DDSk

672

To be handed to the workshop

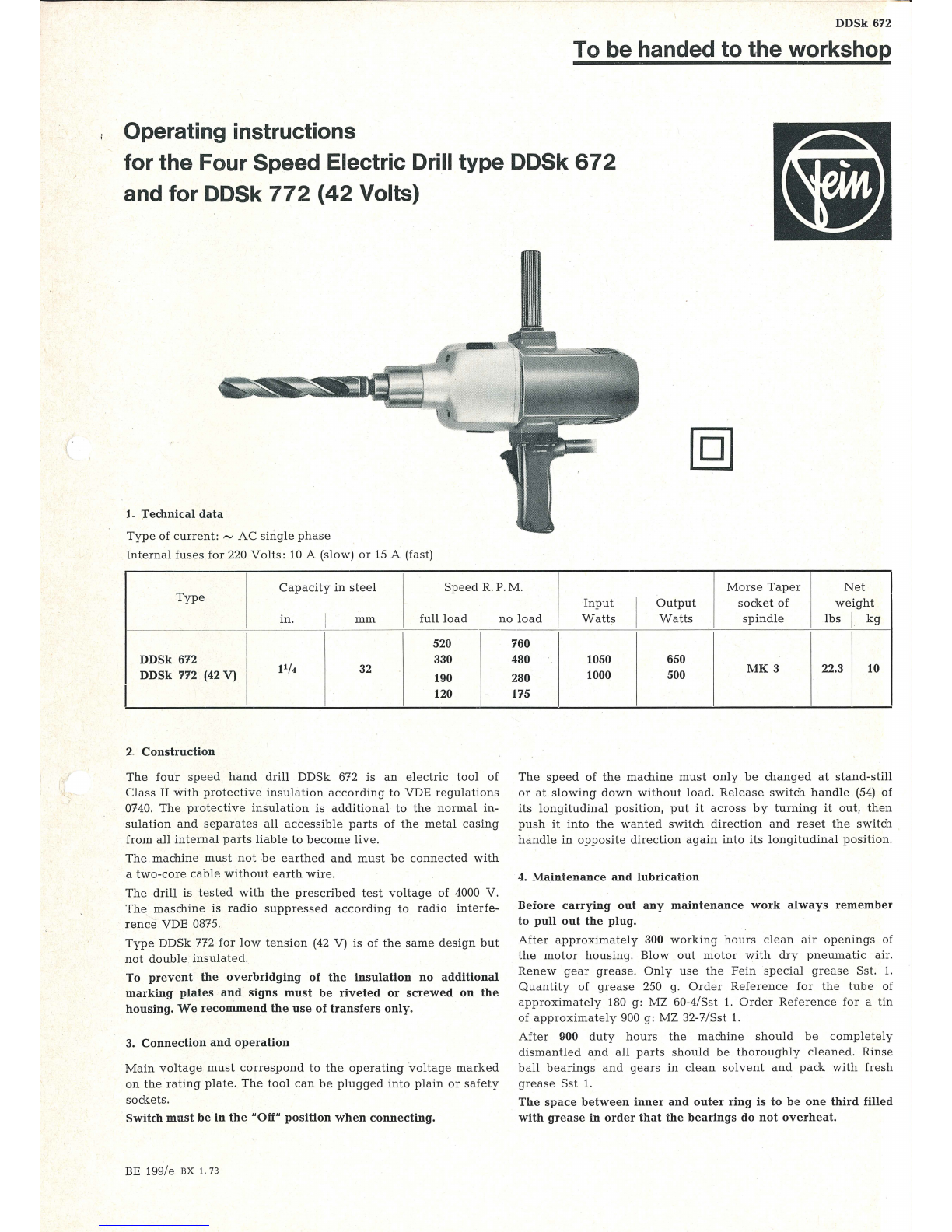

Operating instructions

for the Four Speed Electric Drill type DDSk

672

and for DDSk

772

(42

Volts)

L

Jechnical

data

Type

of

current:

~

AC

single

phase

Int.ernal

fuses

for

220

Volts:

10 A (slow)

or

15 A (fast)

Capacity

in

steel

Speed

R.

P.M.

Morse

Taper

Net

Type

Input

Ou

tpu

t

socket

of

weight

in. I

mm

full

load

I

no

load

Watts

I

Watts

spindle

lbs

J

kg

I 520

DDSk 612 I 330

pj,

32

DDSk 112

(42V)

I

190

I 120

2.

Construction

The

four

spee

d

hand

drill

DDSk

672

is

an

el

ectr

ic

tool

of

Class

II

with

protective

insulation

according

to

VDE

regulations

0740.

The

prot

ec

tive

insulation

is

additional

to

th

e

normal

in-

sulation

and

separates

all

accessible

parts

of

the

metal

casing

from

all

internal

parts

liable

to

become

live.

The

machine

must

not

be

ea

rth

ed

and

must

be

connected

with

a

two-cor

e

cab

le

without

earth

wire.

The

drill

is

tested

with

the

pr

escribe

d

test

vo

ltag

e

of

4000 V.

The

maschine

is

radio

suppressed

according

to

radio

interfe-

rence

VDE 0875.

Type

DDSk 772

for

low

tension

(42 V) is

of

the

same

design

but

not

double

insulated.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

th

e

use

of

transfers

only.

3.

Connection

and

operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safety

sockets

.

Switch

must

be

in

the

"Off"

position

when

connecting.

BE

199/e

BX

1. 73

760

480 1050 650

MK3

22.3 10

280 1000 500

115

The

speed

of

the

machine

must

only

be

cha

nged

at

stand-s

till

or

at

slowing

down

without

load

.

Release

switch

handle

(54)

of

its

longi

tu

dinal

position

,

put

it

across

by

t

urni

ng

it

out,

then

push

it

in

to

the

wanted

switch

direction

and

reset

the

switc

h

handle

in

opposite

direction

again

into

its

longitudinal

position.

4.

Maintenance

and

lubrication

Before

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

After

approximately

300

working

hours

clean

ai

r

openings

of

the

motor

housing.

Blow

out

motor

with

dry

pneu

matic

air.

Renew

gear

grease.

Only

use

th

e

Fein

s

peci

al

grease

Sst

. 1.

Quantity

of

g

re

ase

250

g.

Order

Refe

ren

ce

for

th

e

tube

of

approx

imat

ely 180 g:

MZ

60-4/

Sst

1.

Ord

er

Re

feren

ce

for

a tin

of

approx

i

mately

900 g: MZ 32-7/

Sst

1.

After

900

duty

hours

the

machine

should

be

completely

dism

antled

and

all

parts

should

be

thorou

ghly

cleane

d. Rinse

ball

bearings

and

gears

in

cle

an

solvent

and

pack

with

fresh

grease

Sst

1.

The

space

between

inner

and

outer

ring

is

to

be

one

third

filled

with

gr

ease

in

order

that

the

bearings

do

not

overheat.