LED display Description

Yellow Green Red

Status indicator:

–Piston outside the sensing range.

Red LED: on

Tab. 5: LED displays in normal operation

7.3 Analogue output and switching function operation

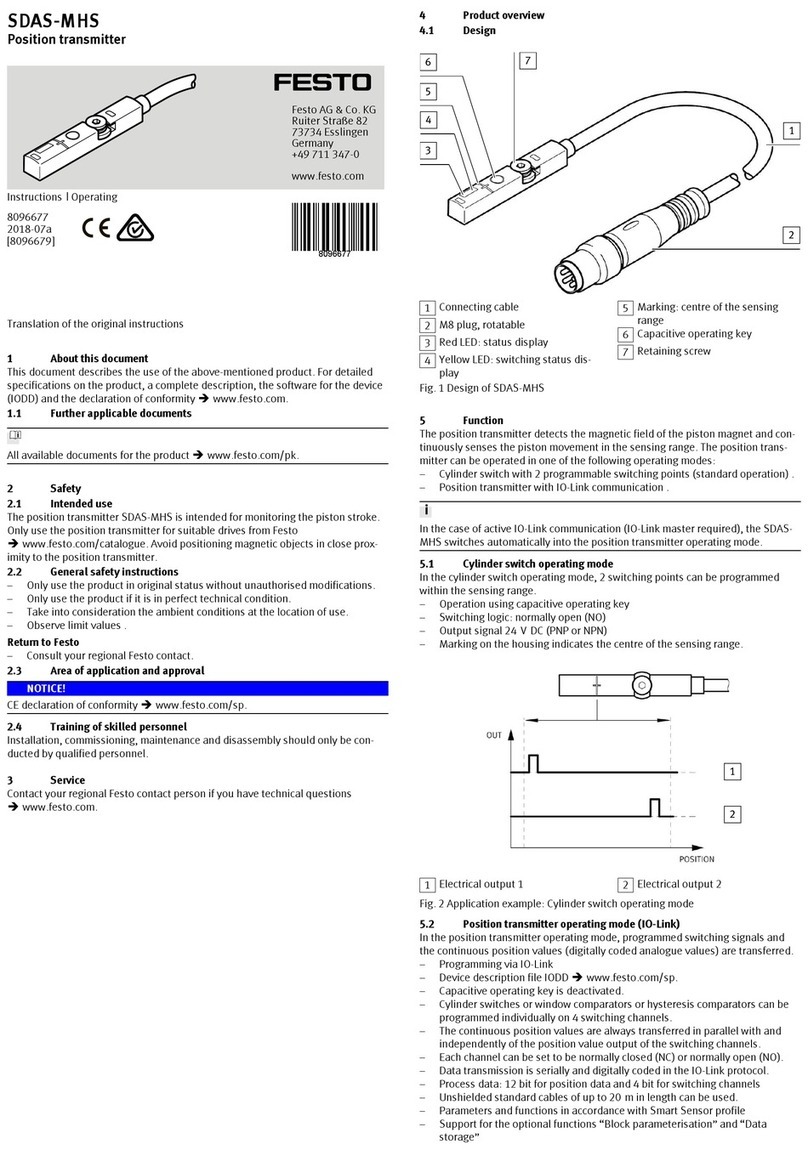

Fig. 5: Settings using the operating key (menu structure)

8Malfunctions

8.1 Diagnostics via LED

LED display Possible cause Remedy

Yellow Green Red

Fault in power supply. Connect power supply.

Fault in connecting cable. Replace connecting cable.

Device is faulty. Replace device.

All LEDs are off.

Hardware error. Switch power supply on/off.

Replace device.

Yellow LED is off.

Green LED is off.

Red LED is flashing.

Short circuit or overload at the

switching output.

Eliminate short circuit or over-

load.

Parameter error. Reset device to factory setting .

Yellow LED flashes at 3 Hz.

Communication error in IO-Link

mode.

Check IO-Link master.

Restart communication.

Check C/Q line.

Yellow LED flashes at 3 Hz

Green LED flashing at 1 Hz

Tab. 6: LED displays in case of malfunctions

If the device detects an error during IO-Link operation, a status message is output

at the IO-Link master. The IO-Link/switching output is not blocked.

8.2 General malfunctions

Malfunction Cause Remedy

Incorrect or unexpected signals

at the analogue output or with

the IO-Link process data.

Drive is not suitable. Use a suitable drive.

Device is faulty. Replace device.

No power supply or impermis-

sible operating voltage.

Maintain operating voltage

range.

Short circuit or overload at the

switching output.

Eliminate short circuit or over-

load.

Magnetic object in the imme-

diate vicinity of the position

transmitter.

Do not place magnetic objects

in the immediate vicinity of the

position transmitter.

Sensor or drive was rotated

180° after initial commis-

sioning.

Reset to factory setting using

the operating key or via IO-Link.

Incorrect or unexpected signals

during initial commissioning on

grippers or in attachments with

ferromagnetic components.

On initial commissioning, move

gripper jaws or piston within

the sensing range, e.g. to both

end positions.

Switching output does not

switch in accordance with the

settings.

Short circuit or overload at the

switching output.

Eliminate short circuit or over-

load.

Device is faulty. Replace device.

Settings cannot be edited. Access protection is active. Unblock operating key (only

possible via IO-Link).

Tab. 7: Possible malfunctions

9 Disassembly

1. Switch off the power supply.

2. Disconnect connections from the position transmitter.

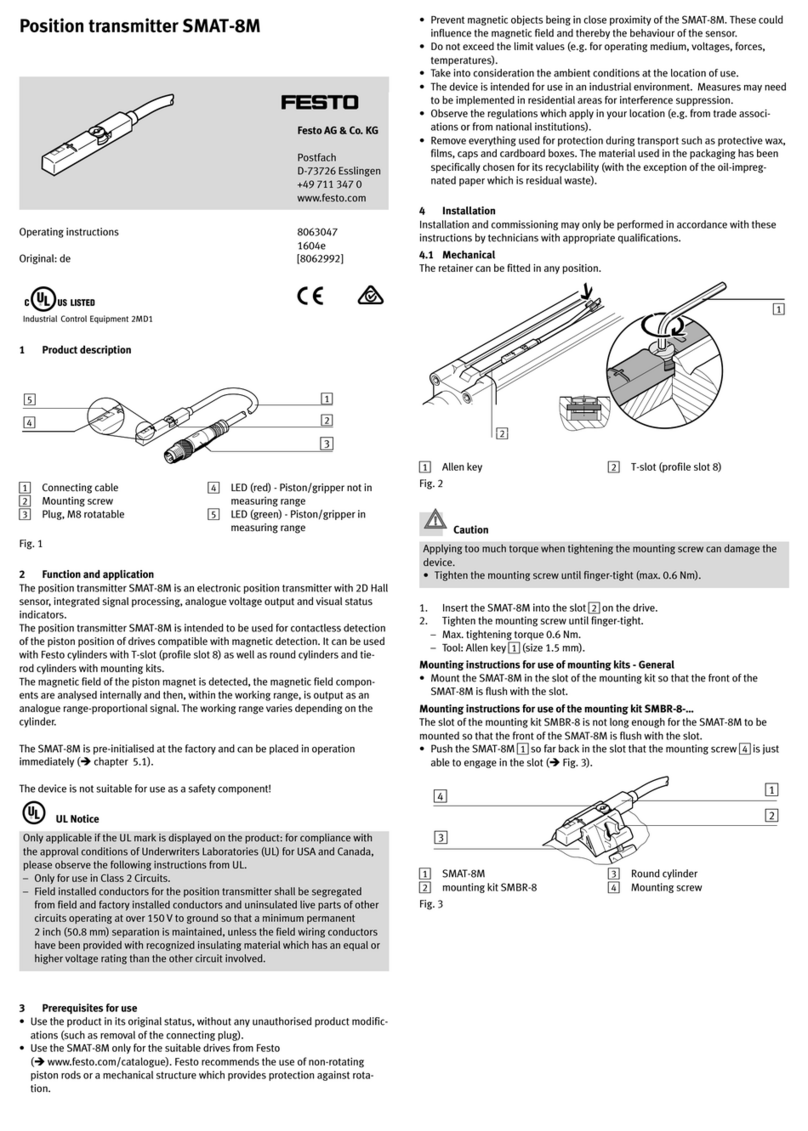

3. Unscrew the retaining screws è Fig. 3.

4. Remove the position transmitter from the T-slot of the drive.

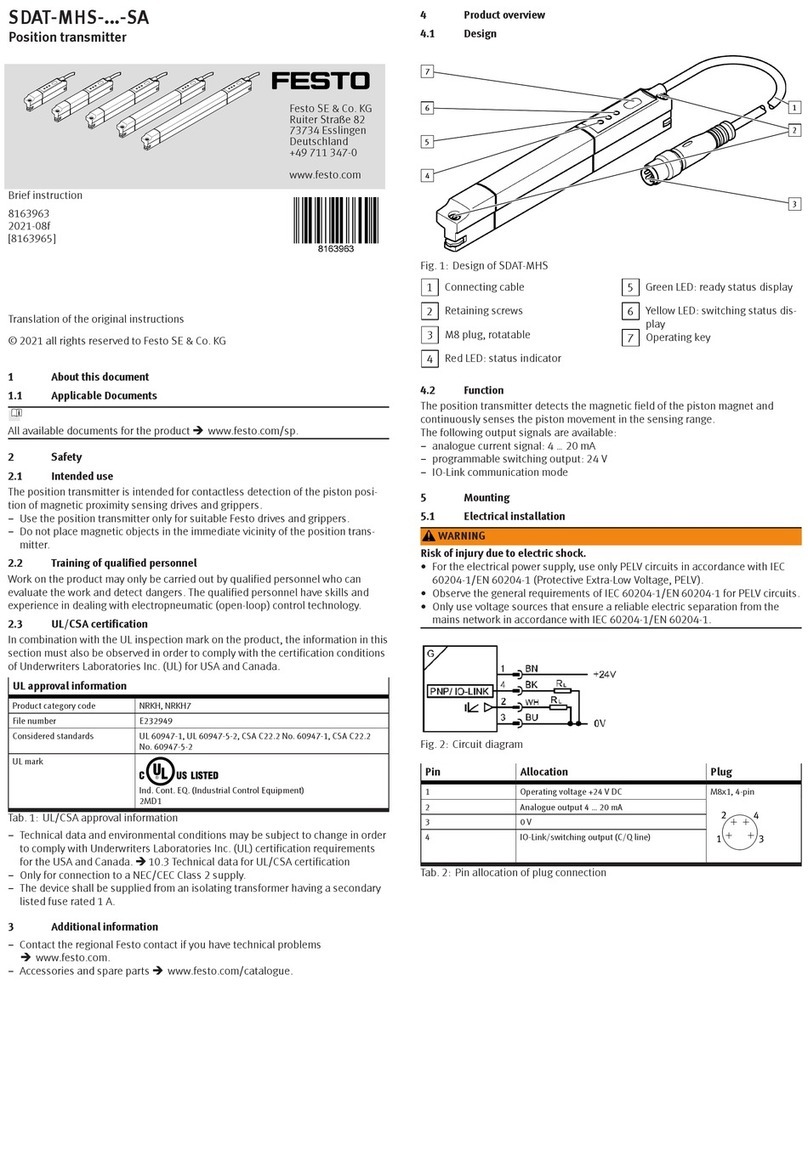

10 Technical data

For the complete technical data è Operating instructions SDAT-MHS.

10.1 General

SDAT-MHS-... 50 80 100 125 160

Conformity è www.festo.com/sp

Note on materials halogen-free

Input signal/measuring element

Sensing range1) [mm] 50 80 100 125 160

Signal processing

Sampling interval typ. [ms] 1

Max. traverse velocity [m/s] 3

Output, general

Resolution of travel [mm] 0.05

Switching output

Switching output PNP

Repetition accuracy of switching point [mm] 0.1

Hysteresis [mm] £ 0.3

Analogue output

Analogue output [V] 0 … 10

Sensitivity [mV/mm] 180 113 90 72 56

Typical linearity error [mm] ±0.25

Repetition accuracy [mm] 0.1

Min. load resistance of voltage output [kΩ] 20

Electronics

Operating voltage DC [V] 15 … 30

Typical signal running time [ms] < 2

Electromechanics

Cable length [m] 0.3

Conductor nominal cross section [mm2]0.1

Mechanical system

Max. tightening torque [Nm] 0.5

Information on materials – housing PA-reinforced, polyester, high-alloy

stainless steel, nickel-plated brass

Immission/emission

Ambient temperature [°C] -25 … +70

Ambient temperature with flexible cable

installation

[°C] -20 … +70

Degree of protection (to EN 60529) IP65/IP68

Condition with IP68: test duration 24 h

1) Type-dependent

Tab. 8: Technical data SDAT-MHS