6en

Safety warnings for drills.

Safety instructions for all operations.

Hold the power tool by insulated gripping sur-

faces, when performing an operation where

the cutting accessory or fasteners may con-

tact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make

exposed metal parts of the power tool “live”

and could give the operator an electric shock.

Safety instructions when using long

drill bits.

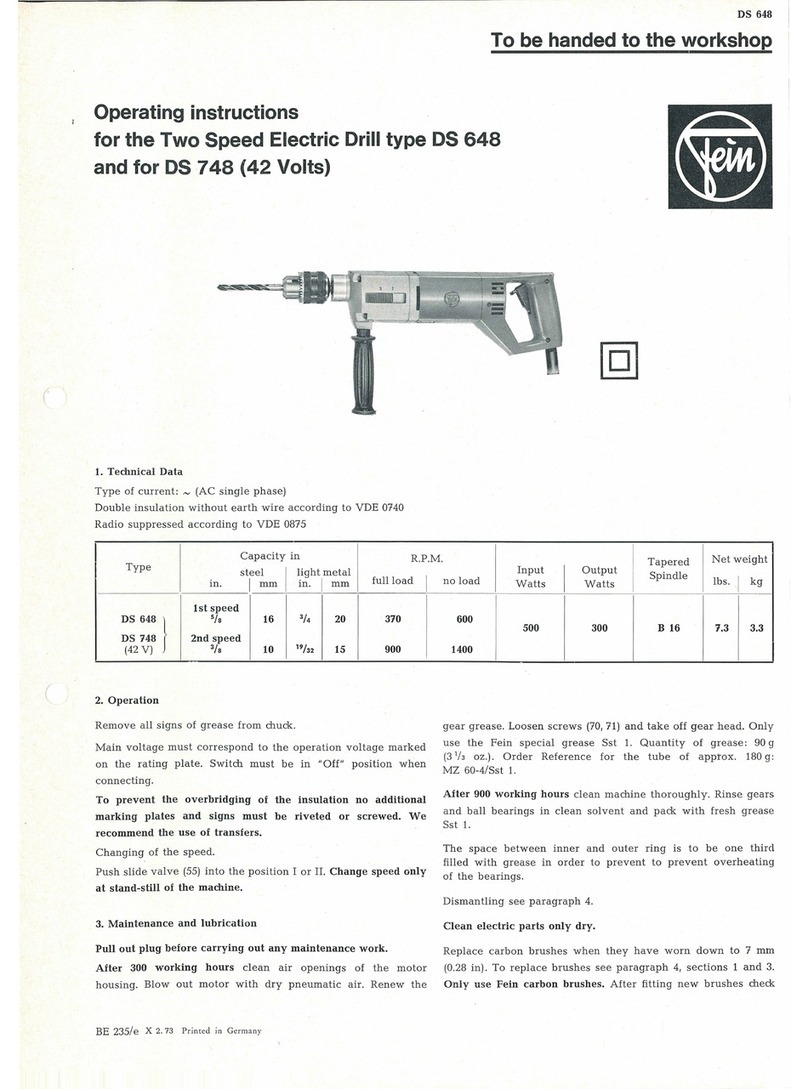

Never operate at higher speed than the maxi-

mum speed rating of the drill bit. At higher

speeds, the bit is likely to bend if allowed to

rotate freely without contacting the work-

piece, resulting in personal injury.

Always start drilling at low speed and with

the bit tip in contact with the workpiece. At

higher speeds, the bit is likely to bend if

allowed to rotate freely without contacting

the workpiece, resulting in personal injury.

Apply pressure only in direct line with the bit

and do not apply excessive pressure. Bits can

bend causing breakage or loss of control,

resulting in personal injury.

Special safety instructions.

Beware of any concealed electric cables, gas

or water conduits. Check the working area

before commencing work, e. g. with a metal

detector.

Wear personal protective equipment. Depend-

ing on application, use face shield, safety

goggles or safety glasses. Where appropriate,

wear dust mask, hearing protectors, gloves

and workshop apron capable of stopping

small abrasive or workpiece fragments. The

safety glasses must be capable of protecting

against flying particles generated by the vari-

ous operations. Prolonged exposure to high

intensity noise may cause loss of hearing.

Secure the work piece firmly. A work piece

that is gripped tightly in a clamping device or

vice, is more secure than if held by hand.

Hold the power tool firmly. High reaction

torque can briefly occur.

Do not work materials containing magnesium.

Danger of fire.

Do not work CFP (carbon-fiber-reinforced

polymer) and materials containing asbestos.

These materials are considered carcinogenic.

Do not rivet or screw any name-plates or

signs onto the power tool. If the insulation is

damaged, protection against an electric shock

will be ineffective. Adhesive labels are recom-

mended.

Do not use accessories which are not specifi-

cally designed and recommended by the

power tool manufacturer. Safe operation is

not ensured merely because an accessory fits

your power tool.

Clean the ventilation openings on the power

tool at regular intervals using non-metal

tools. The blower of the motor draws dust

into the housing. An excessive accumulation

of metallic dust can cause an electrical hazard.

Never look or stare into the light of the power

tool's lamp from a short distance. Never point

the light of the lamp into the eyes of other

persons in close vicinity. The radiation pro-

duced by the lamp can be harmful for the eye.

Do not direct the power tool against yourself,

other persons or animals. Danger of injury

from sharp or hot application tools.

Use and handling of the battery (bat-

tery pack)

To avoid hazardous situations such as burns,

fire, explosion, skin injuries, and other inju-

ries when handling the battery, observe the

following instructions:

Batteries must not be disassembled, opened

or reduced in size. Do not subject batteries to

mechanical impact or shock. Hazardous

vapours and fluid can escape in case of dam-

age and improper use of the battery. The

vapours can irritate the respiratory system.

Liquid ejected from the battery may cause

skin irritations or burns.

When battery fluid from a damaged battery

has come into contact with objects close by,

check the respective components, clean them

or replace them as required.

Keep the battery away from heat and fire. Do

not store the battery in direct sunlight.

OBJ_BUCH-0000000367-001.book Page 6 Thursday, February 14, 2019 2:50 PM