3Festo — YHBP-1 — 2018-11

1 About this document................................................................................................... 4

1.1 Applicable documents.................................................................................................. 4

2 Safety........................................................................................................................... 5

2.1 General safety instructions........................................................................................... 5

2.2 Intended use................................................................................................................ 6

2.3 Foreseeable misuse...................................................................................................... 6

2.4 Training of qualified personnel..................................................................................... 6

3 Further information..................................................................................................... 6

4 Service..........................................................................................................................6

5 Product overview YHBP............................................................................................... 7

5.1 Scope of delivery.......................................................................................................... 7

5.2 Function....................................................................................................................... 8

6 Transport..................................................................................................................... 8

7 Assembly..................................................................................................................... 9

8 Installation.................................................................................................................. 10

8.1 Interfaces of valve unit VPCB-...-T22............................................................................. 10

8.2 Pneumatic installation.................................................................................................. 11

8.3 Interfaces CECC-D-BA................................................................................................... 12

8.4 Electrical installation.................................................................................................... 14

9 Commissioning............................................................................................................ 17

10 Operation..................................................................................................................... 17

11 Service..........................................................................................................................18

11.1 Cleaning....................................................................................................................... 18

12 Malfunctions............................................................................................................... 18

12.1 Repair............................................................................................................................18

13 Disassembly................................................................................................................ 18

14 Disposal........................................................................................................................19

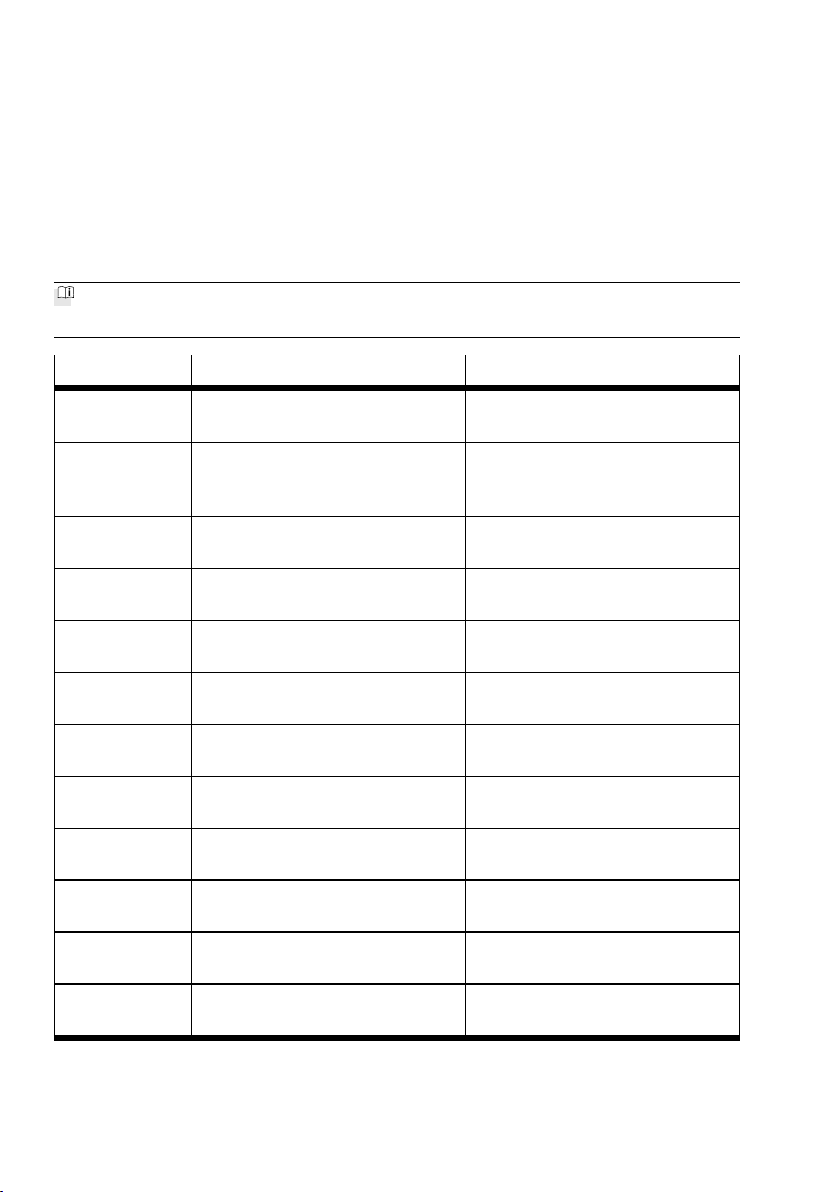

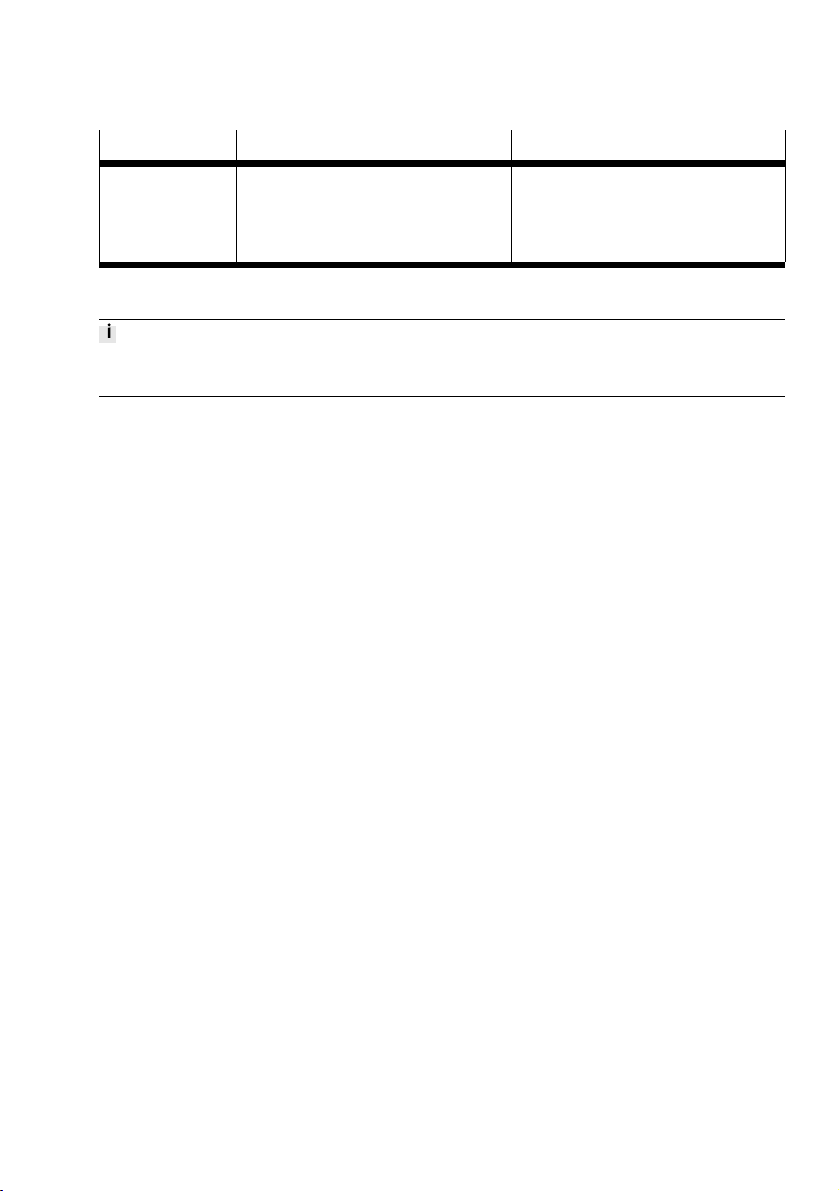

15 Technical data............................................................................................................. 19

Table of contents