MVK 03 / 07

Alle Rechte bei FEIN, insbesondere für den Fall der Schutzrechtsanmeldung.

Jede Verfügungsbefugnis wie Kopieren und Weitergaberecht liegt bei FEIN.

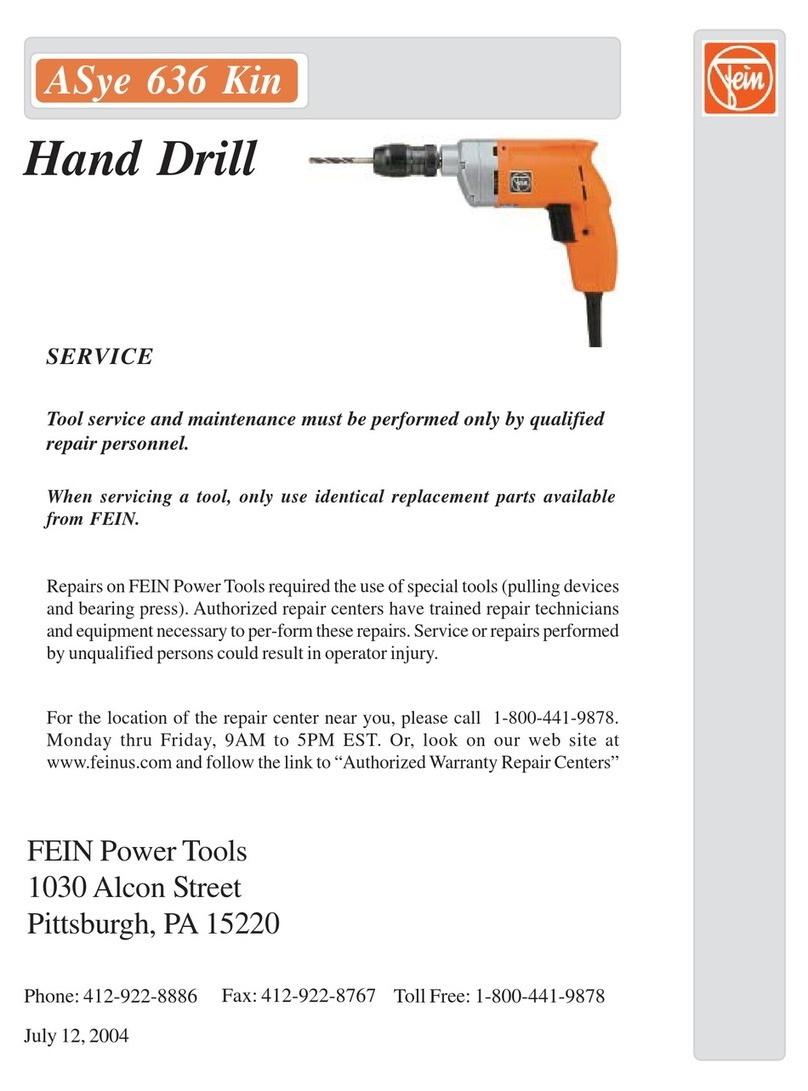

Fein Repair Tool

2.1. General Maintenance Tasks

Check the power cord (900) for areas of damage.

Blow out the motor with dry compressed air.

Check the carbon brushes (2.2.).

Small functional test (3.1.).

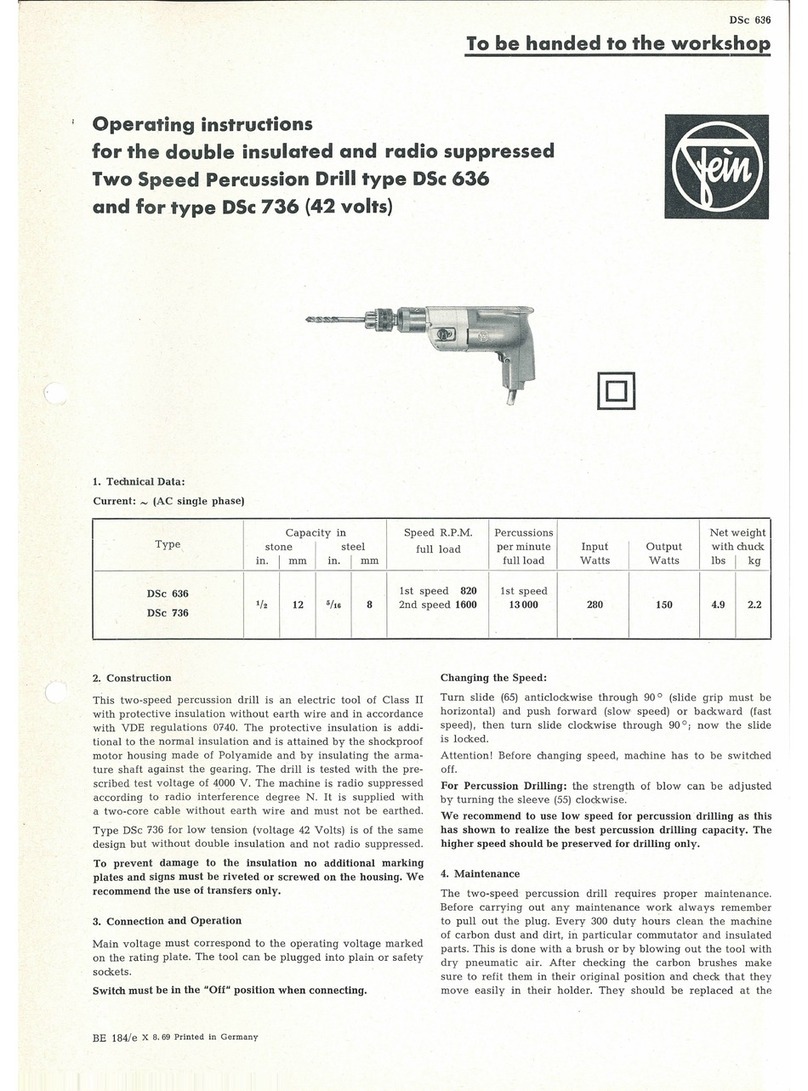

2.1.1. Maintenance intervals:

Depending on the nature and duration of use, no later than after 6 months:

- Clean the drill motor.

- Brush or blow out the brush holder and insulating parts.

2.2. Replacing the carbon brushes:

The drill motor is equipped with carbon brushes that shut off automatically.After the

minimum length of the carbon brushes has been reached, the power supply is

interrupted. If this happens, the carbon brushes must be replaced by an electrical

specialist. If you are using new carbon brushes, make certain to check that they move

easily inside the brush holder.Allow new carbon brushes to run for 15 minutes without

load. Use only

original FEIN carbon brushes!