Festool MFS Fence System User manual

Other Festool Power Tools Accessories manuals

Festool

Festool CMS-TS-55-R Installation instructions

Festool

Festool GC 1000-WA Installation instructions

Festool

Festool CS 70 LA User manual

Festool

Festool ZS-OF 2200 Installation instructions

Festool

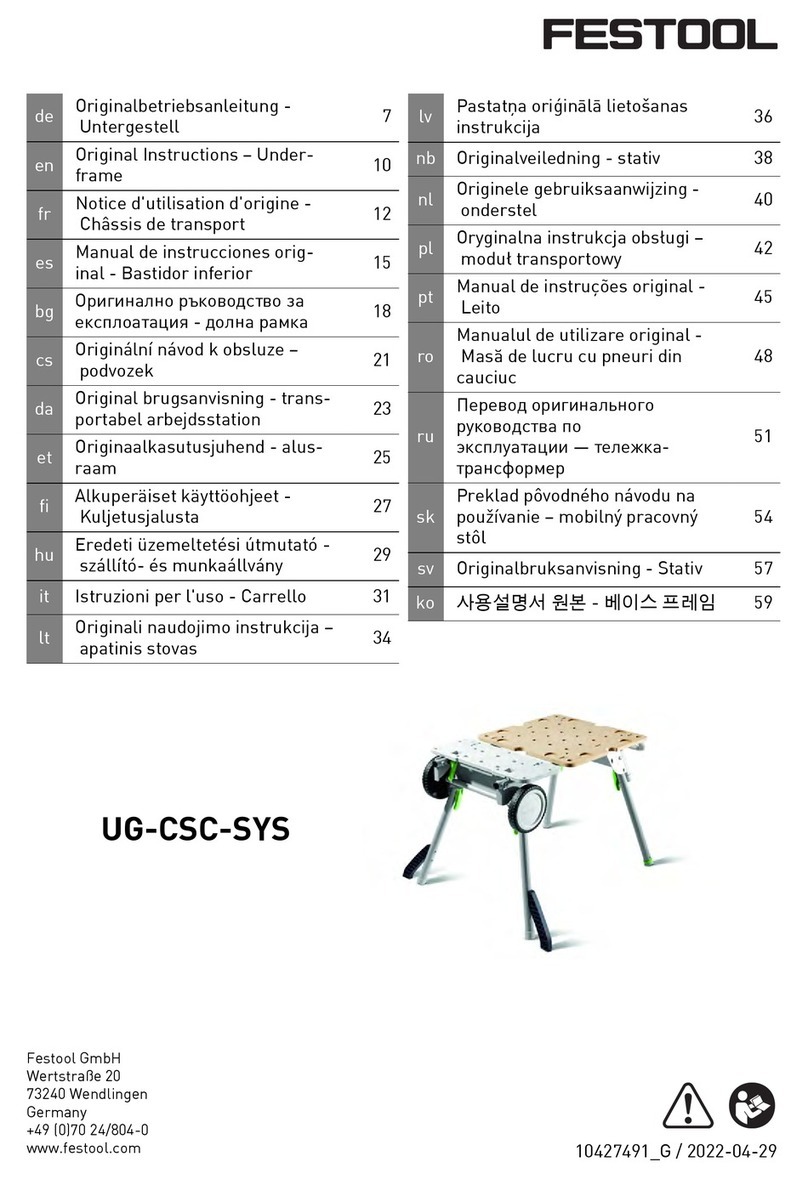

Festool UG-CSC-SYS User manual

Festool

Festool ST TKS 80 User manual

Festool

Festool ZS-OF 2200 User manual

Festool

Festool Gecko User manual

Festool

Festool ASA 5000 Installation instructions

Festool

Festool CMS-PS 200 Installation instructions

Festool

Festool UG-KAPEX KS120 User manual

Festool

Festool RS-HK 160x80 Installation instructions

Festool

Festool APS 900/2 User manual

Festool

Festool CS 70 VL User manual

Festool

Festool AP-KA 65 Installation instructions

Festool

Festool GD D10-40A Installation instructions

Festool

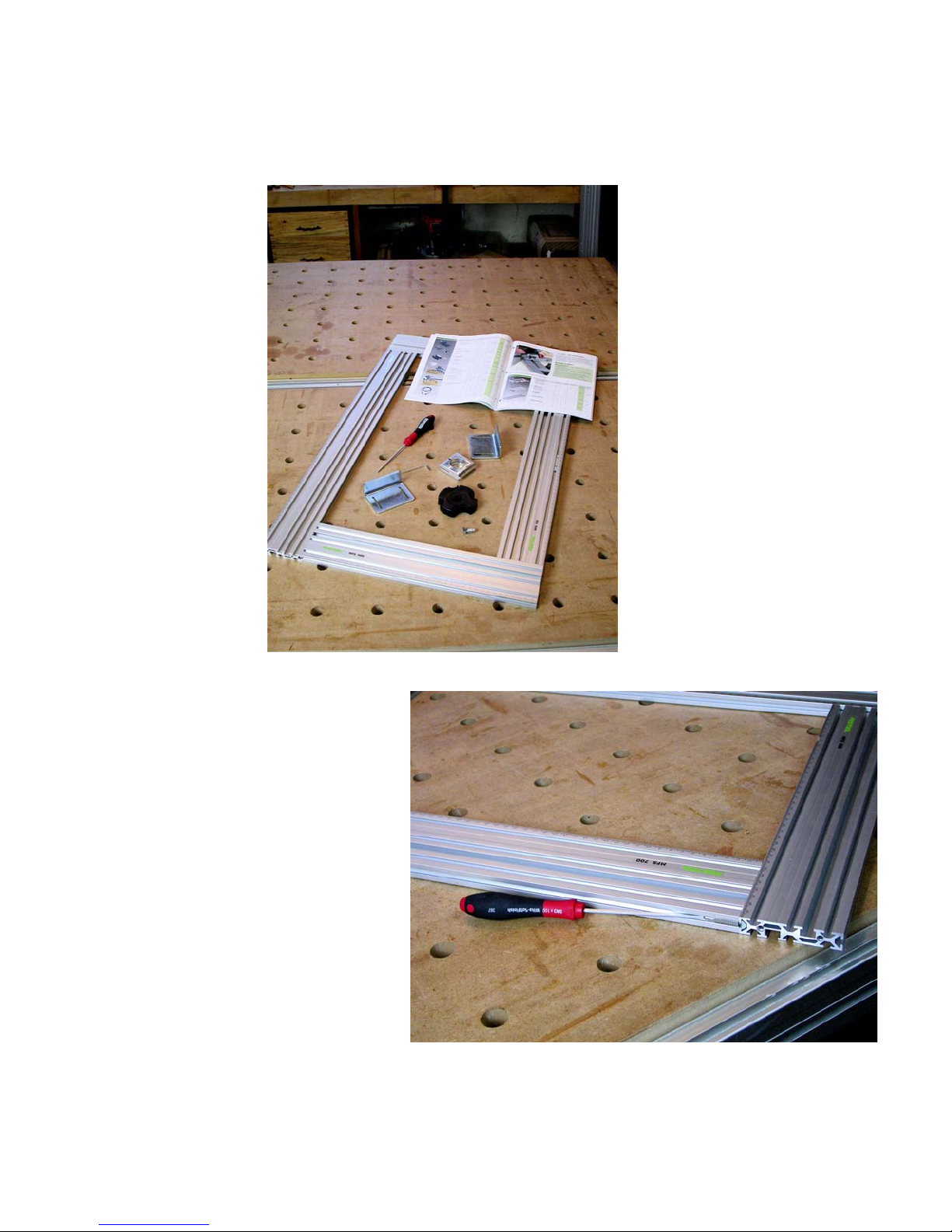

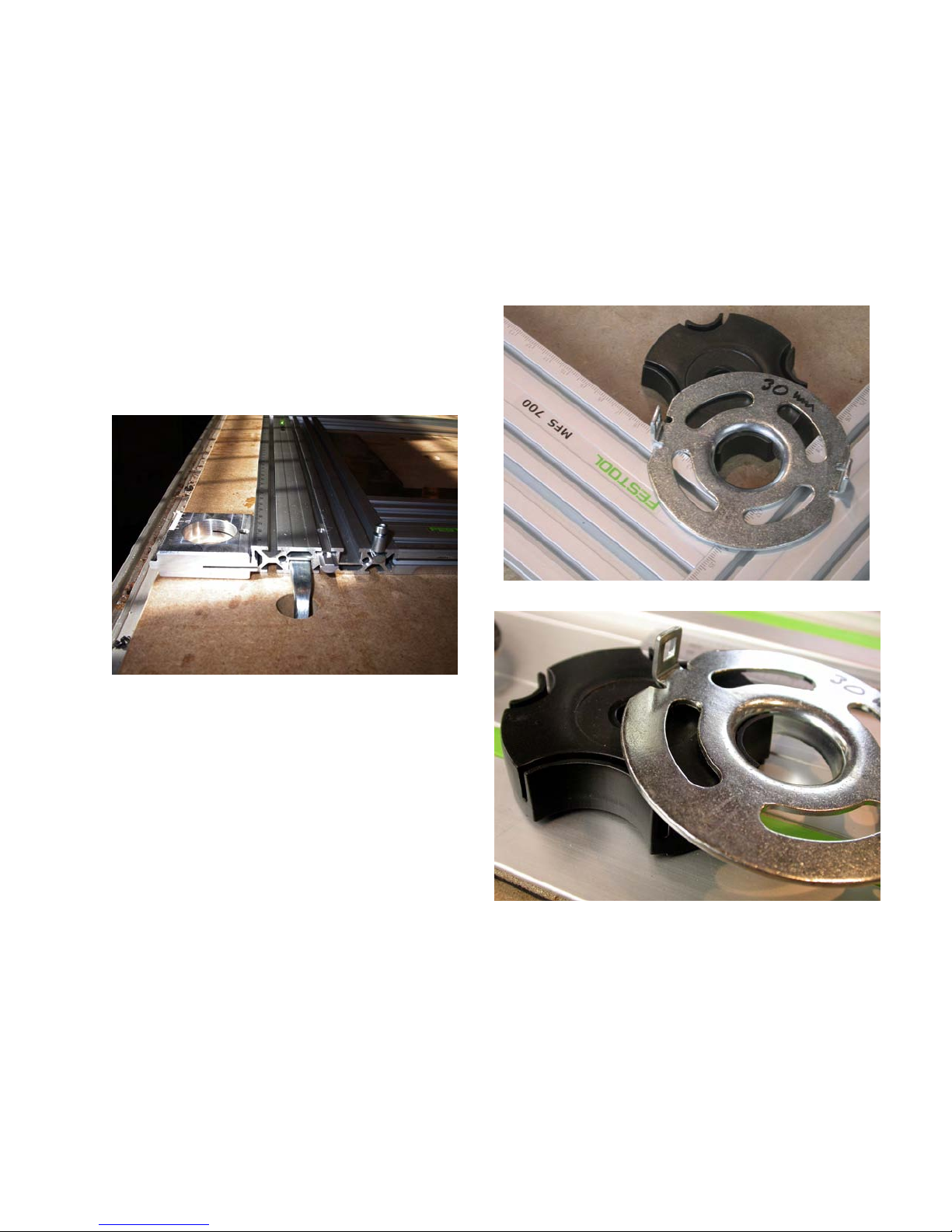

Festool MFS Series User manual

Festool

Festool MFS Multi-Routing Template System User manual

Festool

Festool CMS-TS 75 Installation instructions

Popular Power Tools Accessories manuals by other brands

ADAMAS

ADAMAS B32 Instructions for use

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL 4007841009595 quick start guide

Echo

Echo Speed-Feed Universal 400 LH/RH Installation and loading instructions

SCHUNK

SCHUNK ROTA TB-TBS-EP Assembly and operating manual

Schmid

Schmid RAPID Secure XL Operation instructions

Drill Master

Drill Master 360X user guide