SDAT-MHS

Festo – SDAT-MHS – 2017-11f English 3

1 Product description 5.......................................................

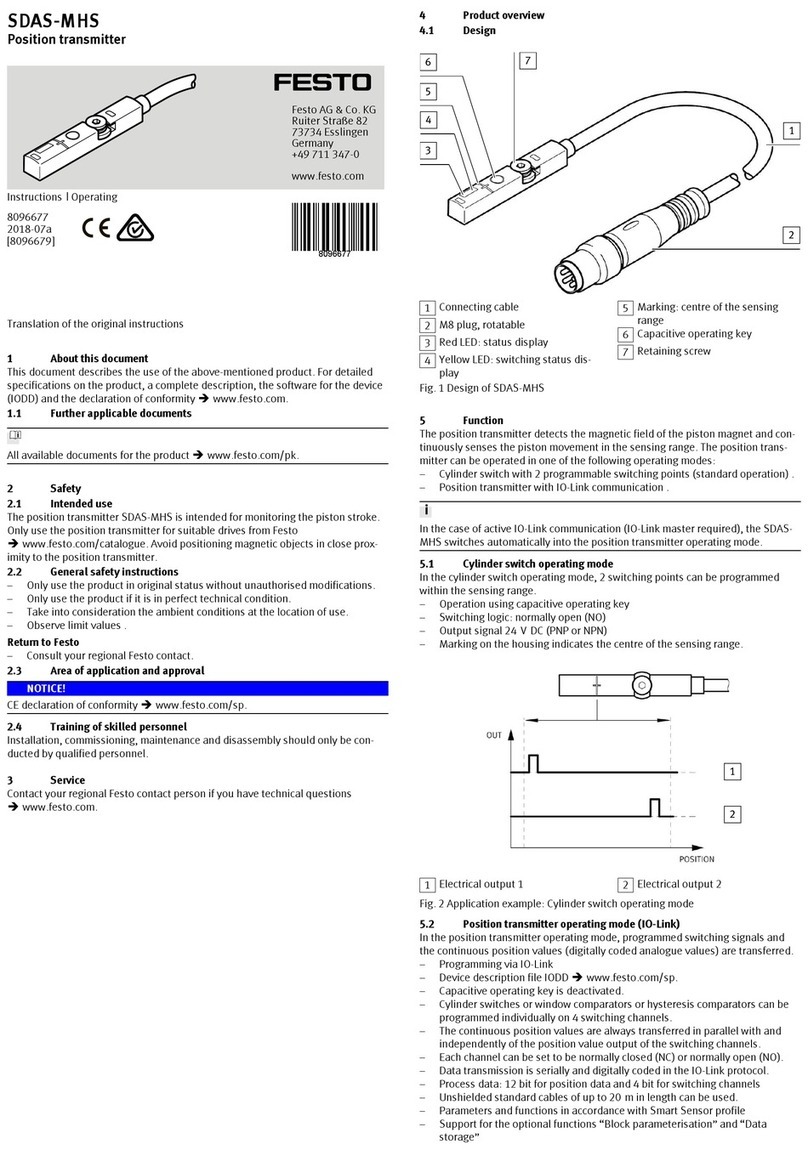

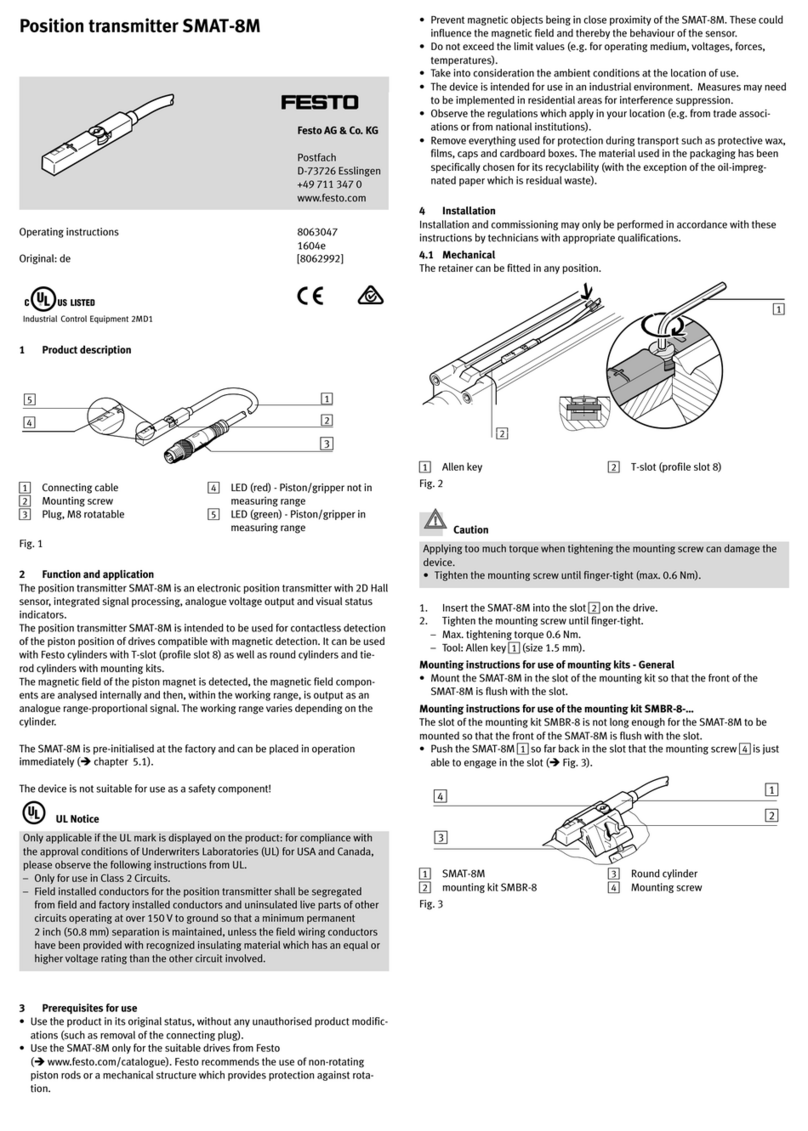

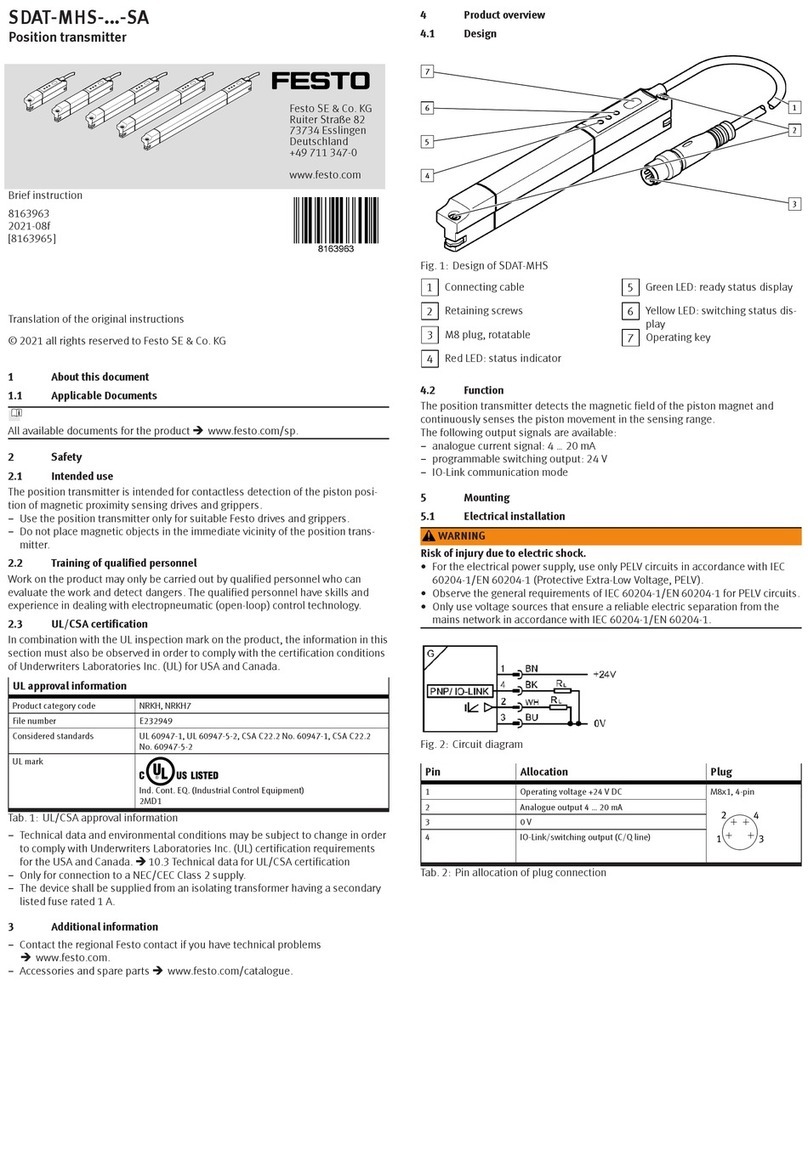

1.1 Overview 5................................................................

1.2 Characteristics 5...........................................................

2 Function and application 6...................................................

2.1 Analogue output function 7...................................................

2.2 Switching functions and switching logic 8........................................

2.2.1 Window comparator 8...............................................

2.2.2 Cylinder switch function 9............................................

2.2.3 Hysteresis comparator 9.............................................

2.2.4 Normally open (NO) and normally closed (NC) contacts 9...................

2.3 Switching output operating mode (SIO) 10........................................

2.4 IO-Link operating mode 10....................................................

3 Requirements for product use 11...............................................

4 Installation 13..............................................................

4.1 Electrical 13................................................................

4.2 Mechanical 14..............................................................

5 Commissioning 15...........................................................

5.1 Set set-up mode 15..........................................................

5.2 Scale analogue signal 15......................................................

5.3 Program switching output 16..................................................

5.3.1 Set window comparator 16............................................

5.3.2 Set cylinder switch function 17.........................................

5.3.3 Set hysteresis comparator 18..........................................

5.3.4 Invert switching logic (NO or NC) 18.....................................

5.4 Block / unblock operating key 19...............................................

5.5 Program IO-Link output 19.....................................................

6 Operation 20...............................................................

6.1 Magnetic direction detection and correction 20....................................

6.2 LED indicators 20............................................................

6.3 Reset position transmitter to factory setting 21....................................

7 Disassembly 22.............................................................