3Festo — SDAS-MHS — 2018-06

1 About this document................................................................................................... 5

1.1 Further applicable documents...................................................................................... 5

2 Safety........................................................................................................................... 5

2.1 Intended use................................................................................................................ 5

2.2 General safety instructions........................................................................................... 5

2.3 Area of application and approval.................................................................................. 5

2.4 Training of qualified personnel..................................................................................... 5

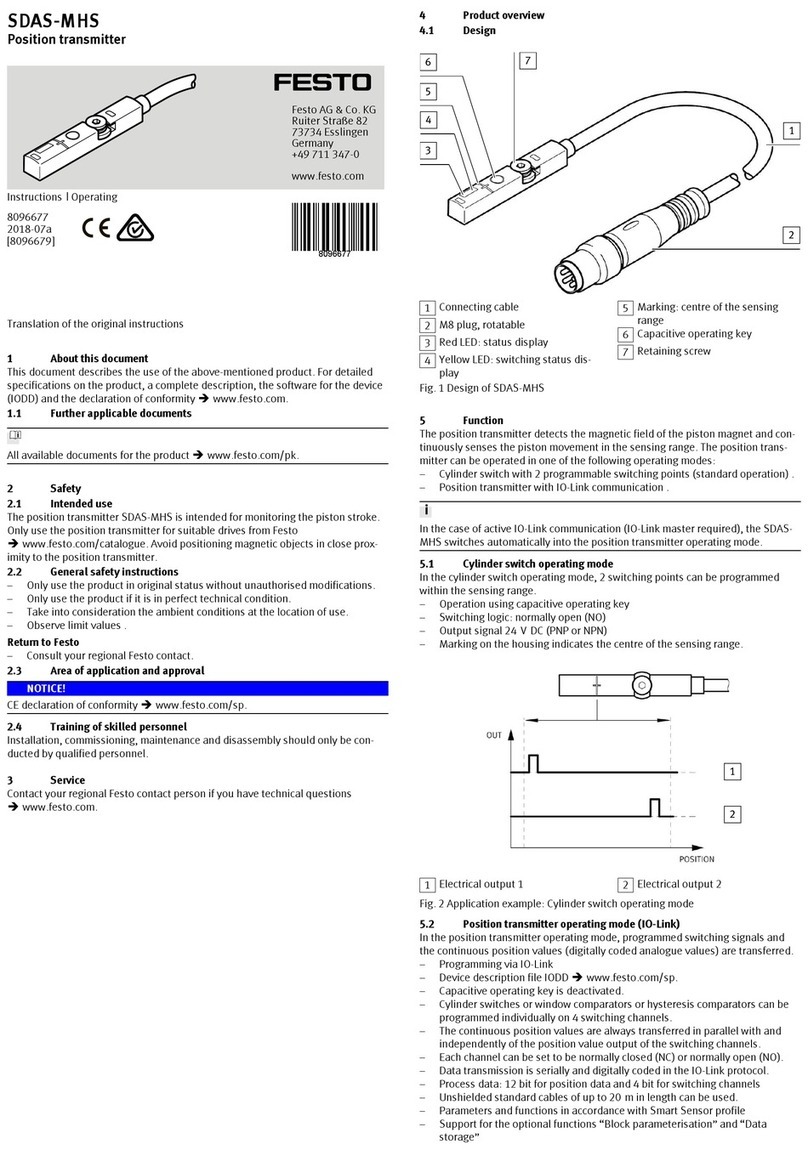

3 Product overview......................................................................................................... 6

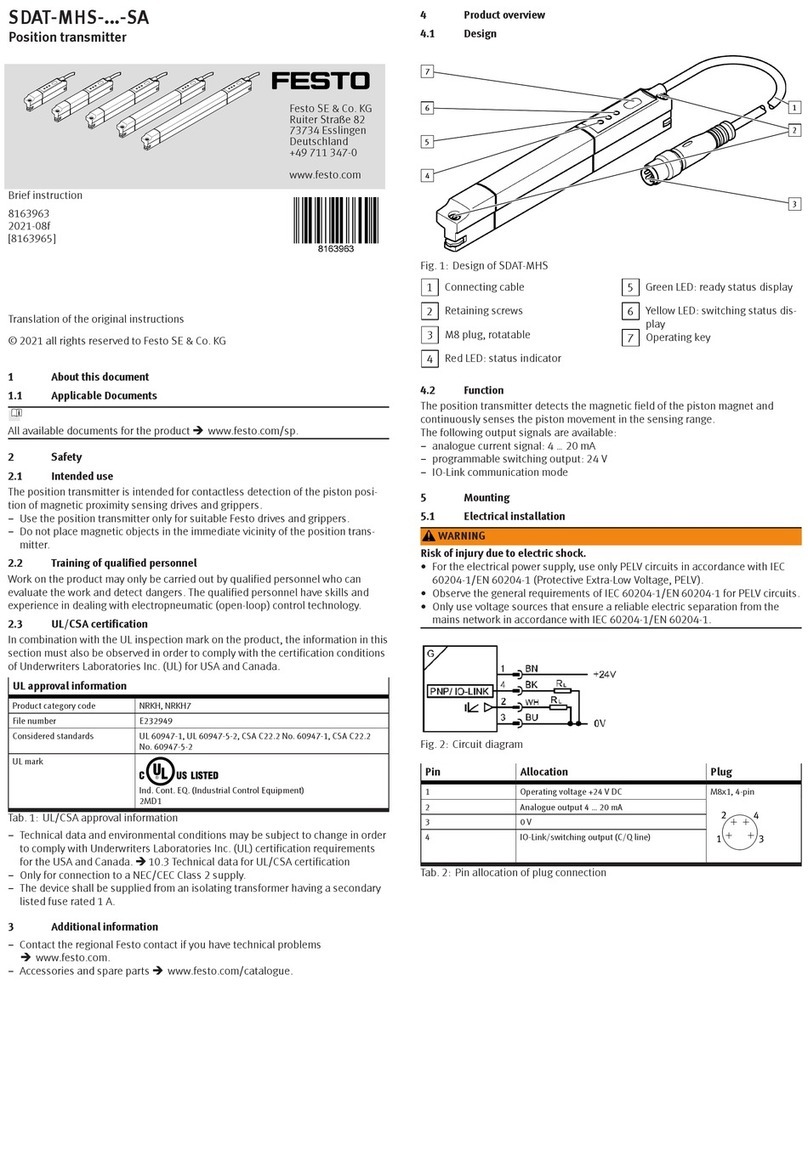

3.1 Design........................................................................................................................... 6

3.2 Characteristics.............................................................................................................. 7

4 Function........................................................................................................................7

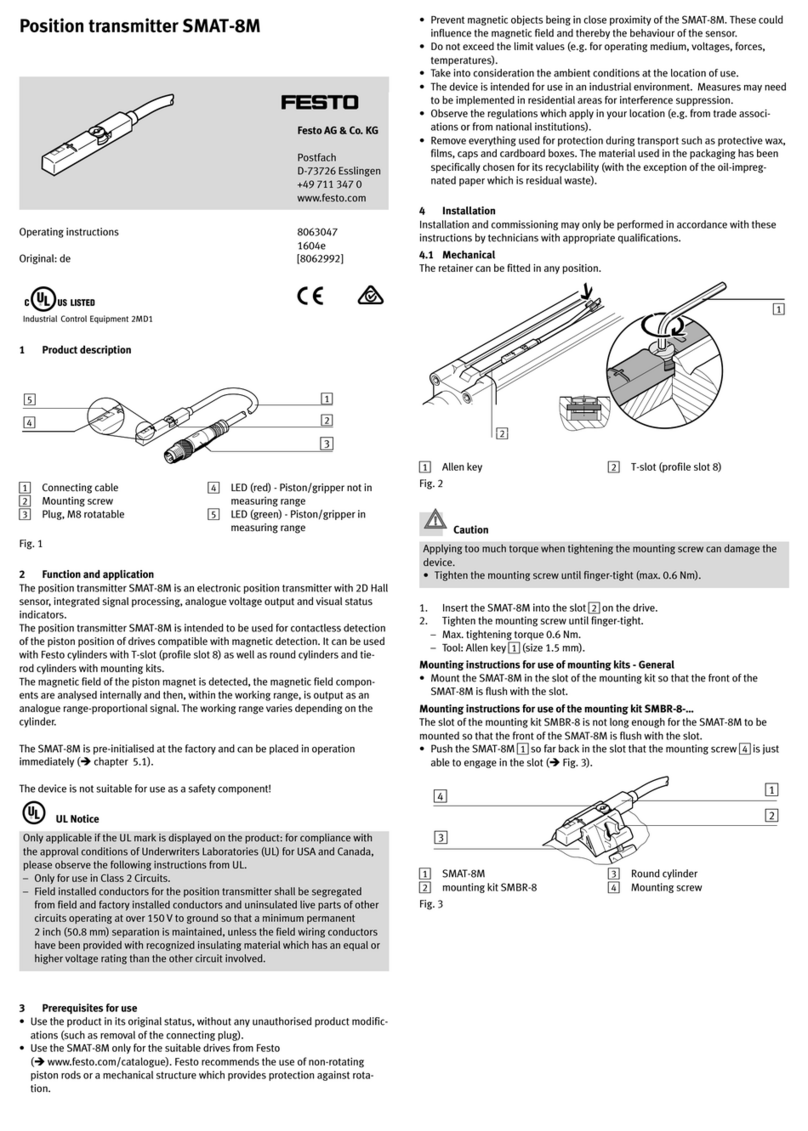

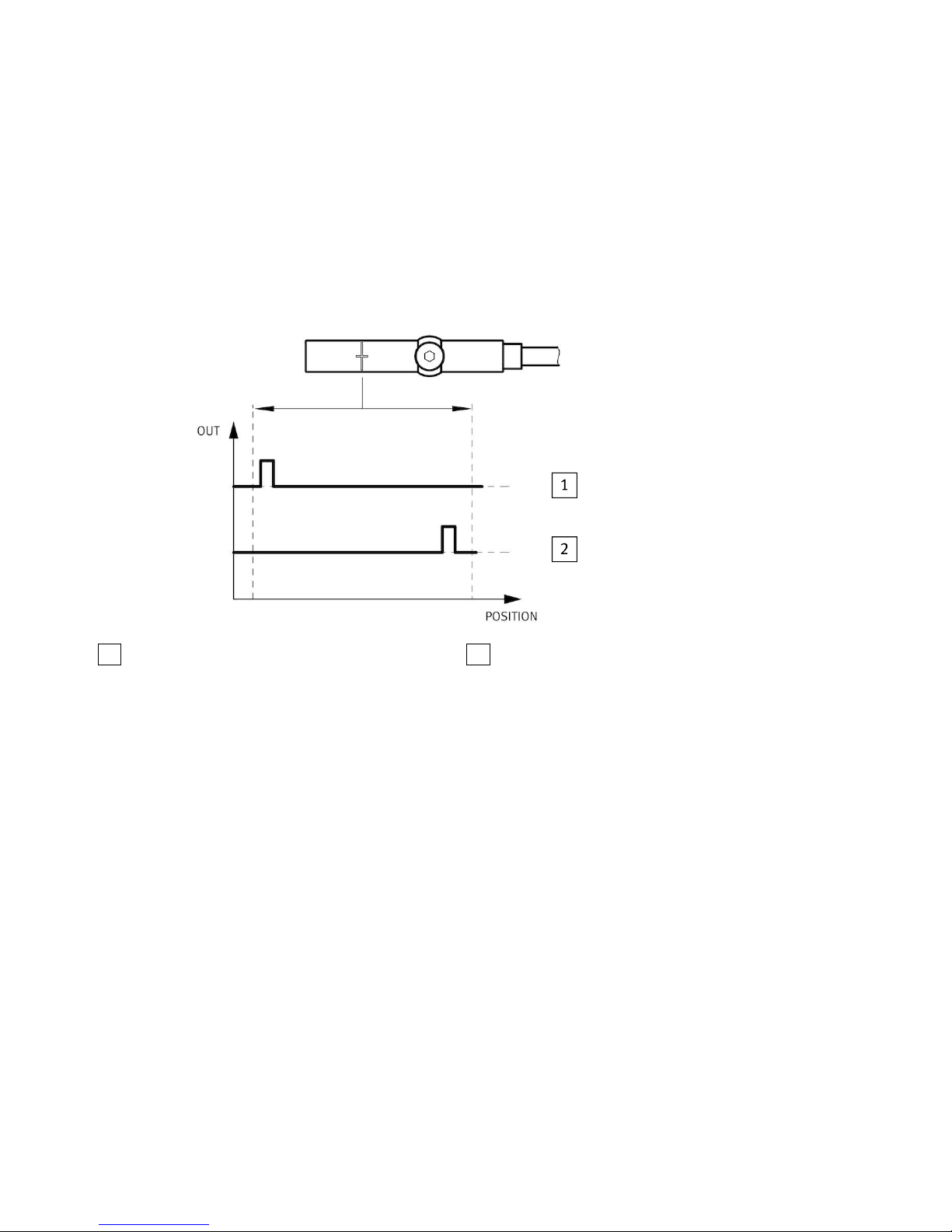

4.1 Cylinder switch operating mode................................................................................... 8

4.1.1 Cylinder switch function..........................................................................................9

4.2 Position transmitter operating mode (IO-Link).............................................................. 10

4.2.1 Cylinder switch function..........................................................................................11

4.2.2 Window comparator................................................................................................12

4.2.3 Hysteresis comparator............................................................................................13

4.2.4 Switching logic, normally open (NO) and normally closed (NC)...............................14

4.3 Additional information on the operating modes........................................................... 14

5 Installation.................................................................................................................. 16

5.1 Electrical installation.................................................................................................... 16

5.2 Mechanical installation................................................................................................. 17

6 Commissioning............................................................................................................ 17

6.1 Cylinder switch operating mode................................................................................... 18

6.1.1 Activating set-up mode...........................................................................................18

6.1.2 Set switching points................................................................................................19

6.1.3 Changing the configuration of the switching outputs..............................................19

6.1.4 Menu structure....................................................................................................... 20

6.2 Position transmitter operating mode............................................................................ 21

7 Operation..................................................................................................................... 21

7.1 Cylinder switch operating mode................................................................................... 21

7.1.1 LED display............................................................................................................. 22

7.1.2 Reset to factory setting...........................................................................................22

7.2 Position transmitter operating mode............................................................................ 22

7.2.1 LED display............................................................................................................. 22

7.2.2 Reset to factory setting...........................................................................................23

8 Fault clearance............................................................................................................ 23

8.1 Diagnostics via LED...................................................................................................... 23

8.2 General malfunctions................................................................................................... 24

9 Disassembly................................................................................................................ 24

Table of contents