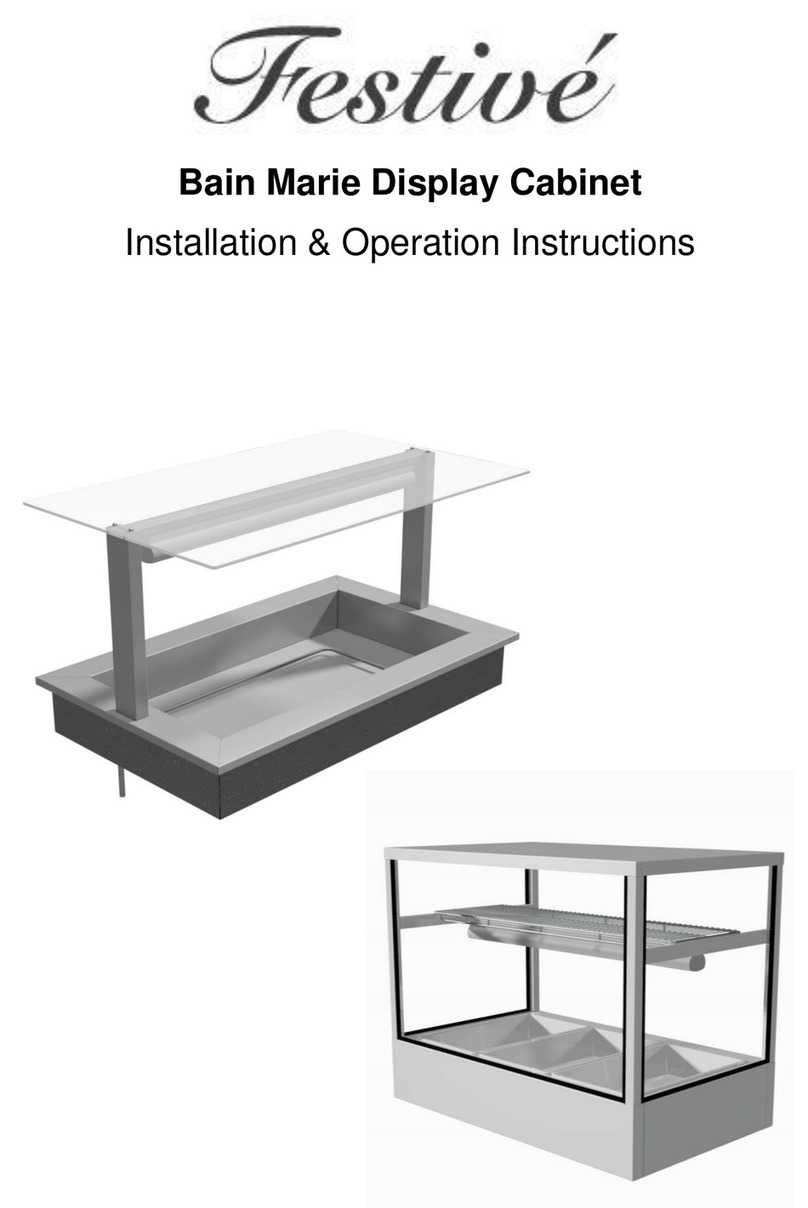

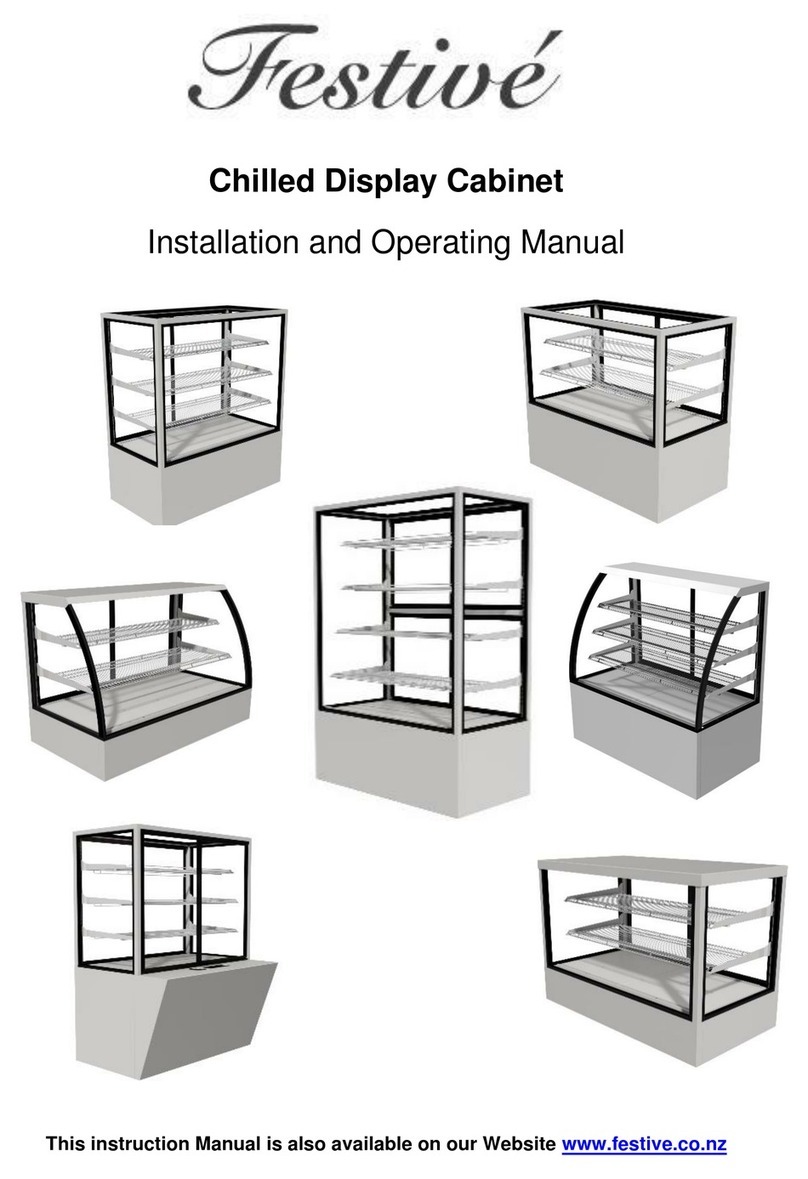

Festive Somerset SC12 User manual

Air Curtain Chill Well

Installation and Operating Manual

1

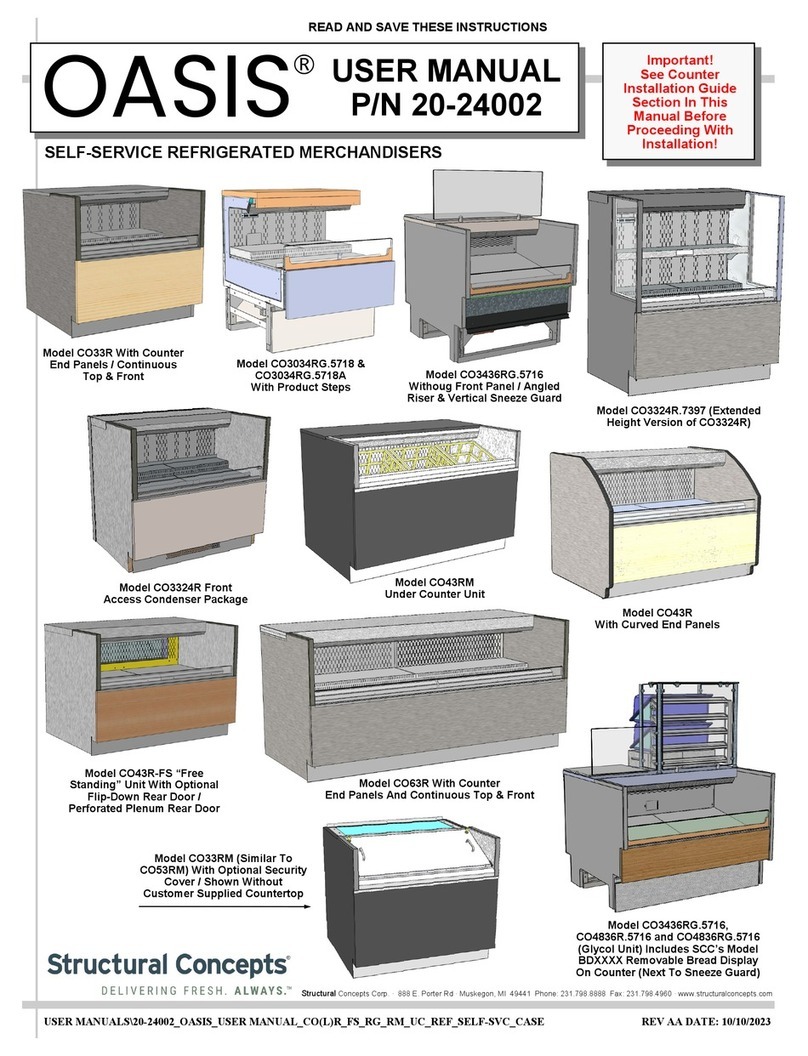

MODELS COVERED

Somerset

SC12, SC15, SC18, SC21. SCRW12, SCRW15, SCRW18, SCRW21

2

TABLE OF CONTENTS

Page

Models Covered

1

Contact Details

2

Introduction

3

Safety

3

Installation Instructions

4-5

Operating Instructions

6

Cleaning

7

Servicing

7

Spare Parts

8

Troubleshooting

9

Joinery Assembly Instructions

10

Warranty

11

CONTACT DETAILS

For further information or help, contact your supplier or:

Email: [email protected]

Internet: www.festive.co.nz

Telephone: +64 3 349 3380

Mail: Festivé NZ Limited

35 Establishment Drive

Hornby

Christchurch 8042

New Zealand

3

INTRODUCTION

Congratulations on purchase of a Festivé food display cabinet. Festivé designs and

manufactures quality cabinets designed to meet the exacting needs of its customers.

Please take the time to carefully read and understand this manual. This will help ensure

that maximum benefit from the cabinet can be gained. If you have any queries contact

your dealer or Festivé.

SAFETY

Please carefully read the important safety information provided below:

•Do not overload your power supply.

•The cabinet must be supplied with the voltage specified.

•Always ensure that the power to the cabinet is earthed.

•Always disconnect the cabinet from the mains power supply before

cleaning, undertaking maintenance or allowing the cabinet to be serviced by

a properly qualified tradesman.

•Keep clear of, and never touch, moving parts.

•Ensure that staff are familiar with the above safety information, as well as all

other information in this manual.

4

INSTALLATION INSTRUCTIONS

In order to ensure that the cabinet operates efficiently it is important to spend time

preparing the area and the cabinet for installation. Some key points and useful advice are

provided below:

1. Location

Cabinets should always be located away from direct sunlight, draughts, and

equipment that generate heat and water vapour.

2. Power Supply

Ensure a suitable power supply exists. Plug the cabinet into its own power point

at the wall (multi boxes are not recommended). Always turn the cabinet on and off

at the wall.

3. Site Preparation

The cabinet should be installed on a level floor, plinth or bench. This ensures

proper functioning of doors and condensate management. Any necessary bench

cut-outs should have been made prior to installation, and a suitable power point

located appropriately. Carefully position the cabinet in its correct position and

ensure it is level. Adequate access to the cabinet for loading and cleaning is

required.

4. Drainage

The cabinet has a drain hose from the evaporator coil. This hose needs to be fed

into a suitably large container and emptied daily or plumbed to the site’s waste

water system.

5. Cabinet Preparation.

Carefully unwrap the cabinet and any other parts supplied. Remove tape and ties

etc.

6. Condenser Unit

Ensure the condenser unit has adequate ventilation. It is critical for the effective

operation of the cabinet that the condenser fan is able to draw in cool air from the

room and disperse hot air into the room. The refrigeration (condenser unit) of the

cabinet will be one of two options: Condenser in Cradle (CIC), or Remote

condenser unit.

1. Condenser in Cradle (CIC)

If the condenser unit is CIC it is already attached to the underneath of the cabinet

by a built in cradle.

5

Condenser in Cradle attached under cabinet

If the cabinet and cradle need to be fitted into joinery, adequate ventilation needs

to be provided for the refrigeration unit as shown on page 10. The drain hose will

need to be fed into a suitably large container and emptied daily or plumbed to the

site’s waste water system.

2. Remote Condenser

If the cabinet comes with a remote condenser unit (supplied separately in a box)

that will need a qualified refrigeration engineer to install and connect. Note: the

pipe distance between the condenser unit and the cabinet shouldnot exceed

2 meters for a capillary based system.

Remote condenser unit

6

OPERATING INSTRUCTIONS

•Switch the cabinet on at the wall.

•Flick down either the one or the two red toggle switches (one for the

refrigeration unit and one for the light, if present).

Red toggle switch

•The electronic controller displays the operating temperature that the cabinet is

running at.

Electronic controller

•The refrigeration unit will begin running and will progressively bring the

temperature down to the factory set point temperature of 2°C.

•The cabinet operates at a temperature differential of 2°C from the set point, i.e.

the refrigeration unit will stop when the cabinet temperature drops to 2°C and

restart when it rises to 4°C.

•To change the temperature setting:

▪push the ‘SET’ button on the controller. The ‘set point’ temperature will start

flicking on the display

▪push the ‘UP ARROW’ on the controller to raise the ‘set point’ temperature

setting

▪push the ‘DOWN ARROW’ on the controller to lower the ‘set point’ temperature

setting

▪push the ‘SET’ button to return the display to the operating temperature

•Load the cabinet with pre-chilled products (food display cabinets are not refrigerators

and should be loaded with pre-chilled products).

•The cabinet is set to defrost at regular intervals. A defrost button on the controller

panel will light up when the cabinet is in defrost mode. The cabinet is fitted with an

intelligent defrost system that will automatically shorten or extend the defrost time

dependent on requirements.

•Always switch off at the wall.

7

CLEANING

It is important that the cabinet is regularly cleaned in order to achieve hygienic and

efficient operation. Some advice on this is provided below:

•Always turn the cabinet off at the wall before cleaning.

•Do not use bleaches and other aggressive cleaning products (chemicals and

scourers) that could damage the cabinet surfaces.

•Never use hot water on glass as this may ‘shock’ the glass and cause ‘thermal

breakage’, i.e. shattering of glass due to sudden temperature changes.

•Clean the exterior with soapy water using a soft damp cloth. Never apply too much

water and always be careful to minimize moisture on and near the electronic

controller and power lead. Dry the exterior immediately afterwards.

•Condenser Unit. Regularly check that the condenser fins are free from dust, as

any build-up will reduce the efficiency of the cabinet and can cause excess power

consumption or even compressor failure. Dust and dirt should be removed by

brushing (use a soft brush) and vacuuming the fins. On occasions dust build-up in

the condenser fins can be extensive and pressurised gas (air or nitrogen) may

need to be blown through the fins to clear them. It is recommended that the

condenser coil is cleaned monthly, and in cases of high dust exposure that four to

six monthly the fins are blown with high pressure gas.

Condenser unit

SERVICING

Regular servicing of the cabinet is important for its ongoing efficient operation. Four

monthly servicing of the cabinet by a qualified refrigeration technician is required to

maintain the warranty of a Festivé refrigerated cabinet –refer Warranty on page 11 of

this Manual.

Lights. LED LIGHT STRIP

•If an LED light requires replacement: Remove LED Light strip

(1) Unclip light strip (2) Unclip cable connecting light strip to cable Attach

replacement simply follow the above instructions in reverse.

8

SPARE PARTS

Festivé endeavours to maintain stocks of spare parts for its customers. If spare parts are

required, please quote both the serial number of the cabinet and the item number(s) from

the list below. It is important to use only Festivé spare parts to ensure compatibility,

performance, and meet warranty conditions.

Item

Description

1

Electronic Controller

2

Temperature Probe

3

LED light strip

4

Condenser Assembly

5

Evaporator Fan

6

Top Glass

9

TROUBLE SHOOTING

Problem

Possible Cause

Solution

Cabinet won’t

start

Circuit broken at the main

power board

Replace fuse/turn circuit breaker on

The cabinet switch is off

Turn the cabinet switch on

Electronic controller is

faulty

Replace the electronic controller

Unsatisfactory

cabinet

temperature

Air circulation is

blocked/impeded

Remove food/trays away from vents

and airflows. Clean/vacuum air vents

Evaporator coil fins blocked

Remove and clean crumb catcher.

Clean coil fins

Evaporator coil iced up

De-ice coil. Adjust defrost cycle if

reoccurs

Condenser fan grill dirty

Vacuum to remove dirt

Electronic controller is

faulty

Replace the electronic controller

Temperature probe

dislodged or damaged

Check probe is held on clip and not

damaged

Ambient temperature is

greater than 25°C

Reduce ambient temperature and/or

move cabinet

Electronic controller needs

adjustment

Adjust electronic controller

Cabinet light

not working

Light switch is off

Turn light switch on

LED light not working

Replace LED light or LED driver

10

11

WARRANTY

Warranty Cover

Festivé warrants to the original purchaser of a Festivé manufactured food display cabinet any

defect in workmanship or material resulting in the malfunctioning of the cabinet while under

correct use. Liability under this warranty is limited to replacing or repairing (at the Company’s

discretion)apartwithoutcharge.Thewarrantysupportforanyrefrigerationunit requiresevidence

of four (4) monthly servicing of chilled cabinets by a qualified refrigeration technician. The

warranty period extends for:

Refrigerated & Ambient Cabinets:

•Parts and Labour for first year: up to twelve (12) months from sale

•Parts Only for second year: twelve (12) to twenty-four (24) months from sale

•Parts and Labour for Refrigeration Unit for two years: up to twenty-four (24) months from

sale. Subject to four (4) monthly servicing by a qualified refrigeration technician

Heated & Bain Marie Cabinets:

•Parts and Labour for first year: up to twelve (12) months from sale

Warranty Conditions

Liability under this warranty does not cover:

•Loss, damage or expense directly or indirectly arising from use or inability to use the

product or from any other cause.

•Any part of the cabinet which has been subject to misuse, neglect, incorrect installation,

alteration, accident or damage caused during transportation, use of abrasive chemicals,

flooding, fire or acts of God.

•Poor or inadequate cleaning of the cabinet that may lead to damage, wear or corrosion

of any part.

•Damage resulting from failure to have four (4) monthly servicing of refrigerated cabinets

carried out by a qualified refrigeration technician, supported by service records.

•Refrigeration failure as a result of inadequate ventilation to the refrigeration unit.

•Installation of remote condenser units.

•Breakage of glass or plastic components or the replacement of light tubes or door seals.

•Improper electrical connections

•Improper adjustment of controlling equipment.

•Fair wear and tear.

•Any damage directly or indirectly arising from the non-use of Festivé supplied parts.

•Any loss, damage or expense directly or indirectly arising from failure to follow product

operating and maintenance instructions.

•Repairs or maintenance carried out by a service agent un-authorised by Festive

•Travelling distance in excess of 160kms return trip from an authorised service agent

•Service outside of normal business hours. If this is required an “out of hours” surcharge

will apply.

Warranty Procedure

All warranty repairs must be pre-authorised by a Festive representative. Direct authorisation to

effect a warranty repair can be made through contact with:

In New Zealand:

Ph: +64 3 349 8380 - Festive NZ Limited

E: warranty@festive.co.nz

In Australia:

Ph: +64 3 349 3380 - Festive NZ Limited

E: warranty@festiveaustralia.com

Cabinet serial number, model, site address, contact details and fault description will need to be

provided.

This manual suits for next models

7

Table of contents

Other Festive Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

frost-trol

frost-trol ONEGA R290 Installation and maintenance manual

Ugolini

Ugolini MT mini UL Series Operator's manual

Fimar

Fimar EasyLine 01 Use and maintenance

METRO PROFESSIONAL

METRO PROFESSIONAL BAIN MARIE GBM1200 instruction manual

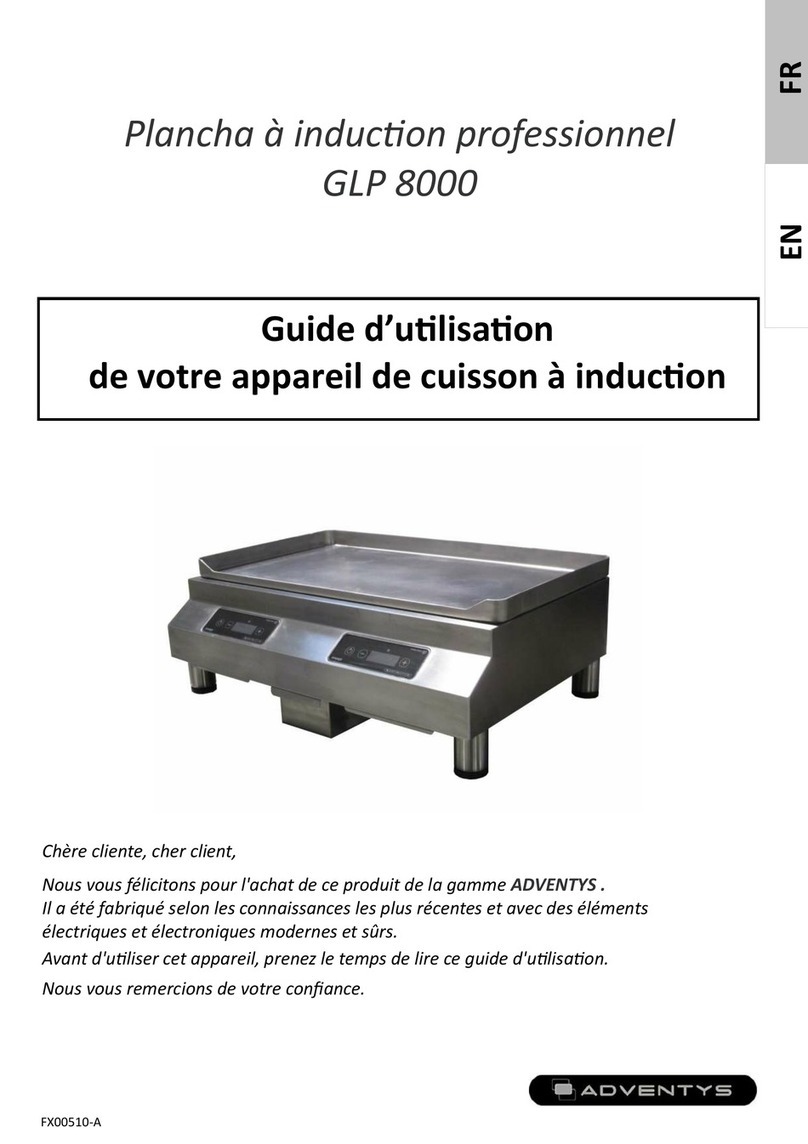

Adventys

Adventys GLP 8000 user guide

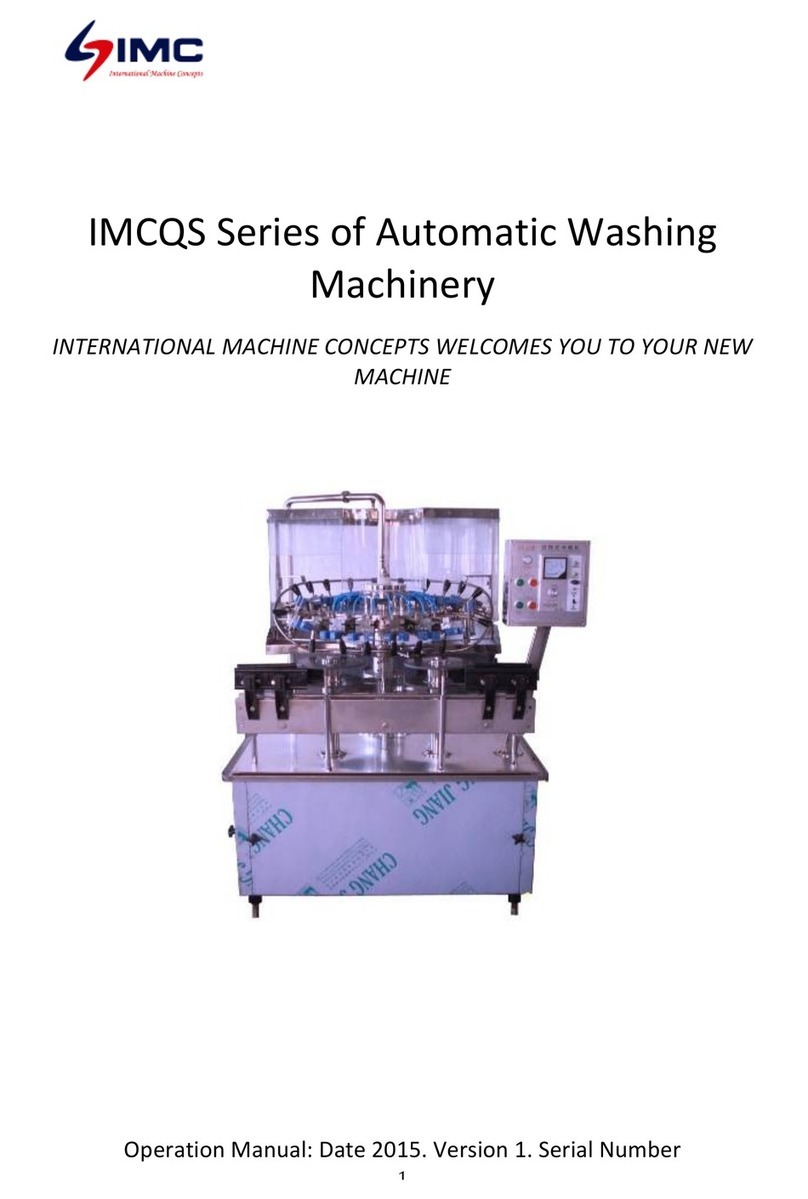

IMC

IMC IMCQS Series Operation manual