Connecting plate/

module connector PAML-...-186

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions

Translation of the original instructions

8082042

2017-11a

[8082044]

For all available product documentation èwww.festo.com/pk

Connecting plate/module connector PAML English.........................

1 Application

The connecting plates PAML-CP are intended to serve exclusively as adapters for

the pneumatic connection and for tube fastening for in-line installation of service

units. The module connector PAML-MK connects two service unit components with

each other. The rear mounting threads on the connecting plates and module con

nectors are used for wall mounting of individual devices or service units.

The product may only be used in its original status without unauthorised modi

fications. Only the assembly and commissioning activities described in these

operating instructions are permissible.

Observe the permissible limit values and specifications.

Only use the product if it is in an excellent technical status.

Take into consideration the legal regulations applicable for the location as well as:

– Regulations and standards,

– Regulations of the testing organisations and insurers,

– National specifications.

2 Installation

Note

Installation should only be conducted by qualified personnel.

Warning

Risk of injury from falling loads.

Take the weight of an individual device or a service unit into consideration. De

pendent on the design, a mounted service unit can weigh more than 100 kg.

Only mount the individual device or service unit on a wall or mounting frame

that can support its weight.

Only mount the individual device or service unit on a flat surface.

Definition

Front plate = front module connector

Rear plate = rear module connector

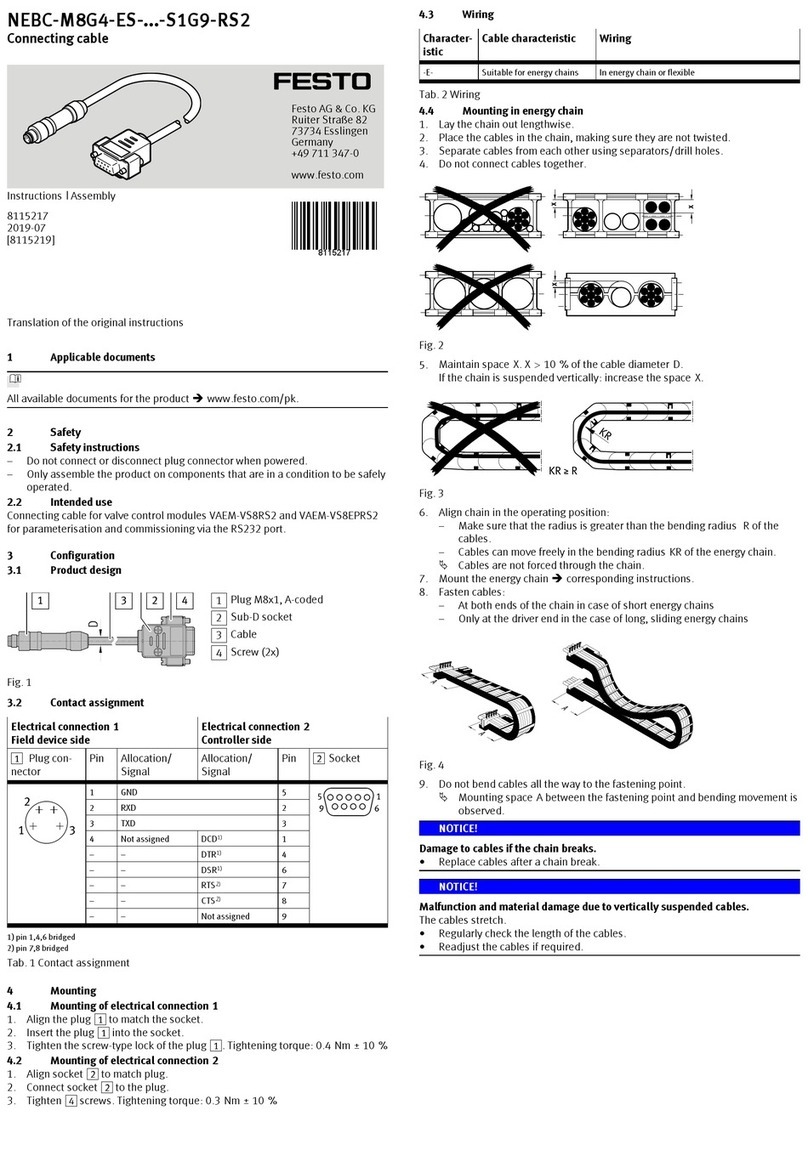

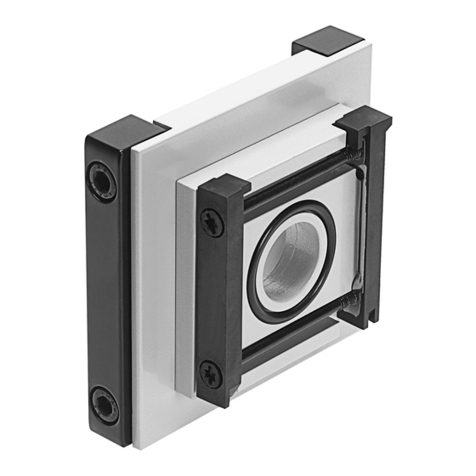

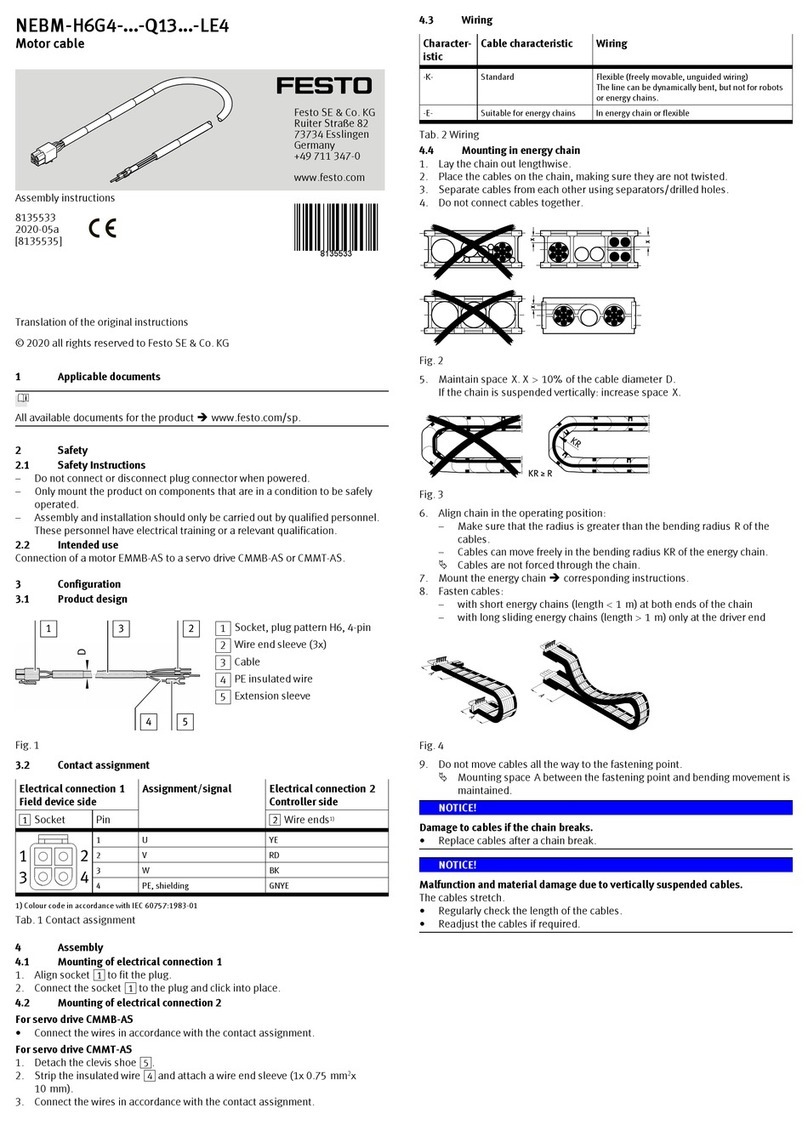

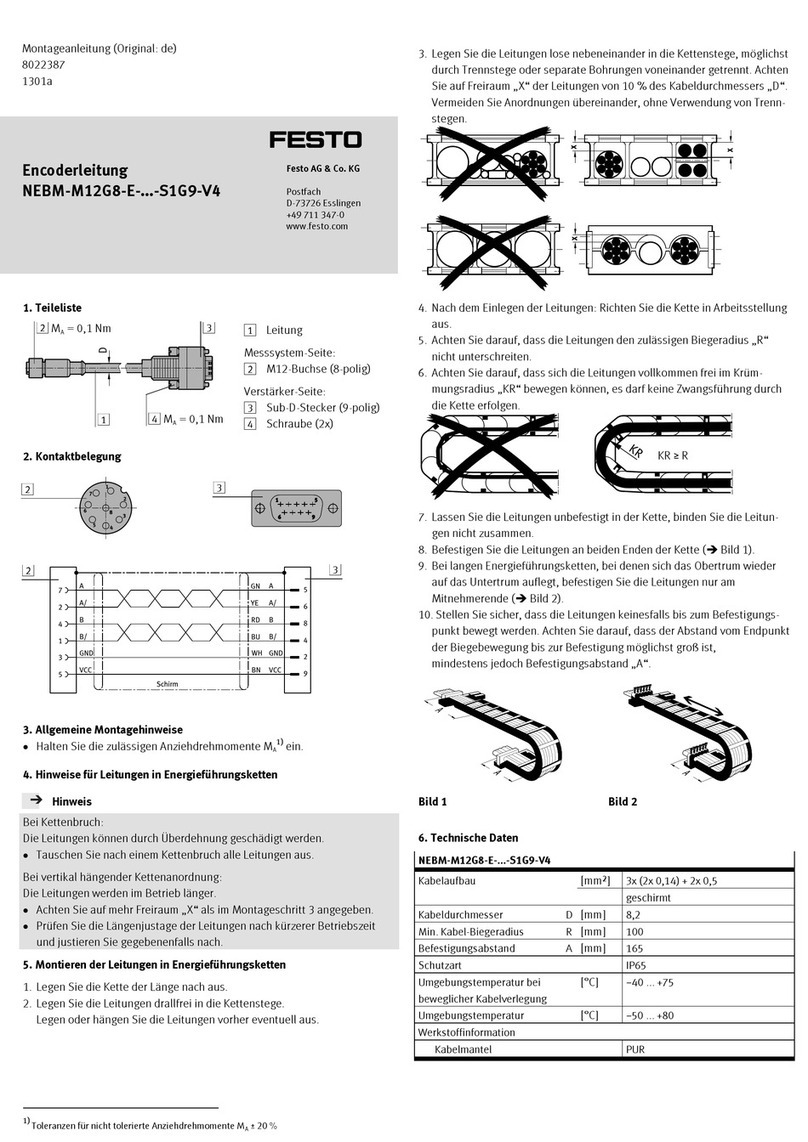

2.1 Assembly of two service units of the same size with module connector

PAML-MK

Note the flow direction from 1 to 2.

The numerals on the product housing 1serve as orientation.

1. First, screw both mounting screws through both holes of the front plate 3.

2. Place the seal 4between the service units.

3. Place the front and rear plate 3and 2in the slots of the service units.

4. Turn the screws of the front plate 3into the rear plate 2.

1

2

3

4

40 Nm ±25 %

Fig. 1

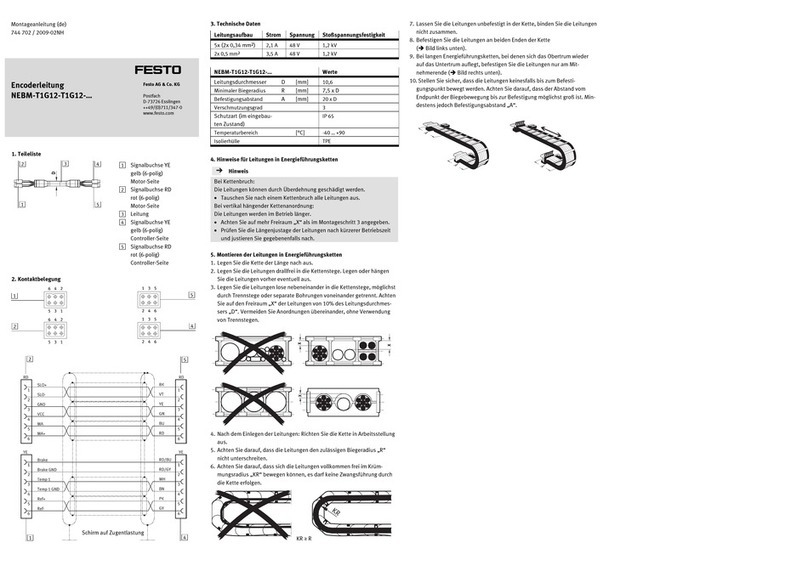

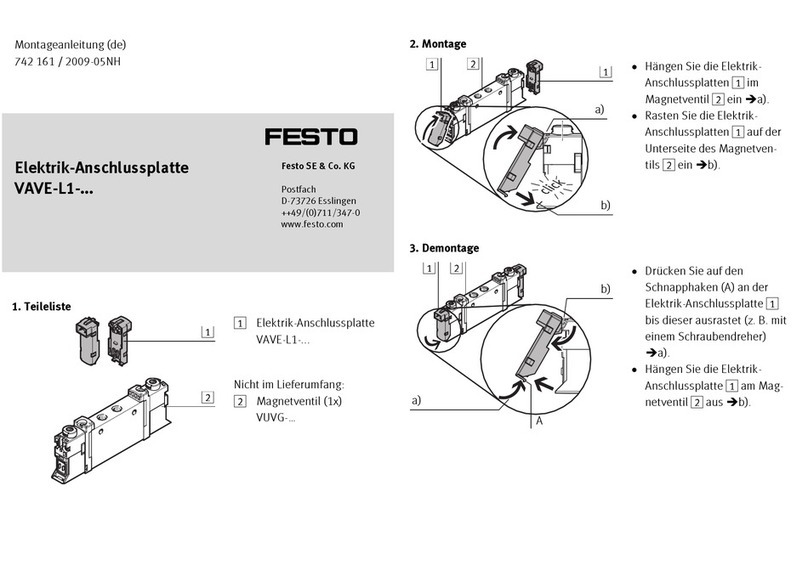

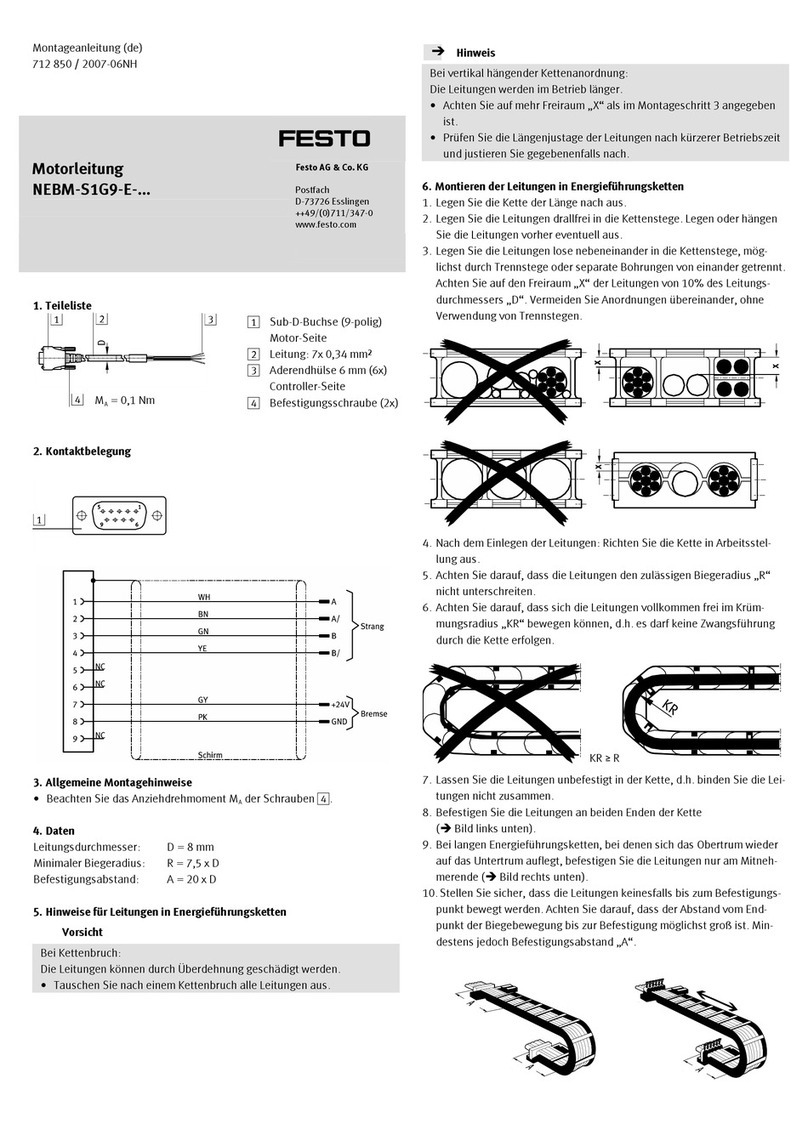

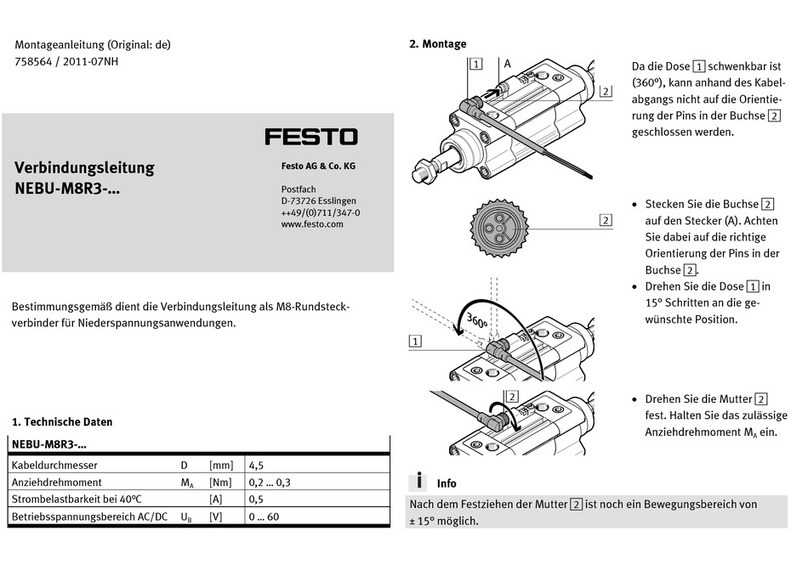

2.2 Mounting the connecting plates PAML-CP

Make sure that the sealing groove, which exists in only one of the two connect

ing plates, lines up with the flat surface on the housing. If mounted correctly, the

stamp number on the connecting plate will be the same as the stamp number on

the housing.

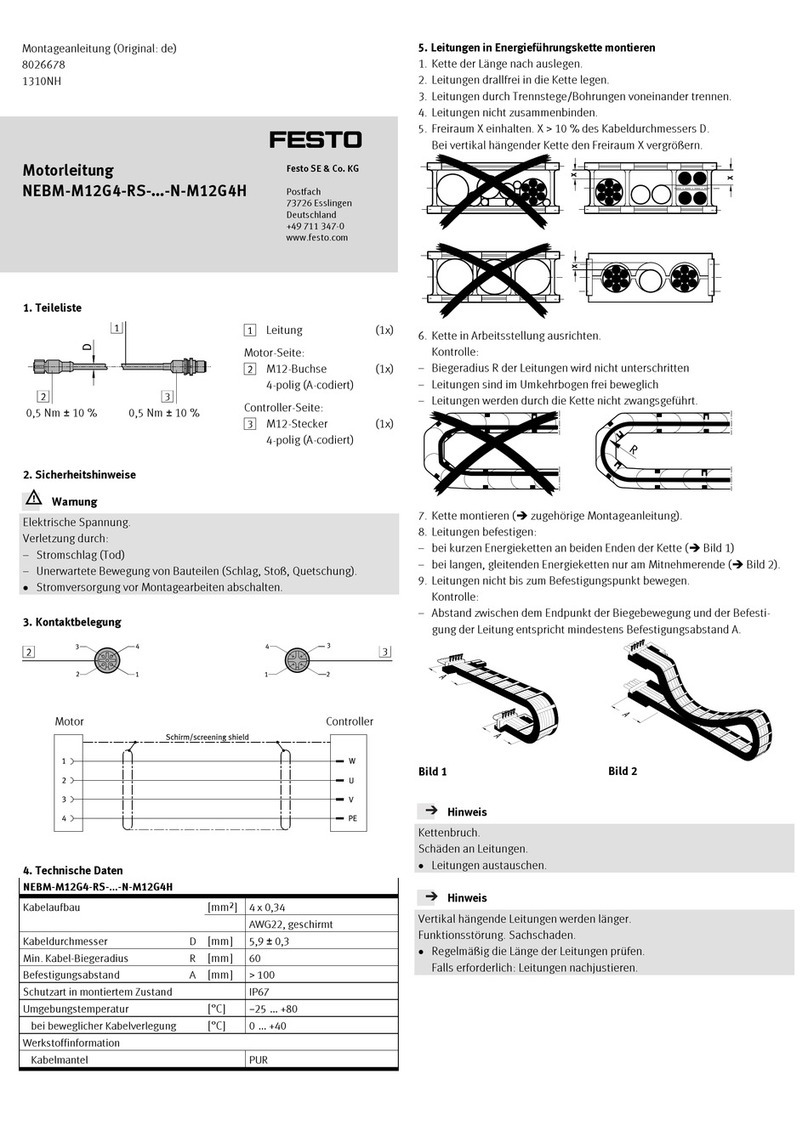

1. Insert the O-rings 5into the designated O-ring grooves.

2. Place the connecting plates in position. Make sure that the connecting plates

are aligned correctly. If mounted correctly, the mounting threads for wall mount

ing 6will point to the rear.

3. Fasten the connecting plates with the appropriate 4 screws M10 7and washers

to the service unit.

4. Observe the max. screw-in depth for the pipe connector, èFig. 2.

Product type ISO 228 Max. screw-in depth

[mm]

Connecting plate PAML-CP G¼12

G1¼20

G1½22

G2 24

G2½26

Fig. 2

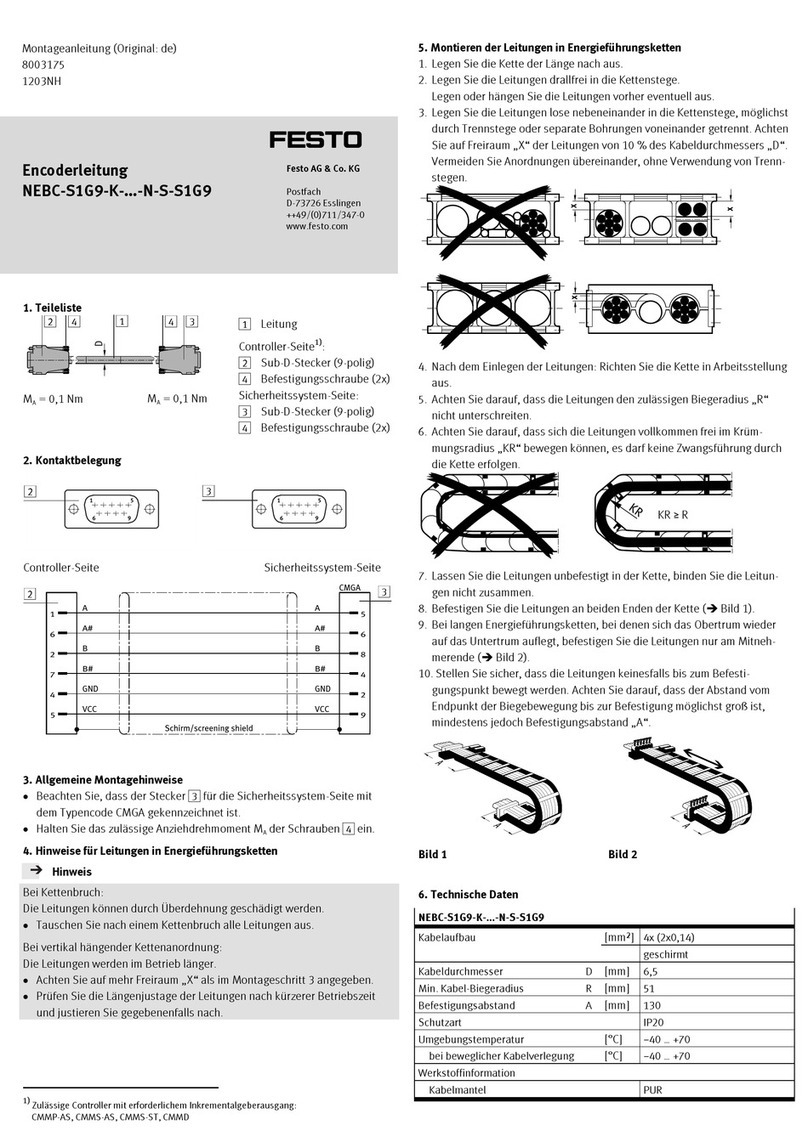

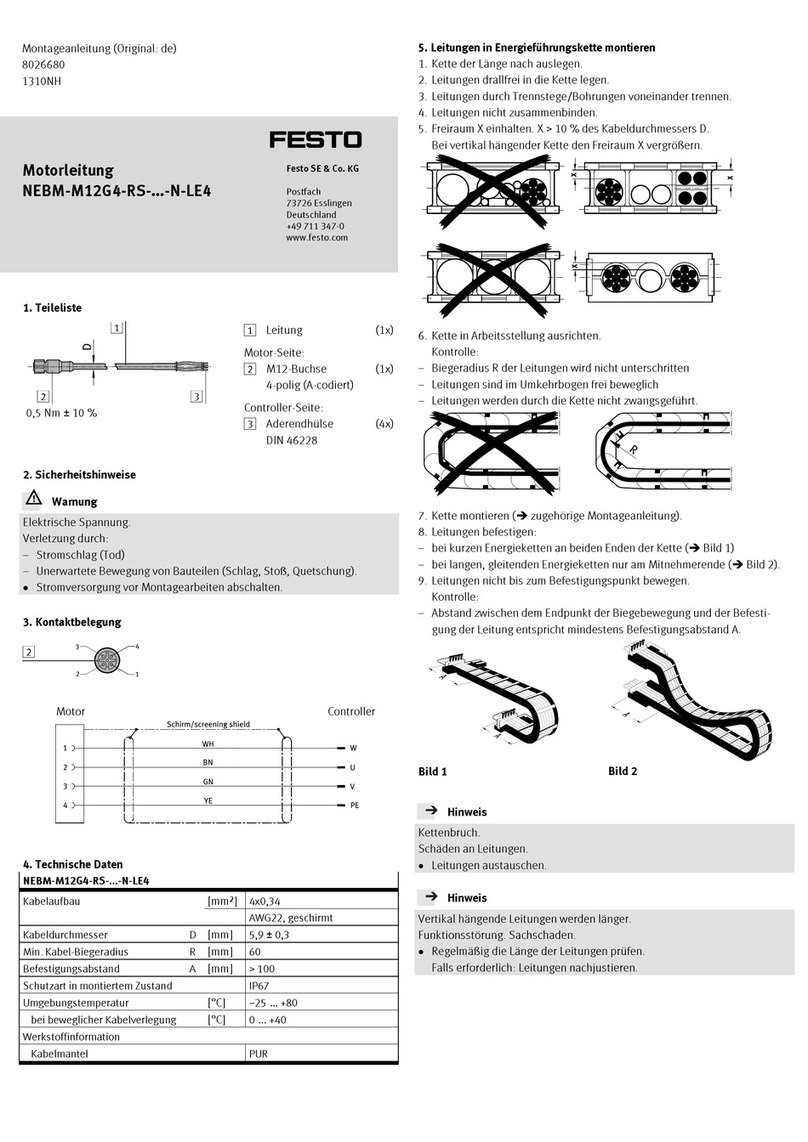

27 Nm ±15 %

27 Nm ±15 %

5

6

7

Fig. 3

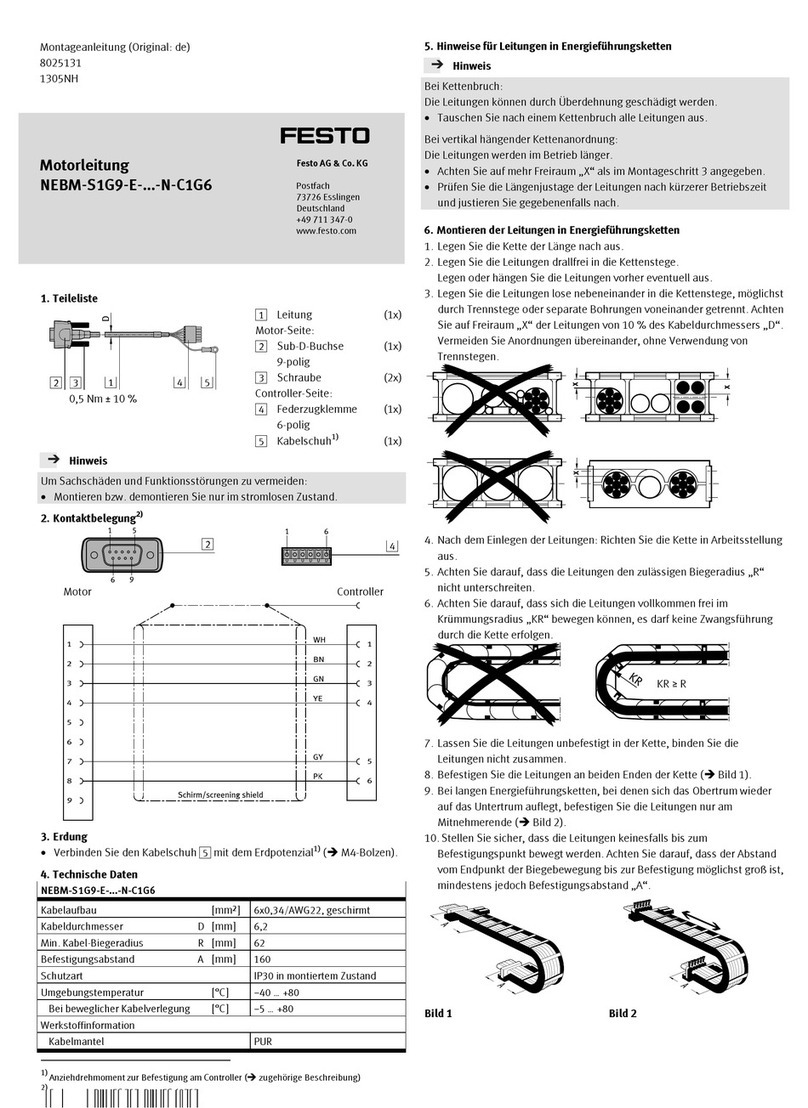

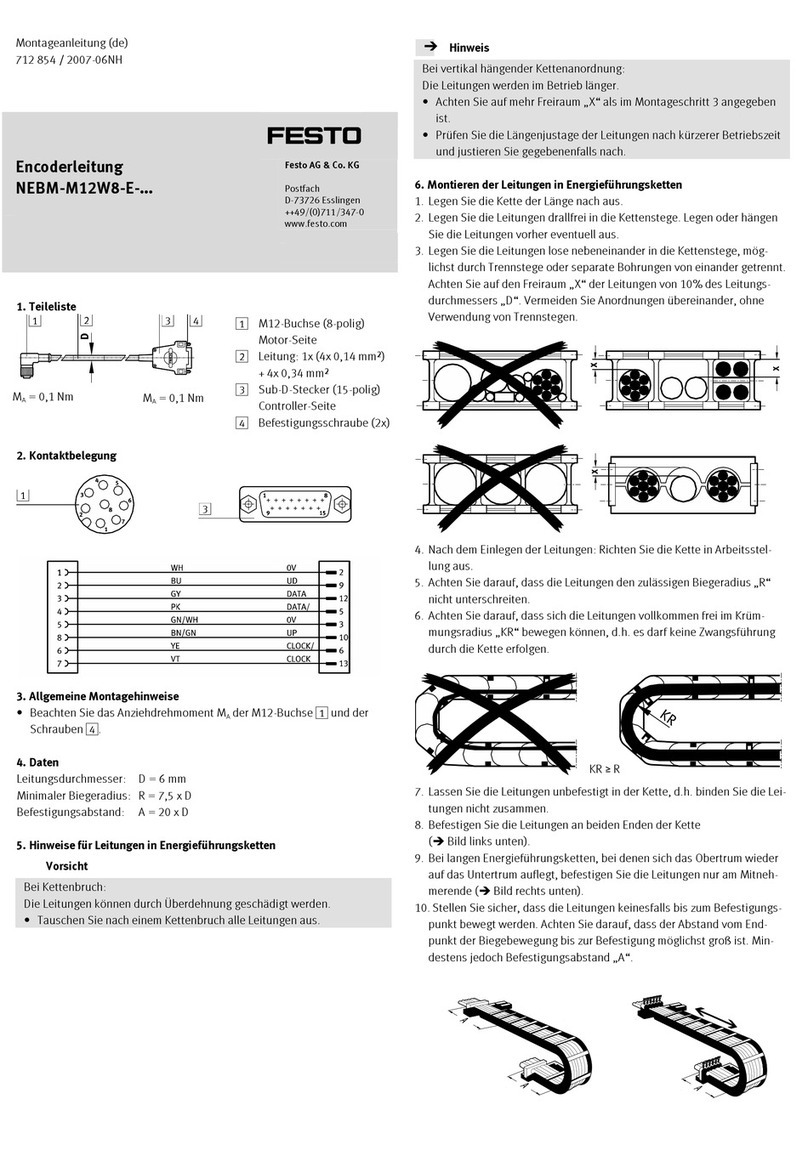

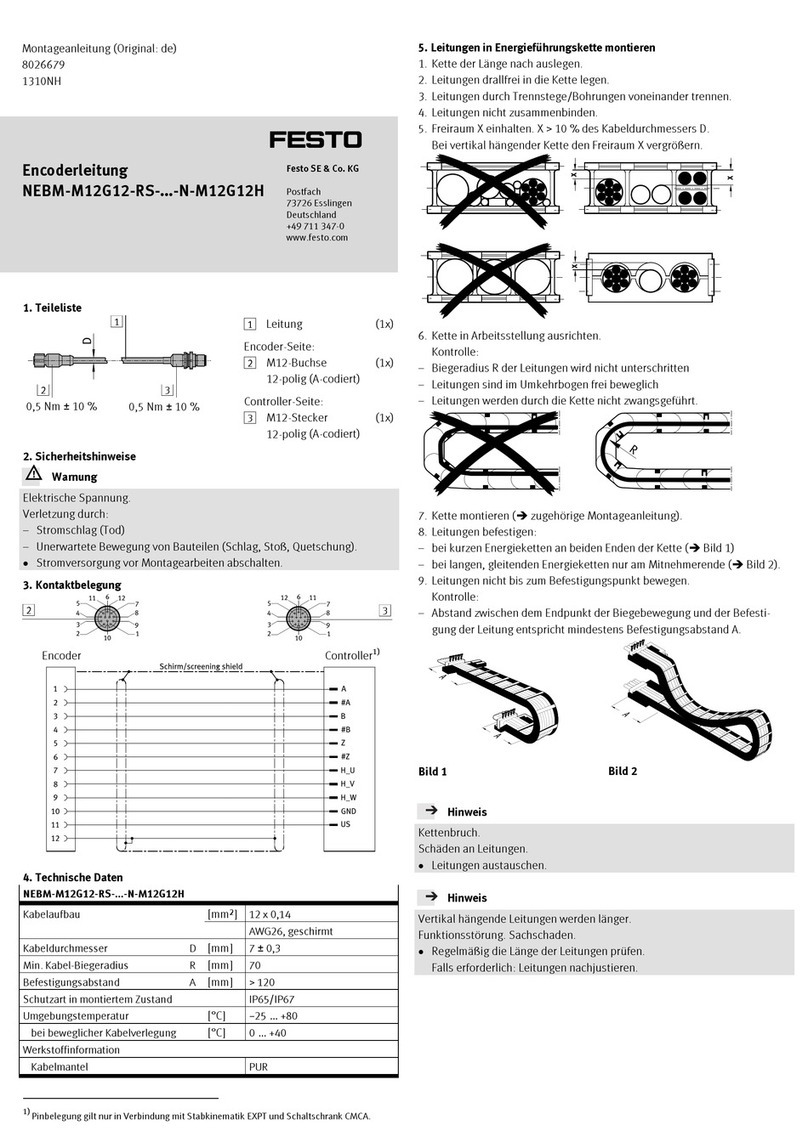

2.3 Wall mounting

To attach individual devices or service units to the wall or a machine frame, the

M12 threads from the rear panel and the connecting plate can be used.

1. Screw M12 screws 8into all of the rear plates and connecting plates from the

rear. For this purpose, use screws with a minimum screw-in depth of 15 mm and

a maximum screw-in depth of 18 mm. The distance between the screw-in

threads is 186 mm in width and 145 mm in height. Exception for the distance in

width for the distributor block PMBL-186-HP3 with half the normal grid width:

93 mm.

35 Nm ±20 %

8

Fig. 4