3Festo — YHBP — 2020-09

1 About this document................................................................................................... 4

1.1 Applicable documents.................................................................................................. 4

2 Safety........................................................................................................................... 5

2.1 General safety instructions........................................................................................... 5

2.2 Intended use................................................................................................................ 6

2.3 Foreseeable misuse...................................................................................................... 6

2.4 Training of qualified personnel..................................................................................... 6

3 Further information..................................................................................................... 6

4 Service..........................................................................................................................6

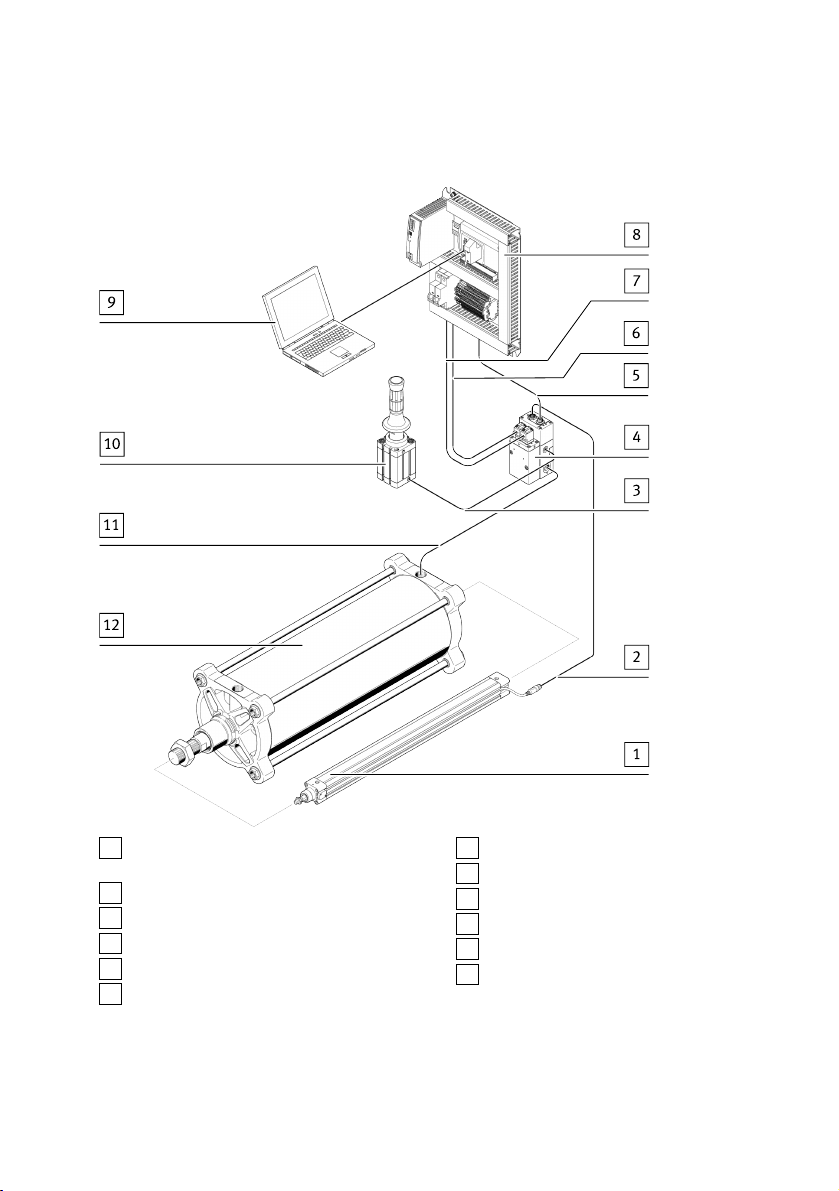

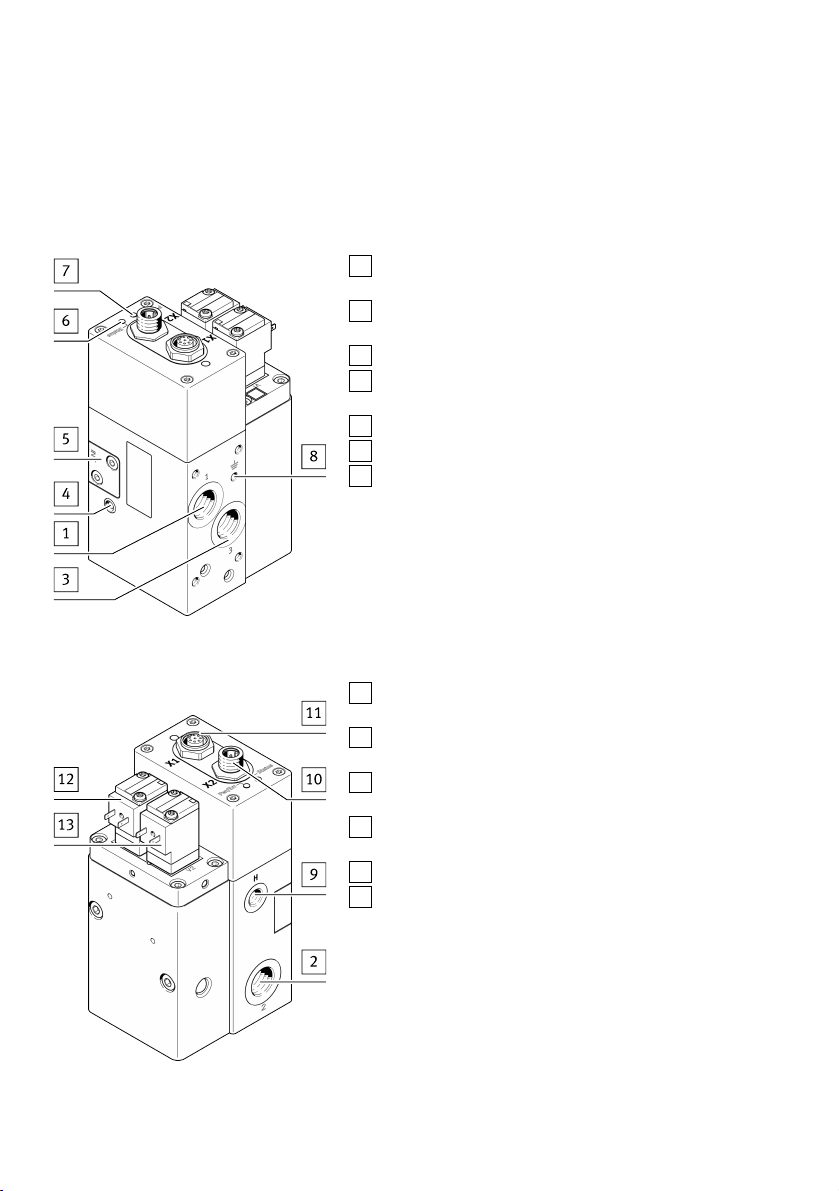

5 Product overview......................................................................................................... 7

5.1 Scope of delivery.......................................................................................................... 8

5.2 Function....................................................................................................................... 8

6 Transport..................................................................................................................... 8

7 Assembly..................................................................................................................... 9

8 Installation.................................................................................................................. 10

8.1 Valve unit interfaces..................................................................................................... 10

8.2 Pneumatic installation.................................................................................................. 11

8.3 Electrical installation.................................................................................................... 11

9 Commissioning............................................................................................................ 14

10 Operation..................................................................................................................... 14

11 Maintenance................................................................................................................ 15

11.1 Cleaning....................................................................................................................... 15

12 Malfunctions............................................................................................................... 15

12.1 Repair............................................................................................................................15

13 Disassembly................................................................................................................ 15

14 Disposal........................................................................................................................16

15 Technical data............................................................................................................. 16

Table of contents