GB

Page 2 of 52

INSTRUCTION, USE AND

MAINTENANCE MANUAL

SUMMARY

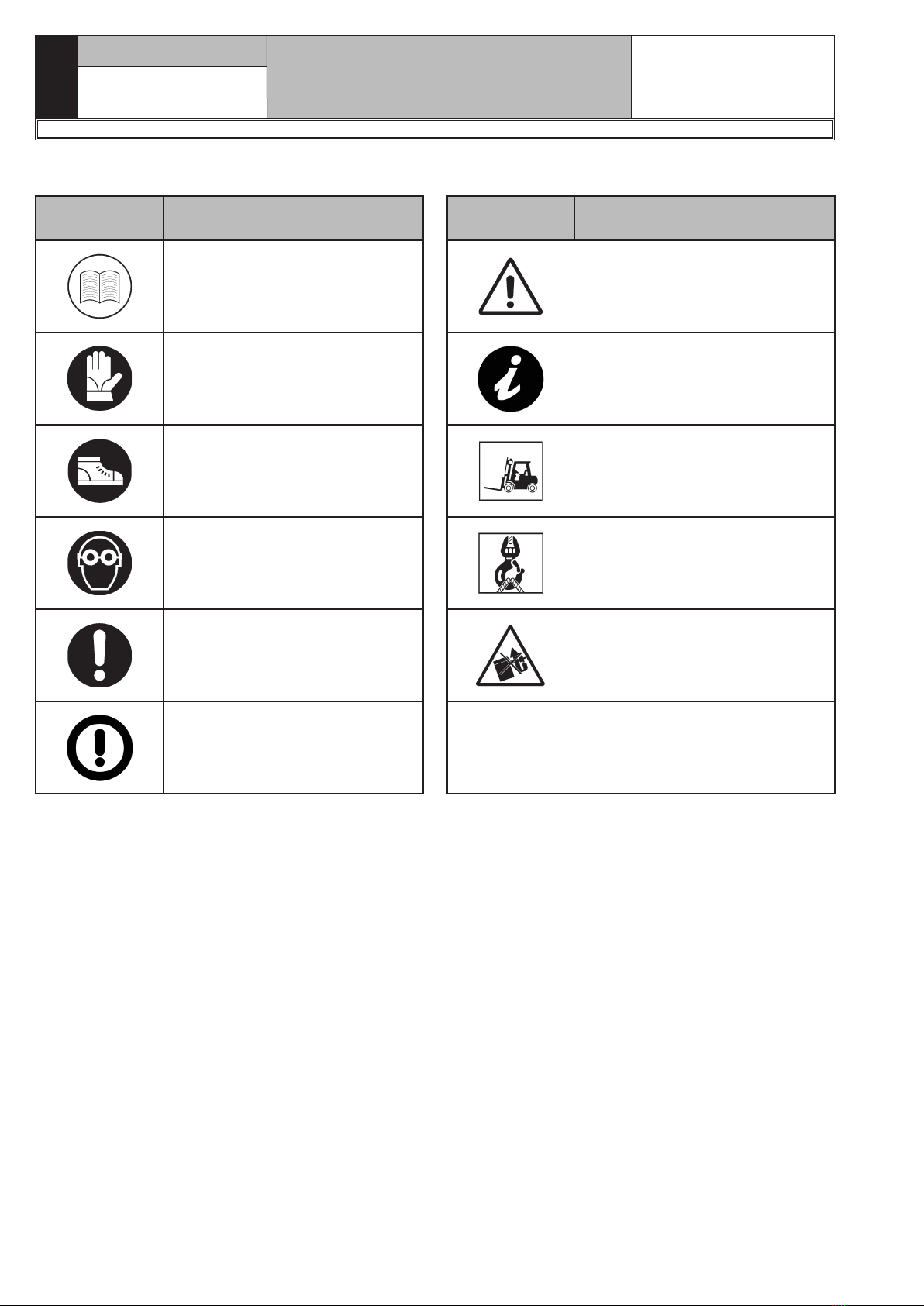

SYMBOLS USED IN THE MANUAL ________ 5

1.0 GENERAL INTRODUCTION __________ 8

1.1 Introduction ____________________________ 8

2.0 INTENDED USE _____________________ 8

2.1 Training of personnel __________________ 8

3.0 SAFETY DEVICES ___________________ 9

3.1 Residual risks __________________________ 9

4.0 GENERAL SAFETY RULES __________ 9

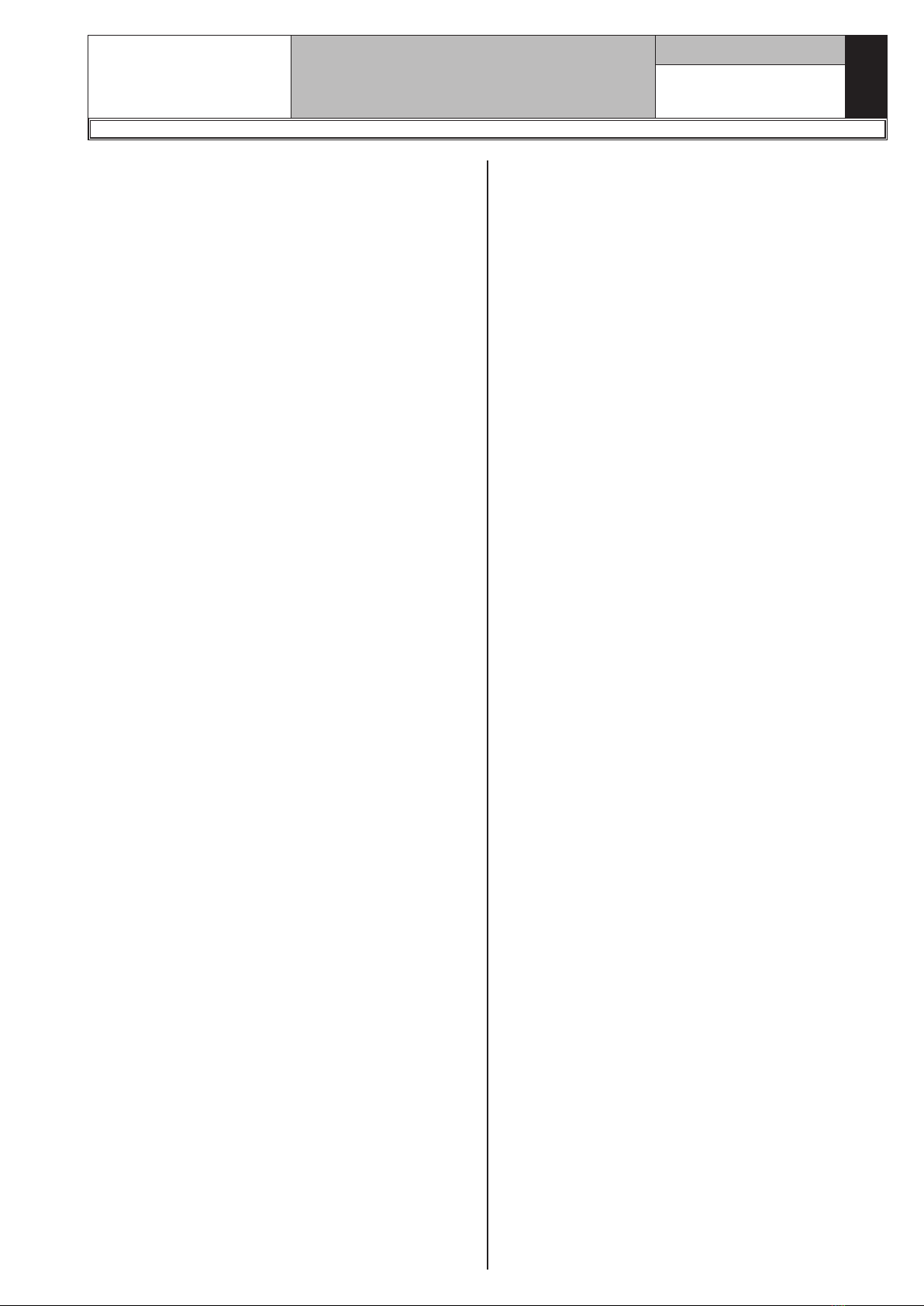

5.0 PACKING AND MOBILIZATION FOR

TRANSPORT _______________________ 10

6.0 UNPACKING ________________________ 11

7.0 MOBILIZATION_____________________ 11

8.0 WORKING ENVIRONMENT CONDI-

TIONS ______________________________ 11

8.1 Working area __________________________12

8.2 Lighting _______________________________12

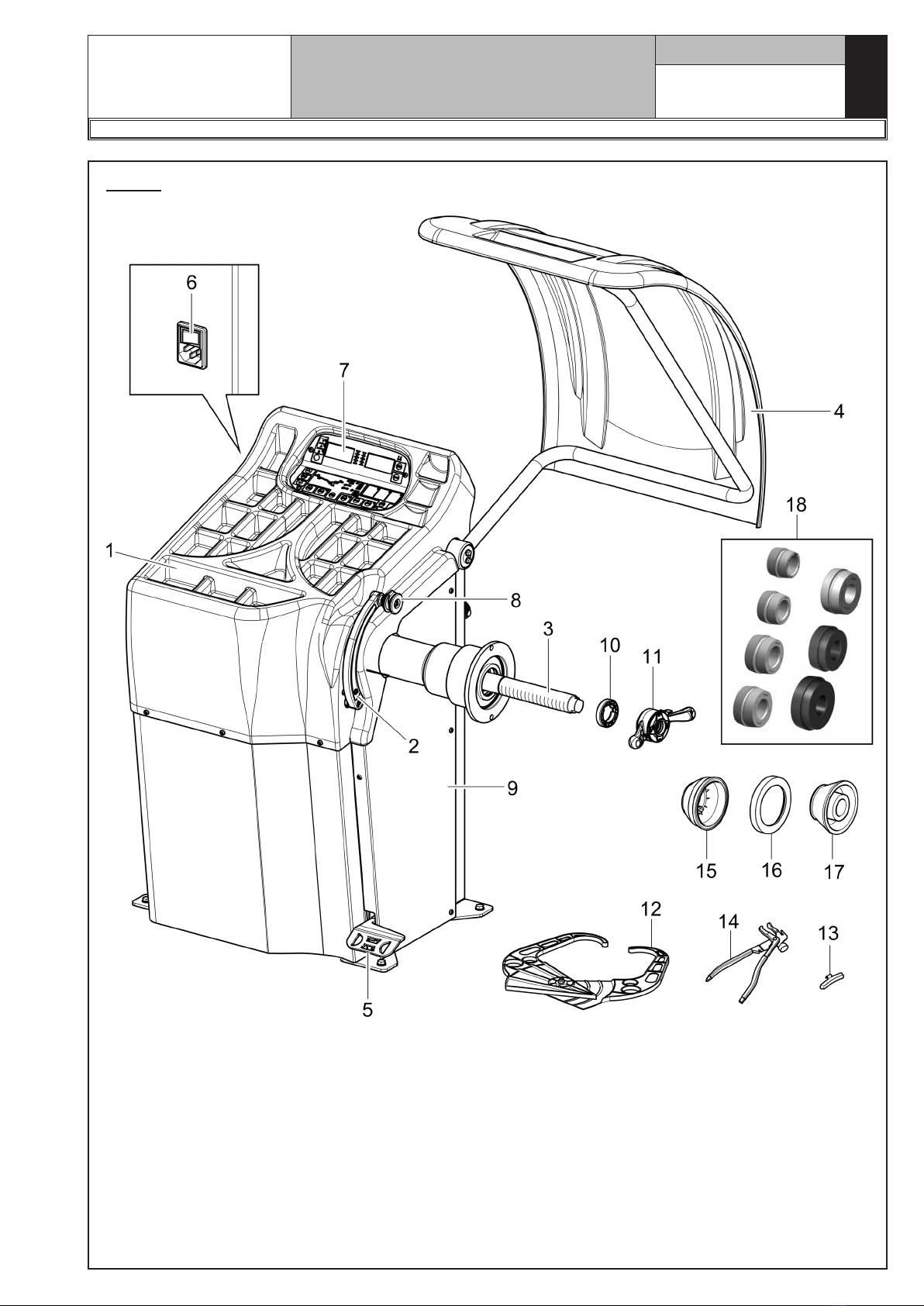

9.0 MACHINE ASSEMBLY ______________ 12

9.1 Anchoring system _____________________12

9.2 Fixtures contained in the packing_____13

9.3 Assembly procedures _________________13

9.3.1 Fitting the mandrel on the flange __13

9.3.2 Fitting the protection guard _______14

10.0 ELECTRICAL CONNECTIONS_______ 14

10.1 Electrical checks ______________________15

11.0 MULTIFUNCTION LED PANEL ______ 15

11.1 DISPLAY and LEDs brightness adjust-

ment___________________________________16

12.0 FITTING THE WHEEL ON THE

MANDREL__________________________ 16

12.1 Wheel assembly _______________________16

13.0 SWITCHING THE MACHINE ON

AND OFF ___________________________ 18

14.0 WHEEL BALANCING _______________ 19

14.1 Determination of wheel dimensions ___19

14.1.1 Automatic wheel dimension set-

ting of distance/diameter __________19

14.1.2 Programs rapid setting and

measurements through distance-

diameter caliper arm ______________21

14.1.3 Entry of measures _________________21

14.1.4 Manual setting of wheel

dimensions ________________________23

14.2 User control function__________________23

14.3 Unbalance measurement ______________24

14.3.1 Indicative display of points where

to fit weight________________________24

14.3.2 Balancing mode____________________24

14.3.3 Dynamic balancing ________________25

14.3.4 ALU-S procedure ___________________26

14.3.5 Static balancing (STAT) ___________26

14.3.6 Positioning the correction

weights on the wheel_______________27

14.4 Measuring the unbalance with auxil-

iary programs ________________________28

14.4.1 ALU1 procedure ____________________29

14.4.2 PAX mode __________________________30

14.5 Recalculation Function ________________30

14.6 ECO-WEIGHT procedure _______________31

15.0 WHEEL BALANCING IN MOTORCY-

CLE MODE _________________________ 32

16.0 SPLIT PROCEDURE ________________ 33

17.0 WEIGHTS HIDDEN BEHIND

SPOKES MODE_____________________ 34

18.0 MATCHING PROCEDURE

(Rim - Tyre Optimization)___________ 36

19.0 CALIBRATION ______________________ 38

19.1 Diameter only gauge calibration ______38

19.2 “Zero mandrel” setting________________40

19.3 Weight measurement sensors

calibration ____________________________40

20.0 USER’S SETTING AND CUSTOMIZA-

TIONS ______________________________ 42

20.1 Selection of unit of measurement for

weights display _______________________43

20.2 Setting measurements units for rim

weight and width/diameter ____________44

20.3 Users’ management - Motorbike mode

- Eco-Weight - Residual static setting__44

20.4 Setting of Repositioning - Comfort -

Guard - Pax____________________________44

20.5 Distance/diameter setting _____________45

20.6 Weights display management _________46

20.7 Setting adhesive weight dimensions __46

21.0 ERROR SIGNALS ___________________ 47

1297-M043-0