Fein ASq 658 User manual

Other Fein Drill manuals

Fein

Fein HandyMaster ABS 18V Quick start guide

Fein

Fein KBH25 User manual

Fein

Fein BOP6 User manual

Fein

Fein BOP6 User manual

Fein

Fein ABS18 Q User manual

Fein

Fein KBB60X User manual

Fein

Fein DSk658-1 User manual

Fein

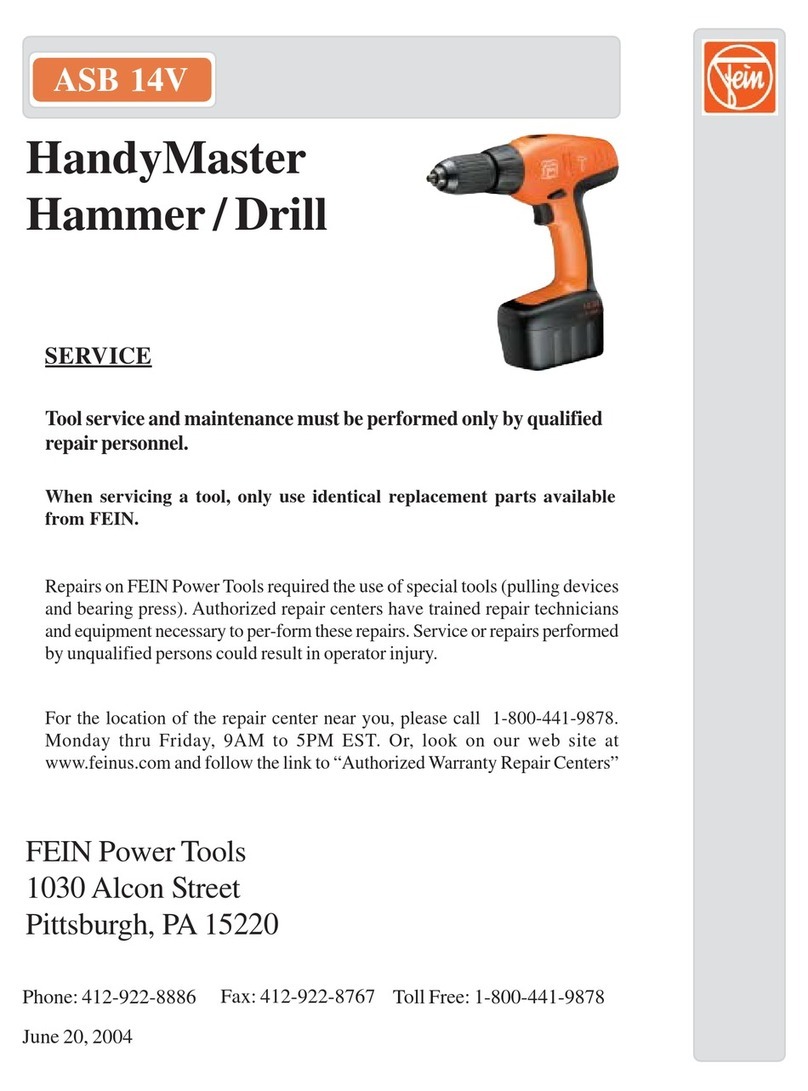

Fein HandyMaster ASB 14V User manual

Fein

Fein ABH 18 Series User manual

Fein

Fein ASy 630 User manual