,

No Pre-coat 1.8” -1.9” 1020-1000 CFM

New Filter,

After Pre-coat 2.1” - 2.2” 1000 CFM

Recommended

pulse range,

initial

2.4” - 2.5” 970-930 CFM

Recommended

pulse range,

final*

2.7” - 2.8” 910-885 CFM

Replace filter** 3.0” - 3.2” 800-700 CFM

6

THE CARTRIDGE FILTER

CAUTION: Before servicing any portion of

the air cleaner:

1. Disconnect the electrical power.

2. Shut off and bleed the compressed air

supply.

The backflushing process may lose effectiveness

on removing collected contaminants after ex-

tended use. (The filter life may be extended by

removing the filter from the cabinet and manually

directing compressed air into the center of the

filter to dislodge contaminants.)

TO REMOVE AND REPLACE FILTER

NOTE: Depending on the contaminant col-

lected, it may be advisable to wear a dust res-

pirator when handling dirty filters.

1. Open filter access cover.

2. Move cartridge filter slightly up and down to

break the rear gasket seal.

3. Rotate the cartridge 1/2 turn to permit any

loose contaminant falling from the top of the

elements.

4. Slide the cartridge filter out of the compart-

ment.

5. Clean any dust deposits from the rear gasket

seal area to assure a positive seal for the

replacement cartridges.

6. Remove excess contaminant from bottom of

compartment by brushing out or by vacuum-

ing.

7. Install new cartridge and replace access

cover.

WARNING !

Electric Shock Hazard

Can Cause Personal Injury or Death

LIMITED WARANTY

Trion warrants the equipment of its manufacture

to be free from defects in workmanship and ma-

terial for a period of 36 months after shipment.

This warranty is limited, however, to the repair or

replacement of defective equipment, which is

returned, freight prepaid, to manufacturer’s fac-

tory. This warranty does not cover any of the

replacement filters in the unit, i.e. cartridge filter,

HEPA (optional), Impregnated after filter.

This limited warranty does not apply to any part

or component that is damaged in transit or when

handling, has been subject to misuse, negli-

gence or accident, has not been installed, oper-

ated or serviced according to Seller's instruc-

tions, or has been operated beyond the factory

rated capacity or has been altered in any way.

Trion’s liability is limited to replacement of defec-

tive parts or components and does not include

any cost of labor (including, but not limited to,

labor required to remove and/or reinstall any de-

fective part) other than Trion factory labor.

Trion shall not be responsible for loss of use of

any product, loss of time, inconvenience, or dam-

age to other equipment or any other indirect or

consequential damage with respect to property

whether as a result of breach of warranty, neglect

or otherwise.

THE WARRANTIES AND LIABILITIES SET

FORTH ABOVE ARE IN LIEU OF ALL OTHER

WARRANTIES AND LIABILITIES, EXPRESSED

OR IMPLIED, IN LAW OR IN FACT, INCLUDING

ANY IMPLIED WARRANTIES OF MERCHANT-

ABILITY AND FITNESS FOR PARTICULAR

PURPOSE.

The foregoing shall constitute the total liability of

Seller in the case of defective performance of all

or any of the equipment or services provided to

Buyer. Buyer agrees to accept and hereby ac-

cepts the foregoing as the sole and exclusive

remedy for any breach or alleged breach of war-

ranty by seller.

7

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE SOLUTION

Unit fails to start No power to the unit

Faulty motor

Faulty control switch

Check circuit

Replace motor

Replace switch

Capture velocity low Dirty Filters

Obstruction in arm

Backflush (Pulse)

Manually clean or replace filters

Remove obstruction

Vibration Foreign object in blower

Dirty filters

Obstruction in arm

Remove obstruction

Backflush, manually clean or

replace

Remove obstruction

Optional cleaning system not

cleaning filters Faulty air diaphragm

Shop air pressure

Check to insure internal air line

is in place. Check diaphragm

operation by removing both fil-

ters and initiate pulse. Replace

if necessary.

Shop air must be 80-120 PSI

filtered and dry.

CAUTION: During maintenance, filter replacement, or troubleshooting, make certain the

power cord has been disconnected and the blower has completely stopped. The unit should

not be operated with the filter access door open.

8

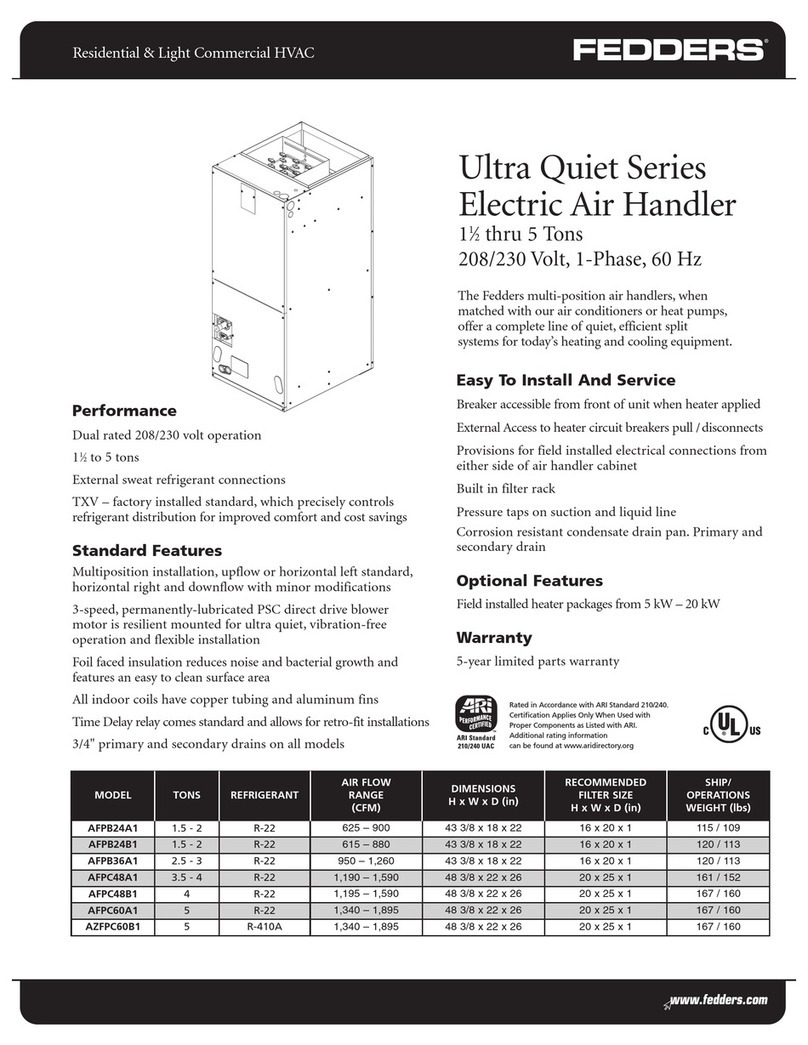

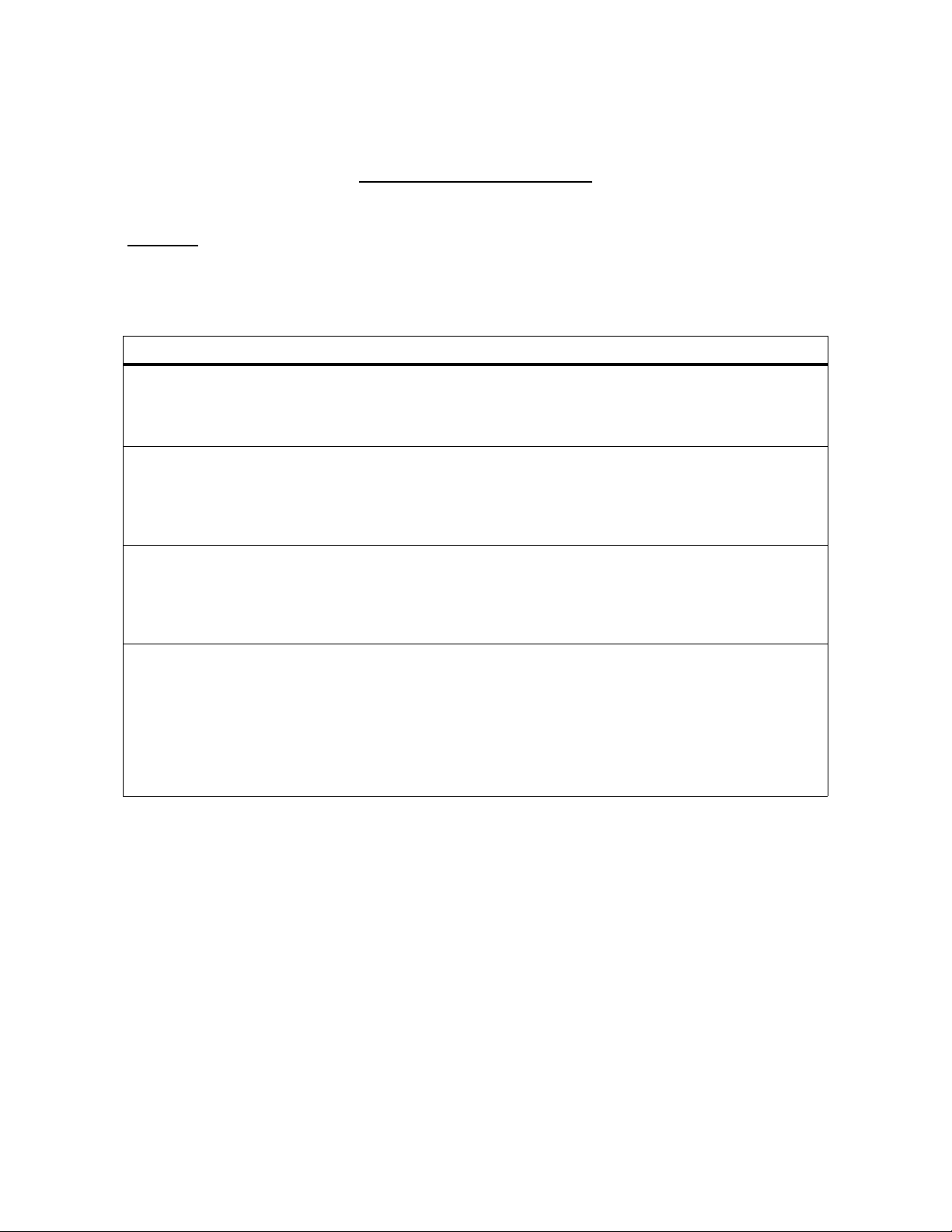

Figure 1—Wiring Diagram

9

Figure 2—Outline Diagram

10

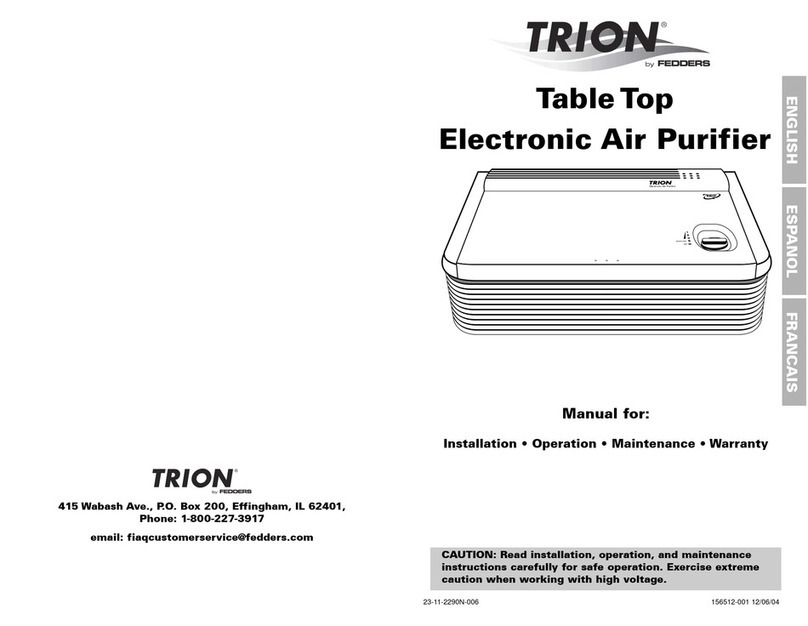

Reference Key Qty. per unit Part Number Description

1 1 251100-001 Cartridge Filter

2 1 145443-001 Minihelic Gage, 0-5”

3 1 150825-001 Motor, 1 1/2 Hp, 120/208-230 volt

4 1 250827-001 Blower Wheel

5 1 256941-001 Impregnated Carbon Filter

6 1 256950-002 Power Cord

7 1 238001-002 Toggle Switch, DPST

8 8 245386-017 Latch

9 2 252122-001 Caster, 5”, Fixed

10 2 252122-002 Caster, 5”, Swivel

11 1 354970-012 Fume extractor (pick-up) Arm

12 1 145439-003 Diaphragm Valve, 3/4” (optional)

13 1.33 147039-002 Hose, 1” ID (optional)

14 1 257214-001 Pushbutton Valve (optional)

PARTS LIST

See Figure 3

11

Figure 3-Parts List Diagram

12

Contact Information

Headquarters

Trion, Inc. Trion LTD.

101 McNeill Rd. The Cavendish Center

Sanford, NC 27330 Winnall Close

Tel. 919 775 2201 Winchester, Hampshire

Fax 919 777 6399 SO23 OLB, UK

www.trioninc.com Tel. 44 0 1962 840465

Trion GmbH Fedders International

Boscstr. 60 No. 728 Fuzhou Rd.

D-50171, Kerpen Rm. 3002-3005

Germany Raffles City Office Tower

Tel. 49 0 2237 922 103 Shanghai, P.R. China, 200001

Fax 49 0 2237 922 104 Tel. 86 21 63403232

Fax. 86 21 63403867

Fedders International Fedders International, Inc.

Air Conditioning 128 Joo Seng Road

A-30, Chintels House #05-01

Kalish Colony DP Computers Building

New Delhi Singapore 368 356

India 110048 Tel. 65 6286 0995

Tel.91 11 5173 0730 Fax. 65 6286 0859

Fax91 11 5173 0743

Table of contents

Other Fedders Air Cleaner manuals