Fein ASzx 648 User manual

Other Fein Drill manuals

Fein

Fein ABS18 Q User manual

Fein

Fein BOP6 User manual

Fein

Fein ABS 18 User manual

Fein

Fein Slugger HoleMaker III User manual

Fein

Fein BOZ 32-4M User manual

Fein

Fein BOP6 User manual

Fein

Fein KBE 35 Series User manual

Fein

Fein Slugger JHM USA 101 X User manual

Fein

Fein KBM 52 U User manual

Fein

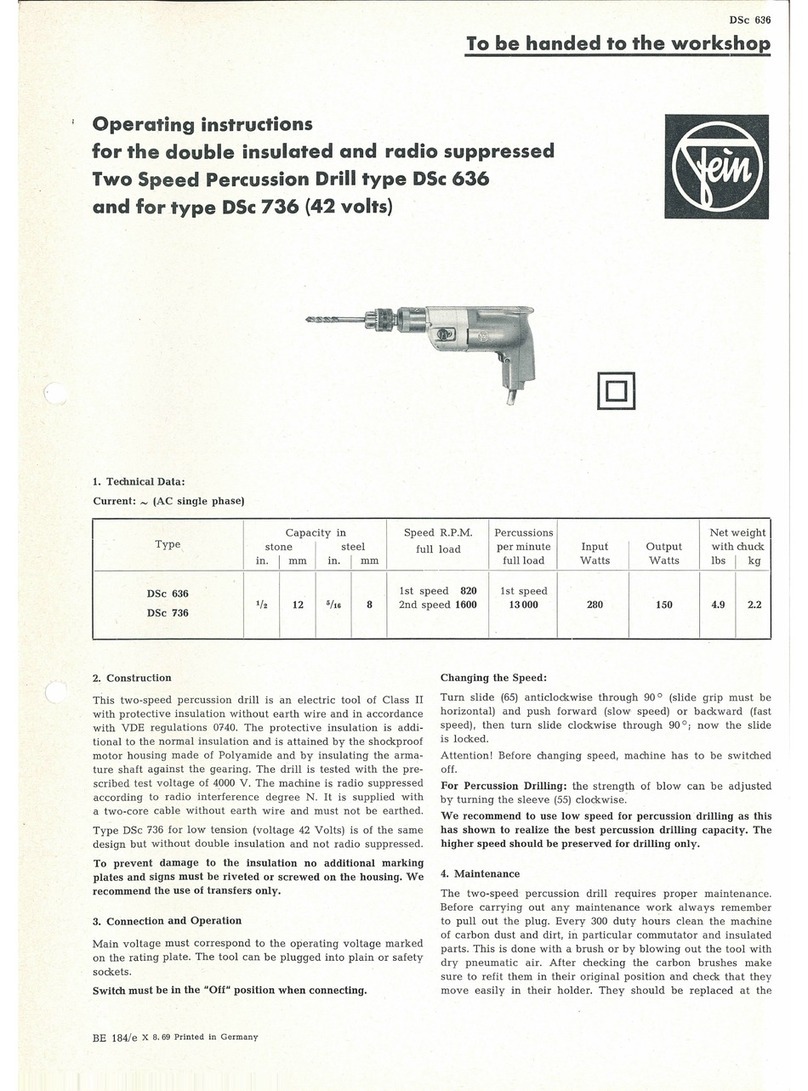

Fein DSc 636 User manual

Fein

Fein KBM 50 Q User manual

Fein

Fein kbb38x Setup guide

Fein

Fein BOS 16 Setup guide

Fein

Fein DSk 658 User manual

Fein

Fein 7 270 27 User manual

Fein

Fein ABS 14 Setup guide

Fein

Fein ASCD18W2 User manual

Fein

Fein ASCM18QM Series User manual

Fein

Fein HandyMaster ABS 12V Quick start guide

Fein

Fein DDSk 111 User manual