FEMA

·

MANUFACTURING FOR INDUSTRIAL AUTOMATION

4

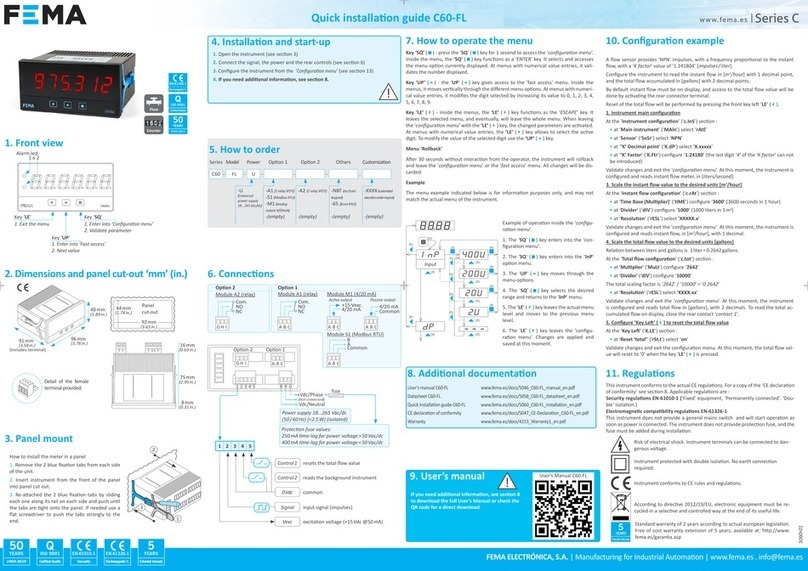

9. Conguration system

CONFIGURATION SYSTEM

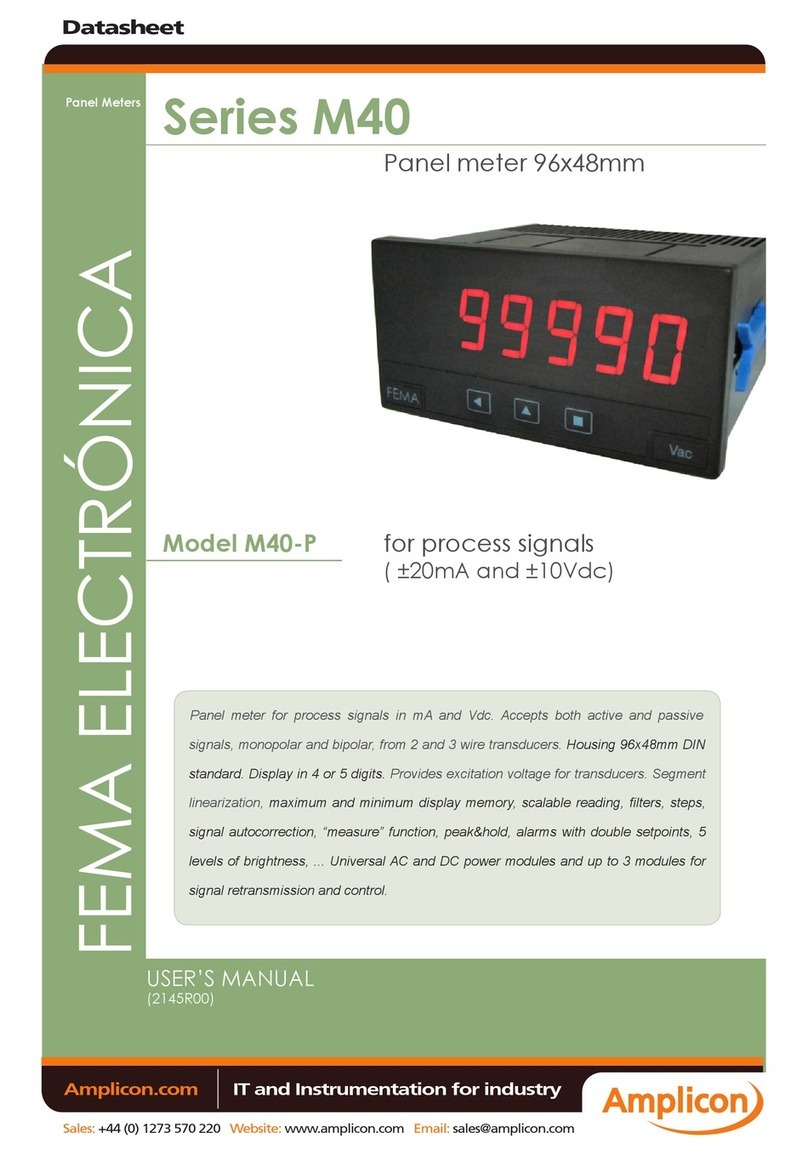

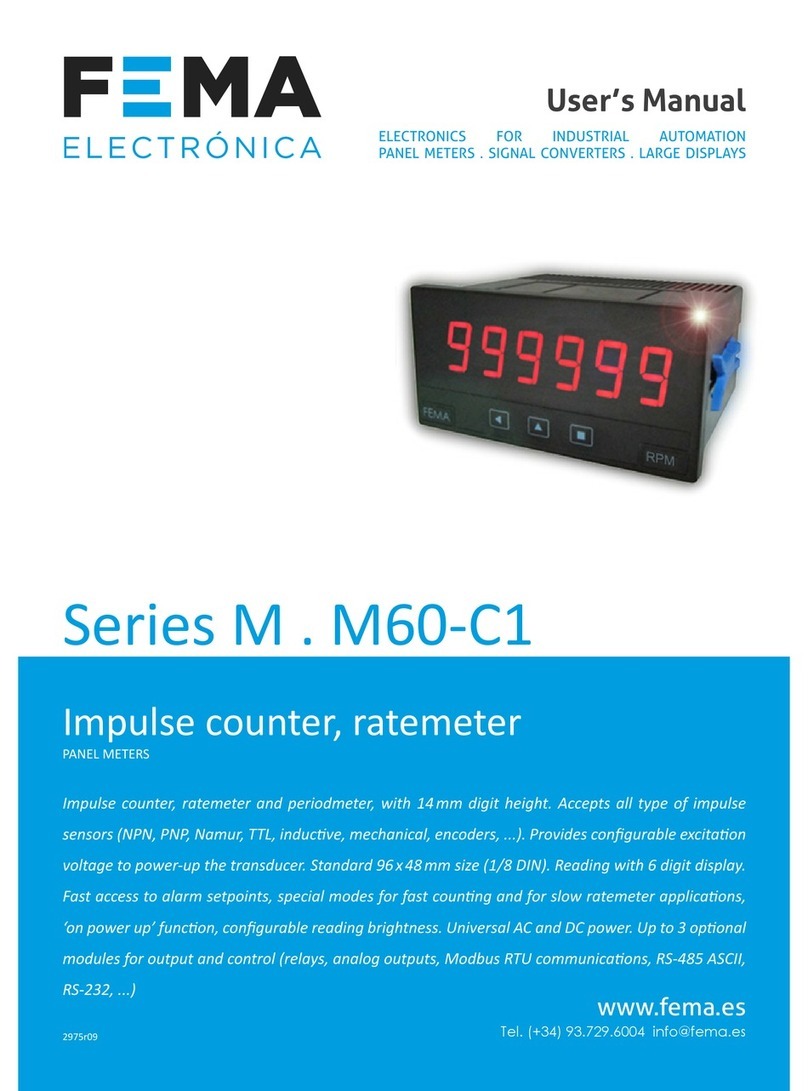

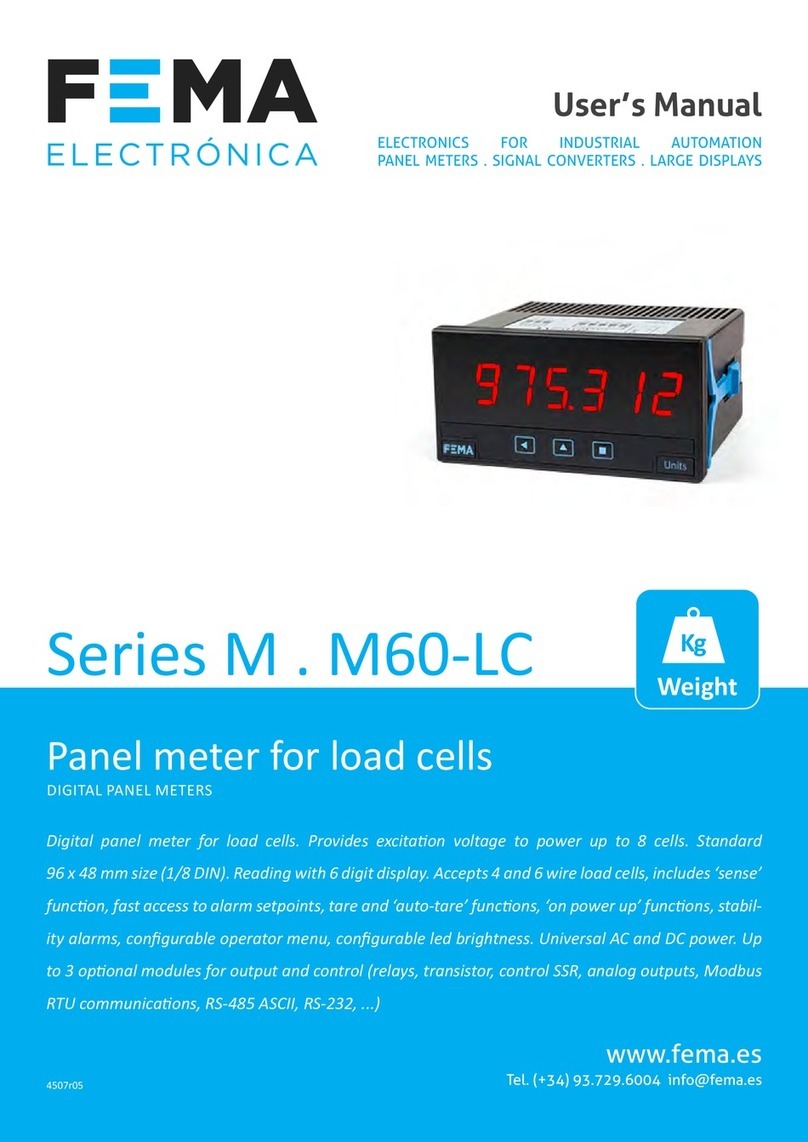

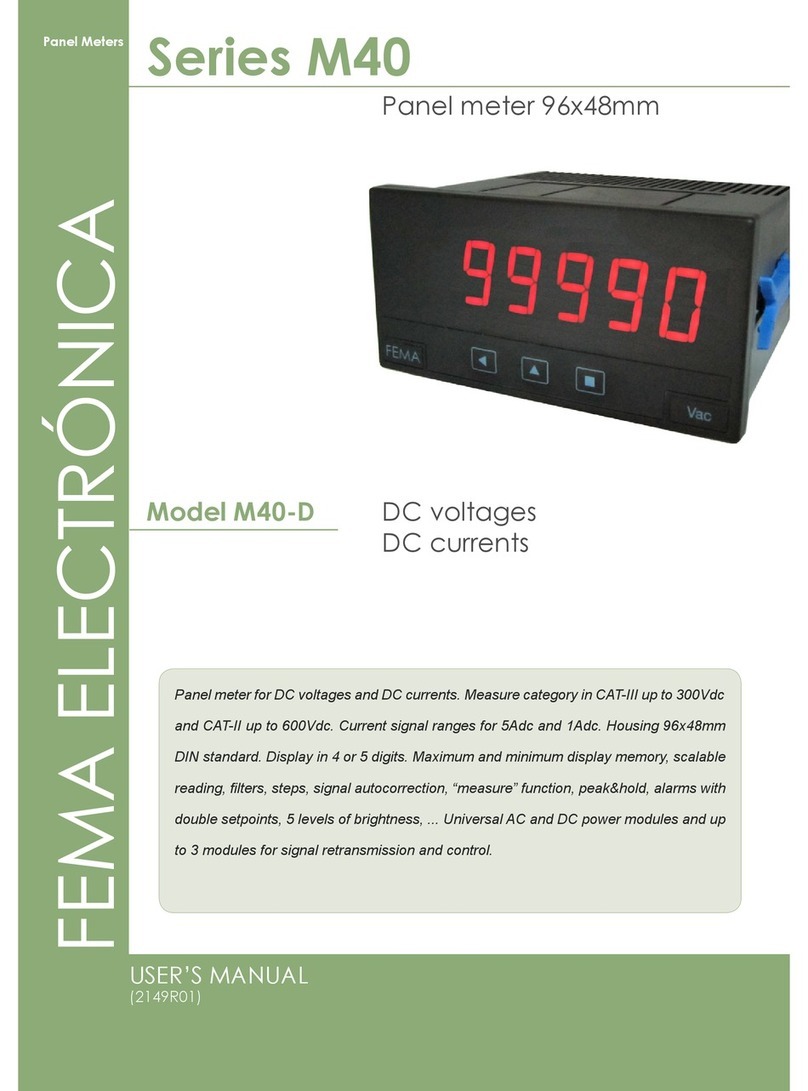

The LP4 loop powered process meter is fully congurable from the

instrument front panel, through a conguration system made of three

push button keypad and the four red digit led display (see Table 4).

AT POWER-UP

When the input signal loop is connected, the instrument applies the

following sequence:

• the ‘display’ shows the rmware version ‘A7.xx’

• the ‘display’ shows the message ‘mA’

• the instrument measures the input signal, applies the congured

scaling, and shows the value on display. The instrument is now in

‘normal mode’ of operation.

FROM ‘NORMAL MODE’ OF OPERATION

From ‘normal mode’ of operation, the operator can access the following

functions:

• key ‘SQ’ (<) gives access to the ‘conguration menu’ (see section 11)

• key ‘UP’ (5) gives access to the ‘fast access’ menu (see section 12)

10. ‘Normal mode’ of operation

HOW TO ENTER THE ‘CONFIGURATION MENU’

With the instrument in ‘normal mode’ of operation (see section 10), press

the ‘SQ’ (<) key and maintain for 1 second. The horizontal leds light

from bottom to top. When the upper led lights, the instrument enters into

the ‘conguration menu’.

If the ‘SQ’ (<) key is released before entering into the

‘conguration menu’, the horizontal leds light downwards from

top to bottom, and the instrument returns to ‘normal mode’ of

operation.

HOW TO OPERATE INSIDE THE ‘CONFIGURATION MENU’

Inside the ‘conguration menu’, use the front keypad to move through

menu entries, parameters, and select conguration values:

•Key ‘SQ’ (<) functions as the ‘ENTER’ key. It selects the menu entry

currently displayed. At numerical value entries, it validates the number

displayed.

•Key ‘UP’ (5) moves vertically through the different menu entries. At

numerical value entries, it modies the selected digit by increasing its

value to 0, 1, 2, 3, 4, 5, 6, 7, 8, 9.

•Key ‘LE’ (3) functions as the ‘ESCAPE’ key. It leaves the selected

menu entry (discarding changes), and eventually, will leave the

‘conguration menu’ (storing changes validated with the ‘SQ’ (<)

key). When leaving the ‘conguration menu’, the changed parameters

are stored, the instrument is restarted, and the new conguration is

activated. At numerical value entries, the ‘LE’ (3) key allows to select

the active digit. To modify a numeric value press the ‘LE’ (3) key

to select the digit to modify, select the ‘UP’ (5) key to increase the

value ‘+1’, and when all digits are modied, press the ‘SQ’ (<) key to

validate the new value.

11. How to operate the ‘Conguration menu’

Table 4 | CONFIGURATION SYSTEM

Display

Key ‘SQ’ (<)

Key ‘UP’ (5)

Key ‘LE’ (3)

Table 5 | Example of how to operate inside the ‘Conguration menu’

Scaling

1. The ‘SQ’ (<) key enters into the

‘conguration menu’.

2. The ‘SQ’ (<) key enters into the

‘ScAL’ menu.

3. The ‘UP’ (5) key moves through

the menu options.

4. The ‘SQ’ (<) key selects the

value and returns to the ‘ScAL’

menu.

5. The ‘LE’ (3) key leaves the

actual menu level and moves to

the previous menu level.

6. The ‘LE’ (3) key leaves the

‘conguration menu’. Changes are

applied and saved at this moment.

(2)

(3)

(3)

(3)

(3)

(4)

(4)

(4)

(4)

(5)

(5)

(5)

(3)

(3)

(6)

(6)

(1)

Note: example indicated above is for information purposes only, and may not

match with the actual menu entries of the instrument.